It is necessary to cut porcelain tiles at home. Glass cutter or any pointed tool

How to cut porcelain tiles for the floor. How to cut porcelain tiles

Measure part of the tiles that must be cut. Set a fishing line for a trimmer cut with a marker on the front side of the porcelain tile. Install a tile cut on a flat surface, place the tile in it with the front side up.

Press the porcelain border to the line-cut, which is equipped with a tile. Cutting tiles is carried out towards the ruler. in the direction of itself. Break the tile at the end of the cut with a light pressure on one of the halves.

To cut porcelain stoneware into two stripes of different widths, one of which does not exceed three centimeters, outline a fishing line for a cutting trimmer. Then make a cut along the boundary line using roller glass cutter. To break off the strip, use pliers.

You can cut the porcelain tile with a corner grinder if the tile cutter is not available. Tile cutting is carried out in the direction from itself, and the porcelain tile in this case is processed from the inside, that is, the front side down.

As a tool for cutting floor tiles, use a cafeller. an analogue of roller glass cutter installed on the bed. The advantage of this equipment is that it cuts and breaks tiles at the same time.

Only one incision can be made on the tile, so the load on the tool should be uniform so that the visible groove remains on the enamel of the porcelain. The cutting fishing line for the cut should not be closer than 0.8-1 cm from the edge of the tile.

In the process of facing the surface of the floor or walls with ceramic tiles, it is often necessary to circumvent separate sections of engineering communications. If you make a hole in the whole tile, it can crack. Therefore, experts recommend first cut into two parts, and only then prepare profiles for heating or water pipes on each half.

How to cut a 10 mm porcelain border. How to cut porcelain tiles at home correctly

Porcelain stoneware is a wonderful finishing material that combined the best qualities of ceramics and natural stone. The material is stronger than granite, wear and tear and racks to aggressive environments. The tile is produced by the industry varied.

Before proceeding to cutting porcelain tiles, it is better to get acquainted with its views first

- Technical porcelain tiles;

- Glazed;

- Matte;

- Polished;

- Structured or with a pattern of porcelain stoneware;

- Dull;

- Aged;

- Thin. Slim.

From tiles of porcelain tiles, you can cut out any shapes and configurations at home. Often use tiles of porcelain tile in the design of the floor, steps of stairs, porch, walls and basements of the house. Although the material is very solid, it often leaves not neat chips at the cut. Types of cutting tiles of porcelain tiles at home. using an angular grinder with a diamond disk (diamond), a tile, glass cutter, a jigsaw, hydraulic hazard (only industrial cutting on professional equipment).

Corner grinder with a diamond circle is often the only option to cut porcelain tiles. But when working with this well.known tool, there are some nuances. The fact is that when the tiles are cut, this work is associated with the release of a huge amount of harmful dust, unpleasant scorched smell and wild noise. Therefore, when working with a corner grinder, it is necessary to protect your eyes with protective glasses, and also put on a respirator.

When the tile is cut, it is necessary to know that the diamond circle must be kept directly without shifting and clearly follow the lines that are drawn on the back of the tiles.

It is necessary to work with the disk carefully, to lead the disk along the line, retreating behind the fishing line for the trimmer cut 2-3 mm from the line towards the chips. And also to press the tool must be strongly and it is necessary to lead it along the line calmly, with a large pressure. If you do the cut in this way, then the cut will be neat, without chips. There is one more advice when working with porcelain tiles. The tiles of ceramic granite must be rigidly fixed, it must be clamped with clamps and screwed to a fixed surface, for example, to the table. The fact is that this must be done, according to safety measures. after all, when cutting on a tool, you need to press hard.

Varieties of facing material and features of its various types

The method of cutting depends on the variety of facing material. The most important thing in this matter is not only the material, but also the role that is assigned to each tile in the composition. Tiles are usually produced in collections. these are thought out in terms of color and pattern. Most collections consists of several mandatory elements.

- Background tiles usually do not have patterns. In collections, several tiles of different colors may be present. It is better to cut the tiles in those places where the background is homogeneous, so cut cladding will not be so striking.

- Borders are small elements that share large color tiles, often they have a rectangular format. If possible, cutting borders can be avoided if these elements do not fit the walls.

- Tiles with decor. this type of tile with a pattern or embossed image. It is better to immediately refuse a decor to cut tiles with a decor. To do this, at the stage of layout, the tiles with decor must be taken to the central places of the room. It is also not recommended to have a tile with a decor under the ceiling or by the floor.

Laying tiles without preliminary layout increases the number of cut elements. If you plan the location on paper, you can avoid a large number of scraps and marriage.

- Floor tiles are usually thicker than wall, so cutting it is more difficult. In addition, large.format tiles are often used on the floor, irregularities in cutting on it are also noticeable.

It is necessary to cut floor tiles more often if the corners in the room deviate from 90 degrees. For this reason, for laying tile coatings on the floor, the walls in the room must be aligned.

Places of adjoining

The complexity of the cut depends on the location of the tile relative to other elements. It is desirable that in these places there are no important and expensive tiles (borders, decor). this moment is decided by the preliminary layout of the elements. For example, borders should not rest against communication or sockets. In places where tiles are joined with sockets, with batteries or plumbing equipment, complex cuts are made on the tiles (circular, semicircular incision).

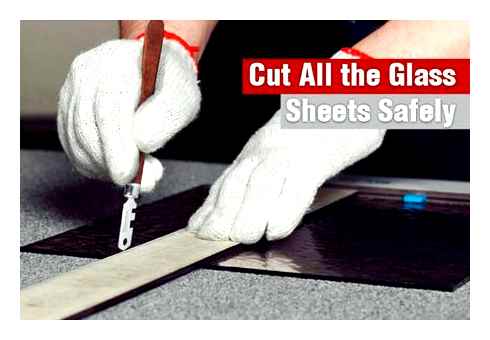

Professional diamond glass cutter for glass tile cutting 2 in 1 glass cutter set manual construction

The number of junctions in which it is better to cut the tiles to minimum at the planning stage.

Tile material

The thickness and strength of the material often depends on the material from which the tile is made. Some materials have high density, respectively, not every tool can cut them. Some materials require a delicate approach and are subject to cutting only by a specialized tool.

- Ceramic tiles are the most common variety, on top it is covered with a decorative glazed coating. The tiles are divided into wall and floor, the latter is usually thicker, it is more difficult to cut it from this.

- Porcelain tile is highly density, this determines its low water absorption. Because of this, such tiles are often used for floors, wet zones and streets. It will be difficult to cut porcelain tiles with improvised means. it is better to cut the cutting with an electric or manual tile cutter.

- Clinker tiles. a type of high density cladding, it is used for external work (cladding, paving sites, etc.). For a thick clinker, an angular grinder or a water saw (electric tile cutter) will be required.

Cut the tiles without tile cutter methods and nuances

Ceramic or porcelain tiles are very solid facing materials similar in many properties to glass. Therefore, the methods of cutting it will be similar. The same glass cutter, but it is worth immediately warning that not all material can be equally cut off even in this way.

For example, a tile with a relief structure will be a difficult task and sometimes even overwhelming and for glass cutter.

The main task of the Reza is that its cut.out side remains even and there are no chips. Often the trimmed edge is located under the baseboard or closed with vertical tiles, in which case you can not be worried at all, but to take a corner grinder with a diamond cutting circle boldly. But with this tool you should be neat, since you can cut off with a lot of chips.

Consider the most effective methods on how to cut tiles without tile cutter and with minimal marriage. Regardless of what you use to perform cut, drill a tile, you should always be extremely neat and not make sudden movements. You can accidentally move the workpiece and break the thin element. It is especially dangerous when it is M-shared and one side is thicker than the other.

It is also important to provide the necessary conditions for such work. They consist in reliable fixation of the material so that he does not vibrate and does not twitch during its processing.

How to cut porcelain tiles at home: Test choice

Before the cut of the material, it is necessary to prepare or, with the need to purchase or rent a suitable device for this task. Each tool that allows you to cope with this task has its own features and in the course of work with it it is necessary to observe certain nuances, which is also necessary to familiarize yourself in advance to exclude possible flaws that can lead to damage to tiles.

Corner grinder

This tool is universal, since with its help many different tasks are carried out and the processing of a huge number of materials is carried out, one of which is porcelain stoneware. Almost any corner grinder is capable of cope with its cutting, because it is not obliged to have high power.

Its turns has a more significant impact. Through a powerful cutting tool, it occurs an order of magnitude faster, but high speed can adversely affect the final result, since in this case the cutting place is not always perfectly neat. Compact corner grinding, which has a low weight, performing work is noticeably more convenient and easier than heavy with huge dimensions.

One of the main advantages of the tool is the ability to perform not only a straight, but also a figured cut of the material. The second advantage of the use of corner grinder is its ability to process porcelain tiles of any thickness and texture, but for this task a special disk is necessary. Thirdly, it allows you to process products designed for styling on the ceiling, walls, floor, as well as mosaics. In addition, you can cut the tile of a corner grinding at an angle of 45 °, make holes in the material and exclude the presence of chips on the front side.

Disadvantages of work through it also have. During the cutting of porcelain tile, a significant amount of dust is formed and there is a probability of deviation from the planned line of cutting. In some cases, after the cut, the cut place needs additional processing. In addition, it is necessary to carry out work extremely carefully in compliance with safety regulations, since the process is quite dangerous and can lead to serious injuries.

Choice of a disk

An important point during the cut of porcelain tiles through corner grinding is preliminary selection of the correct cutting circle. Its cut should be done exclusively during the use of diamond discs that are of two varieties. continuous and segmented.

To determine, with the help of which circles it is better to perform the cut of the material, it is advisable to try both options in advance and only then make the final choice in the direction of one of them. The reason lies in the features of the use of both types of disks, in view of which it is also necessary to familiarize yourself with in advance in advance.

Continuous non.gas circles are usually designed to carry out work in a wet way. In the process of cutting the material, they must cool with water or special liquids, since otherwise they can be extremely quickly worn out.

Such discs are the best option with the need to achieve the minimum number of chips, although certain indicators of the processed material are influenced on the final result, which include, for example, its thickness, quality, relief and others.

Segment circles are more suitable for cutting porcelain tiles with a dry way. The voids present between the segments of the void ensure the cutting of the facing material, but it is extremely desirable in the process of work nevertheless so that the disk does not rotate continuously for more than 1.5-2 minutes and after the indicated time cools down.

This is necessary due to the fact that the circle of steel and diamond spraying, under the influence of high temperature, can succumb to premature wear and destruction. The quality of the cut in this case is affected by similar factors, as when using continuous discs.

Circles differ not only in the view, but also with their thickness, the density of diamond spraying, the height of the cutting edge and other indicators. Basically, on the disks it indicates for what tasks they are intended. When using a corner grinder, it is impossible to carry out work in circles, the thickness of which is less than 2.0 mm. The height of their cutting edge should be thicker than tiles undergoing processing, as this affects the quality of the saw.

note! Before each cut, check the state of the disk. If even small defects occur in the circle, it is necessary to replace it with others, since otherwise the probability of chips becomes much higher.

How to cut porcelain tiles at home with corner grinding

The cutting process with its help is required to be done according to this principle:

- Marking. It is necessary to draw on the front side of porcelain tiles by means of a square and a simple pencil or a construction marker. To reduce the number of chips on the sides of the intended line, you can additionally glue the painting tape.

- Then it is necessary to lay the material on a flat and stable surface. A great option for this purpose as a substrate is to use a piece of foam with a large thickness or something like that. In some situations, it is more convenient to fix the porcelain tile to the surface with clamps or to fix it in the workbench.

- After placing the product, the optimal way for yourself from the number of these options can be proceeded to the saw. At first, a rotating diamond disk installed in a corner grinder with light pressure, you need to go through the intended strip from the beginning once to the end.

How to cut a porcelain tile angular grinder

The work begins by the fact that on the surface of the tiles they draw a fishing line for a trimmer, according to which they will perform a cut. For this purpose, use a special damn with a carbide tower or a very thin marker.

The tiles are placed on a flat surface and fixed with a clamp or tightly pressed to the surface. It is recommended to use a substrate, for example, a plywood sheet or a wood-piece plate.

The cut is performed on the front side. Thus, it turns out that most of the marriage and chips will be on the back side. A disk for tiles on a corner grinder is carried out in the direction of it, each time deepening at 1?2 mm. It is recommended to deviate a little from the line because the diamond circle in the process of “eats” several millimeters of tiles. It is advisable to do it with one smooth movement, avoiding jerks and slowing down at the edge.

If there is an assistant, then he can with the help of a vacuum cleaner removes dust and garbage, in abundance formed during dry cutting.

When processing porcelain tile, corner grinder must strictly observe the safety rules. You can not remove a protective casing from a corner grinder, use circles of inappropriate diameter, as well as work without personal protective equipment: glasses, respirator, gloves.

Cutting with a jigsaw

This method will also require considerable effort and is rather suitable for modest volumes of tiles designed for cutting. Unlike alternative methods, this option involves sawing ceramic granite. By the way, knowledge of how to cut porcelain tiles with a jigsaw will allow you to perform similar operations with a hacksaw for metal. In addition to patience, you should stock up on interchangeable cutting canvases, which will surely require work with dense material.

First of all, it is necessary to fix the file. According to the intended line on the tile, it should be drawn in a jigsaw so that the maximum smooth cut is formed. To exclude the likelihood of overheating of the tool, it is also necessary to moisten the material. This is how the electric model works, but there are also manual jigsaws, which, with appropriate dexterity and efforts, allow you to create accurate and even curly cuts. Again, the main thing is to use the files suitable for specific purposes or diamond wires. Of course, the cutting procedure will take a lot of time, but this is one of the best examples that demonstrate how to cut porcelain tiles at home with maximum accuracy. This method is especially useful if you need to create curved cuts in wall tiles for the further implementation of electrical devices.

Safety regulations

Working with manual tiles is less dangerous than with an electric counterpart. After all, we will not have to face vibrations, noise and rotating disk.

- Put on a protective casing, special shoes.

- You also need to put on glasses to avoid fragments from tiles in the eye.

- Cutting must be carried out in a special place (in the workshop or in a room where no one will go during cutting).

Only adults can cut the dies, which has undergone safety training. You also need to know how to provide first aid for injury.

Whether to wet the tile?

Many experts recommend wetting tiles. You need to do this 1-15, hours before cutting. Thus, it will be possible to soften the working material, make it more obedient. This procedure will contribute to obtaining a flat fault.

Cutting on yourself or from yourself?

Which way to move the carriage, on yourself or from yourself? This question arises in many. It is more convenient for someone to work, cutting the tile in the direction of themselves. Someone is more even a furrow when cutting occurs towards themselves.

How manual tile?

Titty cutter. a tool on which there are runners (guides). a crown with a steel roller from a hard alloy moves along them. On this base and put tiles for cutting.

Models may differ in modification. For example, there are tile cutters with additional. a device that allows you to make round holes.

Before buying, you should also find out from the seller which tile cutter to choose for porcelain tile. The fact is that some models are suitable only for thin ceramic tiles.

Self.cutting porcelain tiles and relief ceramic tiles

I must say right away that due to the hardness of porcelain tile and its embossed surface, it will not work to use a tile cutter for cutting. You can, of course, try, but the result will be a porcelain tile smashed to smithereens. For cutting “in straight” or curly cutting of porcelain tile and relief ceramic tiles, angular grinding machines (corner grinders) with a diamond winning disk are used.

Using a square and a simple pencil on the front surface of the porcelain tile, marking is made.

Attention!

Marking and cutting on embossed tiles and porcelain tiles are always performed on the front side of the material. Otherwise, if you cut off on the back, unwanted chips may appear on the front side.

Having laid porcelain tiles on a flat and stable surface, initially rotating diamond disk of corner grinder pass with light pressure once along a drawn line.

Having completed the first surface drink, a diamond disk is performed at the beginning and at the end of the cut line for the entire thickness of the porcelain tile. These cuts in length are 10-20 mm. They are needed so that porcelain tile does not burst in the area of the corners.

Along the previously performed longitudinal cut, the corner grinder passes with a rotating diamond disk 3-4 times until the porcelain tile is completely cut.

I must say that an angular grinder with a diamond disk is also used for cutting smooth ceramic tiles, for example, when it is necessary to perform a figure cutting. Depending on the previously developed design project, it may be necessary to cut ceramic tiles along a curve, for example, a fishing line for a cutting trimmer is needed not even, but a radius. Such work cannot be done with a plateau, since it is designed only for even cutting in a straight line.

Popular porcelain tile

MARMO Agat PG 01 Lappato 60×120 porcelain

Porcelain tile LUSSO LIGHT PG 01 Lappato 60×120

Caramone border Calacatta Extra white 60.7×60.7

Grande Marble Look Frapccino Lux Rett porcelain. 120×240

Bosco decor beige mix R9 7.river 60×60

Porcelain tile charm Extra Laurent 60×60 TAS.

All collections of porcelain tiles

Making holes in porcelain tiles and ceramic tiles

Holes with a diameter of up to 12 mm in porcelain border are drilled by drill with winning tips. The electric drill should be a power of more than 800 watts, its cartridge must be visible, that is, not “beat” during rotation. If the surface is too smooth and there is a risk that the drill can start sliding, then 3-4 strips of paper adhesive tape are glued to the site where drill will be drilled.

Holes with a diameter of 30, 40, 50, 60 mm on porcelain tiles are made with crowns made of hard.wooped metal with teeth, on which a winning spraying is applied. Initial drilling with such crowns is always carried out at small speeds, and only when the teeth of the crowns go deep into porcelain tiles by at least 3 mm, they proceed to faster drilling. Minus of winning crowns. the ability to perform only standard holes.

A hole with a non.standard diameter, for example, 55 or 68 mm in porcelain tiles or tiles are made by a ballerinka. The ballerinka is a drill with a winning tip, in the middle of which a horizontal holder is fixed in a tripod method. At the remote end of the holder vertically, parallel to the drill, there is a round or hexagonal metal rod, with a cutter installed at the end. For example, it is necessary to perform a hole with a diameter of 58 mm (a hole for the sewer pipe from the sink), which means that 58 is divided by 2 and receive a radius of 29 mm. Next, using the ruler, the position of the cutter holder is set on the ballerinaster so that there is a gap of 29 mm between the cutter and the center of the drill.

Attention!

Drill holes with a ballerinkle with maximum caution. The tile should lie horizontally evenly, and the angle of the central drill in the ballerinka with respect to the tile should be 90 °. The slightest skew and cutter of the ballerina can break the tile.

Holes of more than 100 mm in diameter (for a sewer riser or ventilation duct) in porcelain tackle perform a small angular grinder with a diamond disk. Initially, a couple of pieces of paper tape are glued to porcelain tiles. After that, stuck in the tape of the compass, draw the right circle. Next, a protective casing is removed from a small corner grinder. Cutting holes of more than 100 mm is carried out by holding the corner grinder absolutely in an upright position in relation to the tile, gently producing a cut in a circle.

Attention!

Given that a protective casing will be temporarily removed from an angular grinder, be sure to use protective glasses, long sleeves and gloves during operation, since there will be a lot of chips to fly a lot.

Drilling

- The winning drill. the resource when working with porcelain tiles is very low;

- Diamond crown. in fact, only 15% of the manufacturers pour diamonds, the resource is even lower than in the previous case, the maximum is enough for 1-3 holes;

- Cooled drill-floods-the resource is slightly higher, low performance due to insufficient contact of the cutting edge with the surface;

- Ballerinka. expensive tiles are equipped with this device, rotation is performed manually, the cutter can be hidden and changed by new as it is wear;

- Tubular drill with diamond spraying. the main problem is the start on a smooth surface, therefore, instead of a point on a porcelain border, a marker is drawn in the size of the opening, the tool is installed at an acute angle to the surface, first is removed the glaze, then the glazing is carried out.

Внимание: Трубчатые сверла продаются в специальной упаковке, крепящейся на стену присосками, имеющими в нижней части кондуктор, предотвращающий инструмент от проскальзывания. Внутрь заливается вода, которая подается капельным способом в зону сверления. Обороты дрели не должны превышать 1 500 об/мин для максимального ресурса алмазной оснастки.

Thus, most home masters find how to drill and cut porcelain tiles during the cladding of the internal rooms and facades. The equipment for the power tool has not the same price, so from these options you can choose the optimal option for the existing budget.

Cutting corner grinding

Corner grinding machine (angular grinder). a universal tool for cutting and processing many materials. Due to its universality, it does not apply to specifications. In the household, with the help of a corner grinder, you can solve many issues.

In order to cut off porcelain tiles, almost any corner grinder is suitable. There is no need for high power. A small, light tool is even preferable to use. The turns are more important, not the power. A powerful tool will cut the tile faster, but just the speed here can affect negatively. it will turn out less carefully.

The main issue is the selection of a cutting circle. It is the choice of a circle that should be paid special attention. And this is not about the landing size (it is granted).

Choosing a cutting disk

The material is cut only with diamond discs. Diamond discs produce two types: solid and segment. To obtain the best results, it is recommended to try to make cuts with different cuts. For cutting porcelain tiles, there are features when using both continuous and segmented discs:

OPENING-Manual 2in1 Multi-Functional Glass and Ceramic Cutter Set/review how it works

-

Continuous are positioned by manufacturers mainly for “wet” cutting. T.e. for cutting with water cooling or special liquids. And are not used for cutting without cooling, as they can quickly fail. However, when is the task of obtaining a cut with as few chips as possible, it is a continuous disk that can be better suited. This is situational and largely dependent on the specific material (quality, thickness, relief, etc.) that is processed;

In addition to the type, the discs are characterized by a whole set of parameters: the density of diamond spraying, the height of the cutting edge, the thickness of the disk, etc. It is better to follow the recommendations of disk manufacturers. The discs themselves usually indicate for what purposes they are used.

For cut with manual corner grinding, disks less than 2.0 mm thick are not acceptable. The height of the cutting edge should be greater than the thickness of the tile (affects the cleanliness of the cut).

Advice! Check the condition of the disk in front of each cut. With any deviations, the disk changes, otherwise the risk of chips increases.

Technology

- Put the marking to the tile. For this, it is best to use a construction marker.

- Tile on a flat surface. In some cases, it will be more convenient to fix the tile to the surface with clamps or fix it in the workbench.

- To obtain an even cut, you can additionally strengthen with clamps along the cut line the metal strip. Then it will be necessary to cut along it.

- Cutting is carried out on the front side, since the output is the largest number of chips. You can do a double cut. First draw a small furrow on the front side, and make the main cut on the back. This method will minimize damage to the front surface.

- If there are no strict requirements for the cut, then you can not saw it to the end. Having made cuts, break the stove with your hands.

- It is recommended to lead the tool, starting from yourself.

- Additionally polish the slice if necessary.

General recommendations

Applying a corner grinder, it is imperative to use protective equipment:

- a suit that covers the legs and arms;

- protective glasses (preferably a mask);

- protective gloves or mittens;

- respirator (with a significant amount of work is required).

- The ability to cut an element of almost any shape. For figure cut, good skills in working with tools are needed;

- The possibility of cutting the tiles already laid in place;

- The accessibility of the tool.

- traumatic hazard;

- It is very difficult to get geometrically accurate cuts;

- a large complexity of obtaining a clean cut without chips;

- low speed of work;

- A large amount of dust and noise.

With the help of corner grinder, it will not be possible to get the perfect slice the first time. To obtain accurate cuts without chips, they cut with an indent from the line of 2-5 mm. Then bring to the desired sizes with grinding. This is a rather time.consuming operation and takes a lot of time, therefore it is recommended to be carried out only with elements that will be in a prominent place.

Or use the trick, as in the video below:

Little tricks

All methods are not exhausted by these two ways. With their help, you can get an acceptable result of any sections at home. Round holes in the material are made by a conventional tool without special nuances: drill with solid.melodious spraying, ballerinas, crowns. The only difference is that due to the hardness of the material, the cutting tool will fail faster.

To solve the tile laying problem, you can use the complex approach:

- The most easily tile is cut with a manual tile cutter. The main mass of tiles is recommended to cut it;

- Tiles with cut faces, closed with skirting boards or overlays. In this case, it will be enough to use manual tile cutter or corner grinder (in limited cases);

- There are little tiles with an accurate fitting. Adjust with grinding;

- Put all the whole tiles. Depending on the existing tool, fit the tiles that are closed with skirting boards and overlays. The remaining elements are accurately measured and mark on the tile. Either rent a professional tile cutter, or take it to the nearest construction company with such equipment and cut.

Advice! If you need repair masters, there is a very convenient service for their selection. Just send in the form below a detailed description of the works that need to be completed and offers will come to you with with from construction brigades and firms. You can see reviews about each of them and photographs with work examples. It does not oblige it for free.

What tools are used for cutting

A full list of tools used to cut and drill porcelain tile includes manual or electrical devices.

Handing tiles

A cutting element in a manual tile cutter, as in the glass cutter, is a video, but not carbide, but diamond. When rolling with a clamping force along porcelain tile, microcracks form in the surface layer. Next, the tiles are broken into two parts.

Manual tiles are used as follows:

- Check the condition of the tool: you need to make sure that the video is sharply sharpened and firmly fixed, and the carriage has no backlash. Dumb edge and shook supports will affect the quality of the cut. In this case, the video is changed. If he dangles from side to side, it is necessary to tighten the fasteners. When jamming the carriage, in the guides, when moving, the bearings are changed or the guides are cleaned, lubricated with machine oil. The same is done if there is a backlash. It is useful to drip oil on the video so that it is easier to turn and wear out less.

- Based on the results of the measurements, a fishing line for a trimmer cut is applied to the tile.

- Put the module on the base of the tool so that the video passes exactly along the line. In this case, the carriage is installed on the tile with supporting paws so that its cutting element does not touch.

- With an effort, pressing the tile with one hand to the base, the other is taken by the handle of the tool and set the carriage in the working position: the supports are removed and the video is placed on the tile.

- They bring the video to the beginning of the cut line and, pressing the handle, roll it along the module from one edge to the other. For a high.quality cut, constant effort and speed of movement are required.

- With the second hand they continue to hold the tile, preventing its shift.

- Then the carriage is again installed with supporting paws on the tile and continuing to hold the module with your hand, with pressing the handle it is broken. With low cut quality, the edge is polished by a corner grinder armed with a cutting disk over stone.

The section must be made in one pass. With a repeated rolled roller, the cut will turn out to be uneven.

Electric tile

Electric tile cutting cuts a disk with diamond spraying, rotated by an electric motor. In addition, the engine moves the table along the cut line with a tile fixed on it or a head with a disk (depends on the model).

Discs called sparks are used. They provide a slice of high quality, but need liquid cooling. Two cooling methods are used in different models:

- The speed of the disk rotation at the beginning and end of the cutting slows down.

- The tile is held with hands with sufficient effort to avoid vibration. The module is pressed with hands on both sides of the cut.

- When using a tool with non.flowing cooling, the water in the container is changed more often, otherwise the disk will capture the garbage accumulating in it, which will negatively affect the quality of the cut and the resource of the cutting element.

The disk clogged with a crumb is cleaned by cutting a brick from pressed sand or setting it with the back (in the absence of a indicator of the required direction of rotation).

Corner grinder

To cut porcelain tiles, a cutting disk with diamond spraying is also installed on an angular grinder, but designed for dry cutting (dry cutting).

It consists of segments, which is why the heat sink improves, but the quality of the cut is deteriorating.

Rules for choosing a disk for cutting porcelain tiles:

Matters which way the disk rotates. When installed by the wrong side, the cut is low.quality and the traumatic hazard of the tool increases.

When cutting porcelain tiles, corner grinders adhere to the following rules:

- The disk is periodically examined and when chips and other damage are detected. they change.

- The tile is fixed with clamps. It is useful to attach a steel strip along the cutting line. then it will be easier to cut off the tiles smoothly.

- The operation is performed in one pass. Cutting disk is accompanied by the formation of chips and the more passes there are, the higher the percentage of such defects.

The tile is cut not in size, but with a margin of 2. 5 mm. It will allow you to polish the edge, removing chips and cracks. Grinding is performed around stone.

If the edge is supposed to be hidden with a baseboard or corner and therefore high requirements for its quality are not presented, the grinding can not be done. Also, in this case, it is not necessary to dissect the tile completely: it is cut and then broken.

Eyes protect with glasses, the respiratory tract. a respirator, because a lot of dust is formed. It is possible to reduce its amount in the surrounding space in the process of work, with the help of a construction vacuum cleaner. This will need an assistant.

In order to less damage the front surface, it is recommended to first cut a shallow furrow in it, and then select the remaining material on the back.

A circular saw

You can turn the circular into electric tile cutter by replacing the disk saw with a detachable disc with diamond spray. The tile will have to be served manually to the disk, so you need to act very carefully.

Electric

This tool can be used to cut porcelain tiles of small thickness. To do this, it is armed with a thread with diamond spraying.

Kusachki

Kusachki can break off the edge of a small width-within 1-1.5 cm. To make the cut more even, you can first walk along the tile with glass cutter.

Ballerin

This tool is used to perform large.diameter holes in porcelain tiles.

Reminds the compass: has a central drill and one or two incisors on the legs designated aside.

The distance between the central drill and incisors, and, accordingly, the diameter of the opening of the opening, are regulated.

The choice of tools

For one.time work, it is impractical to purchase a specialized tool. It is more rational to use a corner grinder, which is a universal tool and available in each household.

For dissection by a curve, manual tile cutter is not suitable. Only a hydro.carbrane installation, an angular grinder, an electrolobian and, if there is an appropriate skill, electric tile cutter will cope with this task.

Non.specialized tool does not allow you to perform pruning efficiently. Therefore, it is advisable to apply a combined approach to the home master: most of the modules, the edges of which will be hidden by a skirting board or a corner, cut on their own with a corner grinding or manual tile, and those that will be in sight, take the workshop for cutting with an electric tile.cutting cutter or a hydro.carbard installation.

In view of the absence of pores, porcelain tile is an extremely hard material, therefore, to cut it, you need to choose the right tool and equipment. It is more quickly and more convenient to use an electric tool, manual tiles are suitable only with small volumes of work.