How to tension the vibratory plate belt. The final running-in

Vibratory plates in operation

This article takes a closer look at all aspects of operating a vibratory plate, and explores how to.

You can break vibratory plate usage down into a few things: a long time in storage, transport, active use. You would logically need to do most of the work if you use your plate extensively, so we’ll divide it further into: pre-start, start/stop and periodic maintenance.

Most vibratory plates on the market are about the same, so in this article we’ll look at the average vibratory plate. a reversible vibratory plate with a 200 kg petrol engine. (for example: Wacker Neuson BPU 3050)

Please read this operating manual (hereinafter referred to as the manual) through to the end

Use the transport wheels to move the vibratory plate to a new location.8. This section lists the maintenance intervals for the vibratory plate, which are the same as the manufacturer’s warranty.

The vibratory plate should be serviced on a level, clean surface in a well-ventilated area. The vibratory plate must be in a clean condition.

All engine maintenance must be performed in accordance with the engine manual.

Before performing any maintenance operations, switch off the engine and disconnect the high-voltage cable from the spark plug.

Contact a service center for this work.Requirements for the operating staff.The vibratory plate must only be operated by authorised personnel who have been specially trained in the operation of the vibratory plate and its components, who are familiar with this manual and who have a thorough knowledge of the safety instructions.

- Know the vibratory plate’s design and operating rules firmly;

- Check the technical condition of the engine and have it serviced in good time;

- Observe the safety instructions;

- know how to use protective equipment.

8.1 Check and change oil in the engine crankcase according to the engine manual.

8.2 Check and replace the engine air filter according to the engine manual.8.3 Changing the oil in the vibrator

The vibratory plate assembly may have different designs.

Remove plug with gasket, check that the oil level reaches the bottom of the thread in the oil plug hole.

- Unscrew the oil drain and change plug.

- Install the vibratory plate with the drain hole axis pointing downward at an angle of 15-30º.

- Drain the used oil into the receiving container.

- Set the vibratory plate horizontally.

| DO NOT | Drain the used oil on the ground, a special container should be provided for this purpose (used oil can be disposed at the nearest gas station). |

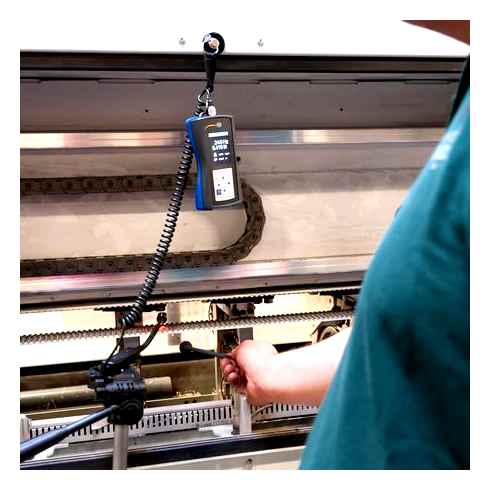

8.4 Check and clean spark plugs according to engine manual.8.5 Checking the tension (changing the drive belt) Proper belt tension ensures optimum power transmission from the motor to the vibrator. Loose belt leads to belt heating, premature wear and loss of performance. If the belt is too tight, excessive wear of the spindle and motor bearings will result.

Step-by-step plan for replacing the V-belt in the drive

Never operate the machine to its full capacity immediately after replacing the belt, even after the work has been carried out. Run in new spare parts beforehand.

The essence of the running-in is to temporarily start the drive under full load, followed by checking and re-adjusting the V-belt tension, if necessary.

Particular attention should be paid to the presence of extraneous noise and vibration during operation, caused by pulleys or bearings. If in this area you feel that the belt is getting noticeably hotter after a short run, the tension in the drive belt is too high and must be loosened.

The ideal total run-in time is 24 hours, but in production conditions it is always an unaffordable luxury, so we can limit the run-in time to night or at least lunchtime. In any case, it allows you to better adjust the tension than with no running-in period, and avoids the need for urgent adjustment or repair in the future.

- As a rule, it is necessary to tighten alternator belt every 15-20 thousand. km. If the system has been driven more than 10,000 km or more, replace the belt every 60,000 km. km. or once every 4-5 years. It is also important to check the tension because the alternator belt stretches over time.

- Some automobiles may have an automatic belt tensioner (tensioning is realized by means of springs). In this case the driver has no possibility to tighten the belt. The power steering system is designed to be repaired by the manufacturer.

- For replacement it is necessary to buy only quality alternator belts, rollers, bolts and tensioners, fully suitable for a particular make and model of car. The power steering system is governed by the GM’s recommendation that the power steering system be left connected to the ACC/ACCESSORY system.д.

The power steering system could malfunction if the vehicle starts to drive after a belt breakage. In this case, the effort to turn the wheels on the steering wheel increases significantly (especially noticeable at low speeds). For this reason, it is necessary to check the condition of the alternator belt regularly, especially if the CPS pump on a particular car is also driven from it.

We also recommend reading the article about what is CPS. From this article you will learn what is the difference between CPS and CPS, and which type of power steering is better and more reliable.

How to Prevent a Washing Machines Shaking and Spinning Noisily

How to check the tension?

Check the amount of tension in the belt before adjusting and tensioning it. Don’t forget that this parameter varies depending on the vehicle model and type of generator set. Optimal values of drive belt tension are specified in the technical documentation of the car, alternator or belt.

The average amount of deflection for a 10 kg weight should be approximately 1 cm.

Faults of a gasoline vibratory plate

If your vibratory plate does not go forward or does not want to start, you should first make sure that the unit is fully prepared for operation and start-up.

For example, users often forget to fill the tank, turn the ignition to the right position or set the air damper. So first make sure you have done everything right. If the vibratory plate still does not work under these conditions, look for the cause.

Some of the most common problems with vibratory plates with gasoline engines include:

- Low oil level. Or poor quality oil. Can make the engine not start or choke. This is why the petrol vibratory plate stops working.

- Contamination of the air filter. This causes the engine to become unstable, or to lose power, or to not start at all.

- Worn or broken spark plugs. Causes problems during start-up. It can also manifest itself as unstable operation.

- Contamination of the exhaust system. Or a burned-out muffler. Affects performance.

- Worn pistons or improperly adjusted carburetor. This can cause the vibratory plate to lose power or be unstable when not under load.

If you do not know how to tune the carburetor, it is better to contact a specialist. This also applies to replacing pistons.

But the rest of your vibratory plate‘s problems can be fixed by your own efforts.

How to check the oil

If the oil level in the ICE drops below the normal level, the engine may not start. This is because it is blocked by a special sensor integrated into the modern engine.

- Place the vibratory plate on a flat, horizontal surface;

- unscrew the oil filler cap;

- insert the dipstick;

- Determine the level by looking at it.

According to the manufacturer’s recommendations, an oil check should be done before each use of the vibratory plate.

The oil filter has its own requirements for changing it. The first replacement should normally be done after 20 hours of operation. All subsequent times the oil is changed at intervals of 100 hours of operation.

How to Clean the Air Filter

Another possible cause of vibratory plates that cause them to stall or become unstable is a dirty air filter.

- Remove the air cleaner cover;

- unscrew the fasteners and remove the filter;

- wash the filter with warm water and detergent (only the sponge filter can be washed);

- dry it;

- soak it in engine oil and remove the excess;

- if it is a paper filter, clean it with compressed air or a vacuum cleaner;

- assemble in reverse order.

if the filter is very worn out, then the best solution is to replace it.

The air filter usually needs to be cleaned and flushed no more than once. After one cleaning, it is better to replace it.

It’s easy enough to do without help.

How to check the spark plugs

Check to see how dirty, worn, and spaced the electrodes are. The owner of the vibratory plate will be required to do the following:

- use a socket wrench to unscrew the spark plug;

- visually check the condition of the element;

- determine the gap between the electrodes, which should be 0.7-0.8 mm;

- adjust the clearance, if possible;

- If the spark plug is badly worn, replace it with a new one.

This is exactly the same as in a petrol engine vehicle.

How To Tighten Fixings On A Vibration Plate

Peculiarities of exhaust system maintenance

This procedure includes the following activities:

- unscrew the mounting screws and remove the cover;

- Disconnect the muffler from the flame arrestor;

- Remove all contaminants with a metal brush;

- If the muffler is not burned out, reassemble the assembly in the reverse order.

If the engine still does not work after all the measures you have taken, and the vibratory plate is not moving, the best solution is to call a service center for professional diagnostics and repair.

The secret of long and trouble-free operation of your vibratory plate is quite simple. First you need to choose a good level at the beginning. Second, carefully study the instruction manual and follow these recommendations. And thirdly, to carry out timely maintenance and try to correct any malfunctions at the first signs of failure.

Who has a vibratory plate? What did you buy or rent?? Have you ever had a breakdown?? What was it? How the problem was solved?

Main faults of vibratory plates

All malfunctions with vibrating plates are related to their main assemblies:

Since the engine is the main component of the equipment, the greatest number of breakdowns is associated with it. Each drive type has its own specific problems, so it’s worth taking them apart.

Malfunctions related to the frame, platen and handle are very rare. Usually these structural elements last several years without any problems.

When there are minor cracks in the soleplate, handle or motor frame, these can be repaired with a welding machine. If the base is badly worn, it is completely replaced. It is also often the installation of new shock absorbers.

Low oil level

Many modern engines are equipped with oil level sensors in the crankcase, which blocks the engine start if the level is below normal.

Place the vibratory plate on a flat, horizontal surface and check the oil level with the oil dipstick.

Oil level must be at the edge of the neck, as shown in the picture. If necessary top up oil or change oil completely.

The repair of rammers in the workshop has a number of features

Diagnostics is free of charge in the service center and is usually carried out in the presence of the client. Vibratory rammers repair is carried out on the highest quality level, using our own spare parts warehouse. Innovative, high-tech equipment and tools are used in the repair process. All this allows you to perform work in the shortest possible time, which in turn protects from downtime of the construction site.

You can always use the services of a traveling specialist or order the delivery of equipment in Moscow and the Moscow region. For on-site repair of vibratory rammers at your site, call us by phone or leave an application online. Technicians leave within a few hours, regardless of holidays or weekends.