How to wash a lawn mower carburetor. What makes the carburetor stop working??

How to flush a lawn mower carburetor

The throttle valve determines the amount of air to be fed, and this directly affects the power of the motor.

In the carburetor system is sucked fuel by the pump (its diaphragm). Then flows through the nozzle in the carburetor. Then the fluid moves through inlet and outlet valves of the pump. Is filtered through a wire mesh. Fuel moves to diaphragm chamber through needle valve.

- Air is fed to the tube with an air baffle (damper). Baffle plate controls the intensity of the air flow.

- Fuel system is necessarily narrowed by the mixer to accelerate the flow.

- Gasoline through the float chamber and restrictor nozzle. Float chamber regulates the temporary volume of gasoline. In the float chamber, the pressure level is neutral and in the tube with constriction, the pressure level is already low. Owing to the pressure difference, fuel flows through the nozzle.

- Acceleration of air flow promotes the fuel (gasoline) transfer and atomization. Finally, an air-fuel mixture of the right mixture ratio or density is obtained.

- Air-fuel mixture is leaking into the engine cylinder through the fuel pipe.

The area of the open air damper determines the level of air density in the system. The wider the choke is open, the greater the fuel consumption and power.

Simply put, adjusting the carburetor on a chainsaw is all about creating a good fuel consistency by getting the airflow correct.

How to Clean a Briggs Stratton 675 Series Carburetor

A simple guide: how to clean a Briggs Stratton 675 Series carburetor. Warning. Before you start, you need to buy an o-ring, as the o-ring in the carburetor reservoir may be worn out. Cleaning the carburetor is messy, so it’s best done outside.

So, how to clean a Briggs Stratton 675 series carburetor:

Cleaning a Briggs Stratton 675 Series carburetor

Before you start, make sure the engine is off and the spark plug wire is disconnected from the spark plug.Use a flathead screwdriver to remove the 40 mm screw holding the air cleaner body in place.

Pull the air filter housing out of the hinge at the bottom by hand.

Use an 8 mm socket wrench to unscrew the three 20 mm bolts behind the air filter.

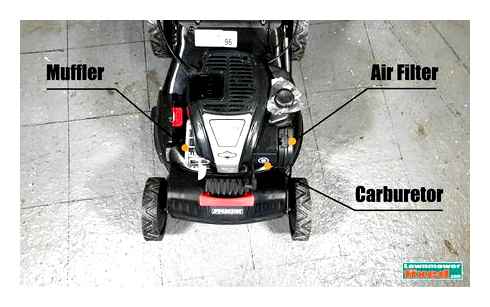

Remove the plastic air filter liner with your hand, exposing the carburetor.

There is a plastic washer inside that can come off when you remove the plastic backing. This is fine; just set it aside and save it for reassembly.

Attention. Before performing this step, make sure you drain the fuel, remove the fuel tank, or clamp the fuel line, otherwise gasoline will be everywhere!Use a 13-mm socket wrench to unscrew the 11-mm bolt on the bottom of the reservoir.Warning. It is very important to clean the bolt at the bottom. It has holes, which, if they are clogged, will not allow your engine to work properly. Clean them with carburetor cleaner. They are easy to miss because the bolt falls out when you unscrew it.

After the bolt is removed from the bottom of the carburetor reservoir, carefully open the reservoir with a metal spatula until it pops out. If you do not have a paddle, a flathead screwdriver will do.Remove the reservoir completely so it can be cleaned or replaced.

Inspect the o-ring inside the carburetor reservoir. If it is dry and worn, it must be replaced before reassembling the unit.

To reassemble the unit, follow these instructions in reverse order.

How does a Carburetor Work?

Subscribe to our Telegram. To be the first to know about new articles on the site.

The electric mower won’t start and won’t linger

Sooner or later, many people experience lawn mower failure. This usually happens after 3-4 years of active use or after storing the unit in an unheated room in the winter.

The mower fails if:

Engine problems occur over time on all devices, whether it’s a simple “Chinese” or an expensive “Japanese”. Moment unpleasant, but do not get upset, because you do not need to rush to the service center. You can try to fix it yourself.

Repair of lawn mower AL-KO (clean the carburetor from BS)

Who can tell you the problem and what is it?When the cold starts lawn mower Brigovsky and when hot does not start! Only if it cools down!

Ivan, I am asking for help. advice on the following question: carburetor is exactly the same as in your video. After winter stopped starting up all checked. not getting fuel. I cleaned the carburetor and nothing squirts when I pump the fuel. You removed the carburetor in the video, pressed something on the diaphragm and you have, when you press the pump, gasoline forcibly started squeaking. I took it off 10 times, cleaned it, squeezed it, nothing. I bought a new gasket with a diaphragm. nothing, no squeaks. What could it be?? Post the video with you and me on Viber 380673049300. Thank you in advance.

Easiest Way To Clean A Metal Briggs Carburetor

Grass trimmer device

The float-type carburetor consists of an aluminum housing with a hole (diffuser). The air is injected through its flow-through opening, and gasoline is drawn through the fuel channels along with the air flow. This is the basis of the device. the fuel chamber. Installed on top of the nozzles, the pump and the mixture adjustment system ensure not only its saturation, but also a uniform supply.

For your information! The float carburetor has been used for decades, and the basic failures of all types are similar. The functioning principle of the device depends on the quality of the mixture, and the adjustment is aimed at ensuring it.

How to determine the cause of failure?

Repair should begin according to the principle “from simple to complex”, that is, the repair is recommended to begin with checking the presence of gas in the tank. If the gasoline engine stops after winter, change the fuel.

Unfortunately, the fuel is not always of decent quality. Consequently, during prolonged idle time, the device may stratify or form sludge. And engines are sometimes very sensitive to fuel quality.

If there is no doubt about the latter, but the lawnmower does not start, you must check the spark by disconnecting the wire with the cap from the spark plug, unscrewing it with the included wrench.

Attach the spark plug to a clean metal surface (unpainted) of the engine by first putting the cap on it and having someone remove the starter.

If an erratic and weak spark appears, the spark plug should be cleaned with a saw or sandpaper.

Another problem that is easy to fix. It’s a clogged fuel hose. They check it by turning it off: if the fuel is not leaking, the filter or the inside is clogged. The filter will need to be replaced, the inside can be cleaned with a needle.

Adjusting the carburetor on a chain saw

Self-diagnosing and adjusting the carburetor can only take a few minutes.

To get it right, start the engine. Your actions are as follows.

- Find idle speed. To do this loosen screw L to the right and then to the left. Turning step. A quarter turn counterclockwise.

- Using the T screw, you can adjust the idle speed of the motor: increase when you turn the screw clockwise, decrease. On the contrary. A well-tuned motor runs steadily with no load and no warm-up. Warm up. Do not exaggerate.

- If you are adjusting a grass trimmer rather than a braid trimmer, turning the T screw sets a larger RPM margin. For both types of devices, stable rotation is set when the blade (or trimmer line) selects the height of cut.

- The last turn of the H screw. It sets the petrol and air speed close to the maximum speed, engine power, engine heating temperature and fuel consumption.

To adjust the motor with the H screw, do the following.

Open the throttle and squeeze the throttle at maximum speed. Turn the H screw clockwise until the engine speed decreases. Slowly turn the same screw counterclockwise until the engine creates a variable speed. Turn the screw back slightly (clockwise) until the engine runs smoothly

It’s important to catch this line. Precise adjustment results in complete combustion and brownish-white spark plug color

The gas spark plug is much darker than a non-flooded spark plug

Precise adjustment results in complete combustion and a white-brown spark plug color. The gas spark plug is much darker than a non-flooded spark plug.

See below for how to adjust the carburetor brush.

Increased fuel consumption and rapid soot formation on the brush brush when using a properly prepared fuel mixture indicate the need to adjust the carburetor. Here’s how to install grass trimmers with carburetors, which have a single screw to adjust the fuel supply.

Basic carburetor problems and malfunctions.

Strainer. There are two problems with this element more often than not:

To find out the reason of the breakage unscrew fuel filter lid to remove the strainer. If it is just clogged with dirt, flushing in gasoline or purging will help.

If there is visible damage on the strainer you must necessarily put a new one. There may also be damage to the fuel supply pipe (when repairing it, practice checking this element).

In most cases the carburetor starter mechanism does not work because of clogs. You should use acetone or the same benzine for flushing.

Blowing out clogged carburetor parts with compressed air is an acceptable and convenient repair practice.

Throttle body, carburetor component bundles, inlet or outlet piping. all of these parts are subject to leakage. You can check for sure in a primitive way. spread soapy foam on the problem area.

How to properly clean a lawn mower?

For proper cleaning of brand-name mowers, we recommend watching the video below.

To eliminate the consequences of mower misalignment, first replace the air filter, unscrew the spark plug and clean the soot from the spark plug electrodes. Pump fuel vigorously with primer into the carburetor. Try to start the engine and let it run for about 5-7 minutes until the black smoke disappears from the muffler. If you can’t get the engine running after several attempts, go to the service shop to have the carburetor cleaned.

Also with a video on troubleshooting typical engine errors on mowers.