Husqvarna Chainsaw Does Not Develop Rpm

Why the chainsaw isn’t picking up steam?

Launching is a complex multilevel process that involves almost all of the saw’s life support systems. That is why the fact that the saw loses speed, turns on intermittently and feels confident exclusively at idle speed should be considered from different angles.

Such factors could lead to this:

- a faulty motor. its motor resource could be exhausted, and the piston rings and cylinder could wear out, deform or even corrode;

- a failed spark plug or the coil itself. as a result, the spark required to ignite the air-fuel mixture is not generated;

- unbalance of the carburetor screws, as well as a number of reasons that could disable it.

The chainsaw does not develop speed: we test the device for malfunctions

The ignition module can be diagnosed for problems visually. For this you need:

- turn out the candle;

- evaluate its appearance (it should not be drenched in gasoline or contain a black coating);

- check the distance between the coil and the magnets (up to 0.2 mm);

- if necessary, examine the spark plug unit for spark supply using a working mains wire.

If, after checking, no defects were found, it is worth moving on to checking the carburetor block.

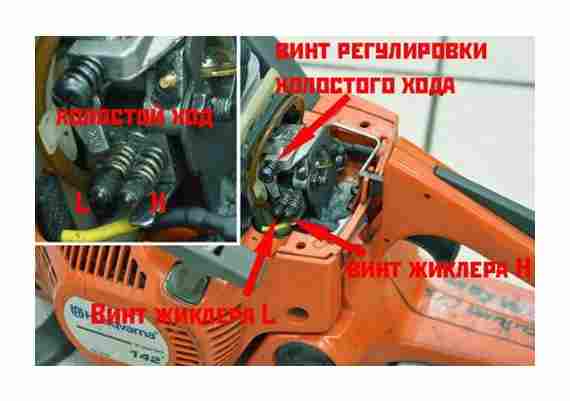

This work unit is one of the most vulnerable in modern chainsaws. New tools, which are shipped from the factory, have basic settings. for low and high speeds, which must be reset after running-in and running-in of all parts. Similar actions are performed if the saw does not develop traction corresponding to the maximum torque according to the instructions.

In this case, you need to reconfigure one of them. the “H” jack, responsible for the saw operation under load. To do this, it is enough to adjust the fuel supply with the engine running at the highest speed of rotation of the chain, using a tachometer and operating instructions.

What if the chainsaw does not idle?

Idling problems are considered constant companions of chainsaws. There may be several prerequisites that could lead to slugs at the time of starting and spinning of the circuit during idle operation, the main of which are:

- clogging of the air and gasoline filter;

- poor quality fuel mixture or improper preparation;

- malfunctions of the ignition module;

- a carburetor whose settings have ceased to correspond to the load on the saw;

- the propulsion elements are deformed or rusted.

A number of actions are sequentially performed:

- flush the fuel hose or replace it with a new one,

- clean the air filter that could be clogged with sawdust and dirt particles. Modern air filters are reusable, they can be washed with the addition of detergent, completely removing them from the saw body;

- check gasoline and engine oil, which may be of poor quality or simply not suitable for working with this saw;

- test candles and carburetor.

Eliminating one or more possible faults usually returns the saw to its former strength.

The chainsaw is not gaining momentum: an overview of the reasons and DIY repair

Malfunctions occur both with expensive German or American modifications of chainsaws, and with their cheap Chinese fakes. It’s nice when the moment of starting the motor tool goes smoothly: the saw warms up and gradually reaches the rated power declared by the manufacturer, which is issued throughout the entire working cycle. Things are worse if everything happens the other way around: after pulling on the gas cable, the unit starts to slip, it works in jerks after short pauses, stalls and starts up again from the pusher.

There can be many reasons for this phenomenon, as well as scenarios for the development of events. Let’s consider in detail each working situation and breakdowns that preceded them.

Other chainsaw malfunctions

A lot of users are faced with a nuisance when the chainsaw does not slow down. The device reaches maximum power in a matter of seconds, which cannot be reduced.

This may be due to the fact that:

- the throttle valve does not function. its spring or thrust element has weakened;

- the toggle switch does not switch well;

- the throttle shaft has lost its corkscrew.

But the opposite can be the case. when the saw is gaining power uncontrollably. The reasons why the chainsaw itself is gaining momentum should be sought in:

- carburetor. it needs to be cleaned or readjusted;

- fuel supply system. gas filter, fuel hose;

- malfunctions of the cylinder-piston or branch pipes connecting them to the carburetor.

There are a lot of breakdowns that manifest themselves through revolutions atypical for a particular part of the working cycle. But an attentive attitude to the tool will help diagnose them in time and return it to normal operation.

Why won’t it start and what to do

Among the malfunctions of a Husqvarna chainsaw, poor engine starting is distinguished. The engine is either completely impossible to start, or it does not start well.

There is no definite answer to the question of why the chainsaw does not start. The main assembly unit of the tool is the engine. The following conditions affect the stability of work:

- mixing fuel;

- air;

- the presence of a spark;

- grease.

A working node is responsible for each factor:

- for the combustible mixture. carburetor;

- for air. a cleaning system, in particular, an air filter;

- for a spark. ignition mechanism and spark plug;

- lubrication. lubrication system and gasoline.

A common reason that chainsaws do not start is non-compliance with the starting algorithm. The motor unit should only be started after complete assembly of all parts:

The chain brake is always on. In order not to lose control of the instrument, you must not start in the air.

Starting the engine in a cold state is done as follows:

- Place the tool on the ground, step with the right foot on the rear handle, with the left hand on the front handle.

- The saw is stable, the chain is not touching the ground.

- With your right hand, take the starter handle, pull the cord, while it is not twisted around your hand.

- As soon as the first flash occurs, return the choke lever to its original position, opening it, and restarting.

- Gas and release. The lock is disabled.

- Transfer the engine to idle speed by quickly turning off the gas limiter.

The warm engine is started in the same sequence, but without opening the damper.

If the start is correct, but the engine does not work, a possible reason is the lack of fuel in the tank, or the fuel chamber of the carburetor is not filled. Check the tank and chamber, fill them with the mixture.

In the event of a malfunction of the ignition system, inspect the candle and check for the presence of a spark on the electrodes. If it is wet (gasoline fills the candle), and the spark is not detected, the part is turned inside out, dried or changed. If it is dry, a spark is present, then there are problems in the fuel equipment. clogging, depressurization of the gas intake.

Magneto malfunctions are also confirmed by a weak spark. Despite the operation of the ignition, there may be no flash in the cylinder, while the plug turned out of the cylinder is wet. Remedy. purging the cylinder with open carburetor flaps.

The system electrodes are caked or oily. This is removed with a wire brush. The candle is washed, cleaned, letting the gasoline evaporate.

Violation of the gap between the side and center electrodes leads to a poor start. The normal spacing is 0.6-0.7 mm. It is fitted with a hem method.

If the ceramic insulator surrounding the central candle or the current-carrying conductor is damaged, the wires are replaced.

No sparks chainsaw

Amateur and professional chainsaws are complex devices. The service life of their two-stroke engines, components and assemblies has its own limitations. For this reason, quite reliable and expensive tools, along with cheap Chinese units, periodically fail and refuse to start. The situation when the chainsaw does not start or stalls is not very pleasant and sometimes confuses the user. How to identify and correct a malfunction by returning the instrument to work.

Starter repair

The starter is responsible for starting the unit. Malfunctions indicate the presence of such malfunctions:

- the spring has burst;

- the pulley is damaged;

- the starter rope is damaged.

Procedure for replacing a worn starter cord:

- the starter is disassembled, the mechanism is removed, after unscrewing the screws securing the case to the motor crankcase;

- the cord is pulled at a distance of 30 cm through the hole in the pulley;

- the return spring is set to neutral;

- the central screw is unscrewed, the pulley itself is removed;

- a new cord is inserted, stretched, while 3 turns are wound on the mechanism and fixed with a screw;

- then the cord is pulled through the groove in the housing and the starter handle.

The tension of the return spring is carried out by rotating it 2 turns clockwise, while taking into account that it is compressed. When replacing a broken part, the spring should pop out after pulling the inner part down.

Husqvarna chainsaw no spark cause

Husqvarna chainsaws are indispensable helpers on the farm. With gasoline powered vehicles, you can perform a variety of construction, logging and simple delimbing jobs. With proper handling of the tool, it will serve for a long time, but during operation, as a result of intense loads, various malfunctions occur.

If minor breakdowns are detected, they do not contact service centers and workshops, Husqvarna chainsaws are repaired independently, while it is necessary to investigate and disassemble the probable causes of defects and ways to eliminate them.

Checking the spark on the spark plug and eliminating the causes.

The first step in looking for reasons why your gasoline saw won’t start is to check the spark on the spark plug. There are many factors that affect the performance of this element. However, the main ones at the initial stage of instrument troubleshooting are:

- Incorrect carburetor adjustment;

- The presence of more than it should be, the amount of oil in gasoline;

- Clogged air filter.

All of them contribute to the formation of carbon deposits on the spark plug electrodes. In 50 cases out of 100, saws do not start on a cold one due to the absence of a spark due to carbon deposits on the electrodes and their corrosion. As a result, the gap either decreases or increases.

Checking the spark plug with an idle chainsaw

Checking for a spark is fairly easy. This will require:

- Remove the tip of the high-voltage wire;

- Unscrew the candle;

- Put the tip back on;

- Lean the candle with a skirt against the cylinder;

- Start with a starter.

If a good spark is observed between the electrodes at the time of starting the engine of the chainsaw, then everything is in order with the ignition unit. If it is not there, then it is worth cleaning the element itself and checking the gap of the electrodes. If necessary, use a special probe to adjust the distance between the contacts.

For candles from different manufacturers, the distance between the electrodes may fluctuate. For some, it may be equal to 0.5 mm. Others have 0.2 mm. Therefore, carefully study the manufacturer’s recommendations.

There may be no spark on the spark plug for other reasons. Of the main faults affecting the poor start of the chainsaw and the unstable operation of the internal combustion engine at idle, from which the tool can stall, the following can be attributed:

- Overflow of the spark plug channel with fuel;

- Lack of contact between the high-voltage cradle and the tip of the candle;

- Failure of the ignition unit.

How to start a cold chainsaw if the spark plug channel is constantly flooding with gasoline? To eliminate the problem while starting the tool, you can use the following algorithm:

- Unscrew the candle with a special key;

- Wipe it with a clean and dry cloth;

- Dry for 20. 30 minutes;

- Remove carbon deposits with a file and adjust the gap between the electrodes;

- Drain the remaining fuel from the spark plug channel and dry it;

- Collect everything and try to start the mechanism.

As a rule, these measures are enough to start the chainsaw and get the job done. However, this extreme measure does not eliminate the main reason why the engine does not start or stalls. improper operation of the carburetor, which needs fine adjustment.

If there is no spark and poor contact of the high-voltage cradle with the spark plug tip, check the connection. The check can be done using a conventional tester. If a defect is found and it is eliminated, the chainsaw should start without any problems.

If the check showed that the contact is reliable, and the saw does not start further, look for the cause in the ignition unit. As a rule, a faulty unit cannot be repaired or restored. A complete replacement is required here.

Chainsaw outlet check.

One of the reasons that a chainsaw does not start well may be a clogged exhaust channel or its muffler. At the same time, a drop in power is noted in the process of sawing lumber and logs. This is most often due to resinous deposits on the spark arrestor or muffler channel, which are formed during the combustion of a poor-quality mixture of gasoline and oil, which impede the removal of exhaust gases.

Resonator clogged with carbon deposits can cause poor starting of the gasoline saw.

Eliminate the reason for the poor start of the chainsaw, in this case, you can remove the accumulated combustion products. To do this, perform a number of manipulations:

- Remove the muffler by unscrewing the screws;

- Remove the cooling panel and gasket;

- Remove the spark arrester;

- Disassemble the resonator housing;

- Wash all elements from carbon deposits with detergent;

- Let them dry completely;

- Collect everything in reverse order;

To prevent dust and sand from entering the cylinder when cleaning the muffler, cover the outlet of the chainsaw engine with a clean rag.

Break-in rules

Chainsaw running in is not carried out for a long time in the twentieth. Therefore, after starting the engine, it is necessary to idle for about 5 minutes, then start sawing trees with a diameter of no more than 10 cm at an average speed.

The technological process is carried out according to a cyclical scheme:

- 1.5 minutes with a minimum load;

- 20 seconds on XX without her.

After operating the first 25 hours, the unit can reach full power, all rubbing parts are running-in.

During this period, the recommendations must be adhered to:

- do not overheat the power plant;

- do not work for a long time at XX;

- do not load as much as possible;

- restrain prolonged slipping of the clutch.

After the final running-in, the following work is carried out:

- inspection of the crank mechanism;

- cleaning carbon deposits on all parts;

- checking fasteners;

- assembly;

- preparation of a combustible mixture;

- carburetor adjustment for maximum power under load.

The saw chain also needs a run-in. Attention is paid to its lubrication and tension. The part is pulled so that it can be freely rotated by hand. Lubrication is carried out by immersion in oil. Then the chain is run at XX for 3-5 minutes. The engine is stopped, the chain cools down and only then the tension is checked.

This video discusses the breakdown of the ignition coil, its replacement and starting the chainsaw. And also watch my.

What to do if the chainsaw does not slow down?

The opposite of the previous situation is when the gasoline tool very quickly reaches high power and does not slow it down. In this case, it can be observed that this cannot be eliminated by either a screw on the body or by cleaning the carburetor. It would seem, what else is needed, the saw works, gives out power as in the instructions. But the problem is that in this case you need ten times more fuel than usual.

The following actions can help:

- checking the throttle cable;

- inspection of the return spring, which could simply slip off;

- sealing the rear flap, which must be very tightly closed.

Usually one of these activities can make a huge difference.

Another technical problem is the situation when the chainsaw itself is gaining momentum, the reason for which is usually more than one. In this case, as well as under load, the saw may start to stall from time to time, preventing it from fully using it for its intended purpose.

Regarding the carburetor, the source of malfunction can be:

- wear of piston components;

- littering it;

- breakdown of the air filter;

- the use of gasoline with a low octane number and inadequate quality;

- damage due to vibration effects of the tool itself.

Each individual model is usually based on a 3-screw adjustment method, and the “H” screw will help to reach the maximum torque.

And yet, if the chainsaw does not develop speed, perhaps even the reason is not in itself, but in the time of the year in which the work is being carried out. So, the minus marks of the thermometer are one of the factors that can completely “knock down” the chainsaw. Many users note that in severe frosts, even pouring hot oil does not help and the grease involuntarily solidifies on the tire. Ice coating on the carburetor and frost on it is also a fairly common thing. What can be done?

Reduce the use of the tool before the onset of the body, or, if the design allows, change the damper mode from summer to winter, which is installed on individual models under the air filter cover.

What can be the reason that the chainsaw does not keep idling?

As they say, start up. it started up, and then stalls and does not have time to move to the next power level. Many conditions can serve this:

- clogging of filtration parts;

- malfunctions of the incendiary system;

- out of adjustment of the carburetor;

- the gasoline drive is defective or damaged during operation;

- muffler or exhaust ducts clogged;

- malfunction of cylinder-piston and installed valves.

Of course, it is difficult to independently diagnose everything at once, but moving through the proposed points you can still get an answer to your question. In half the cases, it is enough to clean the carburetor, check the installation of the jets. and the job is done, the chainsaw works as before.

Everything about the speed of gasoline saws

Modernization does not stand still. And the old chain chainsaws, which, besides being able only to cut wood, emitting a terrible roar and vibration, heard almost for kilometers, are long in the past. Almost silent, sophisticated tools that are now a pleasure to hold in their hands have flooded the market, giving users a feeling of complete happiness and technical freedom.

But, to our great regret, no matter how detailed technically and visually advanced technology is, its breakdowns are a fairly frequent occurrence, which manufacturers speak about only “by default”. Chainsaws are no exception, multifunctional working units that require tremendous attention to themselves from the user in order to recognize the “catch” in time and stop the problem at the earliest stages.

The main of these nuances usually relate to the moment of launch, which should be taken with full responsibility. Let’s look at the main processes that can occur with a chainsaw when the engine is turned on.

Other points that could lead to such consequences are:

- malfunctions with spark plugs;

- problems with the carburetor or simply incorrect adjustment.

The spark plug lends itself to visual diagnostics, therefore, if it is too dry or, on the contrary, very wet, and even with a significant coating on top, it is necessary, if not to replace it with a new one, then simply clean or dry it and try it outside the saw ignition system.

The chainsaw is not gaining momentum. what to do?

over, this phenomenon may be accompanied by the fact that the motor periodically does not start at all, it loses speed, and the load cannot withstand more than idle speed. If you do not pay attention to this problem in time, you can generally “lose” it due to severe overheating.

The main reason for this usually lies in the area of the engine, which is why it is worth taking a closer look there.

The leading reasons for this may be:

- clogging of the carburetor or fuel and air filter;

- violation of the integrity of the hose that supplies fuel;

- depressurization of the leading pipe from the carburetor to the engine cylinder;

- and again incorrect adjustment of one of the screws (usually the H-screw) of the carburetor system.

Therefore, the simplest thing to do at home is to clean the carburetor and filters, both air and fuel. At the same time, it is important to maintain the correct adjustment of the screw elements L and H. Some advise to completely remove the fuel filter from the structure, but this is not an option either, because the carburetor will not last so long.

Therefore, before starting work, you just need to look to see if it sinks, if there are any kinks in the hoses through which the fuel enters, and then take more drastic actions.

As you can see, there are many problems, but an excellent panacea for each of them is timely diagnostics that can answer many questions about a technical malfunction of the device even before they appear.

Filter dirty

Since, for example, a Stihl chainsaw stalls when you press the gas for a simple reason, namely, a simple clogging of the direct breather.

In order to solve this kind of problem, all you have to do is disconnect the (fuel) hose from the carburetor and pay attention to whether the fuel is leaking from it. Since if the mixture flows in a full stream, this means that the breather is not contaminated, but if on the contrary, then the cause of the breakdown has been found.

Filling the mixture when the mechanism is running

Also, the cause of a breakdown can be the direct filling of the mixture with a candle at the moment when the mechanism is started. In order to solve this problem, it is necessary to unscrew and dry the candle, but remember that it cannot be ignited in any case. Excess fuel must be drained through the hole (plug), wait 20-30 minutes, then put it back in place and try to start the tool again.

Why does the chainsaw immediately stall and jam when the gas is pressed

Chainsaws are fairly reliable and uncomplicated designs. Therefore, if you properly care for them and handle them based on the manufacturer’s recommendations, then they fail very rarely and various kinds of breakdowns are quickly eliminated. But if you are faced with this situation and want to personally repair your tool without resorting to the help of professionals, then delve into the information provided below.

In fact, it is unambiguously and precisely impossible to determine the reason why the instrument does not start or stalls when you press the gas, since there are a lot of factors affecting this. But do not forget that, starting from the fact that the chainsaw is equipped with a simple two-stroke engine, conditions such as lubrication, fuel, spark and air are important for its effective performance.

Therefore, the carburetor is directly involved in the preparation of the fuel-air mixture, the filter cleans the air from dust, the ignition unit and the spark plug create a spark, and the gasoline contains grease.

That is why it is necessary to search for the causes of this kind of breakdown in a sequential order, starting directly from the simple ones and gradually moving on to the complex ones. And this is an important factor in the correct repair, since the person who, without thinking, begins to disassemble the carburetor, brings it to risk. Since this kind of unit must be repaired or adjusted directly in special workshops (read about adjusting the carburetor).

Why does the chainsaw stall when you give gas when pressed, and does not start under load at idle

There are often cases when the owners of chainsaws are faced with their breakdown and it does not matter what model of this kind of equipment, since the nature of the breakdowns is almost the same for everyone. Well, the chainsaw stalled, and what next? Undoubtedly, you can refer the equipment to specialized services that will repair your “iron friend” for a fee. But as the saying goes: why pay more?

After all, you can personally disassemble the tool and repair it, since the breakdown may be insignificant, and in the service you will pay a lot for this. But naturally, in order to bring the instrument back to life yourself, you need to be able to understand the reasons for its breakdown and how to troubleshoot it. So let’s learn! In this article, you can find answers to questions regarding situations when the instrument simply stalls after directly pressing the gas. So let’s get started.

Husqvarna chainsaw won’t stay running.

Additional Tips

First of all, what you should remember when purchasing this kind of tool is that certain parts of the saw must be replaced with new ones after their service life (passport) has ended. It is for this reason that the instructions should always be at your fingertips, since everything is described in detail there.

Such parts include: an asterisk (leading), a bus, a part of a system (anti-vibration), and a chain. Since you should not forget that if this “filling” is not changed to a new one at the right time, then these worn-out parts will negatively affect the rest of the chainsaw. It is for this reason that check the depth of the direct toothing quite often. Remember that it should not be higher than a week 0.5 mm.

Insufficient chain lubrication prevents starting and the saw does not develop speed

Many people ask the question: why does the chainsaw stall when I press the gas? The answer may also lie in insufficient chain lubrication (see oil for the chainsaw chain), since the oil line may leak, or the direct channels may simply be clogged. That is why pay attention to the chain, because if it is dry, then, without delay, start cleaning the channels that supply oil directly to the tool tire. After that, inspect in detail the parts where the oil pump fittings are connected to the pipes. But if you notice that the oil leaks at the joints, or found cracks on the pipes themselves, then in the first case, seal the leaks with a sealant, and the pipes will have to be replaced.

Not enough fuel to feed and run the chainsaw at full power

If the chainsaw stalls when gas is added, it means that the fuel is not supplied in sufficient quantities for the full operation of the chainsaw. This may be due to both clogging of the carburetor (its jet) and contamination of the filter itself (fuel). Remember that only professionals should check the first node, but you can clean the second one yourself.

There is no spark and the chainsaw does not pick up speed

The chainsaw stalls when you press the gas due to the fact that there is no spark. This can happen when there is no good contact between the tip of the candle and the wire (high voltage). However, if this kind of connection works correctly, but there is still no spark, then the whole reason is the ignition unit (electronic). It is important to note that these types of parts cannot be repaired, so they can only be replaced.

Do not forget that by examining the spark plug, you can get significant information regarding the breakdown of the chainsaw. Since if its surface is dry, then the reason for this is the cylinder, which is not directly supplied with fuel. That is why you will have to check the entire range of its presentation step by step. If the candle is covered with black soot, then this means that the carburetor is not working correctly, that is, it either supplies a lot of fuel or pours oil directly into gasoline.

Why the chainsaw doesn’t pick up speed and stalls

If the saw cannot gain speed or stalls when you press the gas, then most likely this is caused not by the tightness of the carburetor or motor crankcase. This problem is eliminated by checking for leaks and adjusting the carburetor.

In addition, this malfunction may be associated with a defect in the fuel tank breather. Due to the formation of a vacuum in the fuel tank during the operation of the chain saw, the required volume of the fuel mixture does not enter the engine, as a result of which it cannot gain speed or stalls. If you stop the chain saw, open and close the fuel tank and turn it on again, it will work normally for about five minutes, and then it will stop picking up speed again or stall.

Another possible reason that the saw is not able to pick up speed may be excess carbon deposits in the muffler, which makes it difficult for exhaust gases to escape, which reduces the power and engine speed.

Why the chainsaw stalls, the main reasons.

The chainsaw starts and stalls. the reason

If the chainsaw starts and stalls at the first attempts to do the job, then the reason may be problems with the chain brake or its jamming due to lack of lubrication. In this case, the oil level is measured. If the amount of lubricant is sufficient, then the cause may be in the tube that leads it to the lubricating mechanism.

Another reason may be a broken carburetor. If he only needs adjustment, it can be done independently in accordance with the instructions. If the carburetor needs cleaning or repair, then you cannot do without the help of professionals.

Another possible cause of this malfunction is a low fuel level in the tank. In this case, the saw stalls when tilted, since the remaining fuel mixture ends up in the part of the tank opposite to the place where the suction pipe is located.

Why does a chainsaw stall when heated

It often happens that the chainsaw starts up on a cold one, but stalls during the heating process. This behavior of the tool can be caused by the following reasons:

- The carburetor is incorrectly set. You can identify this problem by how the device is started up on a cold one. If it is performed without closing the air damper, and the engine starts without a preliminary flash, this means that after heating the engine, the fuel fills the candle. The solution to this problem is to adjust the carburetor. Details on carburetor adjustment

- Coil (ignition module) malfunction. This problem can be identified by sequentially checking the spark, first on a cold, and then on a hot motor. If there is no spark on a hot engine, then you need to replace the ignition coil.

- Defective spark plug. In this situation, as in the case of a malfunction of the ignition module, the spark disappears when the engine heats up. It is necessary to replace the spark plug with a new one, and if this does not lead to a solution to the problem, then the ignition module and the distance between it and the flywheel should be checked.

The main causes of chainsaw breakdown

Although the chainsaw is a simple device, from time to time, problems arise in its operation, which can only be fixed by disassembly. The following malfunctions can be cited as examples:

- the chainsaw is not picking up speed;

- the chainsaw stops functioning in the cut;

- the chainsaw starts and stalls;

- the chainsaw loses its power;

- the chainsaw stalls when pressed.

Most often, malfunctions are associated with interruptions in the functioning of the motor, as well as with malfunctions of other systems and components. Proper handling of this technique is essential. When all the rules of use are followed, problems with a high probability lie in the most obvious. When looking for the causes of problems, it is advisable to start by checking the simplest part of the chain saw and end with the most difficult.

What to do if the chainsaw stalls when you press the gas

One of the most common questions regarding the operation of this device: why does the chainsaw stall when you press the gas and what should be done to solve this problem? In such a situation, you need to do the following:

- check the fuel filter;

- inspect the fuel hoses for leaks;

- check the muffler;

- try to increase the speed a little;

- check the condition of the rubber seals on the crankshaft.

Why does a chainsaw stall under load

Sometimes the saw will not function properly under load. This is most often caused by improper adjustment or leaks in the carburetor. In addition, air leaks through the carburetor gasket or crankshaft oil seals may be the cause of this problem. A tool that is unable to function under load also cannot maintain idle speed reliably.

Diagnostics begins with checking the carburetor and crankcase for leaks. If air leaks through the crankshaft oil seals, they must be replaced. If air leakage in the carburetor is detected, the installation of a repair kit of gaskets is required to solve the problem.

If these actions did not lead to the desired result and the crankcase with the carburetor is tight, then the carburetor needs to be adjusted.

If a Husqvarna chainsaw stalls under load, then in case of any deviations in the functioning of the engine, you should first of all check the impulse hose, since this is the most common reason for the breakdown of this brand of chainsaws.

Checking the main systems of the chainsaw

If the chainsaw refuses to work properly, you must make sure that all the conditions required for its normal operation are provided:

- fuel;

- spark;

- grease;

- air.

Then it is necessary to sequentially check the functioning of all its elements. First you need to check the fuel tank. If the cause is not volume and quality of fuel, then spark plugs may be the likely cause of the malfunction. The gap at the candle should not exceed 0.5 millimeters. If it is too small, it means that carbon deposits have been deposited on the candles. In this case, remove the candles, clean them, then reinstall and try to start the chainsaw. In addition, it is advisable from time to time to completely replace the candles with new ones, even if they are in good condition.

Then you need to check the condition of the fuel filter and carburetor. Self-cleaning of the fuel filter is a simple task, but it is best to entrust the repair of the carburetor to specialists.

Why the chainsaw does not develop momentum

There may be several reasons for the lack of traction and poor set of revolutions with a chainsaw. Therefore, you should not immediately begin to disassemble and repair the carburetor, since the reason may be hidden and not in it.

A reliable carburetor is installed on the Stihl ms 180 chainsaw, on which the manufacturer limited the ability to adjust the power and maximum engine speed, therefore, when the traction falls at the chainsaw, the carburetor is the last place where you need to look for problems.

Muffler

You ask, what is the first? The answer is a muffler. The muffler is responsible for exhausting the exhaust gases and extinguishing the flame in them. All combustion products pass through it, which over time can clog it. The situation with a muffler clogged with soot is far from uncommon, but it occurs due to an incorrect fuel mixture.

With a normal ratio of gasoline to oil, the combustion products are not saturated with soot enough to clog the muffler. In the event that the amount of oil is more than the norm, excessive carbon deposits are formed during its combustion. Further, carbon deposits accumulate under the piston rings and in the muffler of the Stihl 180 chainsaw.

The reasons why the Stihl 180 does not develop momentum

Chainsaw Stihl 180 does not develop revs or after you release the gas trigger, it continues to work without dropping the revs. These problems are quite common. Let’s try to understand the reasons, the consequence of which is the occurrence of such malfunctions. Also in this article we will consider how to diagnose if the chainsaw does not pull.

- Why the chainsaw does not develop momentum

- Muffler

- How to check the muffler

- Checking the fuel filter

- Mesh filter in the carburetor

- Depressurization of the carburetor and blockage of the nozzle

- Why the chainsaw doesn’t slow down

- Video

- Output

How to check the muffler

To check the muffler, it must be removed from the chainsaw. To do this, using an 8 mm head, two fastening nuts are unscrewed and the part is removed.

Important: after the muffler is removed, it is necessary to check the integrity of the gaskets between it and the cylinder, since very often they stick and break when the muffler is removed.

You can clean the part mechanically, using screwdrivers or a knitting needle, and then blow it thoroughly with compressed air. The seat on the muffler can be cleaned with sandpaper to remove burnt-on gasket parts.

Install the muffler in reverse order.

Important: when tightening the nuts of the muffler, do not pull the nuts excessively, since the threads on the screws can be torn off.

The second reason why the engine of a Stihl chainsaw can reduce power and not develop speed is a blockage in the fuel system. As a rule, the first place to start looking for a blockage is the fuel filter.

How to fix a husqvarna 372xp that’s running lean (sucking air )

Checking the fuel filter

The fuel filter is installed in the tank of the Stihl 180 chainsaw, and it is not very convenient to pull it out. To facilitate the process, you can take a small piece of aluminum wire and bend it at the end, then use it to hook the fuel hose and remove it together with the filter from the tank. To check the filter, it is necessary to blow into it, if air does not pass, then the reason has been found, and the filter must be replaced.

If the filter is clean, check the fuel hose for clogging. To check, it is necessary to disconnect it from the carburetor and, with the air filter removed, blow into it. If a blockage is found, the hose can be cleaned mechanically, using a wire, and then blown out with compressed air.

Strainer in the carburetor

The last likely place for blockage to occur is in the filter strainer in the carburetor. In the diagram below, it is indicated by the number 13.

In order to clean the mesh filter, it is necessary to remove the carburetor from the Stihl 180 chainsaw. Work begins with the removal of the upper saw cover, after which, using an 8 mm head, two fastening nuts are unscrewed. Further, the filter housing is removed from the guides, after which the air damper rod and the engine control lever are disconnected. Last of all, the fuel hose and throttle rod are disconnected, after which the carburetor can be removed from the rails.

The carburetor mesh filter is installed in the fuel pump chamber, in order to get to it, one screw securing the pump cover is unscrewed and it, together with the gaskets, is removed.

The strainer can only be cleaned with compressed air. Any mechanical methods are strictly prohibited, since the mesh is very soft and easily changes shape. When you press it, it is easily crumpled and bends are formed along the edge of the seat, through which unfiltered fuel can enter the carburetor.

In the process of cleaning, the seat with the filter installed in it must be half-covered with a finger and only after that blow with air, otherwise, the mesh may fly away and it will no longer be possible to find it.

Stihl 180 does not develop momentum, the video of the most common reason can be seen below. In it, the owner of the Stihl chainsaw ms 180 tells his story of solving the problem with a loss of power.