Petrol trimmer does not start because there is no spark

the lawn mower won’t start after winter

In such cases, the unit must be serviced. Remove the fuel system, including filters (air, fuel), disassemble the carburetor, clean and rinse each unit. Blow out the filters with air. Pay attention to fuel quality and octane number.

It should be borne in mind that products of such well-known companies as STIHL, Husgvarna and other brands will not run on cheap, low-octane gasoline.

Suitable fuel for them is from the AI brand. 92 and higher from car gas stations and then from well-recommended ones, since there is also bad gasoline at gas stations. The use of high-octane and high-quality gasoline will determine how long the lawn mower will be used and how long it will last.

It is necessary to take into account one more fact that when the diluted fuel mixture is stored for a long time, its working qualities fall, which also leads to consequences in which the lawn mower does not start. Therefore, it should be diluted in portions, that is, the amount of the mixture that is produced at a time.

The operating instructions clearly describe and explain the mixing ratio of gasoline and oil. Strict observance of the correct proportions will at least save you from several questions, why the lawn mower does not start and what to do in such cases.

the lawn mower starts and stalls. What to do?

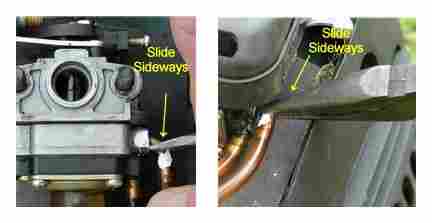

There is a spark, and everything seems to be normal, but the lawn mower will not start, in such cases, you should check the air inlet valve to the fuel tank. A clogged valve leads to the creation of a vacuum in the tank, in which the carburetor does not receive enough gasoline, so the lawn mower will start, but then stall. To exclude this cause, you need to clean the valve and try to start the lawn mower with the tank cap not completely twisted.

2. If this does not start the mower, remove and clean the fuel filter and check all carburetor parts and then try to start. The lawn mower will not start again, the air filter is disconnected, try to start without it, if the mower starts up, the reason is in the air filter, replace it.

the lawn mower will not start, the spark is gone

The loss of a spark entails checking the contacts and the correctness of the gap between them, the conducting wires to the candle and the candle itself.

The way to check the spark is to unscrew the candle, connect a wire to it, put the candle sideways to the motor casing and pull the starter several times as if starting the lawn mower, while you need to look at the coal and the contact of the candle, a spark should run between them.

If there is no spark, take a new candle, do the same procedure, if even the spark is not traced, then there is a problem in the wire or contacts, it is better to replace them.

the lawn mower will not start on a cold

When starting a cold engine, it is not recommended to press the gas. Tilting the mower so that the air filter is on top, press the fuel suction button 5-6 times, set the function switch lever to the “start” position, pull the starter cord several times until the engine starts. After a few seconds of running the motor, turn off the starting system.

The lawn mower will not start or will start but stalls. What is the reason?

To understand this, you need to know the principle of operation of the unit as a whole. It also happens that, just bought, a new saw does not start, and the running around the service centers begins, in such cases it is recommended:

carefully read the instruction manual;

study in detail the method of first starting and running in lawn mowers;

try to understand the principle of the product;

how gasoline is pumped up and so on.

Causes of malfunctioning lawn mowers:

the quality of the gasoline is poor;

incorrect proportion of gasoline and oil;

clogging of the fine filter;

the spark was gone.

the lawn mower will not start when hot

If the lawn mower was recently in operation and has not yet had time to cool down but does not want to start. press the gas trigger, pull the starter cord sharply several times until the engine starts and only then the gas trigger is released. If enough time has passed and the lawn mower has cooled down, then it is necessary to start it as if it was cold.

If the above methods did not help, the lawn mower did not start, then you should contact the service center.

- Blog

- About the service center

- Serviced brands

- Diagnostics and repair prices

- Delivery

- Spare parts

- Contacts

Repair and service of garden equipment.

Specialized service center “Agrotechservice”. comprehensive warranty and post-warranty maintenance of garden and municipal equipment from world manufacturers! We sell spare parts with delivery throughout Russia!

Trimmer malfunctions

The trimmer is a convenient and affordable replacement for a lawn mower. Its cutting part is made in the form of a fishing line, knives or a disk mounted on a drum, which is closed from above with a protective casing. The basis of the design is a bar, which is adjustable in height, at the end there is a comfortable handle and a shoulder strap.

Like any other technique, the trimmer can break down unplanned, and so that the breakdown does not lead to the final failure of the tool, we suggest that you familiarize yourself with this article. The unit can break down for various reasons. Breakdowns occur both with new trimmers and those that have been used for a long time.

DIY lawn mowers repair: troubleshooting and self-repair methods

Do-it-yourself lawn mowers repair: troubleshooting and methods of self-repairing lawn mowers.

Outlet duct diagnostics

Stable trimmer performance can be compromised by build-up of dirt in the exhaust duct or blockage in the muffler mesh. This problem most often occurs during the operation of older generation trimmer models. The issue of dismantling the anti-spark grid and cleaning it is being resolved.

Troubleshooting muffler problems

If at low speeds the engine of the chainsaw works normally, but at high speeds it starts to stall and smoke, the problem may be hidden in the muffler.

To check the quality of its work, you should do:

- dismantling (with obligatory closing of the outlet);

- disassembly (if the muffler is collapsible);

- cleaning from carbon deposits using special detergents or dry method;

- drying (using a hair dryer);

- reassembly and assembly.

To prevent clogging of the muffler during the operation of the chainsaw, you should carefully monitor the composition of the fuel mixture and the quality of its components.

Diagnostics of the candle channel

What to do if the used fuel mixture is in perfect order, but the petrol trimmer does not start as before? The reasons for the failure of the mechanism may lie in the excessive moistening of the candle channel. To diagnose and fix the problem, you must do the following:

It is recommended to dry the candle channel for at least half an hour. However, in no case should you resort to calcining its elements. After all, heating the spark plug can lead to its final damage.

What to do if the function block was serviced in accordance with the above recommendations, but the trimmer does not start, there is still a spark? In this case, it is worth treating the threaded connection with gasoline. The latter does not need to be abundantly impregnated with fuel.

It should only be slightly damp. Why the trimmer won’t start and fill the candle, why does it fill the candle on the lawn mower and how to fix it. It is necessary to resort to such actions to ensure ignition.

After all, no matter how strong a spark the candle gives, there will simply be nothing to ignite in an absolutely dry chamber.

the lawn mower does not start well, does not develop momentum, heats up

Today in the workshop there is a Polish trimmer Bass Polska. The trimmer does not start well, does not develop speed, it gets very hot and stalls. Bass Polska differs little from well-known lawn mowers, such as: ECO, Defort, Eland, Skiper, Groser, Gunter, KW, Shtenli, Belarus, Ural, Patriot, etc. Therefore, everything that has been said applies equally to these lawn mowers.

The trimmer engine can start poorly, rev poorly, lose power, and stall for several reasons. Most often this is due to fuel system or carburetor problems. Last time we cleaned the carburetor in the AL-KO trimmer (link here), which also developed poorly speed and stalls when throttle was released.

But, in this case, we have one more symptom in the history. the engine gets very hot. There are two most likely reasons why the engine can get very hot.

The first one is a faulty clutch, then the front of the engine heats up, but the engine is running normally, its rpm and start is OK. The second is a clogged muffler. With a clogged exhaust, there will be a loss of power, and difficult starting, and a loss of power.

The trimmer is practically new, but the compression is lower than it should be. We will not carry out the standard diagnostic procedure, but go straight to the muffler. Remove the protective cover and muffler.

The plugged muffler assumption is confirmed as soon as we removed the protective cover. Exhaust gases under high pressure burst through the muffler bolt. The bolt is burnt and unscrewed with difficulty.

Already by the bolts, the reason for the muffler clogged becomes clear. Less often this happens due to poor-quality two-stroke oil, more often due to the fact that the proportion is not observed when preparing the fuel mixture. Too much oil was poured, the oil did not burn out completely, carbon deposits formed in the exhaust system, which clogged the passage holes in the muffler cavity. This is exactly the case when you spoil the “porridge” with oil, I urge you once again. please strictly observe the proportion of the fuel mixture. The proportion of gasoline and oil is usually indicated in the instructions for your gasoline tool, as well as directly on the fuel tank cap. In this article, you can learn how to choose and prepare a fuel mixture for a two-stroke engine.

We open the air filter, there was so much oil in the fuel mixture that its remains are clearly visible on the filter element. Wash the filter element in soapy water, blow it with compressed air.

We measure the compression again, with the muffler removed, the compression is normal, therefore, the rest of the engine parts are in good order and suitable for further operation. Usually, in such cases, I just change the muffler to a new one.

The part is inexpensive, so there is no point in washing it in different chemical solutions, wasting time on this, especially since it is not always possible to save the muffler.

It is usual, but not today, today at the request of the client, I will open the muffler, make new holes to replace the clogged ones and weld the formed cavity with electric welding. This is another way to get the trimmer back into operation when the part you need is not available.

We cut the muffler with a thin disc, the pressure inside was so high that one of the baffles broke off. The amount of soot and varnish is amazing.

We drill holes. In this case, I drill with a thicker drill and make more holes. there is no certainty that this tool will continue to be used correctly. Looking ahead, I will say that the engine sound became lower and a little louder, but not significantly. Let me remind you once again that such repairs are extreme and only take place in exceptional cases. Defective part needs to be replaced.

You can’t even see the through hole at the top, it just got clogged with soot.

Further, everything is simple. With a low current, a thin electrode, we weld the muffler body. Putting it all in reverse order.

The scythe worked quite a bit, but the gearbox is already making noise, I lubricate the gearbox. The trimmer is good and works great.

For maintenance, repair and purchase of spare parts for garden equipment, please contact the “tiller-master” workshop. Ag. Ozertso, st. Green 18. tel. 8 017 5123712, 8 029 6741674.

Trimmer Heats Up And Won’t Start

Why won’t the petrol trimmer start? Prerequisites and their elimination

In the near future, the gasoline trimmer acquired the status of the 1st of the main tools in the arsenal of summer residents. And this is logical, because a motorized scythe allows you to quickly put your personal plot in order.

But from time to time it happens that the trimmer does not start on hot or even cool. In such situations, it is necessary to establish the cause of the malfunction without the help of others. Let’s figure out what to do if the trimmer won’t start.

The premises that more often lead to such troubles will be examined further.

Why the gasoline generator stalls

For a number of reasons, a gasoline generator can stall during operation.

The main reason why a gas generator can stall is damage to the internal combustion engine (internal combustion engine). Among them:

Dirty filters. fuel, air or oil.

When contaminated, some models refuse to start, as a result of which the supply of fuel and oxygen stops. The gasoline generator stalls. The cleanliness of all filters must be constantly monitored, cleaned and periodically replaced. Filter screens must be clean and free from oily.

The spark plug is unscrewed, the carbon is cleaned with a sandpaper or a special brush. The treated surface is wiped with alcohol. After drying, the presence of a spark is checked, the candle is installed in place. You can start the installation.

Insufficient voltage.

There are many reasons. poor contact, burnout of capacitors, wear of brushes. In this case, it is necessary to disassemble the entire unit for a thorough inspection.

Problems in the piston system, carburetor or speed governor.

Here it is also necessary to disassemble the unit or carry out major repairs.

Why the gasoline generator does not supply voltage

Sometimes a situation arises when the gasoline generator works, but the output voltage is insufficient. There are many reasons, some of them may include the following:

Weak compression. Including:

- Poorly tightened candles.

- Worn cylinder, piston, piston rings.

- Piston rod sticks.

- Worn cylinder head gasket.

All problems can be solved by repairing or replacing the necessary parts. In some cases, just tighten the bolts tighter.

Ignition problems.

- If necessary, replace the coil and spark plug.

- If the air gap between the coil and the flywheel is not in accordance with the standards, it must be adjusted.

- If the magneto is demagnetized, it must be replaced.

Fuel system problems.

- It is necessary to sort out and thoroughly clean the carburetor.

- All connections in the fuel lines need to be checked and adjusted.

- If the hose becomes clogged, it must be cleaned or replaced. Likewise. with a fuel filter.

Weak air flow.

- If the air filter is clogged, it should be cleaned or replaced.

- If the fuel valve breaks down, it must be repaired or replaced.

Major breakdowns of gasoline generators

Any technique starts to fail over time. This can happen for a variety of reasons. The gas generator may also stall, the diesel unit may stop working.

A gas generator is a device that converts heat energy into electricity. The unit consists of two main parts. an engine and an electric generator. The engine drives the generator shaft, which produces a specific voltage.

Why the gasoline generator won’t start

Periodically, the gas generator refuses to start. There may be several reasons for this, each of which has its own way of elimination.

There is no gas in the tank.

A person may forget to fill the fuel tank, or incorrectly calculate the required volume of fuel. Particular attention should be paid to the motor that drives the unit. It is necessary to add both gasoline and oil to the tank, which is necessary to lubricate the various rotating and rubbing parts of the generator. When inspecting, it is necessary to check the path through which fuel is supplied to the carburetor, in addition to this the engine cylinder. You should also make sure that there is enough oxygen supplied, otherwise the gasoline will not burn.

Condensation in the fuel tank.

Condensation is inevitable with significant temperature changes and high humidity. To solve the problem, it is necessary to drain the fuel, dry the tank, for which you should leave it open for a while. After 4-5 hours, the gasoline previously drained from the tank will sufficiently settle.

No spark in the spark plug.

It is easy to check. just unscrew the spark plug and touch the electrode to the metal and the engine casing. The candle must be held by the insulator; for safety reasons, other parts of the candle must not be touched. If there is no spark, this means either wear of the plug, or the need to replace the lead wire.

Discharging an acid battery.

Some models have it, others do not. In models where it is provided, it provides starter operation as well as ignition. An acidic battery needs to be recharged periodically.

Fuel pump problems.

The fuel hose is disconnected. When the engine stops, it must be cranked 2-3 times with the starter. A jet of fuel should appear on the fuel hose, which is supplied under pressure. In the absence of a jet, the fuel pump needs to be repaired.

Useful Tips

The three main components of the smooth operation of a gasoline engine are gasoline, spark, oxygen. If the engine of a gasoline generator does not start or begins to malfunction, the problem will inevitably lead to one of these components.

The spark is checked first. The spark is checked after each action. Topped up the oil to the level. check the spark. If the oil sensor sticks or there is a malfunction in the ignition system itself, it is worth contacting a service workshop.

Check the air filter if spark is present.

To check, it is enough to remove the filter and try to start the engine without it. If the engine starts, the problem is in the air filter. It needs to be cleaned or replaced. The engine starts up for a very short time during the check, otherwise new problems may arise.

If after the above manipulations the engine does not start, you need to check the fuel system.

To check it, you need to find the drain screw (most often at the bottom) and drain a small part of the fuel. Then make sure that the fuel flows into the chamber. If it passes, try to start the engine. If the fuel does not pass. look for the cause of the malfunction.

Why the gas generator won’t start?

Over time, even the most reliable and high-quality equipment can malfunction (the gas generator does not start for reasons). The gas generator is no exception. There can be many reasons for this.

Most owners begin to panic and seek help from specialists, but in fact, some malfunctions can be fixed on their own, so to speak at home.

In this article, we will tell you what reasons may be due to what not

gasoline power plant starts up, and how can this be dealt with.

There may be several reasons why the gas generator does not start.

So, let’s consider the possible reasons why the gas generator does not start at all, or why when it starts, it immediately “stalls”.

The three main components that keep a carburetor engine running are gasoline, air and spark. You probably already guessed that we need to check these three devices, which are necessary for the engine to work properly.

Lack of gasoline in the tank

The owner of the gas generator may incorrectly calculate the required volume of fuel or simply forget to fill the fuel tank.

First, you need to check the path (through which fuel is supplied to the carburetor).

Secondly, the gasoline mixture may be outdated, that is, which has lost its octane properties.

What can be done? Pour fresh mixture into the fuel tank and try to start the generator again.

It is important to remember that there is a tap on the pipe under the gas tank. So, you need to carefully monitor that it is open.

Fuel hose

Need to check if it is leaking? If it leaks or becomes unusable, replace it.

No spark.

The generator may not start because there is no spark.

What to do?

First you need to unscrew the candle, check its condition, the presence of a spark, if necessary, replace with a new one.

In the event that the candle is filled with a fuel mixture, it must be unscrewed and dried.

Carbon deposits on the candle. clean it with an awl or needle, the electrodes can be cleaned with sandpaper. If there is a strong carbon deposit, then replace it with a new one.

Dry candle. this means that there is a problem with the fuel supply to the cylinder.

If there is a spark and the generator does not start, most likely there is no fuel in the carburetor.

Another reason why there is no spark is the possible sticking of the oil sensor.

If there is no spark, pay attention to the oil level sensor

Learn more about the oil sensor and the oil itself.

Air filter

The next possible reason why the generator does not start. the air filter may be dirty. An unclean filter prevents the passage of the air required for fuel combustion.

What can be done?

Remove it, rinse it or clean it thoroughly, dry it, then reinstall it.

Important to remember! When starting the device, the air damper must be in the “closed” position.

If the engine fails to start, then we check the fuel system.

A little about the fuel system

Causes of fuel system malfunctions:

– fuel does not enter the float chamber;

– fuel has lost its properties during a long idle time.

What can be done?

1. You need to find the drain screw on the carburetor float chamber,

2. Then, using a small container, drain some of the fuel from the float chamber.

3. Make sure that fuel enters the float chamber.

If none of the above helped, then you should contact experienced specialists at our service center by phone: 063 202-90-70 097 023-42-42. Most likely, the cause of the malfunction of your gas generator is in the carburetor, and this is already the work of professionals. Our specialists will be able to accurately identify the causes of malfunctions and eliminate them in a short time.

How to follow the startup procedure correctly

1. First you need to turn on the generator using the key or button to the “ON” position;

2. Then open the top tap;

3. Close the choke on the carburetor;

4. It is necessary to abruptly (it is a prerequisite), pull the manual starter or electric starter.

My weedeater has spark and fuel but it still won’t start

It can be concluded that if you monitor the cleanliness of the air filter and spark plugs, do not start the power plant under load, close the air damper of the generator, leave the fuel valve open, then these simple rules will allow you to extend the life of your gas generator.