Punch what effort should be attached. How to use a perforator correctly

TOP-20 of the best peorators for home and work: Rating 2020-2021 by reliability and quality

The master working in dwellings, where the walls and ceilings are made of brick and concrete, is necessary as air. How to choose a home.makeer that meets precisely your needs, how different models differ, what to pay attention to when buying. these and many other questions do not have a definite answer. We’ll figure out.

The peorator is a specialized power tool, the main task of which is to make holes in concrete, brick and similar solid materials. Most models have a modes switch that turns off the rotation of the spindle and converts the tool into a detection mode. In this mode, it works as an electric jack of a hammer.

What is the difference between a drill and a penetrator

The drill is designed for drilling. Peorator. for drilling. General in these modes only rotation of the working nozzle.

The photo shows a drill and a drill. The drill rotates and cuts off the layer of material with a sharp cutting edge. Characteristic spiral chips are formed.

A carbide nozzle with sharp triangular faces is fixed on the edge of the drill. The drill rotates and at the same time a special mechanism of the penetrator strikes it with blows. The material crumbles, the resulting crushing products are removed from the opening of the spiral part of the drill.

Differences of the drill and the pea not only in the nozzles used. Internal constructive differences are much deeper. The shock drill is equipped with a ratchet. When the user presses on the tool when drilling, the ratchet, as it were, “crushes” the power of this press. At the same time, “drilling with a blow” is imitated.

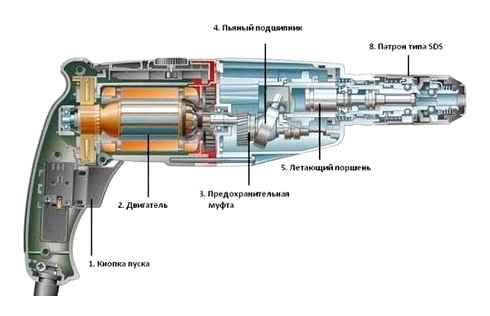

Unlike the drill, the peorator has a special pneumatic piston, which is driven from the electric motor and strikes on the back of the working nozzle.

The drill is tightly clamped in a drill cartridge. The boat is fixed in special grooves, which allows it to move along the longitudinal axis and at the same time transmit the rotation of the spindle.

The video shows the fundamental device of the penetrator.

Generalizing the differences in the drill and the coorator comparable to it in the table:

| Drill | Peorator | |

| Power (typical) | 300-800 watts | 550-1500 watts |

| Rotational speed | up to 3000 rpm. | Up to 1500 rpm. |

| The energy of the blow | No | 2-3.5 J |

| Types of jobs | drilling, screwing screws | drilling, detected, drilling, screwing screws |

| Equipment | Brown, crowns, bits, etc. P. (clamped in a fist cartridge) | Boers, chisels, crowns with a special shank. Drive, crowns, etc. P. (using a special adapter cartridge). |

| Price | relatively small | Big |

Choose a peorator. characteristics that need to be taken into account

Therefore, when choosing a peorator, they are necessarily guided by its constructive features and technical characteristics: engine power, a single impact energy, the diameter of holes drilling, the speed of rotation of the cartridge, the speed of shock, weight.

Peorators can be horizontal and vertical.

In the first case, the electric motor has a parallel orientation relative to the shock axis.

In the second. perpendicular, in connection with which the appearance of the peorator resembles the letter “l”.

Horizontal devices are more practical, they can work in uncomfortable narrow openings. Most household devices are produced in this performance.

The advantage of vertical peorators in their greater power and the presence of the best motor cooling system, therefore it is a prerogative of professional tools.

Number of modes

The operating modes of the device are the most important component when choosing.

When buying a penetrator, it is important to have a concept of possible modes of its work.

This is drilling, drilling, blow.

-

The “drilling” mode is similar to a conventional drill and is designed to form holes in relatively soft materials.

One, two or three operating modes may be maintained depending on the model of the penetrator. The best option is to buy a triple peorator.

Type of cartridge

In 1975, Bosch has developed SDS series cartridges. To install the equipment in them, it was not necessary to use the key-the drill was fixed with one hand (“STECK-DREH-SITZT”. “Insert-twist-preparation”). Technology was adopted from other brands. Now SDS cartridges are the gold standard.

-

– The most common type of cartridges. Found on light and medium models. Fixes the shanks with a diameter of 10 mm with four grooves type of cartridge for heavy peorators. Works with shanks with a diameter of 18 mm and five grooves.

The remaining types of cartridges are rarely used. SDS-Quick was used only on the Bosch UNEO series. SDS-HEX is suitable only for peak and chisel, but it cannot work with boors. Found on powerful units.

Source of power

Peorators can work from a network, battery or compressor. Each type of tools has its pros and cons:

- Network models are connected to the outlet. Suitable for long.term work, do not lose power with long drilling. The main minus is to move around the working site is inconvenient. If the cord is not enough, it may require an extension cord. Far from the outlets, you can work from the generator mobile. They are easy to use in the room (even de.energized) and on the street. you will not have to take a generator with you. Nickel-cadmium batteries lose power as they are discharged, and lithium-ion batteries have no such problem. The total minus. battery tools are more expensive than network, and the time of working with them is less.

- Pneumatic models work on the strength of compressed air and are connected to the compressor. There is no electric motor and battery in the design, so the case weighs less, and it is easier to serve it. The pneumoporatories are fireproof, they can be used in de.energized, polluted and dusty rooms. The main minus is a high price.

Spindle rotation frequency

The peorater shaft has a lower rotation speed than that of a drill. Each model has its own rotation frequency. In different models, it is 600-1500 revolutions for a minute. The more powerful tools, and the higher its performance, the lower the speed of rotation, since the productive devices are characterized by a fairly large diameter of the equipment.

Types of cartridges

SDS-Plus-installed on small models weighing less than 4 kg. The size of the diameter that can make such equipment is about 3 cm. Devices of this type are the most popular among buyers, since they are able to fully satisfy everydays.

SDS-MAX-such cartridges are used to equip professional tools weighing up to 11 kg. The size is large enough, and the diameter of the hole that they are able to do is about 5.2 cm.

SDS-TOP-usually used in Bosch peorators. The diameter of the holes that they break through is 1.6-2.5 cm.

Working modes

The peoporator can not only punch holes, but also perform other functions, for example:

- Ordinary drilling. This mode is no different from the function that the electric drill performs. It can only be used to drill materials with low density, for example, wood.

- Drilling with a blow. This regime is used to perform the progressive-sized drill movements. Almost all peorators are equipped with a drilling function with a blow. Apply it to work with solid materials.

- Hit. In this mode, the tool performs not rotational, but shock movements by type.

When choosing a peorator, you should pay attention to the number of modes that the tool can support. Professionals recommend that you choose devices that support at least two operating modes.

Built.in functions

The built.in functions of the peorator include the following:

- A special limiter that allows you to determine the moment when the drill has reached a mark.

- The speed switch button is required to switch from the drill mode to the drill and vice versa, since they work at different speeds.

- The function of twisting the shaft in the opposite direction may be required when the drill is stuck in a solid surface.

- Overheating protection function and soft start. contribute to protecting the tool from breakdowns.

Types of equipment

When choosing a tool, it is also important to pay attention to the presence:

- Burov of different lengths, which should have all kinds of tips necessary to break through holes.

- Peaks that allow you to knock out horizontal excavations of large depths.

- Shoulder blades, with which the tiles and other facing materials are cooked, very firmly attached to the construction surfaces.

- Special nozzles that allow you to make round holes.

What characteristics are important when choosing a peorator for home

Before choosing a home.made home and buy it, we advise you to pay special attention to the following characteristics:

- quantity and type of regimes;

- power;

- impact energy;

- quantity/frequency of strikes;

- type of cartridge;

- The location of the engine.

Number of modes. The main regime of any pedorator is a jack of a hammer “. The more modes, the wider the functionality of the tool, and the more types of construction work can be performed with its help.

Power. In itself, the capacity of the penetrator for domestic and semi.professional models ranges from 0.8 to 1.8 kW. This is a rather conditional parameter, since depending on the design features of its efficiency can be different. At the same time, it is he who indirectly affects other important parameters: impact strength, speed of revolutions and torque. The higher the power. the greater the performance of the pedorator, however, at the same time its weight. For home use it is better to look for a middle ground.

Additional functions of the penetrator

The convenience of using and the effectiveness of the power tool for drilling holes is determined not only by technical characteristics, but also by the presence of additional options. This is especially important for those who plan to not only choose a peorator for a home, but also work for them often and for a long time.

Another important point, which must be taken into account before choosing a particular brand, or a certain model. its equipment. The wider it will be, the fewer additional accessories will have to be acquired in the future. The quality and compatibility of branded drills, cartridges, brushes and other components included in the set is usually significantly higher than those that can be freely purchased separately. In addition, it is far from always possible to say which of them may be required at a certain moment.

The peorator is the same thing that the shock drill?

Among the population there is an opinion that the shock drill has exactly such a principle of action, as well as the tool under consideration. Therefore, the question is often asked what is better than a drill or this device. However, this is not at all. Although many people call the shock drill, the principle of operation of both types of power tools is very different. If you look at their purpose, then yes, they can make holes, however, the impacts produced have a different effort, as well as other origin.

For example, a shock drill for professional use can be operated as a chipper due to the use of gear, which is called rattling. If you make efforts on the drill, then oscillatory movement will appear along the axis, which makes it possible to make holes. However, counting on high efficiency is not worth it, the strokes inflicted are not too strong. That is why a very solid concrete surface is not to break through a similar drill.

The concrete peorator is specially created in order to make holes in solid concrete, brick or stone. You can also work with it with a spatula, pika or drill nozzle. You can also, for example, install the nozzle of Shtrobert to make small strobes. How to make the strobes we told the water of our articles, if it is interesting, you can study.

The main constructive part is the mechanism of electro.pneumatic or electromechanical action. It is thanks to this mechanism that a shock force is obtained, which breaks holes in stone or concrete. A feature will also be that the worker will not need to apply a lot of effort on the handle. There are such models that the shock part is made exactly the same as the drill. However, this design will have less strength than pneumatic or electromechanical.

If we compare when a peorator or drill is selected, that is, between pneumatic and mechanical systems, then it can be said right away that the pneumatic will allow you to work, applying less effort. Using the mechanical system, you will have to apply up to 3 times more effort than working with pneumatic. That is why, understanding how to choose a peorator for home, it is better to immediately look closely at modern pneumatic, and it is better to leave outdated mechanicals at rest.

What will be more profitable for a shock drill or a peorator should be solved in each particular case.

Nuances while choosing

I can say right away that the tool can have 1 mode of operation, two (that is, hit and drilling), as well as 3 (drilling, shock function and deterrence). devices can be divided into light, medium and heavy. So, the most difficult can weigh from 5 to 10 kg, medium weight. 4. 5 kg, and lungs no more than 4 kg.

Impact strength

One of the main conditions that need to be paid attention to when it turns out which peorator is better to buy for home. As you can understand, it is the main characteristic of the choice of the device. In order to measure the impact force, joules are used. So, the best home peorators can give out from 8 to 15 j. Simple models will work with an effort of 1-2 j. The relationship is simple. the greater the power of the blow, the more hole you will receive. If it has an insignificant indicator, then it will have performance not much better than the shock drill. During operation, such a device will not sell a hole, but simply drill it. In the process of such work, his nozzle will be very quickly washed out, and getting high efficiency will not work.

Continuing to talk about the energy of the impact and how to choose a peorator for homework, it is worth saying that it will not be dependent on what effort you will press on the handle of the tool. The shock drill will be the opposite, there the pressure force is crucial. So, if the consultant in the store tells you about the increased impact power in the model you like, then you should not believe it. You need to know that if the blow energy is more than 10 joules, then the device will quickly fail. All because with such significant loads, refractory elements of the tool will collapse very quickly.

The frequency of strokes

The frequency of strokes is called the number of piston strikes about its boiler. The higher this value, the greater the speed of the holes, for example, by concrete, will be. The total efficiency is just depending on the strength and frequency of the impact. If these two indicators are most harmoniously combined, then the best peorator for home is obtained. That is why, making a choice, you need to look closely at reliable brands that have already established themselves durable and quality products. That is, it is still necessary to study the peorator of which company is the most popular and famous.

Power

Continuing a conversation about how to choose a few words about the right home about power. This tool is not as powerful as drills. This is due to the fact that drilling is much easier than drilling. In this regard, they do not have such a high speed. The power of the devices will vary depending on the cartridges used. So, the cartridges of the type of SDS-Plus will require 400-800 watts, and the SDS-MAX 1-1.2 kW cartridges. In general, choosing the best peorator for, do not focus on power, t.to. it will not be the main characteristic.

Spindle rotation speed

As mentioned above, even a professional tool does not have a high speed of rotation. It varies in the range of 600-1500 rpm based on the class class. The speed of rotation will decrease with an increase in efficiency and power. Everything is explained by the design features of the devices: powerful models have quite large working tools. In principle, rotation is necessary only in order to remove dust from the hole. So, a small working tool needs to move faster, and a large one is slower. Otherwise, the massive nozzle will soon grind soon.

Those devices that have a high speed of the shaft have a significant weight, and this does not add convenience when using. In addition, such devices have a quick wear of spiral grooves that are necessary in order to remove drilling waste.

Maklaus Macro Perforation systems

Thinking about how to choose a good peorator, people do not always pay attention to another significant parameter. This is the option of fastening the drill. Now there are 3 ways. If you have enough a small tool (up to 4 kg) that it is worth choosing an SDS-Plus mount option. A similar cartridge will make holes with a diameter of not more than 3 cm. Most often, for domestic use, the choice of this option will be sufficient, it is the most popular.

A heavy, professional good peorator for a home has a cartridge of SDS-MAX system. It has decent dimensions, but the holes are impressive. up to 5.2 cm.

Relatively recently began to be used another option-SDS-TOP. It is able to produce holes in the range of 1.6-2.5 cm. Most often, such a mounting system is used in Bosch devices.

Now we will consider what different models will differ, which have different number of operating modes and how to choose a peorator for the repair of an apartment.

The simplest are single.mode. They will act in the same way as ordinary drills. If you need to process only metal and wooden structures, then they will suit you.

Tools with 2 operating modes have an axis that can not only rotate, but also perform oscillatory movements.

Devices with 3 modes can strike without rotation of the shaft axis. Such a tool is the most universal, as it is able to perform three different types of work.

Of course, each manufacturer can vary the number of operating modes. However, if you take into account the last type, then of course, it will be more expensive than the rest. However, the choice of such a tool will certainly be successful, as it will help you do a large amount of work.

During the choice of the tool, its design and shape will play a significant role. It should be supported in his hands, feel his ergonomics and understand that it will be convenient to work with him. It is also necessary to look at the presence of lateral handles. They must be removable. They should be removable because you will probably need to drill in tight corners, and having removed the pens, you will greatly simplify your task. These nuances should be taken into account when it is necessary to understand which peorator is better to buy for work.

What to choose a peorator: the top 13 of the most popular models

A pediatrician is an important tool that is necessarily present in a set of any builder, mechanic or master. With it, you can make holes even in strong materials like thick bricks. unlike a drill, the peorator is more powerful and has shock force. This is the basic principle of the penetrator’s operation-with the help of shock and mechanical rotation, the cartridge-prison pierces the hole in concrete, brick, wood or other material. In this sense, the peorator looks like a jack of a hammer.

At the moment, a huge number of peorators are presented on the market. They differ in their technical characteristics, purpose, mechanism of work, cost. Because of this, it can be difficult to choose a suitable peorator. In addition, people often confuse the peorator and shock drill, which is why they risk buying an inappropriate tool. To avoid improper choice, you need to learn more about the peorators and their difference from other tools.

What are the peorators

Peorators are distinguished by the following signs:

- power (domestic, semi.professional and professional);

- type of fastening of the nozzle;

- type of mechanism of the shock system;

- the location of the engine in the penetrator;

- type of power;

- number of operating modes.

Different peorators differ in power, which is calculated in Joules. Household peorators weigh no more than four kilograms and have a capacity of up to five joules. There are enough of them for home repair work, they are suitable for giving or for garage. Such peorators are suitable for simple work and are relatively inexpensive. Semi-professional peorators are more powerful-within 5-7 joules. They weigh significantly more (up to 8 kilograms) and can be used for serious construction tasks. They withstand work in continuous mode and solve the problems “on the stream”. Such peorators will cope with most of the tasks: they will extend concrete walls, partitions or even steel grilles. Professional peorators are the most powerful. they are intended for professional builders and repair teams. The cost of the orator is growing as its power increases.

Peorators are distinguished by a type of attachment. There are three types-SDS Plus, SDS-Max, SDS-Top. SDS Plus-mount for inexpensive household or semi-professional universal peorators. SDS-Max is used in professional devices. SDS-top is a highly specialized cartridge, which is designed to drill small holes, this type of fastening is reliable and durable.

The mechanism of the shock system is pneumatic and electromagnetic. In most cases, a pneumatic system is used in the shock mechanism. The electromagnetic is specific and requires more accuracy, but the holes are faster and the mechanism itself is more durable.

The pedorator engine can be located vertically or horizontally. Vertical peorators are shorter and therefore they are better cooled and can work without breaks for a long time. But they are bulky and it is harder to use in hard.to.reach places, so in most cases the engine is located horizontally so that it is more convenient for the employee to use the tool.

Inexpensive household peorators usually work from the network, while more professional models are often equipped with a battery. Naturally, the transcript with the battery is more convenient. it does not need wires when working. The difference in power between them is vanishingly small, so both types are used by professionals. In everyday life, the battery can also be useful, but the presence of the battery automatically increases the cost of the tool two to three times, so you need to choose based on your needs.

The last difference between the peorators is the number of operating modes. In inexpensive models, two operating modes. drilling and drilling. There are three of more expensive professional models: drilling, drilling and only blows. Thanks to the third mode of operation, the peorator can be used as a jack of a hammer, which is often necessary during construction or repair.

What the Peorator can? How it is arranged?

Is it possible to do without a penetrator on the farm?

How they made holes in concrete before? For this, a special tool was used. Shlyambur. In fact, this is a hollow pipe of the desired diameter, according to the end cut of which were cut by the “crown” teeth.

The older masters are very well familiar with this simple “hand.peopor”. Shlyambur

The holy was prepared for making holes, a weighty hammer. A clean rag turned out to be useful in order to periodically wipe the sweat rolling down his face from excessive efforts, and a set of “strong words”, which helped to transfer the pain easier when the hammer was not on the gentry, but on the fingers of his hand holding his hand. In the process of such deterrence, the playback periodically turned around the axis, and the process continued until the hole reached the necessary depth. Then, a tattered wooden cork was most often firmly driven into it, into which it was already possible to either hammer a nail, or screw the screw.

Performance?. Yes, no! The speed of making holes?. It’s how lucky. It happened that such a strong fragment of crushed stone filling came across, that the “procedure” demanded several visits with breaks, and sometimes even had to refuse the opening started. Even worse, if a reinforcing rod was met in the way of Shlyambur.

The author of these lines received his apartment at the end of 1991. New reinforced concrete nine.story building with bare uninteened walls, nightmares with wild slots along their perimeter. There was no experience in building work in his youth. had to study on the go. It was also very not rich with the instrument, but there were a hukebur and a hammer. And the process of hanging lockers on the walls and cornice-string on the ceiling-crashed into memory very well.

Being on a business trip. On the Tushino radio market, I acquired an electric drill of the Voronezh assembly “Energia”. At that time. a real “miracle of technology”, even with a regulator of the number of revolutions on the trigger key. But the most important thing. the kit included a nozzle designed for shock drilling.

A drill nozzle, which created a certain effect of drilling work

A cartridge came from a drill, then a nozzle was put on a cylindrical neck near the spindle and was tightened with two screws. There were two slots on the spindle, which entered the gearing with the hole in the gear lobby located inside. After that, the cartridge was already screwed to the spindle of the nozzle, it was possible to install and drag on the drill and start work.

The principle was simple “before I can’t”. the transmission of rotation was carried out through the coupling, which has a gear notch, which, when pressing a drill to the surface where the hole was made, slipped along the same gear notch in the nozzle case. This was created, in addition to the torch, also the semblance of the progressive drill drill. By the way, it is on this principle that many electric drifts still work, positioning as equipped with shock function.

The principle of creating a progressive force by transmitting rotation through a couple of gear fruits is still used in many models of electric drifts. The scheme is extremely imperfect, and in the peorators everything is much more complicated.

I can’t say that work with such a nozzle went “like clockwork”. So that such a “shock impact” gives at least some visible effect, it was necessary to lean on the drill with all its mass. But in many areas (for example, when drilling holes on the wall in the area under the ceiling), such an effort was simply impossible, and it turned out more cod without any visible benefit. Winner drill with such drilling in concrete “licked” very quickly. And what is the worst. the gearbox of the drill was terrifying, that is, I had to make frequent and very long breaks in work. The process was built from alternating operations of drilling and processing holes by the player if a solid pebble came across.

In short, hopes were clearly not justified. Therefore, after 8 years, when the overwhelmed repairs, already at a higher level, the drill as an instrument for such operations was not even considered. was not even considered. During this period, the peorators were no longer at all a curiosity. And in advertising newspapers there were many announcements with the offer of such services. the happy owners of the tool made a good business on it. The call on such an ad informed about the price. the dollar for one crumpled hole! The work was a large.scale work, so it was decided that it would be cheaper to purchase its own peorator. At the then level of salaries, the acquisition was nightmarely ruined (comparable to the monthly pay), but never regretted it. Since then, the peorator (already the third in 17 years) has always occupied an honorable place in my instrumental set. over, the for such a tool have not become so “biting”.

Here he is, the “old man”, repeatedly repaired, but still faithfully served for more than ten years. For some reason, the hand still does not rise to throw away.

In a word. there is no doubt! The peorator should have a good host. such an instrument will always find application. And the owner will get rid of many problems with a variety of operations both during construction or repair, and in everyday practice.

What is the focus on when choosing a peorator for home?

First of all, that all the pearators are customary to conditionally divide into three categories. The first includes relatively light models, weighing up to 4 kilograms. “Middle Ages” are usually pulled by 4 ÷ 6 kilograms. And. Finally, a lot of powerful professional models can significantly exceed even 8 ÷ 10 kg. Accordingly, the working capabilities of the tools also change this criterion: if the first is designed for periodic use for drilling small holes or making a fine in a rather supple wall material, then heavy peorators are able to cut through the through channels of large diameter even in concrete monolith, demolish powerful partitions, dismantle thick screeds and t.P.

In a word, even before going to the store, the potential owner must quite clearly imagine what tasks he will set in front of his peorator.

It was, so to speak, unofficial classification. Now let’s turn to operational indicators, which are necessarily prescribed in the technical documentation of the product.

Power consumption

It may seem strange, but this is a parameter, unlike many other power tools, in this case it is by no means a decisive. Of course, attention is paid to him, but against the background of other characteristics its meaning is not so great.

If you even compare, for example, models of the first and second “weight category”, you can see that the difference in their power is not so expressive. So, the orators with the SDS-Plus cartridge can have a power of 400 to 800 watts. And for models with the largest cartridge, SDS-MAX, it is considered quite normal in 1000-1200 W. It is rare, when the power reaches 2000 watts in the most severe peorators. but there it is justified, since when drilling a large diameter holes, the crown experiences a tremendous resistance to friction force.

In small diameters, the main role is played by shock exposure, and the spiral part of the drill to a greater extent performs the function of the screw that removes the crushed material outside.

The speed of rotation of the working spindle

It is definitely smaller than any of the drills. And chasing some high indicators-is not required at all. A normal indicator for the penetrator is the range from approximately 500 to 1500 rpm. By the way, with the growth of the device’s power, as a rule, the number of revolutions even decreases. this, according to the “golden rule of mechanics”, is due to the specifics of the tool. In addition, high speeds will certainly lead to a very rapid wear of equipment. As a rule, in high.quality models, the developers have achieved the perfect “harmony” of the speed of rotation and the shock effect of the tool.

True, the function of changing the number of revolutions, although it is not considered “vital” in this case, will still not be superfluous. this parameter can be varied depending on the type and diameter of the applied equipment used. It is very convenient if the tool is equipped with a smooth speed set system. this allows you to prevent errors at the initial stage of drilling holes.

The traditional placement of the rotation speed regulator is on the launch key

Some modern models, in addition, are equipped with an electronic system for maintaining a stable number of revolutions under load. That is, depending on the density of the material in which the hole is made, the automation selects and maintains the optimal rotation mode. The function is useful, but accompanied by the complication of the tool and the growth of its value. How much this is required by the future owner. let him decide for himself.

Energy and frequency of impacts

But these two indicators directly affect the performance of the penetrator. If the crushing effects of equipment on the material will not be enough, that the tool itself will become no better than a conventional drill.

The energy of the blow is pleasant to evaluate in Joules (J). Even at the very “weak” peorator, it should still be at least 1 ÷ 1.5 J, otherwise the acquisition completely loses its meaning. In powerful models, this indicator can reach 10 or more j. Naturally, they can drill holes and channels of large diameter. But, as a rule. This is the lot of professionals.

The frequency of impacts also affects the productivity of the tool. the more strokes per unit time is on the processed material. the sooner the expected result is achieved. True, any “canons” of the assessment is not put forward here. As already mentioned, high.quality peorators are very balanced systems, that is, the developers laid the “consensus” of all significant parameters.

That is. an extra reason to purchase an original tool of a well.known manufacturer.

Possible mode of operation of the penetrator

But this is a very important selection criterion. The fact is that even one manufacturer can produce very similar models, but with a complete or “truncated” set of possibilities. That is, again, the character and the scale of the upcoming work should be represented.

- Peorators are produced, which have exclusively one function. shock drilling. In principle, this is the basic purpose of the primary.class tool. If this option is quite happy with, you can save a lot on the cost of the purchase.

- The function of conventional drilling, that is, without progressive impact on the drill. True, for its use you will have to purchase a special equipment. It can be a drill with sds shanks. I must say that they do not “shine” with a wide range of diameters, and quite enough. Therefore, more often they choose another option. they acquire an additional cartridge (cang or fast.sounding), equipped with a shank suitable for the selected peorator. Sometimes such a cartridge enters the base set.

In fairness, we note that the function of ordinary drilling cannot be attributed to the main. Both in terms of accuracy of work and by performance, the usual drill will significantly surpass the peorator. Of course, having an additional low.cost device for performing such operations will not hurt. But if there is a high.quality drill in the farm, then on the absence of this function, the peorator can not focus on special attention.

Checking the quality of the goods

Upon your claim, the seller has the right to check the quality of the goods. In this regard, we remind you of the need to provide the purchased goods along with a claim to the return point of the goods or provide the seller with the opportunity to pick up the goods to be delivered to the authorized service center to confirm the deficiency.

A delivery service employee fixes the fact of receiving the goods on the diagnosis by the relevant act filled in duplicate, one of which remains on the hands of the buyer.

Based on the results of such a quality test, the seller will provide you with a response to your claim.

If you do not agree with the results of the quality check, you have the right to submit a written requirement for an independent examination of the goods. Examination is carried out at the expense of the seller. You have the right to be present during the examination. If the examination establishes the availability of deficiencies that arose not through the fault of the store or manufacturer, you must compensate the store for the expertise, as well as expenses related to its conduct.

Article 26.one. Remote method for selling goods

The retail purchase and sale agreement may be concluded on the basis of the consumer’s acquaintance with the seller’s description proposed by the seller through catalogs, avenues, booklets, photographs, communications (television, postal, radio communications and others) or other excluding the possibility of directly familiarizing the consumer with a product or a model of goods under concluding such an agreement (remote method of selling goods) in ways.

Perforator Punch Super 600

The seller must be provided to the consumer to the consumer about the main consumer properties of the goods, about the address (location) of the seller, about the place of manufacture of the goods, on the full company name (name) of the seller (manufacturer), on the price and on the conditions of purchase of the goods, about his delivery, service life, expiration date and warranty period, on the procedure for payment of goods, as well as on the period during which there is a proposal for the conclusion of the contract.

At the time of delivery of the goods, the consumer must be provided in writing about the goods provided for in Article 10 of this Law, as well as the information provided for by paragraph 4 of this article on the procedure and the deadline for returning the goods.

The consumer has the right to refuse the goods at any time before transferring it, and after the transfer of the goods. within seven days.

If the information on the procedure and terms for returning goods of good quality was not provided in writing at the time of delivery of the goods, the consumer has the right to refuse the goods within three months from the date of transfer of the goods. The return of goods of good quality is possible if its presentation, consumer properties, as well as a document confirming the fact and conditions for the purchase of the specified goods are preserved. The absence of a document confirming the fact and conditions for the purchase of goods does not deprive him of the opportunity to refer to other evidence of the purchase of goods from this seller. The consumer is not entitled to abandon the goods of proper quality, which has individually defined properties, if the specified product can be used exclusively by the consumer acquiring it. If the consumer refuses the goods, the seller must return him the amount of money paid by the consumer under the contract, with the exception of the seller’s expenses for the delivery of the returned goods from the consumer, no later than ten days from the date of presenting the consumer of the corresponding claim.

The consequences of the sale of goods of inadequate quality by a remote way of selling goods are established by the provisions provided for in Articles 18. 24 of this Law.