Is it possible to saw tiles with a jigsaw

How to cut ceramic tiles with a jigsaw

Ceramic tiles are one of the most difficult building materials, as they combine hardness and fragility. It is necessary to work with it with a special blade, which allows you to get an even cut without chips.

Cut ceramic tiles with a jigsaw only evenly. Edging and curly cutting will not give a good result, as the tile will begin to break.

You need to cut the tiles with a jigsaw very carefully. This is done in one smooth movement. Stops should not be allowed. The pendulum movement of the canvas is turned off.

How to cut metal with a jigsaw

An electric jigsaw can serve as an alternative to an angle grinder in cases where you need to work with profiles, pipes, sheet metal. It is this material that gives the highest load on tools and files. Be prepared to take breaks from work and frequently change consumables.

The maximum metal thickness that household and semi-professional jigsaws can work with is 10 mm.

Before cutting metal with a jigsaw, you need to select special saw blades.

Set of metal saws Dnipro-M T 118 A are made of solid steel and are perfect for straight cuts. Use the pendulum function to reduce wear and prevent melting of the working part.

How to make a curved cut

A curved cut, like a straight cut, begins with a markup. You should definitely connect a vacuum cleaner or turn on the purge to remove debris from the markings.

Sawing with a jigsaw of figured products is carried out without a pendulum motion. A narrow blade with fine teeth is used, which makes it easy to change the direction of travel.

What is a jigsaw for?

Most often, an electric jigsaw is used to make wood products. This tool has found wide application in the furniture industry, where elements and parts of various shapes are made with its help.

If, when working with an electric jigsaw, you choose the right consumable and cutting mode, then you can:

- make straight and curved cuts;

- sawing circles without damaging the sheet;

- cut thin metal;

- to make products from wood up to 10 cm thick (the Dnipro-M LE-110R electric jigsaw model cuts 11 cm bars);

- cut plastic;

- sawing ceramic and porcelain tiles.

Whether a power tool can work with a particular material will depend on the power and type of the tool (household, semi-professional, professional). Not all electric jigsaws have additional functions, such as an angled cut or the ability to connect additional elements and tools. To find the right tool, read the article “How to choose a jigsaw”.

In this case, you also need to select the right saw blades. The pitch of the teeth, their length, material are taken into account.

How to cut sheet materials straight

The main purpose of a jigsaw is to get an even cut. The easiest way to make it.

The first step is to make the markup, which will serve as a guide when working. If the edge of the workpiece is straight and you just need to make it smaller, use a rip fence. It is a T-shaped device that attaches to the sole of an electric jigsaw.

To reduce the wear of the file, the pendulum stroke is switched on. Move the jigsaw slowly, without jerking. Moving too fast or jerking will have a detrimental effect on the mowing line of the cut and additional processing (e.g. sanding) will be required.

7 uses of the jigsaw. instruction from Dnipro-M

The electric jigsaw is widely used for working with sheet materials. It will come in handy in repairs, carpentry or furniture workshop. With a jigsaw, you can cut soft wood, plastic, drywall, as well as complex materials such as ceramic tiles and metal. Depending on the hardness and brittleness of the material, as well as the type of cut you want to get, the technique of working with a jigsaw will have some peculiarities. In this article, we will talk about how to cut the most popular building materials.

How to cut thin and thick wood

The electric jigsaw was created for working with wood, and therefore it is not at all strange that most of the work is carried out with this material. over, you can cut with equal success:

- solid wood;

- lumber;

- pressed wood.

Different webs are used depending on the thickness of the material. over, they will differ not only in length, but in the frequency and size of the teeth. The thinner the material, the smaller and denser the teeth should be.

To obtain a clean cut on thick wood, use saws with progressive teeth, which are gradually reduced.

How to cut circles

Cutting a circle in a workpiece is one of the most difficult tasks for a beginner. But there is nothing incredible in it, since you can quickly learn how to work correctly with a jigsaw.

- Disable the pendulum stroke.

- Make the markup.

- Drill a hole for the saw blade.

- Install the compass and get to work.

You can make a compass with your own hands. To do this, you need a flat board and a self-tapping screw. The jigsaw is securely fixed on the bar. Next, the required segment is measured (equal to the radius of the circle), and a self-tapping screw is screwed into the center, which will serve as the axis of rotation.

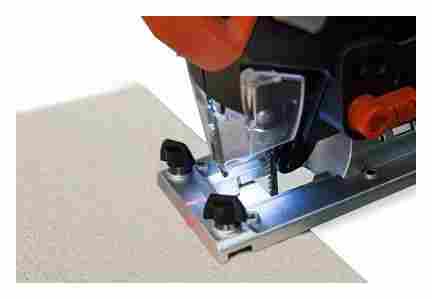

Features of sawing tiles with a jigsaw

The workplace should be stable with as flat a surface as possible, and most of the tiles were pressed tightly against it. The smallest section should be located on the weight, even if it is exactly what is needed for laying. To reduce vibrations, it is better to fix the tile with a pair of three clamps with rubberized clamps. To avoid scratches, a piece of cardboard or plastic can be glued to the metal base of the jigsaw, on double-sided tape.

When a special saw blade is prepared, and the tile is sufficiently moistened, you can safely start processing it. Cutting tiles with a jigsaw has certain features, and is somewhat different from the usual wood, metal, plastic and other elastic materials. First of all, do not rush and try to speed up the slow cutting process by pressing on the jigsaw or increasing its speed, which should range from minimum to medium values. This approach will lead to the formation of serious chips, and strong pressing of the working tool can even crack the tile. Little pleasant, wasting valuable material, time and resource of the saw blade.

To reduce the likelihood of scrap, it is recommended to cut the tiles at minimum speed, while producing medium pressure sufficient to keep the running jigsaw on the line and guide it forward.

Tile preparation

The hard, and at the same time fragile structure of the tile, like glass, is prone to splitting and requires high precision and accuracy in processing. Acceleration of the stroke rate or increased pressure can easily deform the product, ruining the material and negating the effort expended. To cut the tiles with a jigsaw was the most convenient, it must be soaked for a couple of hours in ordinary water at room temperature.

Saw blade selection

In terms of its structure, the canvas on the tile departs from the familiar to us, the classical understanding of the file. It has no teeth, and the role of the cutting element is played by hard abrasive or diamond spraying. The quality and speed of cutting with such a nozzle depends on its grain size. The higher this indicator, the slower the cut, but the higher the quality of the cutting line. A low grit value, on the other hand, increases the cutting speed, but creates more chips in the material. Coarseness is measured in micrometers (microns) and is usually indicated on the packaging of the web.

How to cut tiles with a jigsaw: evenly and without chips

Sawing tiles with a hand jigsaw

A nimble jigsaw with relatively massive saw blades does not always succeed in performing particularly delicate work or cutting with an inner contour. When it is necessary to make a neat, jewelry cut with a complex pattern, a reliable hand tool comes to the rescue. Of course, for these purposes, you can use a jigsaw machine that works with the same thin files, but this equipment is quite expensive and it is impractical to purchase it for a small amount of work.

As you might guess, ordinary saws for wood and metal for a hand-held jigsaw will not be able to cut tiles. To perform such an operation, you will need a special tungsten carbide wire or a diamond-coated file.

The process of cutting the inflow with a hand jigsaw is completely identical to its electric counterpart, except that it takes several times more time and effort. The tile is soaked for a couple of hours, after which it is fixed on a flat surface with clamps and during cutting, it is periodically moistened with water. Once again, we repeat that the speed of manual work is very slow, and it will take a lot of time even for a small figure. Before work, you should understand this and be patient in advance. To understand how to cut tiles with a jigsaw and estimate the pace of work, we recommend watching the following video.

How to cut a chipboard with a jigsaw without chips?

Laminated chipboard is one of the most widespread materials used in the independent manufacture of furniture. You can talk about its advantages and disadvantages for a long time. But it is much more important to learn how to cut chipboard with a jigsaw without chips.

Features and recommendations

Experts and connoisseurs advise doing this kind of work with electric jigsaws just because an ordinary hand hacksaw is too rough. It does not allow you to cut the material straight enough. The correct sequence of steps is as follows:

preparation of tools (ruler, jigsaw, measuring tape, awl or other sharp device for drawing on chipboard);

addition of these tools (if necessary) with a square for laying right angles;

measuring the desired part (with a reserve of 0.2 cm so that you can fit);

drawing a line along the ruler;

actually, the cut along the laid mowing line;

completion of the saw cut with sandpaper;

with very poor quality of the end. rubbing it with a fine, similar in tonality to chipboard.

What else do you need to know?

When it is planned to saw off everything without chips on one side, it is permissible to use saws with both upper and lower teeth. Most craftsmen prefer small, straight-toothed files. Such devices chip less material, but at the same time they work pretty well. After the saw cut, it is best to process the ends with emery stretched over even bars. If there is no ready-made crayon of a suitable color, you can mix different crayons, like paints in the artist’s palette, and get a new color.

In order to cut without errors and, moreover, quickly, you must always take into account the brand markings. There is no universally binding standard for designations yet, but almost all companies strictly follow the classification developed by Bosch specialists. Or at least indicate it along with their own abbreviations and terms. For cutting wood and wood-based products, CV files (sometimes referred to as HCS) are well suited.

For processing laminated panels, Hardwood saws are intended (they are also useful, we note, when processing hardwood).

Some inscriptions indicate in which mode the tool works optimally:

basic. a simple blade that allows you to make a high quality clean cut;

speed. a device whose teeth are set apart (this allows you to cut faster);

clean. a canvas that has not been diluted (usually gives the cleanest cut).

If the workpiece is relatively thick, preferably a saw blade with large incisors that have not been set, then there will be minimal deviation from the vertical. The longitudinal (in relation to the fibers) cut is most often made with helical saws. For a transverse, a straight blade is better. When you plan to make a blank for furniture, it is advisable to choose a less productive, but more accurate tool. Since most of the saws now produced cut the material when retracted, the workpiece will need to be processed from the inside out.

Curvilinear cutting of ceramic tiles, or how to saw it with a jigsaw

In the process of laying ceramic tiles, it is often necessary to make a through hole of a non-standard shape. Ceramics is a tough, yet brittle material that can be cut with a regular jigsaw, but you cannot use ordinary saws for wood or metal. After reading the article, you can learn how to cut ceramics with a jigsaw, and which blades to use.

Cloths for ceramic tiles and porcelain stoneware

Porcelain stoneware is a derivative of ceramic tiles, but it uses higher temperatures and pressures. For this reason, porcelain stoneware is much denser and cannot be cut with carbide saws intended for ceramics. Conversely, diamond blades on porcelain stoneware can be used for common material.

How to Cut Ceramic Tile with a Jig Saw

A feature of a jigsaw file for such materials is spraying. The harder the spray, the better the cut quality and the longer the cutting part will last. The spraying has such a parameter as graininess. The quality of the edges and the cutting speed directly depend on the grit value. The higher the indicator, the higher the quality of the edges and the lower the speed of work.

For straight cutting of ceramics, it is better to use wide blades with carbide taps, for curved. blades with a minimum width. This rule applies to any material that can be cut with an electric jigsaw.

Is it possible to cut ceramic tiles with a jigsaw?

Ordinary users who are not professionally involved in laying tile material often ask questions about whether it can be cut with a conventional electric jigsaw. The question is relevant, since every skilled owner has this tool.

It is possible to work with ceramics, but for this you need to use special attachments and accessories that allow you to do this as comfortably and efficiently as possible.

Work procedure

Before proceeding with the cut of porcelain stoneware or ceramic tiles, a saw blade must be installed in the jigsaw.

Then the tile must be soaked for 5-10 minutes.

At the next stage, the mowing line of the cut is marked, after which the material is securely fixed on a special stand made of bars. At home, you can use a regular kitchen table to fix it. It is important to fix in such a way that the cutting site is suspended.

If a block stand is used for fastening, then its thickness should be greater than the length of the saw blade. This is necessary so that during operation the file does not stick into the base on which the stand is installed.

Basic principles of work

The principle of working with porcelain stoneware is slightly different from how metal or wood is sawn. It is important to consider the following points.

- Tiled ceramics are easily scratched, therefore, when sawing, a plastic plate must be installed on the sole of the tool.

- Before starting work, it is better to soak the tiles in water. This will make the material more pliable and reduce the amount of dust generated during the process.

- During the cut, the material must be securely fixed using several clamps with rubber pads.

- When working with all types of ceramic tiles, the jigsaw pendulum function must be disabled. During the execution of a straight cut, the switch can be set to the minimum position.

- When making a closed cut, the material must be drilled with a ceramic drill, the diameter of which is slightly larger than the width of the blade used for cutting.

Using an electric jigsaw to cut porcelain stoneware is not the best and fastest way. Ceramic blades are necessary when curved cuts need to be made. When choosing, the main requirement is the presence of a hard-alloy coating.

Figured cut

It is problematic to cut small radii with a wide blade. Cutting saws have a beveled back side, which facilitates turning, without chipping, they pass roundings and differ in appearance:

- Small (up to 2 mm) tooth.

- Narrow working part. up to 4 mm.

- Small length. up to 40 mm.

PVC pipes and window sills are sawn with saw blades for wood or metal with a large tooth. Fine-toothed files are also suitable, but you will have to cut at a minimum speed, otherwise the sawdust will soften and clog the blade. it will no longer be sawing, but a cut with heated metal.

For thin plastics and plexiglass, a metal file with small teeth is suitable. For a thick one, you can take a canvas on a tree, turn off the pendulum mechanism and cut at low speeds. Figured cutting of polymer sheets is carried out with a narrow saw in wood.

Cloths for ceramic tiles and porcelain stoneware

Porcelain stoneware is a derivative of ceramic tiles, but it uses higher temperatures and pressures. For this reason, porcelain stoneware is much denser and cannot be cut with carbide saws intended for ceramics. Conversely, diamond blades on porcelain stoneware can be used for common material.

A feature of a jigsaw file for such materials is spraying. The harder the spray, the better the cut quality and the longer the cutting part will last. The spraying has such a parameter as graininess. The quality of the edges and the cutting speed directly depend on the grit value. The higher the indicator, the higher the quality of the edges and the lower the speed of work.

Important:

the packaging of saw blades indicates the grain size, blade width, material from which it is made. If there is no information on the packaging, except for the model designation, then the characteristics can be found on the manufacturer’s website.

For straight cutting of ceramics, it is better to use wide blades with carbide taps, for curved. blades with a minimum width. This rule applies to any material that can be cut with an electric jigsaw.

Important: the packaging of the saw blades indicates the grain size, the width of the blade, the material from which it is made. If there is no information on the packaging, except for the model designation, then the characteristics can be found on the manufacturer’s website.

We read the marking

There is no single standard for the alphanumeric marking of jigsaw blades, but most manufacturers adhere to the European classification from Bosch or indicate it in addition to their own designations.

Saw blades are made from various grades of steel that affect the purpose of the blades and are indicated by logos:

- CV (HCS). elastic alloy for cutting wood, synthetic and wood-composite products.

- HSS. tough high speed steel for hard materials.

- BM (Bi-Metal). connection of the first two grades of steel, withstands significant loads and is suitable for many operations.

- HM. carbide grade for cutting tiles and building blocks.

The purpose of the canvas is also indicated by the marks:

- Wood. soft lumber, fiber boards.

- Hardwood. solid wood, laminated panels.

- Inox. stainless steel.

- Alu. aluminum.

- Metal. sheet metal, profile and pipes.

- Plaster, fiber. fiberglass.

- Soft-material. rubber, polystyrene, carpets.

- Acrylic. plexiglass, polycarbonate.

Sometimes there is an inscription on the file that specifies the type of work:

- basic. a standard blade for a high-quality cut;

- speed. a file with set teeth for fast cutting;

- clean. blade without setting for a clean cut;

- progressor. a file with different teeth for cutting various materials;

- flexible. flexible blade for cutting metal;

- special. for cutting ceramics, plastics and other special jobs.

We cut polymer materials

Cutting wood and everything that is made from it is the main purpose of a jigsaw. Therefore, a wider range of saw blades is produced specifically for wood and is subdivided according to the type of work.

We work with metal

For cutting galvanized profiles and tin products, wave-cut files are used, similar in profile to hacksaw blades. They differ in small (up to 1 mm) teeth, deflected not through one, but in groups of 3-5 pieces.

During constant work, three canvases are taken: for steel, aluminum and for non-ferrous alloys. If you don’t have to cut metal often, then one file is enough for steel, which is also suitable for ebonite and PCB.

In general, a jigsaw is not very suitable for cutting metal: the tool is heavily loaded, and the process is slow. Rather, this is an extreme method, justified only occasionally, for example, when cutting sandwich panels with bimetallic files with small incisors at the edges and large ones in the middle.

Using an electric jigsaw to cut porcelain stoneware is not the best and fastest way. Ceramic blades are necessary when curved cuts need to be made. When choosing, the main requirement is the presence of a hard-alloy coating.

Using an electric jigsaw to cut porcelain stoneware is not the best and fastest way. Ceramic blades are necessary when curved cuts need to be made. When choosing, the main requirement is the presence of a hard-alloy coating.

Clean cut

An operation such as trimming a furniture board or parquet board. requires a smooth and precise cut. Such tasks are performed with lower productivity, but better, using blades for a clean cut, having:

- Teeth less than 3 mm.

- Minor divorce.

Most of the saws are cut by retraction, so the material is placed backwards. To mark and cut from the face, you need a reverse tooth blade. It is not very convenient for them to work. in addition to maintaining the direction of the cut, they have to overcome the pushing force of the tool.

Advice. Cutting the panels laminated on both sides almost without chips allows a specialized saw with two rows of teeth.

Jigsaw tile

How to cut straight with a jigsaw, or why a jigsaw cuts crooked?

Try to answer your question yourself. If you have already tried to saw, and this is probably exactly the case, you have seen how the blade can abruptly go somewhere to the side, making an incision in the wrong place.

After that, sadness will pierce you through and through: everything will have to be done again, because what you have done is a complete marriage. But don’t be discouraged. We will teach you how to cut straight.

To begin with, as written in the instructions for the tool, you should firmly fasten the saw blade between the jigsaw ears.

The file, in the end, should be stretched between one and the second arcs. First insert the file and secure it with one tab, so that the other end fits completely under the second tab (so that the edge is not too small).

Next, you should slightly bend the arcs of the jigsaw so that the saw is at maximum tension during operation. It is very important not to overdo it, otherwise you can “burst” the file before starting work.

Immediately have to change, and this is not comme il faut. In general, we squeeze the arcs towards each other, then we twist the desired eyelet and voila! The jigsaw is ready for use.

Before starting work, check how the file is standing, try pulling it with your finger. If everything is “iron” and tightly, then everything is done correctly.

Then proceed to sawing. Smooth movements, do not rush here, move your hand up and down, up and down.

Yes, yes, it is very similar, but one interesting activity, but still you need to concentrate at this moment. Your eyes should follow the tilt of the blade. It is the slope that affects the line cut.

It is worth tilting a little, and, behold, the line went to the side. Disorder. Right? Right.

In general, if you need to cut something straight, you should draw a line with a pencil, as they did at school.

Follow this mowing line and go. Nearby, just in case, so as not to leave the mowing line, put a ruler. It is desirable that it be iron, otherwise you can spoil the necessary thing.

How to saw with a hand jigsaw?

The question seems to be an ordinary one, but on the other hand, there are a couple of difficult moments.

The first thing to remember, if you still decide to go through torture and choose a file of a couple of millimeters, get ready for nine circles.

over, if Dante’s were all different, then your circles will be the closer to the ninth, the hotter. In order not to explode, like Vesuvius, and not to cover Pompeii with lava, buy about twenty of them. It will be needed.

We have plywood! We have a jigsaw! Nothing is easier than picking up and sawing.

All that remains to be done is sawing. As it was said in one famous film “Saw, Shura, Saw.”. And really, saw it, my dears!

It won’t take long to cut a board in half. However, in order to cut something, some pattern, or, for example, grooves, you will have to spend much more time.

The most annoying thing in this case is that a file of a different size will not work. In order to precisely cut, a different size is bad. With this, you can at least make bends and turns normally.

In order to make, for example, a smooth angle, you need to slowly drive the jigsaw up and down, turning the saw blade full face in the direction you need.

In this case, you need to reduce all the pressure, and it is easy to cut, in one place. Otherwise, you risk getting the cut in the wrong place. As a consequence, spoil the work.

On business. you should, again, stock up on a mountain of patience. You will need more than one day to cut something with this nail file. Better to take another, or, in order not to change the files one by one, buy two jigsaws. It will be much more convenient for you.

How to cut chipboard with a jigsaw?

If you are going to figure out how to cut chipboard with a jigsaw, the answer is one. tedious.

In addition, you will definitely have to choose a different size file. In general, it doesn’t matter what size the file is. What is important is the size of its teeth. The larger the teeth, the faster you will cut.

However, there is a significant risk of chips and chips that you can “cut” in the process, which, of course, spoil the material. The smaller the teeth, the longer you will have to cut, but the work will ultimately be better and more accurate.

In general, everything depends on the person. You can make a masterpiece with wide teeth, you can also do with small ones what they wash down the toilet.

How to cut straight with a jigsaw

How to saw with a jigsaw

Drank, cut, thin. carving. all this is an integral process of creating an interior and decorating.

The method is used for both external and internal processing.

For a long time this craft helped our ancestors in construction, and the results of the work adorned houses, farmsteads, estates, household items.

Nowadays, the art of “sawing” is still relevant, and, as it seems to us, it will always be relevant.

But then came the unforgettable 21st century. In connection with the relentless technical progress, giving birth to more and more devices for processing, sawing and sawing has become a little more convenient and easier.

However, the “most unique” instrument of all time is on the agenda! An old-timer, one might say. Ladies and gentlemen. welcome. His Majesty Jigsaw! Applause!

But before you pick up this royal, let’s figure out how to choose the right jigsaw.

And so, the tool we need is the most ordinary one. Simplest. It is inexpensive.

The most hemorrhoids. choose the necessary files for the jigsaw. At the moment, the market is crammed up to the throat with old samples of files, still Soviet ones, only a few millimeters thick.

If you are going to cut with just such a contraption, in addition to saws, you will have to stock up on unbearable patience, for this is truly hellish work.

Perhaps the most offensive in this matter is that as soon as this two or three millimeter paper warms up well from friction, it has every chance of breaking to hell when cutting some plywood, and you will immediately have to put a new one.

Basically, such a file is enough for several hours of work, and then, if you handle it carefully.

If not carefully, for half an hour, maximum. In addition, it should be added that such files are suitable exclusively for plywood. For such plywood, from which, for example, guitars are made.

For chipboard, metal and other materials, it is better to take a larger file.

In general, if you just need to cut plywood into pieces, squares or rectangles, take a file of five or ten millimeters.

No turns, just one flat road.

How to cut tiles with a jigsaw?

Another milestone in urban planning! … or not? Oh yes! We’re talking about sawing. Again: “Another milestone in jigsaw sawing!” In general, to hell. Let’s get to the point.

In this case, the cutting time increases many times. If you have chosen a hand jigsaw for cutting tiles, it is better to shoot yourself.

No, really, shoot yourself! Do you have any idea how long it takes? If you need to cut one piece of tile, it’s okay, but you probably won’t do this stuff.

Therefore, in general, we change the trajectory. A manual jigsaw is good, but an electric one? It is a versatile tool that allows you to work with a wide range of materials.

This is plywood, fiberboard, and particleboard. There are tiles, ceramics, metal, and a number of other materials, including even stones! But the gist remains the gist. you need to cut the tiles. If so, you will need an electric jigsaw.

In working with any tool, there are secrets and nuances that will help both an intrigued beginner and an experienced specialist.

As a result. an excellent result, there is no need for additional work on sanding and leveling the sawn-off surface. The charm!

It’s simple. The network has a ton of advice from experienced people. All answers are different, all are somewhat similar. The easiest and most obvious way is to entrust the work to professionals, of course.

However, the masters are the masters that they will do everything themselves, but you also want to know how to use this tool yourself.

It is vital to fix the material well on a workbench or saw table.

Experts recommend opting for a saw table, as it allows you to achieve better fixation and has a larger surface size.

Do not forget, however, that the material must be fixed face down, since the tool stroke is directed upwards, which accordingly provides a smoother and more accurate cut on the underside.

During cutting, it is necessary to do so so that the material does not fidget on the table. Cuts can turn out to be crooked and clumsy, you can spoil the material.

Some experts recommend to fix not the material, but the tool itself to obtain a smoother cut, while slowly feeding the material in the direction of the saw blade.

This technique is especially good for curly details. But here everything is simpler: tiles. We take it, put it on the surface and slowly bring it to the fixed instrument. One, two, and you’re done! Nothing complicated.

Surely the first attempts will not do without hack, but everything comes with experience.

In general, saw to your health! Good luck and all the best.