How to trim a ceiling plinth with a miter box

Features of cutting different materials

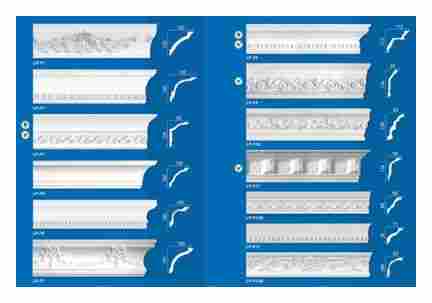

Ceiling decorative fillets are planks of different density, width and hardness, depending on the materials used to make them.

For installation work, it is important to correctly cut the plinth for decorating the ceiling so that its corners form beautiful joints in straight sections or in the corners of the room being decorated.

A ceiling molding made of various materials has certain features during installation and cutting.

- Foam baguette is the most unstable type of material to any, even minor, mechanical damage. But foam products are lightweight and inexpensive. This ceiling molding can be painted with acrylics in any shade you need. Styrofoam is easy to cut, but it also crumbles. It can be processed using a hot wire clamped in clamps, a carpenter’s cutter, a hacksaw, or a simple but sharply sharpened knife.

- Expanded polystyrene molding. Such a product is similar to its foam counterpart, but the strength of the polystyrene material is an order of magnitude higher. Products made from this composition are lightweight and cheap. Styrofoam processing can be done with a sharp knife or metal hacksaw.

- PVC skirting board. This material is easily crushed, after which it is no longer possible to restore its original appearance. For this reason, installation work with such a skirting board must be accurate, as well as carried out without undue application of effort when pressing. You can cut a PVC cornice with a carpenter’s cutter, a sharp knife or a hacksaw for metal.

- Polyurethane plinth is the most durable material, which, unlike gypsum stucco molding, weighs much less, but is not limited by various conditions of use. This type of decoration is easy to install and does not need particularly complicated adjustments. To trim corners, you need a small fine-toothed saw or a regular hacksaw, as well as a miter box.

- Aluminum molding is the most stylish type of material used for modern design, it is lightweight, durable and highly aesthetically pleasing. To fit it, you will need a saw or a hacksaw for metal, as well as a miter box. To process aluminum molding, the master must show jewelry accuracy, since errors and inaccuracies in cutting will be very difficult, and most often impossible to correct.

- Wooden cornice is still a popular and durable material that can be used for ceiling decoration. Its advantages are considered strength, hardness and the ability to withstand loads of a certain complexity. Ceiling cornices made of wood are easy to process, which is performed with an end saw, a hacksaw for wood, and also with a blade for metal. Wooden products retain their original appearance for a longer period than their foam counterparts. If desired, the cornice can be painted or varnished.

If we compare polystyrene and expanded polystyrene, then both of these materials are united by a special softness, which makes it possible to press the plinth to the working surface without leaving any gaps during installation. Most ceiling moldings have recesses for mounting a ceiling lighting system. As for wood and aluminum, it is rather difficult to join corners or cuts of these materials. The same applies to plastic materials. To cut such a baguette, you will need to use a miter box, and the process itself must be done carefully and very carefully.

How to cut corners with a miter box?

The miter box is a professional carpentry device that should be used for the purpose of cutting any workpiece evenly and with a given cutting angle. Outwardly, the miter box looks like a shallow tray made of plastic or wood, on the sides of which there are notches at an angle of 90 ° or 45 °. It is these slots that allow you to cut the cut angle for the corner joint of the ceiling cornice according to such a template. advanced types of miter box are also available, which make it possible to cut molding at an angle of 60 °.

Correctly determine the inner or outer corner at which you need to cut the plinth, you need to based on the measurements of the corners of the decorated wall.

In order to accurately determine the angle, in some cases it will be necessary to trim the wallpaper, subsequently they will not interfere with the installation of the prepared cornice. Cutting of the ceiling cornice is performed for various types of corners of the room to be decorated.

Internal

The molding to be processed, first of all, must be pressed close to the ceiling and the required length must be measured. Then the workpiece is transferred to the miter box and held in this way, so it will be mounted towards the ceiling surface. Firmly holding the workpiece with one hand, they take a saw in the other hand and saw off the part at the angle we need. In the process, when it is required to cut the desired cut of the corner, it is not recommended to press on the saw with great effort. the movements must be done smoothly and carefully. Then you need to cut off the symmetrical part of the second ceiling molding, which will form a joint.

The procedure is performed in a similar way. first, the molding is applied to the ceiling, the place of trimming is marked, and using a miter box, this decor piece is trimmed at the required angle. Next, you need to dock both prepared sections and see how tightly they touch. the cut line can be adjusted by file or emery.

How to cut a ceiling plinth?

- Features of cutting different materials

- How to cut corners with a miter box?

- How to do without a miter box?

- Using a template

- Advice

Ceiling cornice is a decorative detail of the interior, which serves as a kind of decoration located between the ceiling and the wall surface. Using such a decorative product, it is possible to hide minor defects in the wall or ceiling surface, as well as to make a transition between their finishing coatings, dissimilar in structure. The installation of the ceiling cornice is not particularly difficult, it is quite possible to cope with such a volume of work on your own, without resorting to the expensive services of hired craftsmen. One of the important points of installation is the correct cutting and fitting of the ceiling plinth at the corner joints. Let’s take a closer look at how to cut the ceiling plinth.

Using a template

When you do not have a miter box, cutting a ceiling molding is easy if you make a template for this. It can be used to cut both narrow and large cornices. The template can also be useful when there are uneven corners in the room. To make a template, you need to perform the following procedure:

- take a piece of thick cardboard and bend it at the angle that you measured at the place of the inner or outer junction of the walls; cut off the cardboard at the fold;

- take a wooden plank, attach cardboard to it and draw a fishing line, according to the cardboard template; cut off the corner of the plank along the intended mowing line;

- to cut the plinth, a wooden template is used, which is applied over the plinth, and then the desired angle is cut;

- the second corner of the joint is cut according to the same principle.

If, when adjusting the joints, a small gap is found, it can be corrected with a regular finishing putty or with a silicone sealant.

Errors of joints on a wooden or aluminum fillet are removed by grinding the cut points with a file.

The trimming process must be smooth and accurate. To get this skill, experts recommend practicing on small pieces of material.

How to do without a miter box?

For a perfectly even fit of two corners at the junction of the ceiling cornice, you can cut the workpieces without placing them in the miter box, but by marking directly on the ceiling. To determine and mark the inner corner, the length of the ceiling cornice is measured starting from this particular corner. In order to mark the outer corner, it should be borne in mind that in the direction of the room, a wide cornice will go out exactly by the amount of its width.

Let’s take a closer look at how to cut a plinth without using a miter box

- The curtain rod blank is pressed tightly to the ceiling surface, then a straight line is drawn along the outer side of the plinth.

- On the right side of the corner, it is necessary to press the cornice to the ceiling surface and draw an additional straight line, placing it along the outer side of the workpiece.

- Where the traced lines can cross this point and draw a straight line from it leading to the bottom corner of the skirting board. This will give the markup, along which the plinth will be filing at the required angle.

- Further, in the same order, lacing is performed for the left corner on the second ceiling blank.

- The next step, when both corners are cut off, they are folded towards each other and the quality of the resulting joint is checked. If errors are found, they are removed using sandpaper, as well as a file.

- After both workpieces are perfectly fitted, the curtain rods need to be cut to the required length and glued to the wall. Trimming is not done before the perfect race of the corner cuts. During installation, you need to know that for decorating stretch ceilings, the ceiling plinth is not fixed to the ceiling, but only mounted on the wall.

To trim the skirting board for the purpose of joining it in the inner corner of the room, the markings are made as follows:

- the plinth is pressed to the right of the inner corner, and then the line is drawn with a pencil along the ceiling;

- the same is done on the left side of the inner corner;

- in the place where both mowing lines intersect, put a point; as well as the point is also marked at the intersection of two plinths in the area of the inner corner of the room;

- you need to connect both points with a straight line with an angle of inclination inside the skirting board and cut off the skirting board according to the markings;

- fold both skirting boards together and, if the joint is made inaccurately, one of the sides must be cut again; after a perfectly executed skirting board can be fixed to the wall.

When the installation is carried out with a wooden or polyurethane ceiling cornice, inaccuracies in the joining point are corrected with a file. To adjust the cuts of parts made of polystyrene or expanded polystyrene, defects can be eliminated using a sharp knife. This technique of trimming the ceiling cornice is convenient in those houses where the external or internal angle is not kept exactly at 90 °, but has a size, for example, 87 ° or 94 °. The use of a miter box in this case will be ineffective.

External

The outer corner is cut a little differently. Experts recommend first marking and cutting the inner corners, and then preparing the outer corners. The cornice is pressed against the ceiling and a place is marked for trimming the corner. Further, the eaves plank fits into the miter box and is trimmed. The second workpiece is prepared in the same order of execution of the algorithm. When both corners of the cornice are cut off, check their joint quality. If irregularities are found, fit the two parts more tightly.

The considered trimming options are convenient to perform using a miter box.

This method can be convenient when the angle at the junction of the walls is exactly 90 °.

However, in practice, perfectly flat walls are rare; in this case, other methods will have to be used to prepare the ceiling cornice.

How to trim the corners of a skirting board. How to properly cut the corners of ceiling plinths: both with and without a miter box

When planning the premises of their apartment, many people think about how difficult the work can be. However, everything is not so scary: the ceiling plinth can be installed with your own hands. the main thing is to know about some of the features of the materials from which this finishing element is made.

- DIY room repair for beginners step by step. Budget repair rules

- Small insects in the apartment. All the variety of insects in the apartment

- Finishing a new building from scratch. Where to start: sequence of actions

- How to glue the seal on the windows. How to choose how to glue self-adhesive insulation for windows

- Do-it-yourself concrete path in the country. Simple do-it-yourself concrete garden path

- How to wash a polycarbonate greenhouse. How to wash a polycarbonate greenhouse in the fall

- How to glue MDF panels to the wall. Glue method

- How to trim the corners of a skirting board. How to properly cut the corners of ceiling plinths: both with and without a miter box

- Different materials and their features

- How to properly cut the ceiling plinth with your own hands. Ceiling plinth. fillet

- Skirting materials and cutting methods

- Factory ready corners

- How to make a corner on a skirting board. How to make a corner of a ceiling plinth, how to properly fit and cut a plinth

- Video how to trim the ceiling plinth (for outside corners)

How to trim the corners of a skirting board. How to properly cut the corners of ceiling plinths: both with and without a miter box

Factory ready corners

It is worth saying that every master has the opportunity not to pore over precise cutting and fitting of corners.

It is enough to measure the desired length of the workpiece and cut it off at right angles.

All flaws and mistakes will be hidden by this special element. But such a good way to use does not always work out, since the classic dimensions of such factory corners can stand out well from the dimensions of the plinth itself.

Such angles will stand out with their own disproportion, and it will not look very neat. However, if the design of the room and the size of the blanks make it possible to use this method, then you should not disdain them.

For those who have to use one of the options for trimming the plinth for the ceiling, the following tips will come in handy.

How to properly cut the ceiling plinth with your own hands. Ceiling plinth. fillet

To do this according to the rules, it is important to strictly follow the existing recommendations and rules for finishing work. And then you will like the result.

There are no problems in fixing the plinth (this is the name of such an element): almost all types of products are fixed with good glue.

In order to hang the ceiling plinth. even inexperienced repairmen do not have difficulties. They are worried about something completely different: how to cut the ceiling plinth correctly? Almost almost any room, no matter how complex its shape, is equipped with corners.

And in these inner corners, some parts of the skirting board should be aesthetically pleasing and evenly joined. And in rooms with a particularly difficult shape, you will have to be smart about the outer corners. Let’s try to figure out how to be in any of these circumstances, and how to cut the necessary part using the available tools.

Skirting materials and cutting methods

First of all, let’s try to determine what fillet can be made of, and what specific material is better to cut.

On sale today you can find products made of foamed polymer (PVC), wood, expanded polystyrene and polyurethane.

Perhaps one of the very inexpensive skirtings is made of foamed polymer, which is a fragile, soft and brittle material.

Even fingers can dent them, and they easily get creases and imperfections. Cutting an aesthetically pleasing and even corner of a PVC-based skirting board is very difficult.

From an inexperienced craftsman, a huge amount of purchased material can go to waste for this particular reason. Also, this polymer material has high electrostatic properties, which explains its ability to collect dust.

It is best to cut such a plinth with a hacksaw or a sharp construction knife.

Products made from expanded polystyrene are also inexpensive, although this material is considered a very durable similarity to the classic expanded polymer.

It can also be finished with a sharp tool.

Skirting boards made of expanded polystyrene extrusion are slightly more expensive, they are somewhat denser and more difficult to cut. But they crumble much less and can break.

This makes cutting them more convenient and easier. For this purpose, it is good to use a hacksaw or a sharp knife.

Polyurethane ceiling skirting boards are now considered, probably, one of the much more very expensive.

However, they justify their own cost: moisture resistant, as strong and dense as possible, very flexible.

Placed above the stove in the kitchen, the skirting board can change its shape and even crackle a little.

They are perfectly cut with a special knife, without forming a crumb. But these products are very susceptible to temperature changes.

Wooden ceiling plinths are rather weighty and dense products, solid and reliable.

They lend themselves well to finishing with a specialized fine-toothed hacksaw. Also use a good metal blade. So how to cut the plinth for the ceiling correctly?

Different materials and their features

- . The most durable material in comparison with the other two, listed below, the advantages of which are in hardness, impact resistance and the ability to withstand certain mechanical loads. Nevertheless, wooden skirting boards (also called fillets) glued to the ceiling are also relatively easy to process. they can be cut (a hacksaw is used for this), varnished. Wood will add warmth to the interior. Of the minuses, you can name a higher cost than foam. However, wooden fillets also retain their appearance longer than foam fillets.

Styrofoam. Perhaps this material is the most fragile. it is unstable to mechanical damage, scratches and even minor impacts. Of the advantages. light weight, the ability to paint in various colors and ease of processing (it can be cut with a clerical knife. however, very carefully).

Expanded polystyrene. This material can be considered a type of foam, however, its strength characteristics are slightly higher (extruded polystyrene foam is denser than foam). With regard to processing. expanded polystyrene is just as easy to cut with an ordinary sharp knife, and also has a low weight, and this is an important factor when considering the load on the walls.

Popular materials

How and how to properly cut a plastic skirting board

Plinth is an indispensable part of room design. For example, plastic products are gradually replacing wooden ones. Functionality and convenience are inherent in this finishing material, and it creates an aesthetic flow of the wall to the floor or to the ceiling. In the absence of finishing, containing the presence of plinth strips, even offices designed in the same style seem unfinished. The problem lies in the loose abutment of the floor slab to the wall. This creates rough seams that are removed by skirting boards. Fixation is easy to implement without the help of professionals, it is based on the knowledge of how to cut a plastic skirting board and in what ways to install.

Different materials and their features

- . The most durable material in comparison with the other two, listed below, the advantages of which are in hardness, impact resistance and the ability to withstand certain mechanical loads. Nevertheless, wooden skirting boards (also called fillets) glued to the ceiling are also relatively easy to process. they can be cut (a hacksaw is used for this), varnished. Wood will add warmth to the interior. Of the minuses, you can name a higher cost than foam. However, wooden fillets also retain their appearance longer than foam fillets.

Styrofoam. Perhaps this material is the most fragile. it is unstable to mechanical damage, scratches and even minor impacts. Of the advantages. light weight, the ability to paint in various colors and ease of processing (it can be cut with a clerical knife. however, very carefully).

Expanded polystyrene. This material can be considered a type of foam, however, its strength characteristics are slightly higher (extruded polystyrene foam is denser than foam). With regard to processing. expanded polystyrene is just as easy to cut with an ordinary sharp knife, and also has a low weight, and this is an important factor when considering the load on the walls.

How to cut a wide skirting board. Docking of ceiling fillets without industrial miter box

Factory miter box. This is an aluminum, plastic or wooden tray with depressions 45 0 or 90 0. Such a device is rarely used at home, so it is not found in everyone. But few also know how to cut a ceiling plinth without a miter box, so we will consider a few simple solutions that will allow you to dock ceiling plinths in the corners of the room with great accuracy.

How To Use A Miter Box To Cut Trim

When renovating an apartment, installing a new ceiling is often necessary to create a complete design idea. The completed ceiling is decorated with beautiful fillet skirting boards. The baguettes are glued, nailed or screwed along the perimeter of the room, their position is previously marked in the corners at the joints of the walls and ceiling. Ceiling cornices are often rigid and solid strips (although there are elastic silicone ones), so they need to be beautifully docked in the corners of the room with each other, and without a miter box it is difficult to do this, but it is possible.

Fillets for framing the corners of the ceiling are made of polyvinyl chloride (PVC), expanded polystyrene (PPU), polyurethane (PU), polystyrene (PS), polystyrene (PP), wood or metal:

- Foam decorative cornice is fragile, but this does not matter for unloaded ceiling structures. PP skirting boards can have different widths, the standard length is 1 meter, the surface is bas-relief with various patterns;

- Expanded polystyrene. the material is dense, easy to install, the edges of the cornice do not crumble during cutting;

- Aluminum or wood is the most difficult to dock. you need great accuracy, which is difficult to achieve without the use of a miter box. It is recommended to cut the corners of such curtain rods with a sheet for metal, to calculate the correct cutting angle, use the methods below.

Products and the nuances of their application:

Parameters and requirements

Cut with a carpenter’s cutter or a hacksaw for metal

The foam plank is fragile and crumbles easily. It is recommended to cut the PP plinth with a very sharp cutter or a special tool. an electric nichrome cutter

Cut with a carpenter’s cutter or a hacksaw for metal, hot wire clamped in clamps

Durable and aesthetic material.

- How to properly cut the skirting boards to the ceiling. How to properly cut the corners of ceiling plinths: both with and without a miter box

- Different materials and their features

- How to cut the corners of a skirting board with a miter box. How to properly cut corners on skirting boards

- How to cut a wide skirting board. Docking of ceiling fillets without industrial miter box

- How to cut a plinth floor. How and how to properly cut a plastic skirting board

- How and how to properly cut a plastic skirting board

- Choosing the right tool

- Miter box cutting

- Video how to cut corners on a ceiling plinth

How to cut a plinth floor. How and how to properly cut a plastic skirting board

How to properly cut the skirting boards to the ceiling. How to properly cut the corners of ceiling plinths: both with and without a miter box

How to cut a skirting board for an angle other than 90 degrees

Many rooms boast angles that do not correspond to 90 degrees. Such situations arise as a result of shrinkage of the soil and the structure itself, as well as in violation of the technology of wall construction.

In this case, the correct marking with a miter box or drawing will not work, all actions are performed directly on the spot:

- Before trimming the corner of the ceiling plinth, it is applied to one of the walls and an emphasis is made with the end to the other wall.

- A line is drawn along the plinth.

- Perform similar actions on another wall.

- At the intersection of the two lines, a mark is made on one of the skirting boards, which is connected to the corner of the workpiece. An incision is made along this mowing line.

- Repeat the steps on the other plinth and try on both blanks. Make the necessary adjustments.

- The skirting boards are glued in place, the joint in this case must be tight enough.

Cutting the skirting board in the corners without special tools

The question of how to properly cut off a 45-degree angle on a plinth can be solved without a special device. To do this, perform the following actions:

- Take a sheet of paper and apply a baseboard to it.

- Draw two parallel mowing lines to mark the sides.

- Then take a regular protractor and measure 45 0.

- The line of the future cut is drawn along the mark made.

- Before cutting the ceiling plinth, it is laid on a sheet of paper, while controlling the coincidence of the lines and sides.

- The markings from the sheet are transferred to the plinth and a cut is made in the right place.

The disadvantage of this method is the need to keep the saw on weight during the cutting process.

How to cut a plinth for a ceiling

First, a miter box is used to properly cut the skirting board. This device is a special tray that allows you to cut wood, plastic or other materials at the desired angle. The miter box can be purchased in a retail network or made by hand; in the first case, the kit may include a saw. However, a tool available from a home craftsman for cutting materials may well be used.

The device has a recess into which skirting boards or boards are inserted. There is also a saw slot with an inclination of 45 and 90 degrees. For example, you can consider how to cut corners on a ceiling plinth at an angle of 45 0 using a miter box.

Such a process involves the following actions:

- The plinth must be attached to the attachment point.

- Make a mark for cutting.

- Install the plinth into the recess of the miter box, pressing it against the surface of the device with its underside. In this case, the side intended for applying the adhesive must look up.

- A saw is inserted into the hole for a 45 degree cut and the plinth is sawn off.

- Using the same saw or knife, the cut can be corrected by removing irregularities.

- The plinth is glued in place. The task of how to cut the ceiling plinth in the corners is considered solved.

Working with outside corners

As a rule, there may be external corners in the rooms, which also need to be pasted over with skirting boards. The question of how to cut the skirting boards at the corners of the ceiling in this case can be solved in the following ways:

- Using a miter box. Almost the same actions are performed as for internal corners. The only difference is that the glued side of the plinth is pressed against the surface of the device.

- The markup is in place. Similar to the inner corners, a mowing line is drawn on the ceiling and the same technology is used. With a rounded external corner joint, the joint is finalized with a knife.

Self-made miter box

The miter box can be made by hand using wood or metal. The width of the workpiece can be different, the main thing is that it does not exceed the size of the hacksaw, in this case, such a task as cutting off the corner of the ceiling plinth will be easier to complete.

The manufacturing process is as follows:

- A transverse line is drawn in the center of the workpiece.

- From it, in both directions, measure half the width of the workpiece and make marks.

- Labels connect crosswise.

- Now you need to mark the side walls of the device.

- The walls are alternately applied to the base and marks are made in accordance with the markings on it.

- At these marks, straight transverse mowing lines are drawn along the walls.

- Next, they start assembling the miter box. The side walls are attached to the base with self-tapping screws or bolts, depending on the material used.

- Saw slots are made after hollow assembly of the fixture.

Using a factory-made or self-made miter box, you can speed up the process of cutting skirting boards up to 10 times. This is especially important for craftsmen who regularly carry out repair work and are faced with the task of how to cut a ceiling plinth.

Skirting board cutting tool set

Working tools when solving the problem of how to properly cut the ceiling plinth in the corners are selected depending on the material from which the plinth is made, since each of them has its own processing characteristics:

- The PVC skirting board has no resistance to mechanical stress at all. Even light pressure results in irreparable damage. Therefore, no great effort is required during the cutting process. The question of how to cut a PVC skirting board is solved using a blade, a sharpened construction knife or a hacksaw for metal.

- The skirting board made of polystyrene also does not differ in particular strength, but in comparison with polyvinyl chloride it has a higher quality, moreover, it crumbles easily. Cutting the foam ceiling plinth is done with sharp tools, just like PVC.

- Wooden skirting boards have higher strength characteristics and aesthetically pleasing appearance. However, the cost of such products is quite high. For cutting wood skirting boards, it is recommended to use a wood hacksaw with frequent teeth, since the teeth of a hacksaw for metal are easily clogged with sawdust.

How to cut a ceiling plinth in the corners. options and methods

Ceiling skirting boards are an integral part of the finishing of the ceiling space. With their help, cracks and wall defects are masked, they can be used to cover the irregularities of the suspended ceiling structure or wallpaper. In addition, skirting boards complete the interior of the room. One of the problems in the assembly process of these elements is the perfect joining in the corners. The question of how to cut a plinth to the ceiling in the corners is solved in several ways.

Factory corners. an alternative option

Cutting the ceiling plinth at the desired angle is quite difficult, this procedure requires accuracy and precision. With the help of a special device. a miter box. skirting boards can be easily cut at a 45 degree angle. When gluing the skirting board in corners other than 90 degrees, manual marking can be used. In order for the ceiling to look decent after repair, you need to know how to cut off the ceiling plinth correctly, and select tools in accordance with the material of manufacture.