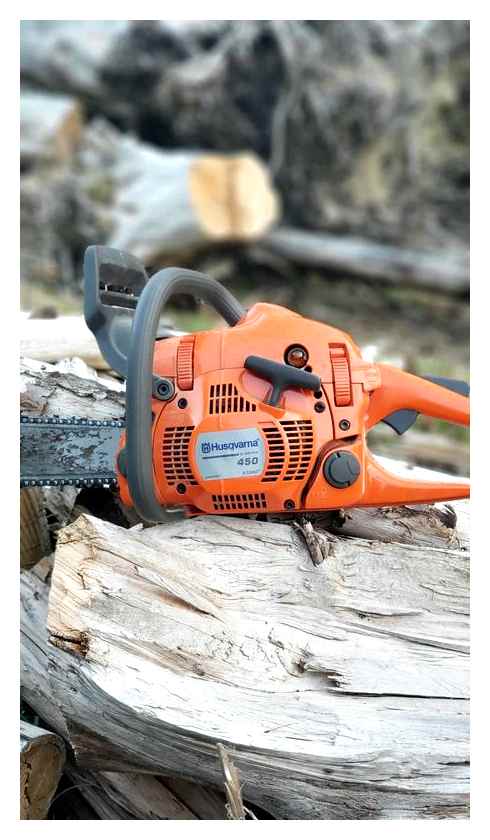

Husqvarna 365 xp chainsaw will not start

Husqvarna 365, 372 chainsaw fuel and lubrication system

Adjusting the carburetor of the Husqvarna 372 XP chain saw allows you to adapt the engine to local criteria, such as climate, altitude, gasoline quality and oil type for two-stroke engines.

The carburetor has three adjustment options:

L = low velocity jetting. H = high-speed jet. T = idle speed adjustment screw.

In the L and H nozzles, the amount of fuel is adjusted to match the throttle of the throttle grip.

If the nozzles are wound clockwise, the mixture will be poor (less fuel relative to the amount of air), and if you unscrew the nozzles counterclockwise, the mixture will be richer.

Poor mixture gives more speed and a richer mixture. Lower speeds. How the Husqvarna 142 carburetor is tuned? The screw T adjusts the position of the idle speed damper.

If screw T is turned clockwise the idle speed will increase, and if the screw is turned counterclockwise the number of revolutions will decrease.

Pre-set and turn on the Husqvarna 365 XP chainsaw

When inspecting the work at the factory, the carburetor was preadjusted. Preparatory adjustment: N = 1 revolution, respectively L = 1 revolution.

To ensure that the Husqvarna saw’s engine parts get enough lubrication (breakdown), the carburetor is set for a small overload of fuel during the first 3-4 hours of operation.

For this setting, the maximum speed is set at 6-700 rpm below the recommended speed.

If it is not possible to check maximum speed with a tachometer, the N nozzle should not be set on the fuel mixture under the preparatory block.

Do not exceed maximum rpm. Adjusting the carburetor on a Husqvarna chainsaw is the main unit for a chainsaw. If the chain saw chain rotates in idle, then, turning the screw T counterclockwise, it is necessary to achieve a complete stop.

Precise adjustment of the carburetor of a Husqvarna chainsaw 365, 372 XP

Chinese chainsaw.Repairing the carburetor.Adjusting the carburetor.

Spare parts Powerful Chinese chainsaw Hunter analog Husqvarna 365

Start the chainsaw and let it run for about 10 minutes.

Place the Husqvarna 365 chain saw on a level surface so that the bar is facing away from you and that both the bar and the chain are in contact with the surface.

Find the maximum idle speed by slowly turning the low-speed jet clockwise and counterclockwise.

When the maximum rpm is found, turn the L jet counterclockwise 1/8. 1/4 turn.

Precise adjustment of the idle speed with the T screw

The idle speed is set with the screw marked T.

If adjustment is required, turn the idle screw T clockwise until the chain begins to rotate.

Then turn the screw counterclockwise until the chain stops.

The correct RPM is the number of revolutions at which the chainsaw engine runs smoothly in all positions with an adequate margin to the number of revolutions at which the chain begins to rotate.

High-speed jet H adjusts the Husqvarna 372, 365 XP chain saw’s power and RPM.

42″ XUHQVARNA chainsaw assembly

Husqvarna 142 chain saw overview, from device to repair

The Husqvarna 142 chain saw is a household tool and is used for cutting wood materials only. Its hallmark: the affordability of a well-known brand mixed with impressive technical features. Take a look at the fruits of our review and see for yourself.

IMPORTANT. Experienced electrician leaked the secret of how to pay half as much for electricity, the legal way. Read more

Technical Data

- Fuel capacity: 0,37l

- Gasoline/oil ratio: 50 to 1

- Recommended gasoline: high octane unleaded

Ergonomic features

Analysis of the above data allows you to note 3 fascinating features. All in all, the Husqvarna 142 is a good value for a domestic chain saw, with about 20% less power than the average pro saw of the same manufacturer. Its cutting headset is standard for Husqvarna and if the need for replacement will not lead to a long search for how else it is called waiting. Thirdly, the manufacturer emphasizes its undemanding attitude towards gasoline quality without mentioning the permissible octane number. Therefore the conclusion of the first step of the review is as follows: the properties of the chainsaw Husqvarna 142 is suitable not only for garden work, but also for completely semi-professional use.

Instructions for use

It’s the only wand often, so in our reviews it is never ignored. It looks not ominous: only 32 pages, two empty ones are for personal notes. There are no traces of translation by electric systems, but in 2 places there are the phrases that hurt the eye a little, for example, “the spark plug does not ignite”.

Almost a third of the annotation is devoted to safety while working with the Husqvarna 142 chainsaw. I was pleasantly surprised by the description of methods of work not only with trees, but also with limbs: A detailed diagram of making sawn cuts without risk is presented. The effect of the tire end shape on rebound capability is very clearly explained.

The features of the 142 Husqvarna are presented a lot with a small disclaimer. Only one model of Champion spark plugs used is listed. But nowhere is it clearly written that it is strictly forbidden to use any other models because of design features. Usually, domestic manufacturers either specify several suitable models, or carefully outline the properties of the required plugs. Because where the description of the complex of ignition programs could have been more informative. This note is not important, because experienced owners can use a specialized manufacturers’ catalogs and find in most cases analogues of any spark plug.

The assembly procedure for the Husqvarna 142 chain saw is described in detail with a detailed explanation of the drawings.

Separate attention is given to self-correcting small problems that arise during the operation. How to troubleshoot the Husqvarna 142 chain saw that doesn’t start or starts and stops is described in great detail. But the section describing the carburetor tuning could be more informative. In particular, to adjust the quality of the mixture it is stated what to twist, but the criterion for the end of the adjustment is not clearly stated.

Husqvarna 142 chain saw assembly

Bar setting, cane setting, and chain tensioning. View catalog.

Disassembling and assembling a Husqvarna 142 chainsaw

In this video, we completely disassemble and reassemble the Husqvarna and replace the piston on the Husqvarna. I’ll show you how everything.

Overall, the instruction manual for the Husqvarna 142 chain saw is user-friendly and contains the minimum necessary knowledge on operation and repair.

Controls

Here in the Husqvarna 142 is the classic minimum. Represented by a switch that takes the On or Off position, an air damper position lever that can be in one of three positions, and a combination throttle position control lever with stop. Only the “choke” needs explanation here. Between the fixed open and closed flap positions, there is a third steady position that corresponds to the half open flap of a chainsaw carburetor. It is used when starting a cold engine after several pulls of the starter with the choke closed. Husqvarna 142 has no primer. Initial fueling is done with the starter grip. Well, the fewer parts, the fewer breakdowns!

READ Hitachi C12RSH2 12-inch Mit Saw Review

Husqvarna 142 in operation

We made the fuel mix based on gasoline AI 92 and branded Husqvarna HP two-stroke oil in the ratio of 50 to 1. It’s interesting to note here that if you don’t have the oil added in the specified ratio on hand, the manufacturer allows the short-term use of quality oil diluted with gasoline at a ratio of 33 to 1.

We operated the Husqvarna 142 for about an hour. As a household chainsaw it’s perfect: practically vibration-free in the hands, completely tolerable noise level and, most importantly, excellent cutting ability. Trunks of fresh pine and dry birch with a diameter of 26 cm were repeatedly sawn in an average of 7 seconds each. Dry oak gave in a little slower; it took approx. 14 seconds to cut a 24 cm diameter log. Cutting speeds are not as fast as on the professional saws we tested, but the cost is not the same. The Husqvarna 142 is not afraid of full power, even the high revs are recommended in the manual. Brakes work perfectly. chain stops instantly.

Then we analyzed the reviews of Husqvarna 142 owners on three specialized forums. We took into account only those publications, the authors of which have been registered for a long time and not professionally use the chainsaw.е. Not every day for several years. The results of the analysis were not surprising and in short: the piston group is reliable, the bar is strong, the saw is handy and undemanding to the fuel. There are infrequent failures, but they are caused by consumables replacement time or mistakes in the fuel mixture.

Husqvarna 365 XP chainsaw. Specifications

The Husqvarna 365 stands out with its solid technical parameters. They include:

- power. 4.6 liters. с.;

- engine revolutions at idle speed. 2700 rpm;

- Maximum engine speed. 12500 rpm;

- Fuel tank capacity 770 ml;

- Oil fill capacity of 420 ml;

- Recommended length of the bar to be used. 40-45 cm;

- The saw chain pitch is 3/8″;

- weight in ready-to-use form. 6.4 kg.

Despite the chainsaw’s high power, it is notable for its low noise level. The Husqvarna does not exceed 114 dB when operating at maximum rpm.

Husqvarna 365 XP chainsaw. Specifications

The Husqvarna 365 stands out with respectable technical parameters. They include:

- power. 4,6 l. с.;

- Engine revolutions at idle speed. 2700 rpm;

- maximum engine speed. 12500 rpm;

- Fuel reservoir capacity is 770 ml;

- capacity of the oil filling tank. 420 ml;

- Recommended length of the bar to be used. 40-45 cm;

- saw chain pitch is 3/8″;

- ready-to-use weight. 6.4 kg.

High power but low noise level. The Husqvarna does not exceed 114 dB when operating at maximum rpm.

Model Package

Swedish Husqvarna delivers the 365 with everything you need for tool assembly and repair.

The chainsaw comes with

- Original bar, 18″ long and 1.5 mm wide groove;

- 3/8″ pitch saw chain with 1.5 mm shank width;

- Instruction manual in Russian.

If necessary the customer can order additional chain for the Husqvarna 365 chain saw, guide bar, original oil for 2-cycle engines, as well as equipment for sharpening the chain.

Other possible reasons

Other malfunctions that many chainsaw owners encounter are when the chainsaw starts, but something goes wrong. It may stall, the chain starts to malfunction or not work at all. Here are some additional things to check if these problems occur.

- There is a small screen inside the chainsaw that is necessary to control the sparks emitted by the engine. This is the spark arrestor and is usually made of fiberglass. It can get clogged with soot from using the tool for a long time, leading to starting problems. The issue is easily resolved by removing the spark arrester and cleaning it with a wire brush. If there is a problem with the spark arrester after cleaning it, replace it with a new one. It is a good idea to replace the spark arrester after 25 hours of chain saw use.

- If the engine starts but the chain does not respond to start. This can be the result of worn out clutch pads. When they become worn from use, they do not interact with the clutch drum, allowing the chain to rotate. If the pads are worn, the clutch assembly must be replaced.

Chainsaw Service

Like any power tool, a chainsaw has many moving parts in the engine. Most people tend to overlook service and maintenance, believing that good quality tools can work effectively without additional maintenance. Over time, use of a chainsaw will lead to wear and tear on parts that should be checked regularly.

Cleaning and properly maintaining important chainsaw parts can be an effective preventative measure. It is important to pay attention to tips that will keep your chainsaw in good condition.

- Make necessary adjustments for tightening nuts and chain tension.

- Clean all necessary parts from debris, sawdust, etc. д.

- Periodic inspection of the chain blades.

- Make sure that all moving parts, such as gears and chain, are lubricated as needed.

Exhaust port or muffler cleaning and effect on engine starting

When the chainsaw is in operation, tar deposits are deposited on the walls of the exhaust port and muffler. Periodically this fouling needs to be cleaned, but most tool owners remember about it only after the chainsaw won’t start. Why it happens? The reason is that the burned products have nowhere to go and the engine cannot start. If the exhaust air duct is dirty, not only does the chain saw lose power but it also stops the engine on its own.

Deposits on the walls of the muffler arise from such factors:

- Using low-quality gasoline and oil

- Incorrect ratio of gasoline to oil when preparing the mixture

- Prolonged use of the tool without preventive care

Cleaning a chainsaw muffler is easy. The cleaning sequence is as follows:

- First remove the muffler mounting screws

- Remove the cooling panel and sealing gasket

- Next you need to remove the spark arrester

- The resonator housing is disassembled

- Clean and rinse all elements from carbon deposits with kerosene or other cleaning fluids. You should wear only a respirator and glasses. Carcinogens are very dangerous to humans

- Wait until the cleaned elements are dry

- Reassemble in the reverse order of removal

When cleaning the walls of the exhaust duct you need to cover the cylinder opening with a rag. This prevents dust and sand from getting into the cylinder. After the muffler and the chainsaw exhaust duct have been cleaned you can start the engine. You can feel the chainsaw’s full power output as you go along.

Exhaust duct or silencer cleaning and effect on engine starting

When the chainsaw is running, tar deposits. carbon deposits. are deposited on the walls of the exhaust port and the muffler. Periodically this fouling needs to be cleaned, but most tool owners remember about it only after the chainsaw does not start. Why it happens? The reason is that the burned products have nowhere to go, so the engine will not be able to start. If the exhaust duct is contaminated, the chainsaw not only loses power, but also stops the engine on its own.

Deposits on the walls of the muffler arise as a result of such factors:

- The use of low-quality gasoline and oil

- Incorrect petrol to oil ratio during mixture preparation

- Continuous operation of the tool without preventive maintenance

Cleaning the chainsaw muffler is not difficult. The cleaning sequence is as follows:

- For starters unscrew the muffler fixing screws

- Dismantling the cooling panel with the gasket

- The next step is to remove the spark arrester

- The resonator housing is disassembled

- Clean and rinse all elements from carbon deposits with kerosene or other cleaning fluids. This should be done only with a respirator and safety glasses. Carcinogenic substances are very dangerous for humans

- Wait for the cleaned parts to dry

- Reassemble in the reverse order from the removal

When cleaning the walls of the exhaust port, cover the cylinder opening with a rag. This will prevent dust and sand from entering the cylinder. After you finish cleaning the muffler and the chain saw’s exhaust port you can start the engine. You can feel the chainsaw’s full power output coming on.

The chainsaw will not start when hot

In those cases, when the chain saw doesn’t start when hot, it is necessary to carry out visual inspection of all main chain saw assemblies. The inspection should begin with the spark plug. Check the spark, inspect the surface of the spark plug electrode, these actions will help establish the direction in which to look for the problem.

Faults in the ignition system

If when inspecting the spark plug, it is found that it is wet and there is no spark formation on the contacts, it means that the problem should be sought in the ignition system, inspect the coil, check the gap between the flywheel and the coil contacts. It is also possible to check how firmly the cap of a high-voltage wire sits on the spark plug, and the plug itself. Try to replace it with a new one.

Trouble in the fuel system

If inspection reveals that the spark is there, and the spark plug is dry, then the problem is in the fuel system. It should be checked starting with the fuel filter. Next, you need to check the fuel hose and its attachment to the carburetor, pay attention to the leakage of fuel from the carburetor and the presence of gasoline in the air filter housing. It is reasonable to start removing a carburetor only if a visual inspection did not determine the cause of the failure.

A characteristic sign of a problem in the fuel system, is an excessive amount of fuel in the engine cylinder. As a rule, signs of this are an excessively wet spark plug and the presence of spark on the contacts of the plug. If this happens, turn the chain saw upside down so that the spark plug hole is facing downward. If it leaks gasoline from the cylinder, it means that the reason that the chain saw does not start is because the fuel overflowed into the engine.

“Pouring” fuel, sometimes due to improper adjustment of the carburetor, or its malfunction.

With the process of adjusting the carburetor, you can get acquainted with the example of Champion 254 saw, watching a video instruction.

What you need to repair Husqvarna with your own hands

To carry out an independent repair of the Husqvarna saw, it is necessary to have some specific tools, which can be bought in specialized stores or make their own. First of all, you may need:

-

Piston stopper. needed to limit the piston’s stroke through the spark plug hole. Used in order to unscrew the flywheel nut and clutch (if necessary, it can be replaced by a lanyard from the starter with knots tied to it);

Tip: When repairing any power tool it may be best to use a pair of tweezers and a medical clamp. You will also need a set of screwdrivers, a slotted screwdriver, and a set of Torx wrenches.

Husqvarna Saw Disassembly Algorithm

The process of disassembling a Husqvarna chainsaw is quite simple. In order to do everything correctly and not to break body parts or the cylinder head, you need to do the disassembly in the following order:

- Top cover.

- Chain and chain brake cover.

- Starter.

- Flywheel and clutch.

- Front handle.

- Carburetor.

- Oil pump.

- Engine.

The order of disassembly may be slightly different, depending on the model of the Husqvarna.

Important: Before you start disassembling your chain saw, you need to clean it. The saw produces a lot of chips and wood dust, which can get into the internal parts of the Husqvarna chain saw when it is disassembled.

Removing the side cover and the saw headset

The side cover, also called the saw chain brake cover, is held in place by two thirteen-head nuts.

After unscrewing the nuts, the cover is removed from the guide rods, after which you can remove the bar and chain from the chainsaw. Some Husqvarna saws have a special tool-less mechanism for removing the starter cover and the saw headset.

Starter

The starter is on the right side of the Husqvarna and is held in place by several screws. Unscrewing that, you can easily remove the starter and thus gain access to the flywheel and ignition coil.

Handwheel and clutch removal

In order to unscrew the flywheel nut it is necessary to unscrew the spark plug and install a piston stopper in its place.

If you do not have a special stopper, you can use an old chain saw starter cord instead. It is necessary to tie knots on a cord at a distance of 2-3 cm, and then, using a screwdriver, insert it through the spark plug hole inside the cylinder. This cord limits the piston stroke and thus prevents the crankshaft from turning and protects the piston from damage.

Once the piston stopper is installed in the cylinder, you can unscrew the flywheel nut. After the nut is unscrewed, you need to use a hammer and a mallet of soft material, make one sharp blow, setting the mallet on the shaft mounting the flywheel. This is necessary to remove the flywheel from the shaft, t. к. The design involves installing and tightening this element with a great deal of force.

To learn more about how to remove the flywheel from a Husqvarna chain saw and how to completely disassemble the saw, watch this video. The master explains the entire process step by step and demonstrates all the necessary tools:

A special wrench is needed to unscrew the clutch. If you do not have a wrench, it can be made from an old head to twenty-two, grinding it in a certain way with an emery.

The clutch has a left hand thread and should be unscrewed clockwise.

Do not try to unscrew the clutch with a hammer and chisel as some experts advise. Using these tools, you risk breaking the clutch housing and increasing repair costs. It can also damage the crankshaft bearings.

Front Handle

Removing the front handle of the Husqvarna is quite easy, because. к. it is fastened to the shock absorbers with screws.

Air Filter and Carburetor

To remove the carburetor it is necessary to disconnect the fuel hose and slide rods from it, it is convenient to do it after the air filter is dismantled, which is installed immediately behind the carburetor and is held by two nuts for 10. After removing the air filter and disconnecting the fuel hose and rods, you just pull the carburettor toward you and remove it from the studs.

Use tweezers and medical clamps to remove the carburetor.

Oil pump

The oil pump on the Husqvarna is mounted on the right side of the chainsaw. It can be removed only after unscrewing the clutch. No special tools are needed for removal.к. the screws are made to fit a common Phillips screwdriver. After the screws are unscrewed, it is necessary to lift the pump and disconnect the oil hoses from it.

Engine

To remove the engine on a Husqvarna chain saw after you remove the carburetor, clutch, flywheel and muffler you must remove the four screws that secure it to the housing.

After the engine is removed, you can unscrew the ignition coil from it, remembering to first disconnect the wires running from it to the ignition switch. The coil can also be removed as soon as the starter motor is removed.

Reassemble the Husqvarna chain saw in reverse order, and tighten the flywheel nut and clutch with the torque specified in the instruction manual of the chain saw.

Husqvarna saw disassembly algorithm

The process of disassembling a Husqvarna chain saw is simple. In order to do everything correctly and not to break parts of the housing or the gas cylinder, you should disassemble in the following order:

- Top cover.

- Chain and fittings chain brake cover.

- Starter.

- Flywheel and clutch.

- Front handle.

- Carburetor.

- Oil pump.

- Engine.

Disassembly procedure may be slightly different, depending on the Husqvarna model.

Important: Before you disassemble your chain saw, you need to clean it. The saw produces a lot of chips and wood dust, which can get into the internal parts of your Husqvarna chain saw when it is disassembled.

Removing the side cover and saw chain

Side cover, or chain brake cover, held in place by two thirteen-point nuts.

After unscrewing the nuts, the cover is removed from the guide rods, after which you can remove the bar and chain from the chainsaw. Some Husqvarna saws have a special mechanism that lets you remove the cover and the saw headset without using special tools.

Starter

The starter is located on the right side of Husqvarna and is held on several screws. By unscrewing them, you can easily remove the starter and thus gain access to the flywheel and ignition coil.

Removing the flywheel and clutch

In order to unscrew the flywheel nut, it is necessary to unscrew the spark plug and install the piston stopper instead.

If you do not have a special stopper, you can use an old chain from a chain saw starter instead. String a knot in a distance of 2-3 cm, and then, using a screwdriver, insert it through the spark plug hole inside the cylinder. The string will limit the stroke of the piston, thereby preventing the crankshaft from turning and protect the piston from damage.

Once the piston stop is in the cylinder, you can unscrew the flywheel nut. after the nut is unscrewed, it is necessary with a hammer and a mallet of soft material to make one sharp blow, setting the mallet on the flywheel shaft. This is necessary to remove the flywheel from the shaft, t. к. the construction provides for installation and tightening of this element with a great effort.

To learn more about how to correctly dismantle flywheel from Husqvarna chain saw, as well as how to completely disassemble the saw please watch this video. The wizard explains the whole process step by step and demonstrates all the necessary tools:

A special wrench is needed to unscrew the clutch. If there is no wrench, it can be made from an old twenty-two head by sharpening it in a certain way with an emery.

The clutch has a left hand thread and should be unscrewed clockwise.

Do not try to unscrew the clutch with a hammer and chisel, as some craftsmen advise. Using these tools, you risk breaking the clutch housing and increasing repair costs. It can also damage the crankshaft bearings.

Front handle

Removing a Husqvarna front handle is fairly straightforward. к. It is attached to the shock absorbers with screws.

Air filter and carburettor

To remove the carburetor it is necessary to disconnect the fuel hose and slide rods from it, it is convenient to do this after dismantling the air filter, which is installed immediately behind the carburetor and is held by two nuts on 10. Once the air filter is removed and the fuel hose and rods are disconnected, you simply pull the carburetor toward you and remove it from the studs.

Use tweezers and medical clips to remove the carburetor.

oil pump

On the Husqvarna the oil pump is mounted on the right side of the chainsaw. You can only remove it after you have unscrewed the clutch. No special tools are needed for removal.к. The screws are made with a Phillips head screwdriver. After the screws are unscrewed, you must lift the pump and disconnect the oil hoses from it.

Engine

To remove the engine on the Husqvarna chain saw, after removing the carburetor, clutch, flywheel, and muffler, you must remove the four screws that secure it to the housing.

Once the engine is removed, you can unscrew the ignition coil from it, remembering to first disconnect the wires going from it to the ignition switch. Coil can also be removed once the starter has been removed.

To assemble the chain saw the Husqvarna should be done in reverse order, and the hand wheel nut and the clutch should be tightened with the torque, whose value is stated in the instruction manual of the chain saw.

Husqvarna

Husqvarna 372 XP Specifications

Engine type. Gasoline Working volume of cylinder, cc. 70,7 cm3 Maximum power, kW. 3,9 kW (9600 rpm)./Power rating at operating RPM, L.с 5,3 л.с. (9600 rpm./rpm) No-load rpm. 2700 rpm./Spark plug. Champion RCJ7Y 5776166-02 (61141), Husqvarna HQT-1 5774840-01 (63893), NGK BPMR7A Electrode gap. 0,5 mm Fuel tank capacity 0,77 l Torque, max 4,3 Nm / 6600 rpm.rpm Chain lubrication tank capacity. 0,4 l Chain lubrication pump type. Variable flow Chain pitch. 3/8″ Chain link thickness. 1,5 mm / 0,058″ Equipped bar length. 45cm/18″ Recommended bar length, min/max 38-71cm/15-28″ Chain speed at max. RPM. 21,4 m/s Equivalent vibration level, front/rear handle. 3,5 / 4,0 m/s2 Guaranteed sound power, dB(A). 115 Weight (without cutting equipment), kg. 6,1 kg

Husqvarna and STIHL chain saws repaired with your own hands

Uncomplicated design and reliable in operation chainsaws are very popular among homeowners and gardeners. When handled properly, this tool lasts a long time and rarely breaks. over, it is not very difficult to eliminate the cause of chain saw malfunction with your own hands, especially if you know where to look for the cause.

The Swedish manufacturer’s tools are capable of turning hard work into a simple occupation. Husqvarna 137, Husqvarna 240 and Husqvarna 365 chainsaw models are notable for three distinctive features:

If the tool is operated strictly according to instructions and troubleshooting in time, it will please you with its reliable and stable operation. Correctly serviced with genuine spare parts, the saw can be used for a long time.

The main cause of chainsaw failure most often become engine failures, which can manifest itself as follows:

The ignition system, piston group or fuel system are the cause of troubleshooting. Often the reason of bad work of the tool can be connected with clutch, brake system, lubrication mechanisms, tire.

The ignition system

Repair of chain saw “Husqvarna 240” with their own hands, as well as any other model, should begin with the search for faults in the ignition system.

First of all, experts recommend taking out and examining the spark plug. The condition of this element will indicate defects in the work of the fuel system.

- If the spark plug is completely dry, it means that the fuel mixture is not getting into the cylinder. In this case the plug is screwed in place and the fuel system is repaired.

- If the spark plug is heavily covered with fuel mixture, there may be a violation of the rules for starting the machine, or a poorly adjusted carburetor. It is necessary to cut off the fuel supply and start the starter. This is done in order to remove the excessive fuel. First you need to clean the spark plug with a sharp object, then wash it with detergents, dry it with a hair dryer and install it in place. After that, the tool is started and its operation is checked.

- If there is no fuel residue on the spark plug, it should be cleaned, washed and checked for spark. Its absence can indicate a gap between the flywheel and its magnetic core or a breakdown of the ignition module.

Malfunction in the ignition system may be due to the use of bad oil or improper petrol to oil ratio.

Fuel system

If the fuel does not flow into the gasoline saw tank, there can be two reasons for this:

In this case, the fuel is not supplied in full, and the tool does not start or starts and immediately stops. Repair consists of cleaning the air filter and cover.

It is important to remove the filter with care so that dirt that clogs it does not get into the carburetor. It can be cleaned and washed with ordinary detergents.

Carburetor Repair

The heart of any chainsaw is the carburetor, with which the majority of tool failures are associated.

Repair of this unit with your own hands consists of disassembly and cleaning. If the defect is serious, you should apply to a service center for help.

STIHL chain saw malfunctions most often due to the use of low-quality gasoline or oil. To keep the carburetor from breaking down, it is necessary to follow some preventive measures:

- You should always follow the instruction manual when starting the chain saw.

- It is not recommended to store gasoline in a plastic container. This is to avoid the risk of excessive fouling.

- The fuel mixture should not be stored for a long time, as it loses its qualities over time.

STIHL chain saw repair with your own hands

This brand is very popular among both individuals and professionals. This easy-to-use and reliable tool can last a long time without repair. STIHL chain saw does not start or stops right after starting. What to do in these cases you can learn by watching the video instruction.

If the chain saw won’t start

The causes should be looked for one by one, from the simple to the complex. Do not immediately disassemble the carburetor, which is equipped with many different parts and small elements.

The first thing to do is to check the availability of fuel and pay attention to its preparation. The mix should consist of high-quality gasoline and oil, the brand name of which is written in the instruction manual that came with the saw.

It is possible that the chainsaw will not start if the spark plug is flooded with gasoline when it is started. Fix the problem by drying or replacing the plug and draining the excess fuel.

It is quite common that if there is poor contact between the spark plug boot and the spark plug wire that is attached to it, there may be no spark. In this case, the connection should be repaired. If it still fails to start, the ignition module is most likely defective. It must be replaced with a new one.

You can’t count on your chainsaw starting and working without a clogged filter. It should be taken out, well cleaned and rinsed, paying special attention to the mesh.

Sometimes the saw engine does not start due to a malfunction of the cylinder piston group. In this case you will need a repair manual:

- Unscrew the bolts and remove the cylinder from the cylinder block.

- Check the integrity of the piston and cylinder.

- If damaged, replace the cylinder with a new one or repair by boring the mirror to the piston size.

- Check piston ring wear and tear and replace if necessary.

For a tool that has been running on relatively normal fuel these procedures may be quite enough. The saw can now be assembled in reverse order.

Some parts of chain saws Husqvarna and STIHL need to be replaced at the end of their service life. These time limits are written in the instruction manual that came with the tool. It also tells you how to start the tool correctly. If you follow the instructions, distinguish between hot and cold starting, and use the chain saw only as intended, you will seldom need to repair it.

How to Repair a Husqvarna Carburetor with Your Own Hands?

Defects of the carburetor can be detected during operation and diagnostics. Most of them can be eliminated on your own, with minimal knowledge and without going to a specialized repair center.

- Replacing various gaskets at the joints of sealed parts;

- Cleaning or replacing the carburetor filter elements;

- Replacing pump or valve components;

Almost all of the above parts can be positioned as a repair kit used for short-term carburetor repairs. By installing them, the carburetor of the Husqvarna 137 chain saw can forget about malfunctions for a long time, and the adjustment will become easier.

Tuning the carburetor: highlights

Reassemble the carburetor only after a complete cleaning, drying and blowing with compressed air. Remember that some gaskets and seals may need to be replaced even if not damaged.

To the adjustment of the carburetor can start on condition of its correct defectoscopy, quality assembly and flawless reassembly on the engine.

Principles of carburetor adjustment

- H and L screws adjust the ratio of air to combustible mixture, t.е. throttle position. Turning the screws clockwise leads to depletion of the mixture and the transition of the motor to low revolutions. When unscrewed (counterclockwise) the mixture is enriched and the engine speed increases;

- The T screw is responsible for adjusting the idle speed: turning it clockwise increases the number of revolutions, turning it counterclockwise decreases it;

- screws are adjusted in L-H-T order.

The general algorithm of adjustment looks like this:

- At first, the highest idle speed revolutions are found by turning the L screw, followed by a ¼ turn back counterclockwise. If the chain rotates at idle turn the T screw in the same direction until it stops completely.

- When the engine is warmed up and running at full throttle, you should turn the H screw ¼ turn to the left, then let the engine run for 10 seconds to check the indicator of maximum speed with a tachometer. It should match the number listed in the machine’s data sheet.

- After calibration with the L and H screws, the idle speed is adjusted with the T screw. If everything is done correctly, the motor will work evenly in all its positions.

The carburetor calibrator is on the chain saw

After the adjustment is complete, you only have to put the chainsaw cover back on with the insulating gasket, and then you can get down to the main work. If the settings are correct the engine will get the optimum fuel mixture. This will ensure its normal efficiency, as well as the overall comfort and safety of working with the tool.