Interskol p 30 900er disassembly

How to Disassemble the Interskol P 30 900er

Advantages:Price, power. Drills faster than any I have ever held in my hands. beast.

Disadvantages: broke after 4 years, and it is not possible to replace the chuck. the screws are covered with a metal ring.suitcase uncomfortable, shallow (you have to bend the wire from the handle peoratora), handles broke the suitcase, I had to kolhozhivoit

Comment:I lowered the sockets and switches, kneaded the concrete, drilled a lot.Power enough to quickly drill holes. heats up? but it makes the job go faster. If you work around the house, it is one of the best solutions. to work 8 hours a day, choose the one with a vertical percussion mechanism.Too bad it died after 4 years

Advantages:Price of course, out of competition in this segment.

Disadvantages:Turnovers are low (general impression), the steel band fastening the front handle quickly fails. Tight suitcase.

Comment:The quality of workmanship in the last 5 years has fallen. The first one after the repairs is still working, the second (bought 3 years after the first one) is half a year old. In the second one the reversing contact plate burned out, but it is a trifle. No speed since the first one (the change of trigger did not help). The overall impression of the new peorator is much lower than the old one of the same model. Too bad, I expected the same quality.

Disadvantages:Small case, nothing extra in the kit

Overall it is good, sorry they do not put any goodies in the kit

Advantages:Powerful, not expensive, repairable. It is survivable enough.

Disadvantages: You can run into a defective copy. A couple of years ago there were up to half of them. The defect was mainly in the cartridge, the chisels came out when chiseling.

Comment:I have four of these peoratots, plus bought it as a gift for friends. Once I bought it as a rush job and surprisingly I liked it. Since then it is my main working tool. The great thing about it is that it is versatile. The power allows me to do a mixer and a chisel. And relatively compact. It’s true the case is bad but I use cases from other torches I had many.It is an ideal tool for home or cottage. If it is not misused it is good for a long time. Quite enough to make a complete renovation of the apartment, with cable channels and splices. 1. Although for such cases it would be better to use a more powerful torch, most of Chinese torches with 4.5-6.0 Joules are very powerful.The problems with this model are most often.1. Failure. Happens, and therefore should be checked immediately when buying so that when working nothing crunchy and generally without the alarming sounds.2. The chuck. The drills can fly out when chiseling. At the same time when this model was on sale there were no such problems. And a couple of years ago, half of all the guns came with defective cartridges. The good expensive Boschev drills were holding up much better, but the cheap Chinese chisels were flying out in a jiffy. It was treated by replacing the cartridge under warranty or by your own efforts (ball, clip, spring).3. May have some problems with the mode switch, it is necessary to clean it from time to time (2 minutes), as well as with different mechanical parts. But that is after rather intensive use, mostly while chiseling.There were never any problems with the electrical part, everything is reliable. Even with the dust.If you have been drilling for a long time, the screwdriver gets hot and you need to give time to cool down.In general, it is a good machine for home and even professional work, if not to demand too much from it.I prefer this model mainly because of its versatility which is due to the good power and good impact force. As an on-duty tool it is almost ideal.

How to disassemble the Interskol p 30 900er

Interskol peorators are statistically among the most reliable tools. Failures are registered much less frequently than in more popular Makita, Bosch, Hitachi models.

The main rule: choose a model that is designed for the load and intended for the planned work.

The proper use of your Interskol torch in accordance with its intended use allows you to use your Interskol torch for a long time.

But as with any tool, there are different malfunctions that require repair of the orator by yourself, especially if it is out of warranty.

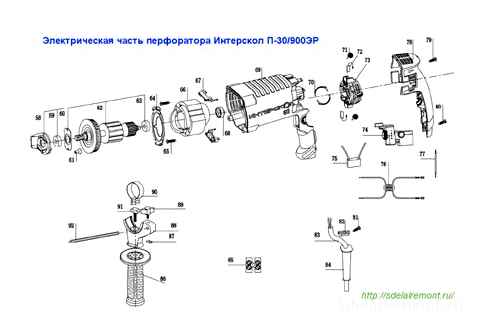

In order to repair Interskol perforators, to correct malfunctions you should thoroughly study the construction of the tool, its diagram, and lubrication cards. Any repair of the Interskol battery charger starts with disassembly.

Classification of Faults in Interskol Perforators

Interskol shock absorbers are very repairable, simple and reliable.

Any user who can hold a screwdriver, a hammer and understands electrical engineering at secondary school level can do hands-on repair of Interskol orators.

All malfunctions occurring in Interskol Perforators are divided into three groups:

The Interskol mechanical group of faults

Let’s take all malfunctions on the example of the Interskol P-26/800ER.

The first group of faults includes breakdowns associated with the failure of the percussion mechanism parts.

This group of failures appears in the following way: when working the machine drills, but can not chisel.

Wear of rubber o-rings

The impact force weakens gradually. As the rubber rings wear out, air leaks into the pneumatic shock creation system. The shock force weakens, the shock becomes hard. In addition to the loss of pneumatic properties, the strikers, striker, press masses are destroyed.

Repair of the Interskol pistol when the o-rings are worn is to replace them with new ones.

Installation of new rubber o-rings is made at any disassembly of the pen with obligatory lubrication of o-rings with the lubricants inert to rubber products. This type of grease includes domestic grease of Cyatim-224 type, produced in accordance with GOST 9433-80.

Rubber o-rings are lubricated with a thin layer of Ciatim-224 and put on the proper part, previously washed of old grease in a solution of kerosene and gasoline mixture.

Destruction of strikers, drums, barrels, pistons

In case of heavy wear of rubber sealing rings and their untimely replacement the press mass is destroyed pos.16, barrel pos.36, catcher housing pos.40, striker pos.45. Crushing causes nicks, cracks, distortions, jams on parts.

The defects can be eliminated by exchanging with new parts and compulsory exchange of the seals.

Piston rupture pos.47 come in two varieties:

Repair of the Interskol P-26/800ER and its destroyed piston is performed by replacing the piston for a new one. When purchasing a piston, carefully check the surface roughness of the internal surfaces of the piston. It should be brought to a mirror shine.

Failure of barrel pos. Not very common. Main cause, scratches on the inner surface if the strikers, firing pins, blows are out of order.

If the depth of scratches is not too great, the scratches can be removed by lapping. If scratches are too deep, it is not possible to ensure air tightness and this will affect the performance of the piston in impact mode.

Destruction of rolling bearing

The shock impulse is created not only by pneumatic system of the shock mechanism, but also by transformation of rotary motion into reciprocating one at the expense of work of the roller bearing pos.60. There are cases of destruction of the bearing ring.

Interskol P-26/800ER bearing destruction the repair of the Interskol P-26/800ER is the total replacement of the part.

The transmission of torque to reciprocating torque can be interrupted by slippage in the splines of the toothed combination wheel pos.62 in the splines of the anti-friction bearing pos.60.

Disassembly of the Interskol P710ER drum beat mechanism

The structure of the shock mechanism and the disassembly procedure for the Interskol 710ER is slightly different from other models.

The main differences in the design of the intermediate shaft, the shaft of the percussion mechanism and the mode switch.

Figure of the impact mechanism and the intermediate shaft of the Interskol P710ER

The Interskol 710 EP is an impact-rotating machine. Consists of an electric actuator and an actuating mechanism. For the electric drive a commutator motor is used. The blade’s action mechanism is essentially a combination of a compression-vacuum-type hammer mechanism and a rotary mechanism. The reciprocating motion is transmitted by means of a roller bearing.

The diagram shows the order of disassembly of the barrel pos.15 (marked with a reddish arrow), beater and striker assembly (marked with a blue arrow). Green arrow indicates parts of the mode selector.

The intermediate shaft consists of the shaft pos.47 and its mounting parts. Disassembled simply, according to the attached diagram, does not require any special knowledge.

Disassembly of the Interskol p 24 700er

Repairing the peorator with your own hands. how to repair it quickly?

Necessary tools and materials

Whoever has ever worked with the rotary table knows how difficult the conditions of its use are. That’s why the repair of peorator with their own hands. such a popular request on the Internet. Today we will talk to you about absolutely everything that concerns the repair of this tool.

What you need to know about repairing the?

There’s no doubt that owners of such expensive equipment want their devices to be of high quality, to perform 100% of their work. First of all, proper use of the tool will prevent serious damage, as we will tell you later. And, of course, the timely repair of the device. In this case, any small failure should already be a cause for concern and preparation for repair.

- Unstable operation of the peorator in working mode;

- The appearance of strange noises when you turn on the torch;

- The smell of burning;

- The tool does not chisel, although there are no visible reasons for this.

When that happens to your machine, it is time for a repair. Like any such work, it requires attentiveness, understanding the cause of the breakdown and knowing how to deal with it. And your very first step in the repair is to disassemble the tool into its components. For many people even this stage causes difficulties, and therefore it is necessary to know everything to the nuances. how, what and why!

Disassembling the torch. a quick troubleshooting

Imagine that your tool suddenly stops working or you urgently need to replace a faulty part. The easiest way. to take the torch to the service center for repair, but it takes time, and thus for some time will stop your work. But if you know how to disassemble it, it’s much easier to do the rest. It will also save you money because you don’t have to pay for repairs.

- Begin at the upper part: first remove the rubber nipple, then the washer, then the spring, and finally the ball.

- After you have removed the ball, unscrew the screws that hold the housing, remove the handle cover, if available, and lastly disconnect the stator wires.

- Removing the brush holder.

- The next step is to separate the gearbox and housing until a gap is formed. It is through this we will remove the switch.

- After that the body of the rotary table is put upright and fixed with a vice and all its parts are carefully taken out of the device.

Repairing the Penetrator. The Interskol P26 800ER does not hold the drill

In this video I will tell you how to fix the Interskol P26/800er with SDS drill bit not holding.

The review with disassembly of Interskol P-24/700ER// how to disassemble the Peorator//

If you liked the reviews subscribe to the channel, it is important to me /// Next review will be for Zubr.

No matter what kind of breakdown you have, you have to clean the body. sometimes it is dust and dirt that prevents the device from working properly.

Repair your torch yourself step by step

To repair a device such as a peorator, you should be as prepared as possible, which will reduce the financial and labor costs to a minimum. It is not bad if you are more or less familiar with the construction of the pen, you know what parts and components it consists of, which will allow you to quickly replace a broken part. The most often it comes down to banal replacement of defective elements which include:

It is worth noting that it is easiest to repair tools of the light class, given that such a peorator is excellent for construction work in the home. But the breakdowns of more serious equipment can be much more complicated, and only professional masters can cope with them. In any case, whatever class of tool you are interested in, find a model with a vacuum cleaner. this device will save you time on cleaning, and also make the work safer, because it reduces the amount of dust.

Another problem is in the breakdown of windings, rewinding of the armature and starter, which also arise due to dust. Repair consists of thorough cleaning and replacement of those parts that cannot be repaired. However, prevention is a more reliable method. To do this, you need to clean the device every two weeks, impregnate it with varnish or grease. By the way, it is necessary to pay attention to the choice of lubricant. So, there are several rules. First, it is better to buy the solution of the same manufacturer (Bosch, Makita, Enkor) as the torch itself, in this case the oil or varnish will be perfect. If you don’t have a formula on hand, then the right oil for the diesel engine will work for you.

The second most popular cause of failure is brush wear, no matter how much your tool has cost. even the most expensive models are prone to this problem. To replace them is very easy: disassemble the motor according to the above described scheme, find the worn brushes and put new ones in their place. It is just necessary to choose the right one: carbon, graphite or carbon-graphite. So, graphite brushes have a long life, but because of the hardness of the material the collector can suffer. Carbon elements have a short service life, but they are in good contact with other parts of the tool. The purchase of the third variant is considered to be optimal and inexpensive.

There can be problems with mechanical elements of the device. Every model has the switching modes, and they often fail, especially the cheap ones. The work algorithm is the same. disassemble the peorator, find the broken parts, replace them. The main thing is to get the right parts for the model in question. A similar problem often plagues cartridges that are subjected to maximum load. First of all, protect them from dust and dirt by washing the elements with grease. But if the cartridge does break, we have no choice but to replace it.

Now you know how to fix the peorator, and you see that most of the breakdowns are reduced to simple cleaning or replacing the faulty parts. But if you disassemble the tool, and there are no visible reasons, it is better to take the device to the service center. specialists will find the cause and fix it faster.

Disassembling the Interskol p 30 900er Geareducer

Failure: The torch stopped beating almost immediately after purchase. Т.е. there is practically no wear and tear on the tool.

Remedy: Removal of viscous grease from the striker, promo mass and grease around. The prommass was sticking on the striker because of the grease. The problem is more likely to recur, t.к. the grease should get there eventually. What’s where look in the drawing on the P-30/900ER p-30_900er_kat.pdf.

Possibly can be fixed without disassembly. We turn on the torch, turn it on and wait for the torch to warm up until your hand is not burning. The friction will heat up the grease and maybe it will work.

Tool holder was bought a year ago. Within a month of sporadic use, the torch mode has faded. It used to work sometimes, sometimes not. Peorator stopped beating in any mode, the drill is fine. Now I need the peorator mode again.

Started to disassemble, as usual first do, then look for instructions. Without the disassembly manual, the puzzle took half a day to unravel:

Disassembling the tool holder. Pull back the cover and remove the rubber plug, remove the ring lock, then remove everything that comes off.

Removing the drill/mix/peeler switch knob. Here was the tricky part. At first there were unsuccessful attempts to pull out the gearbox from the aluminum housing. It turned out that it is necessary to turn the knob to the extreme secret position in a clockwise direction and pull it out by gently wiggling it. In the process of not very careful attempts to extract the handle, it was damaged badly. But in spite of all the damage after the final assembly everything worked as before. Below is a photo of the position of the handle, when you press the latch button it can be pulled out by wiggling it up:

Here the damaged knob is pulled out too much, the catch holding the knob in the normal position is broken, this does not matter when it is assembled. And a photo of the correct position of the inner mechanism under the shift knob:

The two metal pins should be in the leftmost position. The metal tab on the shift knob must fit between the metal pins. Left upper cavity.

Unscrew the plastic cover on the cutterbar. Removing the brush springs. Pull back the brushes.

Unscrew the 4 main screws and divide the housing into 3 parts. The aluminum plastic part of the body and the gearbox with the rotor. The rotor can not be unscrewed. When putting the rotor back in, it will be difficult to fit the rotor bearing into the rubber retainer on the shroud handle, you need to lightly wipe the outer rim of the bearing with grease, only very lightly.

Disconnect the piston and the barrel. Next, we clean the grease off the striker in and around the piston, then off the fret located in and around the barrel.

Principle of operation: the die, fixed inside the piston as a result of longitudinal reciprocating motion hits the punch, the punch flies off and hits the nozzle, fixed in the chuck of the piston, giving about 3 % energy.3 J. The prommass then flies back to the firing pin and everything repeats. The striker does not strike the tool directly, the prommass rationing the energy transmitted to the nozzle.

Mechanical Faults

With mechanical damage is a little harder: the perorator consists of many parts, so immediately to establish the cause of failure can and even can not be. The main thing is to take a closer look at the details, and after identifying the breakage neatly remove it. Here are the most likely damage that you can do to correct at home.

- Switch. Most devices are equipped with switches. Myth mechanism and subject to breakage. If the peeler stops chattering, it is most likely due to frayed trigger fingers. They routinely come in contact with rotating parts during operation and will wear out.

- The detent spur that holds it in the gearbox housing is broken, which contributes to the spontaneous switching of modes. Of course not to change the clamp, if you are not embarrassed by this discrepancy, it works anyway.

Change the switch. If there is no suitable switch, and the work cannot be suspended, of course turn the worn-out part 180 degrees, you can continue working.

Пеоратор Интерскол П-30-900 эр Нет удара. Диагностика

- Cartridge. This part of the mechanism succumbs to more load, which leads to its breakage. If it is the case with the cartridge, it must be replaced. the only thing that prolongs its life is preventive care: rinsing off dust with gasoline, cleaning dirt, etc. д.

- the compressor ring and the striker. They are sometimes broken because of the heavy loads they are subjected to. When the pressure is too high, the firing pin stroke is shortened, which can lead to malfunctioning. If it breaks, there is only one way out: Replace it.

- Gearbox. If the reducer fails, it is necessary to carefully disassemble it and check the details one by one for our customer. The most vulnerable place of the gearbox is of course the bearing. first check its integrity. if it is necessary to change it. On the contrary it is intact, the reason is probably in the seat. It can wear out and may not hold the bearing properly. Then the gearcase itself has to be replaced. Of course the gears in the gearbox can fail. It’s easy to spot them visually but they can’t be repaired. they’ll have to be replaced.

- Oil leakage. If it leaks (note that this does not happen often) the packing has to be replaced. It’s in the neck of the housing.

- Operation can also be affected by dirt. This is indicated by a rattling or grinding noise. To avoid similar problems, often clean and lubricate interior of the chuck. The principle is to use only type 1 grease, the same type used before.

Design features of the SDS-plus quick-action chuck

Let us start with the differences in the design of the fastener assembly of the chuck.

The principle of disassembly of clamping cartridges is almost the same for all torches.

Interskol saws use a SDS-plus quick-action chuck. To work with Interskol rotary tool it is necessary to use tools with SDS-plus shank.

Disassembly of the quick-action chuck

Disassembly of the quick-action chuck will be considered on the example of the Interskol P-26/800ER.

After setting the torch on the back of the handle remove the protective sleeve pos.1, remove the washer pos.2 and pull out the locking ring pos.3.

The washer pos.4 and locking ring pos.5. The next step is to remove the pressure sleeve pos.6.

For releasing the locking ball pos.8 must be pressed on the special washer pos.9. Remove the ball and take out the conical spring pos.10.

The design of the Interskol P-30/900 ER quick-action chuck has fewer parts. But the order of disassembly is the same.

The quick-action chucks of Interskol P-600ER and P-710ER are practically identical and are disassembled in the identical sequence.

The Intersol P-30/900ER quick-release chuck

Parts of Interskol P600ER and P710ER quick-action chuck are dismantled in the following sequence

- remove special ring pos.1;

- Release sleeve releasing pos.2;

- the special ring pos.3 and pull out the ball pos.4;

- take out spiral spring pos.5.

With all Interskol torches the mode switch must first be removed to remove the gear case.

Disassembling the mode selector handle in the Interskol P-26

Tilt the peorator sideways and turn the mode knob pos.28 counter-clockwise to the stop with the button depressed pos.26. Remove the knob from the gearbox housing.

Never change the mode knob while the torch is in operation.

Features and models

As of this year, the company supplies to the Russian market 7 basic models of gears, differing by power input and impact energy. An important feature of all models is the SDS clamping system, developed by the famous Bosch. For all models, except for P-1200K-M, where SDS-max fastening is used, SDS-plus system is typical. Also all company’s rotators are distinguished by two handles, one of which is fixed, and the second can be rotated up to 360 degrees. Let’s look at the range in more detail.

- “P-650K” is the least powerful and most budgetary company’s torch. With only 650 watts this tool develops a shock frequency of up to 3,900 beats per minute with 2.6 Joules of energy and a spindle speed of up to 1,000 rpm. With these parameters it can drill holes in concrete up to 24mm in diameter.

- “P-800K” is distinguished by the power of 800 W, which allows it to develop a frequency of blows up to 5200 beats per minute with an energy of one blow of 3.2 J. But the speed in the drilling mode for this model is not too superior to the previous one, and amounts to 1100 rpm. The maximum diameter of drilling in concrete is 26 mm.

- “P-800K-V differs from the previous model by its more compact dimensions, ergonomic handle-head (which noticeably increases its convenience and safety) and higher impact energy up to 3.8 Joule.

- “P-900K”. Structurally, this model almost does not differ from the “P-800K”. By increasing the power consumption to 900 W it was possible to increase the impact force to 4 J with the same rotation speed and impact rate. Such a powerful impact allows using this model for making holes in concrete up to 30 mm in diameter.

- “P-1000K”. Further increasing the power up to 1 kW allows this device to develop the impact energy of 5 Joules. Spindle speed for this model does not differ from the previous ones, but the frequency of blows is even a little bit lower. only 4900 rpm.

- “P-1200K-M”. Despite the considerable power (1,2 kW) and ergonomic design, it is not very efficient to use this model in drilling mode, because speed in this mode is only 472 rpm. But the impact force of this model is 11 J, which allows you to make a hole in the concrete with a diameter up to 40mm.

- “P-1400K-V”. Like the previous model, this heavy-duty chain is intended exclusively for construction but not for domestic use for drilling in relatively soft materials. With the power of 1,4 kW it has the impact force of 5 Joules, the frequency of blows reaches 3900 per minute and the drilling speed. 800 rpm.

The structure of the drum assembly and disassembly procedure for the Interskol 710 EP is slightly different from other models.

The main differences in the design of the intermediate shaft, the percussion unit barrel and the mode switch.

The scheme of the impact mechanism and the intermediate shaft of the Interskol P710ER

The Interskol 710ER is a rotary impact machine. Consists of an electric actuator and actuator mechanism. Collector motor is used for electric drive. The executing mechanism is basically the combination of compression-vacuum-type hammer mechanism and rotary mechanism. The reciprocating motion is transmitted by the roller bearing.

The diagram shows how to disassemble the barrel pos.15 (marked with a reddish arrow), beater and striker composition (marked with a blue arrow). Green arrow indicates the details of the mode switch.

The intermediate shaft consists of the shaft pos.47 and its mounted parts. Disassembled simply, according to the attached diagram, does not require any special knowledge.