How To Untangle A Chain From A Chainsaw

Chain design

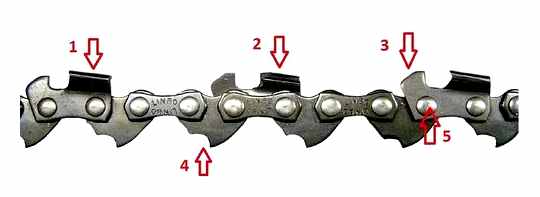

The saw chain consists of the following elements:

- Left cutting tooth.

- Right cutting tooth.

- Cutting depth stop.

- Leading link.

- Rivet.

For the chain to cut well, it is necessary to sharpen each tooth on the left and right sides. However, in order not to spoil the sharpening, it is important to know what shape our teeth on the chain are. There are two common forms of saw teeth:

- Chipper. This is the more common tooth shape and is found in almost all chains. Here the profile is somewhat rounded, so it is much easier to sharpen it with a round file. However, in practice the chipper dulls a little faster than the chisel.

- Chisel. The cutter profile in this case looks like a seven. Such a cutter has a rather small contact area when it comes into contact with wood, so it encounters less resistance. For this reason, in one cut, it makes a greater depth of cut, which means that the speed of cutting a log will be higher (in comparison with a chipper). But sharpening it without damaging the edge is much more difficult.

Saw chain sharpening methods

There are three ways to effectively sharpen a saw chain:

- File.

- Angle Grinder.

- Sharpening machine.

Chain sharpening angle grinder

If you have an angle grinder, you can sharpen your chainsaw chain much faster. It is best to use a small, 125-disc angle grinder. Sharpening is done at low speeds. There are two ways to sharpen an angle grinder.

Sharpening the chain with a file

This type of sharpening can be used directly in the field. It requires a round file, a holder for it (clamp) and a vise for clamping the tire.

To sharpen with a file, you need to perform the following manipulations:

- Clamp the tire in a vice. If you are in landing and did not take a vise with you, then you can clamp the tire by resting it on the log.

- Place the clip with the file on the chain so that it creates an angle of 30 °.

- With light movements forward (away from yourself), we sharpen the tooth. With a new file, it is enough to make 5. 7 movements. If the file has already been used several times, then more movements will be required.

- After the tooth has been sharpened, remove the file with a clip and scroll the chain to the next tooth. After passing all the right teeth, turn the saw (or change the position of the file) and sharpen the left teeth.

Some file holders have a filed template on which the turning angle is already marked. So you do not have to “figure out” this angle. But from experience we will say that you need to practice well until it turns out to sharpen the chain perfectly smoothly with a file.

How to sharpen a chainsaw chain with your own hands: 3 proven methods

The quality of sawing wood with a chainsaw largely depends on the sharpness of the chain. How to sharpen a chainsaw chain with your own hands at home? We will show you three good ways.

The speed and quality of sawing wood with a chain saw depends on the sharpness of the chain. It needs to be sharpened from time to time. How can this be done? We will tell you about three reliable ways that you can sharpen the chain yourself. One of them allows you to sharpen the chain directly in the field, while the other two require a special tool and electricity.

Method 2

In this case, it is the angle grinder that needs to be fixed immovably. Can be clamped in a vise or screwed to a workbench with a bracket. Sharpening is done as on a conventional grinding wheel. We hold the chain with our hands and turn it so that the tooth sharpens at an angle of 30 °.

With this method, hands are less tired, since you need to hold the chain, and not the angle grinder. However, the chance of getting injured increases significantly. We recommend using this method infrequently or not at all, since safety is still more important than speed or quality of sharpening.

Method 1

We install the chainsaw on the table, and clamp the tire with a vice so that it does not move during operation. We set low revolutions on the angle grinder (if there is only smooth adjustment, then slightly press the start button). We direct the disk at an angle of 30 ° relative to the plane of the tooth and tilt it slightly (as shown in the photo). Press down on the tooth with light, soft movements.

With this method, the main thing is not to overheat the tooth and not to grind off too much metal. It is much easier to grind teeth, sharpening in this way, than with a hand file, but the sharpening speed increases significantly.

Chain straightening with a sharpener

Straightening the chain with a sharpening machine is one of the most convenient, fast and high-quality at home. True, you will have to purchase a machine, which costs about 2,000. 3,000 rubles, but then forget about problems with chains.

The sharpening machines have a chain holder (1) with a blocker, with which you can fix the chain. It also allows you to set the horizontal chain sharpening angle in the range from 0 ° to 40 °. We put a chain on it and set the angle we need. Then, using the lever (2), we adjust the angle of inclination of the grinding wheel, that is, at what angle it will go under the tooth. Before starting sawing, lower the blade onto the chain and set the stopper (4) in the desired position so that during operation do not lower it further and cut the chain. Sharpen each right tooth, then turn the holder with chain 180 ° and sharpen each left tooth.

The advantage of this method is that even an inexperienced operator can sharpen. Also, the machine has a protective cover (3), which will prevent injury during operation. However, as we have already said, you will have to spend a little money on purchasing a machine. If you need a good model, but do not want to overpay for famous brands, take the Champion C2001, which is by far the best budget model.

Power tools for working with wood:

How to sharpen a chainsaw chain with your own hands

Everyone knows that the saw chain, which is used in chainsaws, needs to be sharpened periodically, but not everyone knows how to do it correctly. Determining that the saw requires sharpening the chain is very simple, for this you need to inspect the sawdust, and if they consist of fine dust, then the tool needs to be sharpened. If sharpening is impossible, it is worth replacing it with a new one.

We will analyze the main ways with which you can, without problems, sharpen the chain on a chainsaw.

Description of the sharpening process with files

The first thing to start with straightening the saw chain on the saw is placing the tool on a flat surface or table. In forest conditions, a large diameter chock is well suited for this. Next, you need to inspect the saw chain for any defects, it can be cracks, completely broken off teeth. After inspection, you need to set the brake in working condition, thereby blocking its movement on the tire.

It is advisable to put a stand under the tire, as it you can use a log, a piece of a branch of a suitable diameter, or the manufacturers of sharpening tools have special clamps to hold the bar in the process of sharpening the chain.

The chain is sharpened by moving the file from the inside of the tooth to the outside. In this case, the file must be parallel to the special mark on the chain. This mark is applied by the chain manufacturer to indicate the standard sharpening angle.

The tooth to be sharpened should be located approximately in the middle of the tire, this is necessary for the convenience of work, during the sharpening process, you need to move the chain along the tire, remembering to set the brake to the working position each time.

Ideally, manufacturers advise to carry out the same number of file movements for each tooth, but in practice this is not always possible, because The teeth have different degrees of damage to the working edge.

To facilitate sharpening the saw chain with a file, special holders can be used, with corner markings applied to them. The markings are made not only for the standard cross cut, but also for the longitudinal.

Tool holders are also handy if you don’t have sufficient sharpening experience. Experienced sharpeners do not use holders for sharpening, but can only use special devices that support the file.

Another sharpening device is a hand-held saw chain straightener. It uses a regular file as a sharpening tool, which can be replaced independently. The machine is mounted directly on the tire, it also has the ability to adjust the angle of sharpening of the tooth and a special stop that holds the sharpened tooth.

Manual sharpening machine, perfect for beginners. Along with electric models of sharpening machines, manual has its undeniable plus in the form of a low price. Depending on the manufacturer of the hand-held machine, their appearance may differ, but the principle of operation is the same for all.

The depth of cut is adjusted with a flat file, so that there is a difference between the upper cutting edge of the tooth and the height stop.

As can be seen from the figure, the depth gauge is ground in such a way as to bring the gap indicator to the factory value. Below is a table showing the main values of the angles, as well as clearances for the most common types of chains.

As a rule, the size of the gap is corrected using a special die. It is installed on the chain during sharpening, after which the depth gauge is grinded.

Electric grinding machines

To straighten a large number of chains, as a rule, in service centers or in manufacturing plants, electric sharpening machines are used. Depending on the manufacturer, the design of the machines may vary, but they have the same principle of operation.

The saw chain is installed in a special guide, which is mounted on the basis of the turntable and has a special retainer to hold the sharpened tooth. The latch can be moved horizontally. Electric emery is installed at an adjustable angle to the sharpened tooth, which is activated by the operator by pressing the start button. The immersion depth of emery, as well as the angle at which the sharpening is performed, can be adjusted. The dive itself is performed by the operator. The chain is straightened with a special grinding wheel, which can be changed if necessary.

How to sharpen a chain on a chainsaw with your own hands

A person who has a chainsaw in his household should know how to sharpen a chainsaw chain with his own hands. There are several ways:

- Sharpening with a file (the most common method of sharpening, because it allows you to sharpen the tool directly at the cutting site.)

- Sharpen using a special machine (this method is used in service centers, but can also be used on a personal farm)

- Sharpen using an angle grinder. To sharpen in this way, certain skills are required. Uncommon method, because K. Difficult enough to sharpen with an angle grinder correctly.

In this. You can familiarize yourself with the sharpening process, the most popular methods and tools used for this.

File

For sharpening and straightening saw chains, two types of files are used. First, this is a round file with a diameter corresponding to the rounding diameter of the working edge of the saw tooth.

For sharpening saw chains of household tools, round files with a diameter of 4, 4.8 mm are used, due to the fact that they have a small tooth. For professional models, more powerful chains with a larger tooth are used, and accordingly files with a diameter of 5.2, 5.5 mm are needed.

In order to sharpen correctly, it is not enough to sharpen only the cutting edges of the tooth, you also need to adjust the cutting depth limiter. If this is not done, the chain will not cut into the material to be cut to the required depth, which will significantly reduce the speed of work and, just like in a situation with a blunt chain, can lead to overheating of the saw motor due to insufficient load on the motor. This work is done with a flat file.

Sharpening with a file

The first thing you need in order to sharpen the chain, or tweak it a little, are special files.

How to sharpen with an angle grinder (angle grinder)

The method of sharpening the saw chain using an angle grinder, the least common due to its insecurity. In order to straighten the chain teeth using an angle grinder as a sharpening tool, it is necessary to install it in a vice and clamp it securely. Then the tool is switched on and the sharpened edge of the tooth is placed on the rotating surface of the disc. A tooth sharpened in this way can differ significantly from that sharpened with a file, because In the process of dressing using an angle grinder, it is difficult to control the sharpening angle.

A big disadvantage can be considered the possibility of a notch with an angle grinder with an angle grinder of the eyelet for attaching the connecting link of the chain, which in the future will lead to a break during work. If, in the process of carrying out work using a chainsaw, the need arose for sharpening, it is better to use a special tool than to come up with various tricks that can result not only in financial losses, but cause serious injuries during their implementation.

Sharpening the chain is not as difficult as it seems at first glance. Any person, after studying the process of straightening chains, is able to sharpen the cutting set of his tool on his own. Even if the first time you manage to do it is not very high quality, you should not despair, because K. With every next try, the result will be better and better.

We work with a file

The best solution is simple gadgets for sharpening work. This set includes a round and flat file, special holders, a gauge template, a hook for removing chips, etc. Structurally, “adaptations” may differ, but the functionality has a common logic.

Hand-operated machines

The design of such a machine is similar to a bow saw. Only where the saw blade is located is the round file. With such a machine, you can sharpen and straighten teeth, adjusting the proportionality of the upper edges to the smallest (control) size. The mechanism allows you to accurately set the parameters. After adjusting the “control” tooth, sharpening is carried out in two or three movements. And then the transition. to the next tooth.

When it is necessary to grind off the stopper, we change the round file to a flat file.

Advantages of the method: Allows you to sharpen teeth, including those that have lost their original shape, with a high quality, convenient and without large physical costs.

Disadvantages: The price of the tool and the distance from the possible site of the saw operation.

“After finishing the“ sharpening procedures ”, blow the chain with compressed air (from a compressor or pump) and put it briefly in clean engine oil. Of course, almost no one does such events, but for the chain, they will only benefit. “

What to choose for sharpening is up to you. This is due to how often you use your chainsaw. From the accuracy of handling it. From the quality of the purchased chain. And, of course, from the opportunity to spend a certain amount. The methods cannot be compared, because as the German proverb says. “apples should be compared with apples”.

Sharpening angle grinder

Professionals consider this work to be primitive. There is a risk of tire damage, and not only.

Process (seemingly easy, but really difficult)

- The chain also stays on the bus;

- We attach a metal cutting disc with a thickness of 1.5-2 mm to an angle grinder. It is advisable to take not new, that is, with a worn edge;

- We put a barrier in front of the chain and the tire (the chip will come off);

- We carry out sharpening at the desired angle;

- Upon completion of work, the chain must be properly tightened.

With a professional approach and a “full hand”, the number of sharpenings in this case can be more than 7.

“For a beginner, it is better not to“ experiment ”with a saw, a chain, etc. With your body parts! “

Sharpening angle grinder

Professionals consider this work to be primitive. There is a risk of tire damage, and not only.

Process (seemingly easy, but really difficult)

- The chain also stays on the bus;

- We attach a metal cutting disc with a thickness of 1.5-2 mm to an angle grinder. It is advisable to take not new, that is, with a worn edge;

- We put a barrier in front of the chain and the tire (the chip will come off);

- We carry out sharpening at the desired angle;

- Upon completion of work, the chain must be properly tightened.

With a professional approach and a “full hand”, the number of sharpenings in this case can be more than 7.

“For a beginner, it is better not to“ experiment ”with a saw, a chain, etc. With your body parts! “

What to do if the chain sags

If the chain slack, there is a risk of injury to the operator. the saw blade could break or simply fly off the guide sprockets. Of course, modern chainsaws have safety and emergency stop systems, but these systems do not always work correctly.

It is important not to install a chain with defective or damaged saw links on the chainsaw, in addition to the danger of breaking at any time, such a chain will sharpen the guide grooves of the bar, which will lead to its distortion, uneven cut and failure of the guide bar.

Due to which the chain can sag during even short-term operation?

- There may be problems with the guide bar. Sometimes, due to an oversight of the operator or due to severe wear of the threads of the fixing bolts in the place where the guide bar is attached, vibration may occur, which causes the chain to loosen. Check the condition of the fixing bolts and, if necessary, replace them with new ones. When the bolts are tightened enough, these problems do not arise.

- With enough careful handling of the chainsaw, over time, any chain can wear out. Trying to repair it or collect one from several is a useless exercise. If the chain headset has stretched due to natural causes, then it is best to get a new one.

- The asterisk is skewed. Sagging can occur due to the misalignment of the sprocket teeth. In this case, it would be best to contact a service center to repair and adjust the position of the guide sprocket. It is quite difficult to fix the drive sprocket in the correct position, because you will have to dismantle many small parts, remove the guide rail, and then assemble everything in the reverse order.

Topics. some expert advice:

- Before starting work. run in the chain. To do this, run the chain at a low speed for ≈ 1 minute. During this period, the lubricant will fall on every necessary part, and the chain and the sprocket will warm up and “rub” to each other. If necessary, adjust the tension (after the chain has cooled down);

“Announcement in the newspaper: Changing the chainsaw for a prosthesis”.

I hope the information was reasonably useful. If yes, then subscribe to the blog for updates and share the article with your friends. All the best to you. Good luck!

Quote of wisdom: It’s not about the word, but the tone in which this word is pronounced (Belinsky).

The chainsaw chain is the element that is subject to the greatest stress and overheating. From such influences, it can break, fly off the guide rail, or simply become dull from prolonged use. For timely maintenance or replacement with a new one, you need to know how to independently remove the saw chain from the chainsaw and install it back. The step-by-step algorithm of these operations will be shown below.

Advantages of the method: Fast, cheap and does not take away energy;

Disadvantages: Requires special skills, a steady hand and the ability to comply with safety techniques.

Tips for installing a new chain on your chainsaw

Sharpening the saw chain with a diamond-coated attachment. Pila.Prom.Ua. spare parts, accessories and equipment for forest and garden.

The diameter of the round file is directly related to the chain size:

- – Chains with ø 1.3. require a file of ø 4 mm (used much more often);

- – Chains with ø 1.6. require a file ø 5.2 mm;

- – To sharpen the depth gauge, use a flat file.

Sharpening process

- Having previously “turned on” the chain brake, firmly grip the tire of the chainsaw in a vice (a firmly clamped saw is the key to successful sharpening)

- Position the template so that the arrow points towards the nose of the tire. Be sure to mark (with chalk) the tooth from which you started sharpening, otherwise you can go along the second circle;

- Sharpen in the direction of the arrows. Remember, there is a special factory cut on each tooth in the chain. It indicates the maximum sharpening angle.

- In addition to the cutting tooth, there are stops on each link. Their sharpening is carried out as needed. This is necessary when, as a result of sharpening, the height of the tooth decreases, and problems arise in the operation of the chainsaw. How to sharpen a chainsaw chain lessons from how to sharpen a chainsaw chain on. As a rule, the limiter is sharpened after 2-3 sharpening of the teeth;

“If you don’t have the skills to sharpen, it’s better to start with inexpensive chains.”.

Recommendations:

- The file should not go beyond the upper part of the cutting edge by more than 1/5 of the working part of the file. The pressure is carried out with the same effort;

- The movement of the grinding tool is performed in one direction “away from you”, and the number of movements for each tooth should be equal;

- To sharpen a vertical plane, the file position must be at right angles;

- For sharpening a horizontal plane, file position, at an angle of 20-30 °

- If there are teeth of different heights, the reference is the smallest.

Advantages: Ability to “charge the saw” in the field. At the same time it’s cheap.

Chain tension

The chain of the chainsaw together with the guide bar is subjected to the greatest stress during operation, unlike other parts of the chainsaw. Over time, it lengthens in size due to boring gaps in the connecting links. This process occurs with absolutely any type of chain, therefore, when using a chainsaw, it is necessary to periodically monitor the correct tension of the chain and its wear.

The state of the chain depends on:

- Her life span;

- Safety of felling or timber loosening;

- Internal combustion engine resource.

If the chain is overtightened, the efficiency of the sawing work decreases, the motor and transmission are subjected to increased loads. The guide bar heats up a lot due to increased friction, the operating mode of the chainsaw goes into excessive consumption of the fuel mixture.

Chain tension

The chain of the chainsaw together with the guide bar is subjected to the greatest stress during operation, unlike other parts of the chainsaw. Over time, it lengthens in size due to boring gaps in the connecting links. This process occurs with absolutely any type of chain, therefore, when using a chainsaw, it is necessary to periodically monitor the correct chain tension and its wear.

The state of the chain depends on:

- Her life span;

- Safety of felling or timber loosening;

- Internal combustion engine resource.

If the chain is overtightened, the efficiency of the sawing work decreases, and the motor and transmission are subjected to increased loads. The guide bar heats up a lot due to increased friction, the operating mode of the chainsaw goes into excessive consumption of the fuel mixture.

Chain direction and which side to wear

A chainsaw chain, if you look closely, has saw teeth pointing to one side. Therefore, it is very easy to determine the correct direction of the saw teeth on the guide bar: if you place the chainsaw itself in the plane in which it is in operation, then the row of teeth located on top of the guide bar, with sharp edges should be directed to the end of the bar. While, the row of teeth, which is located at the bottom of the chainsaw, with sharp edges should point in the opposite direction, towards the drive sprocket.

How to install a chain on a chainsaw

The chainsaw chain is the element that is subject to the greatest stress and overheating. From such influences, it can break, fly off the guide rail, or simply become dull from prolonged use. For timely maintenance or replacement with a new one, you need to know how to independently remove the saw chain from the chainsaw and install it back. The step-by-step algorithm of these operations will be shown below.

Why does the chain come off

Many, even the most experienced users of chainsaws, have encountered in their life a situation where the chain jumped off the guide bar during operation. The most common cause is insufficient chain tension or wear.

In 80% of cases, the stretched chain links slip from the teeth of the drive sprocket, and it flies out from the guide under the action of centrifugal force. Although sometimes the problem appears due to the incorrect position of the sprocket relative to the axis of rotation or a loose saw bar on the chainsaw.

What to do if the chain sags

If the chain slack, there is a risk of injury to the operator. the saw blade could break or simply fly off the guide sprockets. Of course, modern chainsaws have safety and emergency stop systems, but these systems do not always work correctly.

It is important not to install a chain with defective or damaged saw links on the chainsaw, in addition to the danger of breaking at any time, such a chain will sharpen the guide grooves of the bar, which will lead to its distortion, uneven cut and failure of the guide bar.

Due to which the chain can sag during even short-term operation?

- There may be problems with the guide bar. Sometimes, due to an oversight of the operator or due to severe wear of the threads of the fixing bolts in the place where the guide bar is attached, vibration may occur, which causes the chain to loosen. Check the condition of the fixing bolts and, if necessary, replace them with new ones. When the bolts are tightened enough, these problems do not arise.

- With enough careful handling of the chainsaw, over time, any chain can wear out. Trying to repair it or collect one from several is a useless exercise. If the chain headset has stretched due to natural causes, then it is best to get a new one.

- The asterisk is skewed. Sagging can occur due to the misalignment of the sprocket teeth. In this case, it would be best to contact a service center to repair and adjust the position of the guide sprocket. It is quite difficult to fix the drive sprocket in the correct position, because you will have to dismantle many small parts, remove the guide rail, and then assemble everything in the reverse order.

How to untangle a chainsaw chain

When removing an old chain or putting a new chain on the guide bar of the chainsaw, it can become tangled. It can also happen with careless transportation. When the chain is tangled, it folds into rings.

It is necessary to put the chainsaw chain on a horizontal surface and unwind the rings in different directions, while pulling the blade in such a direction that the diameter of the rings increases. Sooner or later, the chain will unravel into its natural position.

There is another way. you can rivet one link of the chain and straighten it, then connect it into a ring and rivet the riveted links back.

Step-by-step installation algorithm

Not all modern chainsaws are equipped with a setting wheel, which greatly simplifies the procedure for installing the saw blade. Systems with a setting wheel are generally a rarity among household chainsaws. Therefore, it is very important to know the technology and sequence of installing the chain on the chainsaw.

Key points to pay attention to:

- Prepare a level surface on which you will assemble the chain and bar. This will minimize the chance of damage to the chainsaw or loss of small parts. A tire is laid out on the prepared surface and a parallel chain next to it.

- Remove the sprocket protection, on modern chainsaws it is enough to unscrew the wing nut, on older models, you may need a spanner wrench of the appropriate size.

- At the base of the guide bar, turn the sprocket all the way to the right. Only in this position is the chain installed.

- Then the chain is successively placed, link by link, on the fixing groove on the guide rail. Install the chain from the top of the guide, gradually turn it so that the bar is always on top, and the chain is on the bottom, this will allow it to always be taut and fit into the guide groove without problems. Be sure to wear thick protective gloves when performing this step, as your fingers will touch the cutting edge. Viewed from above, the cutter is always forward towards the end of the guide bar.

- Put both the tire and the chain on the drive sprocket.

- Secure the chain sprocket cover in place. Make sure all mounting pins line up with the holes. Incorrect installation with distortions or not completely can cause extraneous noise, rattling.

- Make sure that the guides “go” into the special mounting chute.

- After installation, check that the chain is secure on the chainsaw and on the bar. Everything must be securely fastened without backlash.

An important point is the degree of tension on the chain after installation. Setting the correct tension is easy and takes less than three minutes. First you need to loosen the nuts on the protective cover. Using the freely rotating adjusting screw, catch the correct tension so that the chain does not pull away from the edge of the guide bar more than 3-5 mm.

It remains only to tighten the nuts and check the tension. If correction is needed, adjust the tension again.

How to install the bar and chain on the chainsaw, see the following. Which presents a clear algorithm of actions:

There are many models of chainsaw chains on the market now. First you need to know which standard size is right for your chainsaw and not make a mistake in buying. The second step is to properly install it on the chainsaw. This is a somewhat laborious process, but if you know how to dress and adjust the chain to the saw bar yourself, then the happy owner should not have any problems. We tried to describe in detail the process of installing a saw blade on a chainsaw.

We hope that after reading this article, you will succeed the first time. But in order to minimize the occurrence of problems with the chainsaw and chain in the future, do not forget 3 basic rules:

- If the chain is worn out and sagged, replace it with a new one;

- If vibration appears during sawing and the cut is bad. watch the chain tension on the chainsaw;

- Never use saw blades that are defective or repaired by dubious specialists, your health and those of those who are nearby are much more important than a little savings on buying a new and reliable chain.