How To Sharpen Band Saws On Wood

Common mistakes

If a person tries to sharpen a saw for the first time, it is difficult for him to fulfill all the requirements and remember the nuances of the technological process. However, violation of these rules leads to the fact that the efficiency of using the band saw is significantly reduced, the load on the blade increases, which leads to premature rupture.

Professionals recommend avoiding such mistakes:

- with mechanical sharpening, the abrasive stone is not positioned correctly relative to the saw profile. In this case, the sharpening of the teeth will be uneven;

- excessive force when the saw and the grinding wheel contact. As a result, the metal overheats, dross appears, which leads to premature wear of the cutting edge;

- burrs remain on the canvas. After sharpening, all roughness must be eliminated, otherwise microscopic cracks will appear on the metal during operation;

- using your own sharpening angles. Many inexperienced craftsmen believe that only sharpness is important for saw teeth, therefore they shamelessly violate the geometry of the cutting edge profile recommended by the manufacturer. It is important to understand that the shape of the tooth has been tested over the years; it is useless to try to experiment here.

Instead of a conclusion, we add that each band saw has a certain resource, so the blade cannot be sharpened indefinitely. Manufacturers guarantee correct tool operation until the total blade width is reduced to 65% of the original size.

How to correctly sharpen a canvas?

According to statistics, more than 80% of cases of device ruptures occur due to non-performance of sharpening techniques. The need for sharpening is revealed visually. by the appearance of the teeth themselves or the state of the cut (increased unevenness of the plane).

The stones for sharpening tape blades are selected based on the stiffness of the teeth. For sharpening products made of carbon and alloy steel, corundum stones are used. Bimetal blades require borazon (CBN) or diamond discs. The configuration of the blade grinding wheel must be determined based on the characteristics of the tool. It can be dish-shaped, flat, cup, profile.

Before starting work, it is advisable to let the canvas hang in the unscrewed position for 10-12 hours.

Conditions for sharpening canvases with your own hands:

- ensuring the systematic removal of metal according to the shape of the section of the tooth;

- avoiding excessive pressure on the disc (this can cause annealing);

- ensuring the integrity of the height and shape of the section of the tooth;

- the indispensable presence of liquid for cooling;

- control of the absence of scoring.

Typical instructions for sharpening blades say that sharpening should be carried out either along the front surface of the tooth, or both along the front and back. But this is theoretically. In fact, most specialists, and even craftsmen from the people, perform it only on the back plane. so, they think, it is more comfortable.

Easy Band Saw Sharpening Jig

By and large, regardless of the abundance of rules and conditions, these devices are quite undemanding in terms of sharpening. They can be dealt with both by means of a specialized sharpener for tape blades, and by hand. In addition, circles of various configurations and substances can be used for processing.

Before sharpening the tape, it is advisable to familiarize yourself with the key methods for performing this procedure.

Sharpening recommendations

During the work of the canvas, its rupture is very often observed. This is due to the fact that it is poorly sharpened. This is due to the concentration of stress in the blade profile, if the sharpening is carried out at a low-quality level. The need for the procedure is determined by the condition of the band saws. If the surface roughness of the cut increases, this leads to a bluntness of the tool.

Sharpening of the tool is carried out using diamond, electrocorundum, CBN discs. Their choice directly depends on the characteristics of the material being processed. The sharpening of the blade, the production material of which is tool steel, is carried out with corundum wheels. The procedure for bimetallic tools is carried out correctly if a diamond or CBN wheel is used. The instructions will tell you how to carry out this procedure. The most important thing is that the angle does not change in the process.

Wheels of various diameters can be used for sharpening. The choice of one of them is determined by the parameters of the device. For this purpose, profile, flat, dish-shaped, cup circles are most often used. Sharpening is correct if the peripheral speed is 20 to 25 meters per second.

The principle of sharpening tape blades

If there are chipping on the tool, chipping will be observed on the edge of the workpiece. That is why it is imperative that sharpening is carried out correctly. During this process, it is necessary to work not only with the front, but also with the back of the canvas. Sharpening devices can be carried out in different circles. In this case, it is necessary to take into account the angle of the canvas. If you want to carry out the procedure correctly, then you need to learn it from a specialist.

In order for the band saw equipment to work efficiently, it is necessary not only to select it correctly, but also to sharpen it in a timely manner. For this purpose, special circles are most often used. This procedure is as simple as possible, which allows it to be easily performed by a master without appropriate experience.

What errors can occur during the sharpening process?

Error 1. Burnt sinuses of the teeth of the product

The reason for this phenomenon lies in the excessive efforts of the grinding wheel. As a result, the tape becomes blunt quickly.

Error 2. Incorrect angle of inclination and imperfection of the shape of the sinuses of the teeth.

Several factors can lead to this situation:

demolition of the eccentric of the sharpening device;

error in setting the angle of inclination of the machine head;

inconsistency of the profile of the grinding wheel.

That’s all. Now you know how to sharpen a band saw correctly, and what tools and accessories may be required for this.

Characteristics

Sharpening a band saw has a number of the following features:

- it is forbidden to use abrasive discs and hand sharpening tools with uneven wear of the working surface;

- when turning, it is important to perform all movements evenly, without jerking, uneven movement of the tool, since there is a high probability of violation of the geometry of the teeth;

- on the machines used, liquid cooling is required to prevent overheating of equipment and tape;

- after the completion of the work, there should be no burrs and chips on the surface, as they can negatively affect the quality of the cut;

- when sharpening a tool for winter use, it is important to increase the angle of inclination of the teeth to 90 0. However, it is unacceptable to use such a tape for woodworking in the summer due to increased loads on the cutting edge;

- when sharpening on machine tools, you need to make sure that the disc is correctly positioned relative to the belt profile;

- the speed of the grinding wheel is selected so that the metal is not red-hot, since in this case it will lose its strength properties;

- if the band saw was operated without maintenance or the recommended service life was exceeded, then during turning it will be necessary to remove a larger layer of metal in one pass;

- to control the quality of the sharpening of the tool, it is recommended to use a new tape as a reference;

- It is forbidden to change the factory shape of the teeth, as the saw will become unusable;

- the need for sharpening is determined by the degree of tooth wear by 35% of the original dimensions.

Uneven abrasive disc

Saw types

Band saws for their intended purpose are:

- Universal. used for cutting materials, cutting performance depends on the density and properties of the workpiece;

- Specialized. designed for cutting a certain class of materials, have increased wear resistance, allow cutting workpieces with maximum productivity.

According to the material, the following types are distinguished:

- bimetallic. the edge and blade are made of materials of various properties, which provide the best processing conditions and high cutting speed;

- carbide. they are characterized by increased wear resistance, are used for cutting strong, brittle hard materials;

- made of carbon steel. universal saws for general use, have limitations on cutting speed, processing productivity is average.

Features of sharpening band saws

A well-sharpened band saw for metal and wood is the key to productivity and long tool life. As a rule, such services are provided by special organizations, but if you know the sequence of actions and features of the process, you can sharpen a blunt saw on your own.

Drank service

To service the canvases, it is not enough to sharpen the teeth, it is also necessary to dilute them. These two procedures are performed in succession: they start with setting the teeth, and finish them with sharpening. It is required to strictly observe this chronology of works. Breeding is carried out in order to reduce the friction of the saw in the process of cutting a particular material (wood, metal, plastic, etc.). There are several methods of dilution, which depend on what elements need to be obtained subsequently, processing and the strength of the starting workpiece.

How to sharpen band saws on wood

Recently, among the repair and construction tools, the so-called band saws are gaining more and more popularity.

Those who own such a tool will probably be happy to know that it is so easy to sharpen it that you can do it yourself, without handing over the unit anywhere. The main thing is to know the technique of sharpening and acquire the materials that you will need for this. Well, if the service life has ended or the blade has broken, then you can purchase a new band blade for wood, meat or metal on the website of the company “Lentopila”.

Full-profile sharpening

For such a sharpening to be successful, it is necessary to use automatic machines. Elbor circles are specially mounted on these devices.

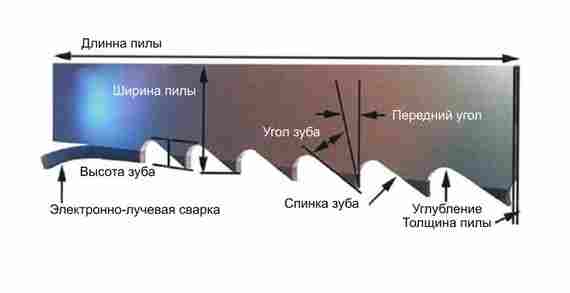

It is not easy to sharpen yourself in this way. Full-profile technology requires a specific grinding wheel for a specific band saw blade. In this case, it is worth taking into account the shape of the teeth, as well as their dimensions.

This type of sharpening has some features. So, it is done in just 1 movement of the circle. At the same time, immediately sharpening 2 teeth located closest to each other.

This method allows you to smooth the transition around the base of the teeth. The main disadvantage of this sharpening method is the need to operate a certain grinding wheel for processing the saw, depending on what is the characteristic of its teeth.

Sharpening edges

This method is somewhat simpler than the previous one, and therefore an ordinary person can also use it to sharpen a band saw on his own using a special machine.

In order to return the former sharpness only to the edges of the teeth of the product, it is enough to correctly use the engraver or file.

However, the sharpening will be of better quality and will be produced much faster if you use the machines designed for this, which take this technology as the basis for the principle of operation. If you operate the machine, then you also cannot do without the selection of suitable wheels.

A conventional sharpening machine includes:

- base;

- various drives that drive the grinding wheel and saw blade;

- special mechanism that secures the saw for the upcoming sharpening.

In order to control the operation of the machine, a special electronic unit is used. Sharpening the band saw should be done very carefully.

Beginners may accidentally miss the angle of inclination, or widen the space between the teeth, which leads to slight deformation of the tool and deterioration of its performance.