On the corner grinder heals the nut heavily.

What are the ways to unscrew the protracted nut on the corner grinder?

Corner grinder, or corner grinder. a universal tool with which you can perform a wide range of actions. It has a simple mechanism of action built on the rotation of the shaft by an electric motor. Necessary for cutting metal parts, polishing the surface and grinding of various materials. One of the frequent problems during the operation of a corner grinder is a bite of a nut that holds a disc. This does not allow you to replace the nozzle, and with a strong effect, you can damage its thread, break the key or break the body.

As a rule, such a problem occurs on an angular grinder with the diameter of the working surface in the range of 150-180 mm. When a strong torque occurs, the disk bites. This leads to the fact that the nozzle cannot be removed with a regular key even with the application of serious physical efforts.

The second common reason is the use of a disk for an angular grinder, which does not correspond to the factory parameters of the tool. This leads to a violation of the process of the entire mechanism and jamming. In rare cases, the nut is not amenable to unscrewing when rust on its thread. Most often this is found with prolonged use of the tool or storage without changing the nozzle.

Important! Drks for angular grinding selief is produced typical sizes, the diameter varies from 115 to 230 mm. The landing shaft itself is produced with a diameter of 22.2 mm, when using old models, the adapter is required.

How to unscrew if you drag out?

To begin with, we will answer a frequent question: “In which direction the nut is unscrewed on the corner grinder?”

Remember! You need to unscrew the disk rotation. T.e. If the disk rotates clockwise, then you need to unscrew the nut.

The easiest way to unscrew the disk fastening is to put the key, and then hit several times with a hammer with average force.

If this did not help, there are alternative methods of solving the problem:

- Warm the mounting mechanism using a burner, which will lead to the expansion of the metal. As a result, the design will become moving;

- With the help of a small metal plate, the disk to the nut itself. Continue to grind until its surface is in contact with the nut and begins to twist it;

- insert a steel pipe into the nuts of the nut, use it as a lever to unscrew a protracted nut. You can not apply too much effort so as not to disrupt the thread;

- Lubricate the thread with machine oil, for example, WD-40. Wait 3-5 minutes, and then try unscrew the mount with the key. Using this method, you can get rid of rust inside the planting shaft;

- If you need to remove a circle that have not been used for a long time, you can start twisting the fasteners even more. After that, try to weaken it again;

- A boiled or rusted thread on an angular grinder can be treated with turpentine, vinegar, white spirit or solvent of rust. After processing, you need to wait for at least 30 minutes, and then try to twist the nut again.

If a situation arises when you are left without a key, you can cut down a stuck fastening with a chisel or stuck it with a second corner grinder with a disk for metal. After that, you will have to restore the thread, and also look for a spare nut. If the circle still does not give in, you can try to combine different methods. For example, treat the shaft with machine oil, and then start to unscrew the nozzle with a lever or tap the mechanism with a hammer.

Important! You can not unscrew the mount with great force. This can lead not only to the breakdown of the thread, but also the breakdown of the corps itself is an angular grinder.

What to do if the nut jams?

A common problem when working, an angular grinder is a jammed nut. The first thing to do in such a situation is to determine the direction of rotation of the disk. In the same direction, it is recommended to unscrew the jammed nut. There are several most effective ways to solve this problem.

- Use an ancular key and a end head. To do this, it is necessary to strap the surface of the ore key on 4 millimeters, which has 17 millimeters. On the head of the end 24 millimeters, to grind the four ledges that will be combined with the holes of the flanes nut. Then the face key is placed under the disk, and the head of the end is placed on the nut of the corner grinding machine. After that, the ratchet should turn it in the direction of rotation of the disk.

- Apply a gas key. Knowing the laws of physics and using the gas key, you can increase the moment of strength, as the length of the shoulder will increase.

But you should not make too much effort, since you can melt the flange and damage the spindle rotation fixer.

Corner grinder, or corner grinder. a universal tool with which you can perform a wide range of actions. It has a simple mechanism of action built on the rotation of the shaft by an electric motor. Necessary for cutting metal parts, polishing the surface and grinding of various materials. One of the frequent problems during the operation of a corner grinder is a bite of a nut that holds a disc. This does not allow you to replace the nozzle, and with a strong effect, you can damage its thread, break the key or break the body.

The reasons for biting

As a rule, such a problem occurs on an angular grinder with the diameter of the working surface in the range of 150-180 mm. When a strong torque occurs, the disk bites. This leads to the fact that the nozzle cannot be removed with a regular key even with the application of serious physical efforts.

The second common reason is the use of a disk for an angular grinder, which does not correspond to the factory parameters of the tool. This leads to a violation of the process of the entire mechanism and jamming. In rare cases, the nut is not amenable to unscrewing when rust on its thread. Most often this is found with prolonged use of the tool or storage without changing the nozzle.

Important! Drks for angular grinding selief is produced typical sizes, the diameter varies from 115 to 230 mm. The landing shaft itself is produced with a diameter of 22.2 mm, when using old models, the adapter is required.

How to remove a grinding disk: important points

Without a tool, it is almost impossible to remove a grinding disk on a corner grinder. To remove the circle, you need to loosen a large number of screws, nuts, which is very difficult to manually do. Nuts, washers, screws are very tightened and are not amenable to manual promotion.

- Disconnect a grinding machine from the network;

- wait for a complete stop of the grinding disk;

- Use the wrench to turn the nut on the corner grinder counterclockwise;

- Remove the protective casing;

- Install a new wheel and tighten the nut.

When processing inappropriate material on the wrong grinding circle, you may encounter two potential risks. The disk may crack or break with the formation of a huge number of pieces of grinding circle. Pay attention to the compliance of the materials from which the discs are made, and the scope of their application:

- Aluminum oxide disc is designed for steel, carbide steel, iron. Alloy steel, high.speed steel and similar metals in composition;

- Carbide Carbide Disk works with brass, cast iron, bronze and other soft metals. It is also intended for processing stone and non.ferrous metals;

- Aluminum ceramic oxide is very abrasive and used for steel, solid metals. The main task of the disks. accurate grinding;

- Zirconium clay. Another type of grinding circle intended for steel and most solid metals.

To understand how quickly and without damage to remove the grinding circle, read the advice of specialists. Take a note of the following important knowledge that will help you cope with the task:

- Pour a rag or fabric in the hole of the grinding circle so that it does not scroll when the nut is weakened on the corner grinder;

- Do not pull the nut too much and control the efforts that you make to achieve the goal. The rotating wheel must hold the nut well and tightly;

- Use the oil lubrication oils to simplify the process of replacing the circle;

- If the nut is very tightened, use a hammer with which you can make a little effort and spin the nut;

- Check the state of the grinding circle. Experts advise simply tapping it with a metal tool. If a deaf sound can be traced, this indicates a breakdown. A sonorous sound. an indicator of a working disk;

- After replacing the grinding disks, be sure to check the performance of the corner grinder, being on the side of the tool. Exclude possible injuries;

- Carefully read the operating instructions. It contains a lot of useful information that will help you use the table grinding machine correctly, including the replacement of the circle;

- The method of promoting the nut largely depends on the type of angular grinding machine, the features of its design.

How you should not unscrew the nut

When clamping the disk, the operator spends a lot of time on its release. This leads to irritation of a person, as a result of which inappropriate ways to eliminate the problem are applied.

We will tell you how you should not act when jamming:

- Metal hairpins in the holes can lead to a weakening of the clamp, but more often they lead to a huge load on the gearbox, as a result of which the corner grinder is damaged by one of the structural parts;

- A larger diameter nut, torn by a huge key, will lead to damage to the teeth of the gearbox and a breakdown of threads;

- Heating with a gas burner is not the best option, this method is unlikely to help, but the physical properties of the metal will violate.

It is much easier and safer to cut off a clamped disk on both sides of another corner grinding and unscrewing a shaken nut without problems.

How to prevent clamping

Problems with a working tool is always better to prevent. To do this, we work extremely carefully, we make sure that the disk does not jam and break. We also recommend using special nuts. They are more expensive than usual, but unhindered are unscrewed in case of clamping.

Special gaskets are also considered to be the chassis. They are perfectly protected from jamming. You can make it yourself at home by cutting out of paranite.

How to unscrew the nut on a corner grinder if you eat

I tried to stop the button, take a standard key and crush, knock with a hammer. to no avail.

I took it home, stalled the button, tried to use the gas key. it doesn’t go and that’s it, I only scratched the nut. At the same time, I remembered how often I had heard about cases when a nut on a corner grinder is unscrewed with great difficulty.

How easy it is to unscrew the nut on the corner grinder (corner grinder) if it was clamped

First of all, it should be broken to the ground that remains of the broken detachment disk.

This is done very simply, you just need to take the pliers. At the same time, we use protection products. glasses and gloves, as metal fragments will fly.

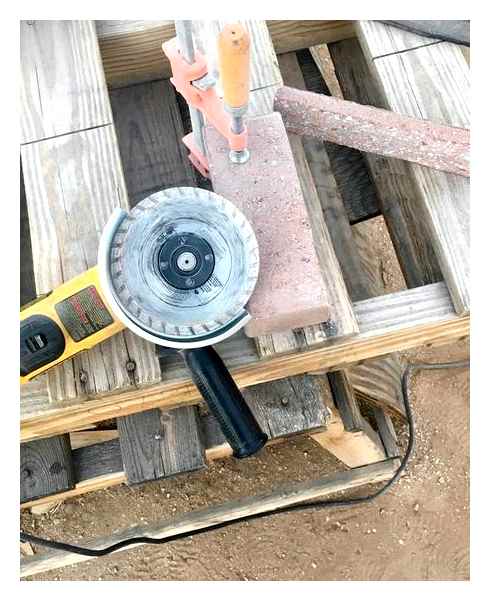

The result should be the following:

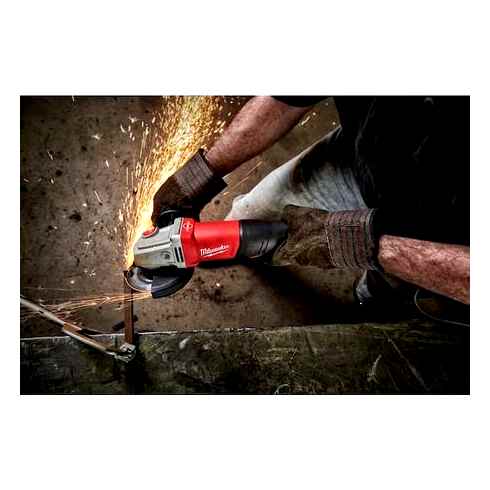

Milwaukee Angle Grinder Repair. How to Replace the Flange Nut

Next, we find a piece of metal, the thickness of which is less than the disk of the corner grinder.

A stuck angle grinder nut is solved by Louise Wells

Next, you need to turn on the corner grinder and with the help of this piece to hide the rest of the disk between the nuts.

After everything is standing, we unscrew the nut inside not even with the key, but with our hands.

This is how it is done, very simple and fast. over. safe for bearings of corner grinders. Because if the nut does not unscrew, many are immediately arm themselves with a hammer and try to unscrew the nut, tapping it.

What to do so that this is not repeated

If you do not want to fall into this position, before squeezing a new disk, you can put a puck under the nut. from plastic, paper or cardboard. In this case, the nut will be unscrewed without effort.

Today, a cutting stone or disk can not often be found in proper quality, therefore, when they break, it often turns into a problem.

Naturally, improper operation may be the reason. But now you already know how to unscrew the nut on the corner grinder.

If there are questions or something is not clear, then you can look at everything on

How to make sure that it does not bite a nut with a disk on a corner grinder

And a few words about the prevention of such unpleasant precedents again. You can use small gaskets from cardboard, inserting them between the disk and nut. In extreme cases, we use a smaller diameter of the disk, unless of course the nut is spinning on top. As a result, it will be possible to unscrew such a nut without problems. It will not hold it, it will snap on the thread.

And a small video, about the problem of which I studied on my own experience.

How do you not try to unscrew the clamped nut

Squeezed nut on a corner grinder is always unpleasant. This problem deprives the opportunity to work with the tool, and its solution takes a significant amount of time. All this is reflected in the mental state of a person, as a result of which we begin to be nervous and perform not quite logical actions. I want to say that there are a number of ways to unscrew the clamped nut on a corner grinding, which is not worth using (well, of course, if you are dear to your power tool, and soon you do not want to buy a new corner grinder).

- There are holes on the nut that serve to unscrew it using a special key, and also provide ventilation and counteract it with excessive heating. Some “comrades” instruct the openings of any core or hairpin, after which they beat it with a hammer. By their logic, this method will help unscrew the clamped nut. Perhaps this will happen (and that is not a fact), but this is what the load on the gearbox will be crazy. this is definitely. The result is an ambulance of one of the main structural elements of the corner grinder.

- A similar situation occurs when the same nut is welded on top, but larger, and with the faces. After that, they clamp the lock and try to unscrew it with a heftybide or take a large shoulder. The result may be a broken latch and licked teeth in the gearbox.

- Someone is trying to warm the nut with a gas burner or cutter. This method very rarely helps, and the chemical properties and strength of the metal you definitely violate. If you need to unscrew the nut in any way, it is easier to take another corner grinder and cut off two parts from the opposite sides. So it will weaken and accurately give in.

A simple way to unscrew the clamped nut

And now, let’s look at the most gentle way to unscrew the clamped nut on the corner grinder. I will not say that this method is a panacea from such a problem, but of all the existing opportunities it is the most optimal. To get started, you need to find a piece of metal, up to 1 mm thick. I recommend taking a plate that will be even thinner, about 0.8 mm. It must be squeezed in a vice. The dimensions of this product do not play a special role. What will be at hand, then take. The main parameter is the thickness. If you take the metal thicker 1 mm, then nothing will come of it. Next, you need to break off the remnants of the disk. Most likely, a piece flew away from him. To do this, you can use your hands or ordinary pliers. It is necessary that one nut is left, and the residues of the disk is not visible. You should get the same as in the photo. Only a small part of the abrasive disk that is clamped between the two nuts remains. We need to extract her. Next, you need to carefully insert the metal plate between two nuts, where we have a piece of disk left. Thus, we begin to cut. Now you understand why the metal should be thinner than the disk closed in the corner grinder. After a while, the remnants of the disk will just stand. You will feel it right away, after which you need to turn off the corner grinder. After performing such manipulations, the nut on the corner grinder is unscrewed even with your hand. It is very important to clamp the sheet of metal in a vice. In no case do not hold it in your hand. The most important thing is safety precautions. Yes, and during this process, the nut is very heated, take into account this.

If you want to learn more about the tools for working on wood and about crafts performed with their help, be sure to read the material on this link.

How to unscrew the nut of the disk on the corner grinding (corner grinding) if it is jammed?

I can not unscrew the nut on the corner grinder (corner grinder).

How to unscrew the protracted nut-fluine on a corner grinder (corner grinder)?

A disk broke on the corner grinder (corner grinder), and the nut dragged on. how to unscrew it?

I will tell you the simplest and most convenient method of unscrewing such a nut- “jammed”. This method will not demand from you something additional (where to get a vice working in the basement, somewhere on the road, or a gas key, a chisel, etc.D.). Yes, and the chisel is not the best way out, how much I have grown over the Bulgarians with the “ducked” nuts, with broken stoppers. It’s scary to look at them. Heating is the right direction (proposed). but the wrong execution method. I think it will not be difficult to break the disk to the base of the nut, then we find in a wooden block, or something like that, turn on the corner grinder and nut, as it were. As a rule, there are enough minutes for good heating, the nut is unscrewed by “once”. One inconvenience, can “need”.

The jammed nut on the corner grinder (corner grinding) is a fairly common problem that everyone solves in its own way, but that it is an annoying (albeit natural!) a misunderstanding takes a lot of time and effort is for sure.

First, determine the direction of rotation of the disk, because the nut will need to be unscrewed in the same direction. If we climbed on the Internet, it means by the forces of a stationary key, it was not possible to unscrew the nut. it is either broken or bent.

There are some ways to unscrew the jammed nut on the corner grinder.

With a gas key with good lips, a flanic nut on a corner grinder is quite narrow, and the capture is required quite good. Often, the nut is thus turns out to unscrew, but do not make great efforts-you can break the fixer button (if it is still intact!), its design is designed for the application of the effort of the possible when using only a stationary key.

- If the fixer button on the corner grinder is still broken, then you will have to remove the gearbox cover-this is three or four bolts under the disk. The disk is usually broken down to the nuts. The lid is unscrewed, the gear is removed from the gearbox and clamped between aluminum sponges in Tesy and the nut is unscrewed using the methods indicated here.

- A drill is clamped in the pedorator, only the detection mode is set (without rotation), and an effort to unscrew the nut (to the edge of the nut or to the hole under the key pin).

- The nut is heated by thermophen (gas burner, soldering lamp) and is unscrewed much easier, with the same stationary key or gas.

- If the disk is broken, you need to remove its remains with plots to the radius of the nuts (well, or break the whole disk if it is not sorry), hold the leaf iron with a thickness of equal thickness of the disk or slightly smaller. Turn on the corner grinder and literally “exude” the disk about the edge of the iron.clamped iron. When the remnants of the abrasive disk between the goals are standing with a diameter of less than the diameter of the clamped planes, the nut will also unscrew by hand.

- This method is the same as only instead of a piece of metal, the same abrasive disk is clamped in TIS. the process is faster, but you must be neat so as not to spoil the fixed disk of the geometry of the nuts, the geometry of the nuts. Otherwise, then you have to handle the planes.

Well, now let’s try to protect ourselves from now from unnecessary body movements to unscrew the jammed nut and possible damage to the tool.

- I advise you to twist the disc nut to almost do not make efforts on a stationary key. during the rotation, the nut is delayed itself, as much as necessary to hold the disk.

- After the nut is unscrewed, you can weld a regular nut with faces under the lacture wrench (which one to choose. depends on the diameter of the shaft thread)

- Do not neglect the installation of cardboard gaskets under the nut of corner grinder, this reduces jamming.

- After the cardboard gaskets that are supplied from the corner grinder end, you can cut down the gaskets from the thin nylon (old plastic canists) in the case of jamming it can simply be melted with a regular burner or soldering lamp and the nut will unscrewed by hand.

- And finally another main advice, I thought that I know everything, but as it turns out there is no. All discs have on one side glued paper with the characteristics of the abrasive fraction and purpose. On the same side (from the side of the paper), the inner puck of the disk has a wide ring. So put the abrasive disk of this particular “paper” side to the gearbox.A wide washer from this side prevents snacking, and when unscrewed by the disk, it will slide along a motionless (inner flange) facilitating unscrewing the nut. Since this is done by the manufacturer (photo).

What to do if the nut jams?

A common problem when working, an angular grinder is a jammed nut. The first thing to do in such a situation is to determine the direction of rotation of the disk. In the same direction, it is recommended to unscrew the jammed nut. There are several most effective ways to solve this problem.

- Use an ancular key and a end head. To do this, it is necessary to strap the surface of the ore key on 4 millimeters, which has 17 millimeters. On the head of the end 24 millimeters, to grind the four ledges that will be combined with the holes of the flanes nut. Then the face key is placed under the disk, and the head of the end is placed on the nut of the corner grinding machine. After that, the ratchet should turn it in the direction of rotation of the disk.

- Apply a gas key. Knowing the laws of physics and using the gas key, you can increase the moment of strength, as the length of the shoulder will increase.

But you should not make too much effort, since you can melt the flange and damage the spindle rotation fixer.

How to unscrew the nut of the disk of the corner grinding of the grinder (corner grinder) if it is bitten

So, if there is no key, even if it is inserted and slightly hit with a hammer, we begin to use something more serious.

The first thing you can try, but again without fanaticism, is to take the rod, insert into the holes on the nut and using the hammer, move the nut in the direction of its promotion. Here is the main thing not to break the button and not to disrupt the holes, as here

The second that many advises is to warm the nut. We warm the nut. As a result, it is a little, but physically still obliged to expand. Changing sizes can help, or maybe not.

No need to pull to the extreme until the stopper of the holding button from the scrolling or the button itself does not burst. In this case, it is not a tool that you unscrewed, but often it is the corner of the corner grinder.

The third method is the most effective, and no matter how strange one of the safest for the most corner grinder. We take the edges of the disk on the nut.

Next, we use a thin metal plate or other disk (thinner), and maybe the second angular grinder with the disk. In this case, the broken disk must be coated with either a plate or disk. We try to sharpen the disk so as not to damage the nuts holding this disk, because they will still come in handy. So sharpen the whole broken circle, until it is stuck and the nut is not unscrewed.

If you use the second disk or metal plate, then it is better to insert them to keep in the vice. Since holding such items is dangerous. This method is the most effective!

How to make sure that it does not bite a nut with a disk on a corner grinder

And a few words about the prevention of such unpleasant precedents again. You can use small gaskets from cardboard, inserting them between the disk and nut. In extreme cases, we use a smaller diameter of the disk, unless of course the nut is spinning on top. As a result, it will be possible to unscrew such a nut without problems. It will not hold it, it will snap on the thread.

And also a little video. About the problem that I studied on my own experience.

How to put a disk on a corner grinder correctly

Grinding wheels have different diameters, different thicknesses and different purposes. Some are made for metal processing, others are processed, and others work on wood.

A disk of such size that will not exceed the size of the protective casing should be installed on the corner grinder. The size of the installed disk is indicated in the instructions and on the marking table of the corner grinder.

The thickness of the disk is selected according to the technological parameters of the processed material. All discs (grinding circles) have their own classification. The shape of the disk, the abrasiveness of the material, granularity, hardness, accuracy class and the class of imbalance are classified. It is the last meaning that some discs begin to beat during work.

The grinding circle has a front and reverse sides. The front side is considered the one on which the marking and the manufacturer is applied to the manufacturer. When installed on an angular grinder, the front side should be located on top.

The disk is installed in this way. So that during the operation of the spark with particles of the processed material flew towards the working. This is due to the issue of safety precautions. If the corner grinder breaks out of the hands, then it will not fly towards the employee.

Therefore, to work with a corner grinder, it is necessary to put on protective clothes or a dense apron. Eyes and open parts of the face must be protected with a mask or at least with protective glasses.

Heating

The clamping nut must be heated with a thermophen or gas burner so that the metal becomes more pliable. Then twist it with a universal key or hands. But the risk of this method is that you can ruin the parts of plastic and gearbox elements.

Why is the nut on a corner grinding of a tuning. the main reasons

You can bite the puck on a corner grinder for several reasons:

- If you delayed the disk with a key, what to do, it is categorically not recommended;

- If the disk is damaged angular grinder;

- In the event that the disk on the corner grinder is jammed.

In addition, as it was noticed more than once, the puck on the corner grinder is more often bite, the larger the diameter of the disk. For example, when using 125 disk, a nut is much less common than when using 180 or 210 disks.

This is due to a high torque. At the time of the disk on the metal, the force is much higher. Therefore, the washers on grinds with large discs are bitten most often.

How to unscrew the nut on the corner grinding (corner grinding) if it is bitten

If the stop button works, then first you need to try to unscrew the disk on the corner grinder with standard methods, using the key to the tool to these purposes to these purposes. However, most often all this does not help, or the stoppers button does not work.

In this case, you need to use a hammer and a chisel. To do this, the chisel is installed on the nut on the nut, and then a hammer is carried out on it (to unscrew the nut). counterclockwise. In most cases, this method of unscrewing the nut on the corner grinding, if it was bitten, should help.

If this method does not help, then you can try to warm up the nut gas burner or a construction hairdryer. When heated, the metal tends to expand, so the nut should begin to spin with a regular key from the kit.

The third way, if nothing helps, is associated with the overwhelming of the old disk. First you need to break it off, and then turn on the corner grinding and using something sharp, for example, a knife, make the rest of the disk. A method is really good, and it helps in advanced cases.

How to make sure that it does not bite a nut on a corner grinder

Well, the last, how to make the nut on the corner grinder does not bite at all? Everything is simple, and for this you need to use a cardboard lining for a nut.

You can also use a smaller diameter disk or use a special nut for a corner grinder, which can now be bought in almost any construction store.