Is it possible to undercut eco veneer doors

Veneered or ecoveneered doors: which is better??

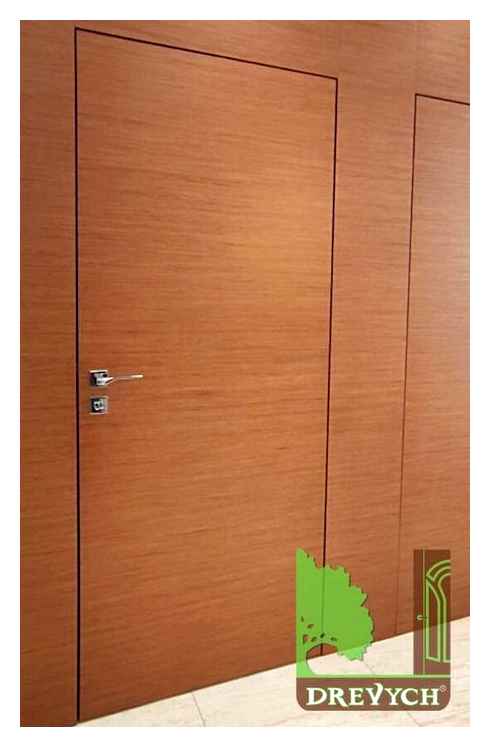

Buying an interior door of natural or artificial veneer, each of us thinks about its aesthetic and practical function. After all, the design should not only conveniently delimit the space and effectively separate the main working zones, but also fit harmoniously into the interior. But an important factor in the right choice of interior doors are materials and finishes, the quality of which determines whether the facade will not warp or fade, reliably protects against noise and withstand the action of moisture. To varying degrees, the comfort of future operation will provide veneer doors and eco veneer, which is better to buy after familiarizing yourself with the nuances of manufacturing, advantages and disadvantages of each type.

Peculiarities of veneer and eco veneer doors manufacturing

The main difference between the door structures of veneer and eco veneer is the use of different facing materials. In the first case, in the manufacture of doors natural wood is used, and in the second artificially created polymer (a type of plastic). As the basis for laying the finishing coating is a high-strength timber, fiberboard, as well as solid coniferous wood. In high-end veneered models, such a blade can be made in the form of a solid array, t.е. billet, joined of several parts. For the budget counterparts of eco veneer a lighter, budget version is made of two sheets, which are internally connected along the contour with slats, in the middle they have stiffening ribs, and the cavities are filled with corrugated cardboard.

As the top layer, the veneer or eco-veneer is applied to the door leaf facade. If thin sheets of natural veneer material are to be used, hot-pressing technology is used. After strengthening on the basis of veneer strips, a moisture-proof composition and varnish is applied to the surface, which ensures the completeness of the appearance and protects the product from mechanical damages. The eco-veneer is fastened after the film is heated and applied in a vacuum. The elastic material is characterized by excellent adhesion to each projection, tightly adhering to the surface.

Veneer products are widely used not only in the manufacture of interior doors, but also in the finishing of furniture, wall partitions, etc.д. The use of veneer and ecoveneer makes the products much lighter and cheaper, so the technology of solid wood imitation is successfully introduced in production. An important advantage of manufacturing veneered and ecoveneered doors is not only saving resources, but also preserving forests from logging!

Natural veneer and eco veneer in whitened oak

Veneer: types, distinctive features and advantages

In order to imitate solid, expensive natural wood, interior doors are veneered with natural veneer, which is the thinnest (up to 3 mm) sheets of different species of trees. Depending on the raw material, the veneer has different shades. It is a natural, modern finishing material, which fully repeats the unique texture inherent in a particular kind of wood. Lacquer treatment can slightly tint the surface.

The following wood species are used in the production of veneer:

Oak: the resulting cladding material is particularly tough, with great texture and a variety of brown shades.

Walnut: walnut veneer has a beautiful textured pattern, a light gray shade and a high price.

Pine: A great budget option that can be used

Maple: a difficult material to work with, almost white in color, but easily tinted with artificial coloring.

Wenge: an expensive ornamental wood with a variety of tones, from creamy white in the sapwood to dark brown in the heartwood.

The thinnest, securely glued slats are made on special equipment by planing and pressing wood chips. Depending on the intended use the veneer thickness and cutting method is chosen (semiradial, radial, tangential, etc.).). In terms of appearance, the material can be natural, i.e.е. unpainted with natural texture, and colored, the shade of which has been changed by dyes or coatings. There are strong and durable cross-linked veneers, represented by strips of wood glued along the edges, as well as reconstructed veneers, which are made from tropical wood species. According to the method of manufacture veneered material is:

Planed: a thin strip is cut by rotating a steamed log parallel to the log fibers;

Planed: after dividing the log into bars a thin strip is cut across the fibers;

Sawn: a method of cutting coniferous wood into planks;

Fine-Line: realistic reproduction of wood grain through a combination of staining, gluing, pressing and sawing.

Natural veneer is elegant and graceful, fitting perfectly into any interior, being practical when used correctly. Gentle care involving the cleaning with a soft damp cloth without the use of aggressive cleansers guarantees a minimum life span of twenty years without the risk of desiccation, blistering or discoloration. Veneered doors cost much cheaper than solid veneered constructions, but they are also notable for their high performance parameters (durability, noise insulation properties, air permeability and ecological compatibility). A door of this type, which is a simple construction with a spruce or pine base and an outer skin of a thin wooden layer of oak, ash or other wood species, has optimum impact strength and resistance to external influences.

What is eco veneer?

Concerned for comfort and ecological compatibility of their homes, more and more homeowners prefer practical interior doors with eco veneer linings. It is a new progressive material, created on the basis of natural wood fibers with addition of special binding substances. The multilayer material is difficult to distinguish from natural veneer by sight, especially in elite collections. The successful external imitation of natural wood is as close as possible to the natural pattern, not only in pattern, but also in texture relief. The structure of expensive eco veneer has a 3D effect. Looking at doors with this finish it is hard to believe that in front of you is a polypropylene film!

Eco Veneer is an environmentally friendly building material representing the innovative CPL plastic of the new generation. In its composition there are natural wood fibres bound with a small amount of polypropylene and pressed by special technology. Auxiliary substances included in the composition are used to imitate the shade and texture of natural wood. Synthetic material is adapted for long-term use in aggressive environment. The following indicators can be attributed to the advantageous advantages of doors made of eco veneer:

Moderate cost: the price of eco veneer doors is an order of magnitude lower than structures made of solid wood or veneered models.

Long life: with proper use and proper care, manufacturers give a warranty of 10-20 years.

Eco-friendly, hypoallergenic: no chlorine-containing substances, heavy metals, formaldehydes are used in production.

High level of mechanical strength: no cracks, chips, scuffs, dents.

Resistance to chemicals (alcohol, solvents, acids, alkalis, etc.).): high-tech plastic does not react with reagents.

Resistance to atmospheric effects: no burning out, color changing even under direct sunlight.

Moisture-proof, vapor-proof: installation of door constructions is possible in rooms with high humidity

Resistance to temperature fluctuations: appearance of cracks or other damages at sudden temperature falls is excluded;

Incombustibility: plastic has fire-resistant properties (melting point of polypropylene is 180o C).

Eco Veneer is dielectric and absolutely safe for humans and the environment. The material does not require additional care, and application of any detergents is allowed. During usage, the surface has virtually no wear and tear compared to laminated models. Thanks to a huge choice of color solutions, including unusual design extravagances, you can effectively decorate your interior. If you want to change the overall design, the eco veneer surface can easily be painted or applied. Easy care, aesthetic appearance and reasonable price allow to install eco veneer doors not only in living rooms, but also in public institutions.

How to choose between veneer and eco veneer?

When deciding which door is better in eco or veneer, consider the style of the room and the purpose of a particular room, assess available finances. The price of natural material is about twice as high as synthetic plastic, and the difference in cost ranges from 2,000 to 10,000 Cheap interior doors with eco veneer finish to the touch is different from the veneer coating is missing relief, and the surface looks unnatural, a little rough. Admirers of the solid elegance of the natural pattern of valuable wood species will appreciate interior doors of veneer, which are endowed with the energy of nature. The most inexpensive kind of natural veneer is fine-line, which is an order of magnitude cheaper than the peeled and planed veneer material.

Although veneer has excellent aesthetic qualities, it is not very durable, being subjected to damage under strong external impact. With constant rubbing in a certain place or exposure to sunlight can change the original appearance, unlike eco veneer, which is more difficult to spoil. If an eco veneer door requires restoration after serious damage, the king-shell models have the possibility to replace the whole element. Scratches and chips on veneered doors can be sealed with mastic, by picking up a compound, matching the color. There is no other way to restore the coating. If you want to renovate a door that has lost its appeal, the eco-veneer construction can only be washed, and the veneered door leaf can be varnished.

In the production process of polypropylene synthetic components are used, which reduces the quality of air exchange, in contrast to the breathability of the natural coating. But both varieties of door facades are environmentally friendly and hypoallergenic, although veneer has the advantage, because it is a completely natural product, while the eco-veneer is a plastic film, although harmless to health and the environment. Polypropylene plastic is not afraid of temperature and humidity fluctuations, so eco veneer doors are approved for installation in bathrooms and showers or kitchens. And veneered products are not suitable for rooms with high humidity.

Any structure will last more than one year, but polypropylene film is more practical and durable in use. The maximum sound and noise protection is ensured by natural materials. The eco veneered door construction uses a lightweight hollow frame, which reduces sound insulation. When selecting the design of an interior door, stylistics and the overall concept of the room should be taken into account. Veneered products are perfect for installation into classic, loft or country interiors. Models of eco veneer of original colors will look appropriate in modern informal interiors, decorated in the spirit of modern, high-tech, pop art. Choosing between veneer and ecoveneer facade finish, take into account all the pros and cons of the materials, as well as personal preferences and capabilities!

Water dispersion acrylic enamels are best suited for painting interior doors Lacquer for wooden doors is more often used for solid wood constructions. Varnishing, like painting, protects doors from moisture, bright light, and other outside influences. There are transparent and tinted varnishes.

Doors made of veneer can be finished with polyurethane, glyphthalic or water based paints. Do not use nitro paints for veneer. it can get dull spots. The best option for staining veneered doors is with water-based paints.

How to choose doors from eco veneer

Eco Veneer is a collective image. With natural veneer has nothing in common, except a similar name. Although, no, there is still common, but it concerns the practical properties, about which we will speak further.

Marketing name with a fashionable prefix eco introduced to attract the attention of consumers. People create associations with the natural material, and interest is the first step to purchase. Another thing is that this move is quite justified, because eco veneer really has something to show.

Put some 646 thinner on a cotton swab and wipe the scratch with a very light touch. The solvent will slightly corrode the plastic, so keep a damp cloth handy to quickly remove acetone residue from the surface at the right time.

Vinegar and olive oil will disguise minor scratches and imperfections. Mix the components in proportions of 1 to 3 and rub the resulting mixture on the scratches on the door or furniture. Then wipe the surface dry with a clean cloth; Walnut quickly fills the scratch grooves and leaves no residue.

If you have a hollow door, you can’t cut too much off the bottom. These doors are just a wooden frame with two fiberboards attached to it, and you can’t cut them more than 1 cm; if you have a hard fiberboard or laminated board door, you can remove a little more. There are two types of interior doors: a panel (smooth) door and a slab door. The panel door is fully recessed into the door frame and mounted on hinges. Overlapped doors are partially recessed into the door frame and their edge is on the outside of the door frame. Doors of this type are installed on cylindrical hinges, which allow lifting the door by removing it from the door frame.

Eco veneer features

The coating is produced by means of vacuum technology, which makes the product long-lived and wear-resistant. Doors made of eco veneer are light, not afraid of temperature changes, mechanical damages, hygroscopic. They are attractive for long time: they do not grow dim, do not burn out under sun rays, they do not get scuffed and the surface does not become deformed.

They are indispensable for use in bathrooms and premises with high humidity, unlike wooden doors, which do not tolerate humidity and are prone to mildew. Doors made of eco veneer are used in offices, hospitals and children’s institutions, as well as in apartments, as they are safe for the health. An ordinary damp rag and available detergents will solve all pavement maintenance problems without special recommendations or restrictions.

Beautiful design, a variety of colors and textures make them attractive to the buyer. Affordable price and versatility (eco veneer is cheaper than natural veneer), ensure their competitiveness in today’s construction market.

Choosing the manufacturer and retailer is a crucial moment. Eco veneer doors have their own design handwriting. Professionals here will give you a comprehensive consultation, and specialists will provide all the necessary services for door installation. You achieve the necessary balance of price and quality.

Doors

For interior doors the eco veneer is the best substitute for heavier and more expensive materials. Wide choice of door leaf, characterized by high durability and excellent aesthetic qualities, allows choosing the best option for any modern interior. Looks like eco veneer interior doors are exactly the same as natural wood of expensive species. For example, visually it is difficult to distinguish it from rosewood, cherry or oak. Eco veneer is distinguished from wood only by the feel, but in some parameters it is even more reliable.

What is eco veneer

Lovers of everything natural, including doors, have the opportunity to choose the best color for the most sophisticated interior style. With new technologies the structure of eco veneer door leaf gives an optical effect of volume, which has advantages not only over artificial coatings. In construction supermarkets and online stores, laminated wood veneer door panels are quite a common commodity, but not many people are familiar with the name yet.

This material was invented recently thanks to modern technology. Eco Veneer is classified as a new generation material CPL, i.e. connoisseur’s laminate, a high-technology multilayer cloth on the basis of wood fibers and synthetic resins. The process of receiving this eco-material is also interesting, as it is subjected to long pressing for strength.

The eco veneer production uses continuous presses at high temperature under conditions that are controlled for all parameters. High pressure and vacuum treatment are used to produce particularly tough eco-materials. Pressing the billet into the module gradually increasing the pressure so that all gaseous particles are completely removed from all layers of the material and the material’s integrity is thereby increased.

The natural wood fibers are carefully dyed individually in the workshop, glued and then vacuum-pressed. New staining technology eliminates unexpected color variations in one batch, but reproduces any variation of wood grain and gives products of the right shade. At the output the material acquires a unique surface, something between natural wood and plastic film coating. It is supplied to door manufacturers as a roll, thanks to the use of progressive vacuum technology.

The name ecoveneer is directly associated with environmental friendliness and similarity with natural wood veneer coatings. It differs favorably even among natural materials, moreover, eco veneer is somewhat more economical than laminated wood counterparts. The example of interior doors with eco veneer photo distinctly demonstrates the decorative properties of the material.

Features and advantages of eco veneer

A new material, made by progressive technology, based on colored wood fibers with the addition of binder resins, is now widely used for joinery doors, furniture, etc. Interior doors made of eco veneer not only look very impressive, but also in many other respects have advantages, which are easy to trace by reviews.

- Ecovene is made of natural wood fibers, but the technology of its production gives a more stable form. The door leaf is not afraid of temperature changes, it does not warp from high concentrations of moisture in the bathroom or kitchen.

- By appearance eco veneer fully imitates the texture, hue and pattern of natural wood. Only an experienced carpenter or carpenter can distinguish these doors from their wooden counterparts by sight and touch, most guests will not notice the difference.

- Eco Veneer has a durable laminated finish that resists abrasion and other influences.

- The improved characteristics of eco veneer doors are more durable than wood, and their resistance to mechanical stress has been proven in practice.

- Binding synthetic resins and wood fibers of the material are environmentally friendly materials, thus giving the name eco veneer, doors made of it do not give allergic reactions like some lacquers for wood.

- Such door leaf is slightly lower in cost than other products, but is not inferior to expensive doors in all respects. Natural veneered doors are more expensive, but they are easily damaged by pets, and the eco veneer is the most scratch-resistant.

- Important aesthetic advantage of the material is the possibility to produce high-precision imitation of any rare wood, such as mahogany or wenge. Eco veneer is able to reproduce the play of reddish and chocolate colors of the wood, with 3D effect, like natural-looking interior doors eco veneer wenge.

- The range of colors of the decorative coating made of eco veneer includes alder and walnut, white oak and ash, wenge and beech.

- Eco veneer doors are highly practical and durable, even with frequent use.

- Demanding for veneered doors will surprise you. This material is much cheaper, though visually resembles veneer and solid wood, and surpasses them in hardness.

- Durability of interior doors made of this material has a high-strength coating which protects from all negative influences. These doors will stay in the house for a long time, and their warranty period should be specified when purchasing from managers.

Standard dimensions of eco veneer panels

- In the construction supermarkets and websites there are standard door leaf, height up to 2000 mm, but by special order it is possible to buy interior doors up to 2200 mm.

- The thickness of the door leaf of this material is 44 mm.

- The door width from 600 mm with ecoveneer, and further in the size range of 700, 800 and 900 mm.

- This material is made of coniferous and other types of wood. Interior doors are available with eco veneer glazed leaf and plain, blank leaf with wood texture. There is also a combined leaf: 6-10 mm glass and chipboard panel. Transparent, frosted and decorative glass.

The difference between eco veneer doors and natural veneer

Specialists distinguish separately natural veneer, ecoveneer and reconstructed veneer, i.e. fine-line. Eco Veneer is a natural-based artificial material that complies with European standards, imitating the relief and texture of wood. Natural veneer is a thin layer of valuable wood species.

Under the influence of strikes or falls of heavy objects on the door made of eco veneer products do not crack and do not break. Their hard surface will not chafe, crack or chip as it often happens with ordinary veneer or even laminated veneer panels. Important point: these products are not subject to the damaging effects of direct sunlight, they do not burn out and do not lose their decorative properties.

Interior doors and all attendant elements of the door leaf are veneered from all sides. All parts of the construction are thought out, make up a single set and are connected by dowels and glue. This way of fastening of details guarantees maintenance of leaf geometry during use, as in the case of interior doors eco veneer profil doors.

The eco veneer coating very truly imitates the natural wood texture, and its three-dimensional play of color, like the natural mother-of-pearl of expensive wood, is striking in its plausibility. Stable pattern and color depth of multilayer coating imitates wood in details. In all parameters, doors made of eco veneer look like natural wood, but without natural knots, which is the only visual difference.

Eco Veneer is a rather new material, so it is not known how it will look in a hundred years, but its high strength makes it impossible to doubt the durability of such doors or furniture. In addition, resistance to fading and chipping confirms that even after time the appearance of interior doors, swing or sliding, will remain as beautiful.

Doors with a coating of natural veneer will always be appreciated by consumers, but imitation natural shades of veneered door perfectly replaces it. Ecocoat competes with natural wood and it is not a marketing ploy, although trendy materials often cause exactly this kind of consumer reaction to novelties. It combines the strength of plastic and high decorative properties of solid wood. For example, the eco veneer doors are visually indistinguishable from the veneered door of natural analogue, but they are cheaper. However, a person who works with wood can tell the difference between ecoveneer and natural wood veneer from a close distance, but it will retain its original appearance for decades without needing repair for many years.

What do you pay attention to when buying an interior door?

The design of an interior door must be reliable and convenient in performing its basic functions. Pay attention to its latches and locks some latches and open from the inside of the door or only from the outside.

Give priority to natural and environmentally friendly materials, harmless to health. Clarify from the manager the class of fire safety of the goods you are looking at, as well as the safety of the glass. For children’s rooms, it is better to refrain from such an insertion.

Aesthetic qualities of the door are not less important in the first place, look at the overall appearance and quality of the construction. The color is matched to the overall interior.

Carefully examine all surfaces, there must not be any scratches, which can be hidden by the price tag or packaging. The entire leaf should be smooth, clean and homogeneous, without overlaps or incomprehensible inclusions, there should only be a spectacular wood structure.

Doors of dubious quality are often additionally toned or varnished to hide a dirty tone. With an additional layer tends to hide the defect, but the structure of the natural wood will also be partially hidden.

Check the door not only when choosing a door but when giving it out so you will not find not eco veneer door but a dubious imitation of a cheap laminate when installing it.

Purchase doors only with a perfectly smooth surface that is pleasant and smooth on contact. You can scrape a little with your fingernail from the face cheap materials and coatings will give some mark or dent from your fingernail.

The foma of the product is not less important flawless rectangle, exactly fit in the door frame, where the difference between the opposite ends should not exceed 1 mm, all corners exactly 90.

When buying clarify you need only the door leaf or the entire box on the doorway. It is equally important to check all connections, hinges, locks, hinges and decorative inserts. Do not pay attention to intrusive advice of the store advisor, who is interested in selling unsaleable or defective goods. The door should not overlap or have even the slightest hint of a gap or loose fit. Quality doors should not cause the slightest doubt on all these requirements.

When placing an order for the purchase of eco veneer door or any other door panel it is important to clarify the moment of installation if it is a store installation or self installation as it can influence the total price of the door. It is best to entrust this to professionals, taking into account the peculiarities of the material.

What is important to consider when installing an interior eco veneer door

Before installing any door, it is important to eliminate all possible causes of misalignment level the walls and soffits and floors, especially at the threshold. After dismantling the old door correct the doorway and strengthen the rickety structure with a wooden bar to avoid warping or loosening.

In the production of door leafs all parts of the bowls are included, and if you buy a separate door leaf, you can also use a ready-made door opening. In this case, it is important to make all the holes for fasteners and locks on the solid door leaf, and best with a machine or hand router. Often all of this work can be done right in the back of the store. The edge of the leaf must look neat for reliability of operation, it is important to perform fastening and hanging of the door on the hinges well.

To install the door leaf, prepare all the tools, mounting foam, glue, hardware, level, marker and more. Assembling foam is needed when installing the bow 1 small balloon will not be fully consumed. Once the doorway is framed, you only have to fix the hinges and hang the door leaf. After the work with a drill, the holes are closed with special stoppers in accordance with the color of the leaf. Finally, the lock and handles are installed, and the threshold is decorated. Detailed installation of the interior door is better to see in the video.

Tip: All eco veneer door materials are safe for health. Eco Veneer does not emit any harmful substances into the environment, even when mechanically and thermally influenced. The material is widely used not only for doors, but also for stairs, furniture and other structures, where wood or its imitation is usually used. Doors made of eco veneer look nice in offices and public buildings, in houses of original architecture and in standard-design apartments. Thanks to their ecological compatibility, doors made of this material are recommended for children’s rooms. Care for interior doors made of eco veneer is extremely simple enough to wipe them periodically with a sponge detergent for visible dirt, and a glass cleaner will wash the prints of children’s hands on the inserts. As a rule, reviews of interior doors made of eco veneer on the sites only positive.

Features of eco veneer

Eco veneer is produced with vacuum technology, which makes the product long lasting and wear resistant. Doors made of eco veneer are light, not afraid of temperature drops, mechanical damages, hygroscopic. They are attractive for a long time: they do not grow dim, do not fade in the sunlight, they do not get scuffed, and the surface is not deformed.

They are indispensable for use in bathrooms and rooms with high humidity, unlike wooden doors, which do not tolerate humidity and are subject to mold. Doors made of eco-veneer are used in offices, hospitals and children’s institutions, as well as in apartments, because they are safe for health. An ordinary wet rag and available detergents will solve all problems on care of the covering without special recommendations and restrictions.

Beautiful design, a variety of colors and textures make them attractive to the customer. Reasonable price and versatility (eco veneer is cheaper than the natural veneer), provide their competitiveness in today’s building industry market.

The choice of the manufacturer and seller is a responsible moment. Eco veneer doors have their own design handwriting. Professionals will give you comprehensive advice and specialists will provide all necessary services for door installation. You will achieve the necessary balance of price and quality.

What’s better. doors made of eco veneer, PVC or natural veneer?

Our favorite natural wood is present in the composition of any interior door (except plastic, of course), but in different condition and quantity. The decor, the cost of fittings, the size of the leaf these attributes certainly determine the aesthetics and the final cost, but they are not the main actors in the pricing, but the base and finishing materials. Oak is oak, and no 100% eco veneer clone can encroach on the blue blood of the aristocracy.

Duplicate will never reach the level of the original, and the same rule applies when comparing the natural veneer and wood film. The appearance of the latter is due to a high consumer demand for doors under 7000 in price. But we must give credit to technologists, manufacturers and designers who have tried to bring the quality and visual appeal of inexpensive doors closer to the level of elite models.

If you really want to make a beautiful renovation and not to overpay you have to understand the finishing materials thoroughly. Eco veneer, PVC and natural veneer doors are very expressive, stylish, with glass, stained-glass and capitals, and cost 2-3 times less than doors made of 100% solid wood. There are hundreds of variants, but it is wrong to choose the model according to its beauty only. Each coating has its own characteristics. They set the main properties of the construction, make it more or less water-resistant, durable, practical. On the differences between PVC, ecoveneer and natural veneer doors, as well as the rules of choosing our material.

Fundamental difference between synthetic and natural veneer

It reproduces exactly the beauty of the wood pattern, since it is a natural material, but in production conditions it is impossible to achieve 100% similarity with the solid wood.

The discovery of natural veneer technology has brought a new segment of environmentally friendly, inexpensive doors to the market. On the one hand, the natural beginning has suffered. On the other hand the leafs became stable, because the solid wood door frame is covered with glued laminated fiberboard, and they do not crack, do not undulate, do not deform over time, under the influence of a negative microclimate.

Veneered door with oak veneer

The main characteristics of natural veneer doors:

Allowed humidity in the room of 60%, periodically (as in the bathroom) can be up to 100%;

Recommended operation in the temperature range of 10-30 degrees;

The quality of the veneer depends on the species, the technique and the thickness: a cut of 0.5. 4 mm. Strength and durability of the finished product do not depend so much on the veneer, as on the lacquer coating. often apply varnish:

Nitrocellulose: creates a surface with a beautiful matt texture. Inexpensive costs. Resistant to UV and high temperatures. Allowed for maintenance with mildly aggressive chemicals;

Polyurethane: durability is achieved by applying varnish in several layers. Protects against sun, light bumps, scratches, chemicals in detergents. Odorless;

Two-component polyurethane: in quality, durability is superior to the composition described above.

PVC and eco veneer why they are needed when there is natural veneer

PVC and eco veneer synthetic films of the polymer group. The presence of different base components (polyvinyl chloride and polypropylene) is their main difference from each other. How it is manifested in the practical properties of finished products in no way, there is no difference between them.

Classic door with eco veneer finish

Now we propose to talk about the similarities and differences between the natural material and its artificial counterparts:

How to tell the difference between natural veneer and eco veneer and PVC, because all the websites talk about their striking similarities;

Do the characteristics of materials determine the scope of their application Which are stronger and more durable.

Films for interior door design have been derived with one goal in mind: to meet the growing demand of buyers with relatively low incomes. for doors with such finishing start from 3000. The technologists had to think how to make the coatings as similar as possible to expensive solid wood or veneer products. Textures were elaborated, methods of obtaining relief surface, formulas of new dyes were invented, equipment for polymer wrapping was improved, everything was done to make the result close to the prototype.

We must pay tribute to the manufacturers and designers who have done a lot to improve the quality of design, appearance, strength and resistance to moisture. Still, nature is a unique artist. Everything that is created in the natural environment, then has a high value and is inaccessible to humans. This means that externally veneered doors and doors with film coating will be different:

The pattern is unique, there are practically no repetitions. The annual rings are pronounced. The surface has a clear pattern and texture, like a real tree.

The characteristic feature of the pattern is the presence of small incisions, imitating pores. They are applied by the rollers of the rolling mill. They are the same distance from each other, and a fragment of the pattern repeats itself periodically, in t.ч., in materials created to match different solid wood species

Natural color that is not covered with heavy enamels, but protected with varnishes, paints

It is impossible to recreate an absolutely accurate replica of oak, ash, beech, alder, pine. Artificial veneer loses in the naturalness of the reliefs, the location of the small inclusions

No two models with the same pattern

100% identical coatings are found in the same batch

On practicality, many say that the films are better we do not agree. Varnishes protect the veneer from scratches, moisture, impacts no worse, in addition, the lacquer coating can be renewed.

The prefix eco makes eco veneer closer to veneer or still PVC

It’s incredible what results a well-planned marketing can lead to. It’s good, if marketers’ ideas have a rational basis, and are not just a substitution of concepts. Remember the chocolate? After all, we usually call everything packed in a beautiful wrapper with a foil layer, and it is not important that one product is entirely made of cocoa powder and costs about 200 and the second is a cheap substitute of palm oil. It’s the same for interior doors. Eco-Veneer and natural veneer are only phonetic brothers, but similarities in pronunciation are the only thing that unites the materials. Eco Veneer is a polypropylene film with a decor and wood grain pattern printed on it.

Classic box doors with white matte PVC film cladding

The question remains open as to the differences between PVC and eco veneer (polypropylene). There is no critical disagreement in properties, both materials are moisture-resistant, beautiful, practical, produced in a wide range of colors, textures, but:

Note: The flammability of the material in our case does not make it more toxic. PP decomposes into water with carbon dioxide. Under the influence of high temperatures toxins are still released, but from the combustion of dyes. PP is flammable, which means it is more dangerous in case of fire, but by the volume of toxic emissions is at the same level as PVC

A rich variety of colors and textures. There are films in a natural palette, as well as reds, blues, etc.

Color range is based on natural colors and patterns, because eco veneer is meant to be a cheap substitute for natural veneer

Glossy coatings turn out less bright, the surface gets an orange peel, the reason is the minimal thermoplasticity of PVC

Production of doors with glossy finishes is one of the priority lines of the high-performance industry

Otherwise, there are only similarities between PVC and ecoveneer:

Both materials are used to finish paneled, milled, but mostly king-shell doors;

The leaf is not fully wrapped, each element is wrapped individually;

The flapless method of production provides reliable protection against moisture, soot, and dust.

What are the differences in the inner filling of the door panels?

Any coating is only a part of the cost of the whole door and its properties. It makes a huge difference how and what the undercoating is made of. Reliability, durability and together with it the service life depends on it.

Veneered, ecoveneered and PVC doors are in most cases prefabricated models, very similar in material and construction. Inside each is a frame made of fiberboard and inexpensive pine beam or LVL.

Reliability and durability depends mostly on how it is made. In similar designs everything can be done with high quality or it can be done economically, when the producer lightens the construction in every possible way to decrease the costs (prices).

When you see two doors in the store, veneered and film, and the price is almost 2 times different and the seller says that this is because of the coating is not entirely true. If you start to understand and try which door is heavier, it turns out that the veneered door is denser. The thing is, veneered doors are mostly in a different, more expensive product segment. That’s why it is no longer worth saving on the wood-fibre board. The doors are more solid, with few cavities, and all of the elements are stronger and heavier.

Natural veneered veneered panel doors. Doors of this design are also available with a film finish.

Veneered doors and products under the film come in four varieties:

Smooth panel doors: normal models with plain exterior and interior side without any décor;

Milled panel: also made of two solid panels, but with thick fiberboard, to be able to make a decorative milling on the surface or install flush glass inserts;

Carcase: composed of two side mullions and transversal inserts between them;

Panelized: mostly classical models consisting of 2-3 (number reaches 12) inner inserts and trim.

From the price point of view the most expensive doors are made of natural veneer, and not only because of the high prime cost of the coating. In order to show the prestige of the product not only in the price tag, the highest grade of lumber, the strongest and thickest boards Fibreboard. From inexpensive membrane structures they may differ in strength, heat and noise insulation, since they have not a honeycomb cardboard inside, but a solid beam and fiberboard.

A couple of words on each type of construction:

As brightly display the beauty of wood texture as possible, but have no other decor;

The most inexpensive models in the line of veneers and foils;

Can be matte, glossy, consist of 6-8 pieces of veneer, stacked in different directions of the fibers (in chessboard order);

Modern structures are installed in interiors in the style of minimalism. Concealed installation is preferable on the level with the adjacent walls

Eco-veneered panel door installed in the bathroom. The leaf has a decor in the form of flush glued frosted glass with a pattern and metal moldings on the sides.

Carving is performed on special CNC machines. A huge number of decors can be programmed, thereby expanding the product range;

Filling: honeycomb core inexpensive doors with ecoveneer, PVC. Polymer or solid plates in veneered designs are more expensive;

The fields of application are the same: living quarters, bathrooms, offices.

Veneered milled panel with glass and glazing beads.

Only under the coatings Eco Veneer and PVC natural veneer is not used;

Due to the high plasticity of the films it is possible to wrap each element (crossbars, pillars, lintels) individually;

No edging: the ends are paneled completely without joints, hermetically sealing the wood inside. Therefore, quality film doors are 100% water-resistant;

Decor: everything that would look logically on the background of the modern interior. Metal moldings, glass panels (black, matte, ornamental);

Repairable: a kingpin with a defect can be removed and a new one can be installed. No glue on the details in a king-size door. Instead, use dowels, so it is not difficult to disassemble the product;

The only limit to the scope of installation is the style of the room and the size of the opening.

Double-leaf sliding doors with ecoveneer in wenge.

Ways to achieve a unique design: using glass or blank panels of different sizes, glazing beads, baguettes, wooden plates, patination technique, etc.;

Panels are fastened to the trim with wood glue. Bonding does not allow you to disassemble the design, to change the panels in the case of deformation or defects;

The surface requires additional protection from moisture and negative environment in general. The veneer is covered with varnish and paint;

Fibreboard panels: as veneered doors are in the medium price segment, they are not made with honeycomb core.

Double veneered ash veneer door.

What doors are more durable, practical and exacting in maintenance?

What does the service life of the door depend on?? What guideline manufacturers use when they set warranty time limits for their models?

In general, the service life of the concept is relative, because it depends not only on the quality of materials, their properties and compliance with the technology of assembling, but also on the conditions of use. Subjective factors disregarded, but the most durable are considered to be interior doors:

From materials of the highest grade of well-dried wood, Fiberboard boards of great thickness;

Of the highest quality coatings: thick films not less than 0.4-0.5 mm, natural veneer 1-4 mm;

Used in rooms with a favorable microclimate.

If the risk of deformation is minimal, there are no animals in the house, and optimum humidity and temperature are maintained, the service life of a quality veneered door reaches 15-20 years, doors made of PVC and ecoveneer 10 years.

Doors ekoshnon, which the owners were not afraid to order in the office center.

Basic rules of care for interior doors:

It is desirable to maintain humidity in the room no higher than 80% for panels under the film and 60% for the natural veneer;

PVC is more demanding to the temperature. It is not desirable to install doors on the sunny side under the direct rays of ultraviolet light, as the first changes in the structure of the material can be detected by heating up to 70 degrees. The rule does not apply to polypropylene (eco veneer) and veneer;

Any door should not be installed near heating appliances;

Do not use abrasives or solvent-based chemicals to remove dirt. It is enough to wipe with a soft cloth and special detergents.

A door in natural American walnut veneer with rhinestones on the glass.

The practicality of the door is an indicator of the durability of coatings, materials, fittings. It also depends on the strength and thickness of the foils, veneer: the bigger it is, the less chance of cutting, piercing the leaf. If we consider the frameless way of finishing foil structures, they win in terms of practicality. It is impossible to perform veneering without interrupting at the joints. Since it is the end part of the leaf, which is in contact with the door leaf, that wears out faster, natural models are more vulnerable.

When choosing hardware, pay attention to the beauty of the material and its properties. Inexpensive gold-painted plastic will soon fade. Handles and hinges made of heavy brass, stainless steel bronzed, silvered, gilded or aged look perfect against the expensive solid wood. After finding out the name of the manufacturer of door fittings, don’t be lazy to search the internet for real reviews of the company’s products.

Which are the best to install in the bathroom

Wood is hygroscopic. Accordingly, doors made of natural veneer should absorb moisture like sponges. This would be the case if the manufacturers had not coated the veneer with several layers of lacquer after a thorough sanding of the surface. This coating completely covers the door from moisture, including the joints and the joints in the structure of the leaf.

Corrugated door with a glossy PVC film finish, installed in the bathroom.

PVC and eco veneer doors are another matter. Their resistance to moisture depends on the quality of gluing the final coating, processing edges, the places where the joints of the door leaf parts. Basically, they can be easily put in the bathroom, in the kitchen.

Modern Interior Doors, Eco Veneer from Doors For Builders

Both film and veneered doors leave the upper and lower edge of the door leaf untreated. It is recommended to treat it with lacquer by yourself before installing in damp places.

How long the door will last in the bathroom depends among other things on: whether there is an effective automatic ventilation system in the bathroom (with humidity sensor for example), whether the room has underfloor heating or whether there is a powerful towel warmer.

All advantages and disadvantages of coatings

Synthetics will never be able to surpass the beauty of a natural material, but that’s not all that interests buyers, each coating has its own equally important pros and cons.

Now in more detail: the advantages of veneered doors:

The veneered door surface will blend with solid wood flooring or wood fronts on furniture as well as solid wood doors. But it can also be combined with ordinary laminate, stretching the overall level of the room, making it visually more expensive;

Availability of almost the entire arsenal of décor suitable for solid wood doors (with the exception of brushing);

Availability of doors with all-natural, wooden surface: veneered products can cost 7-10 thousand And to look as good as 20 thousand.;

High strength: the elements of the panel doors are glued to each other;

Small defects can be repaired at home: minor ones with color paste, larger ones just sand this part of the leaf well and varnish it in the same shade.

Veneered doors with large fusion-decorated panes.

If an irreparable defect appears on the panel, the door will have to change, since it is impossible to disassemble and reassemble the construction;

Should be installed with great care in rooms with high humidity.

Reduced vulnerability at the point of closure because of the lack of an edge;

Glossy mocha-colored PVC-finish door.

Small defects on PVC and Ecovene doors cannot be rubbed out: if the film is damaged, either the frame or the whole leaf will have to be replaced. The second point in the short list of disadvantages of film doors is absence of individual charm inherent in natural counterparts, and unsuitability for installation in image-conscious interiors.