Put the ignition on the gas tanker Huter. Magneto – design and scheme of work

trimmer for grass what gap on the coil

The most vulnerable element of the carburetor engine is the spark plug. This also allows us to judge the possible causes of the failure of individual nodes of the gasoline engine. The following procedure is recommended.

The gap should be adjusted when installing a new electric module on a magnetic engine. The optimal distance between the flywheel and the ignition coil for most chainsaws is 0.2-0.4 mm.

With such a small gap, an accessible measuring device cannot be used for direct measurement. In practice, Husqvarna saws are used, cut out of thin and flexible sheet material of the desired thickness. When it is installed, it is clamped in the space between the flywheel and the reel, and then removed.

To avoid ignition adjustment, use the tool carefully, avoiding blows. In particular, this applies to chainsaws with electronic chips in the ignition system, since they are very sensitive to mechanical damage

Settling of the ignition on the trimmer. How to set a ignition on a benzoca

On gasoline trimmers, both two.stroke internal combustion engines (ICE) and four.stroke. But the ignition system there is no different from each other, so the repair and configuration of this complex of accounting programs for ignition of fuel will be identical to different types of internal combustion engine.

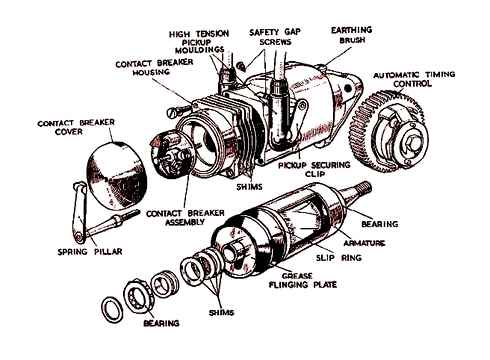

The ignition system of a two-stroke ICE consists of 2 parts: flywheel and coils (magneto). The figure below shows how they look.

There is a impeller on the flywheel, which works like a fan for cooling a motor. There are also permanent magnets on one side of the flywheel, the figure is shown by the arrow.

Passage POP Design and Smart Storage space.

When the flywheel rotates in the coil, an electric current is produced, which serves for a spark on the spark plug. The spark appears at the moment when the magnets are directly under the magneto.

From time to time when the engine does not start, the ignition adjustment will be necessary. Naturally, first you need to check the serviceability of a candle and a high.voltage cable with a cap.

It is necessary to adjust the ignition on a two.stroke engine to ensure timely ignition of fuel in the combustion chamber of the motor. Below is a scheme, you can understand the principle of operation of the internal combustion engine.

The spark in the candle should appear at the time of compression of the fuel piston, when it does not reach the top of the upper dead point (VMT) more than the best. When the piston passes through the VMT, the fuel mixture is ignited, under the influence of which the piston goes down under the action of the energy of the explosion.

If for at least any reasons (to a greater extent this is due to the shift of the flywheel to the shaft relative to its starting position), the fire of fuel occurs earlier than the piston passes, then it will come back, and the crankshaft scrolls in the opposite direction. Such a movement can damage the starter knot, cut off the launch cord, etc.D. Then there is an early ignition of fuel.

Also, you will like a later ignition on the trimmer more for you: the piston after compressing the fuel, which did not ignite, goes down, and in this case there is a spark. Then the engine will either not be launched or significantly lose power and will be poorly gaining momentum.

But such tasks with early or late ignition on two.stroke ICE are quite found from time to time, because the flywheel with magnets is already established in the correct position, which is completely synchronized with the movement of the piston. In addition, the flywheel is fixed on the shaft using a key and nut. Therefore, the wrong installation of the part is excluded.

For the most part, the ignition adjustment is to set the correct gap between the magneto and the flywheel.

Magneto is the main detail in the ignition system of the motor and is a coil with primary and secondary windings located around the core. Often, due to the malfunction of the magneto, the spark on the spark plug disappears, and the fuel ignition does not occur. To check the coil, it will be necessary to use the tester, and fulfill the following acts.

- On the tester, going into the resistance measurement mode, you need to set 200 Ohms. In this way, the primary winding will be checked.

- Connect one tester electrode to the “mass” of the coil, and the 2nd-to the contact emerging from the magneto. Normally, the resistance will be from 0.4 to 2.7 Ohm.

- To check the secondary winding, it will be necessary to install the device switch by 20 kOhm. Further, one probe of the device is inserted into the cap of the candle, and the 2nd-is connected to the “mass”. Normally, the properties of resistance should be in the range from 4-6 kOhm and above (depending on the model).

When a circuit is broken, the device will show infinity, and when close. 0 (zero).

The first way

You can check the work capacity of the magneto using a tester. To do this, you need to perform such a sequence of actions.

- True tester: use the resistance measurement function and set 200 Ohms to remove measurements of the primary winding.

- The 1st electrode of the measuring device is put on the “mass” of the magneto, and the 2nd-to the output contact. If the primary winding is working, the characteristics should be from 0.4 to 2 Ohms.

- Install the tester switch by 20 kOhm to diagnose the secondary winding. Then bring the 1st probe into the cap of candles, and the 2nd-to the “mass”. If everything is in order, the characteristics will diversify from 4 to 6 kOhm, depending on the model of the trimmer for the grass, whether it is Patriot 547, Husquarna 128 R or a technique of another brand. If the chain is cut off, the infinity value appears on the tester display. And if there is a short circuit, zero will be displayed on the screen.

Proper care for the chainsaw

There are no unnecessary phrases in the operating instructions, everything that is proposed is aimed at the trouble.free operation of the lawn mower. Cleaning all parts after each cycle of work contributes to the light removal of not hardened residues and dirt. You need to clean only cooled nodes. This technique contributes to the quality of the air cooling of the engine and the gearbox.

For refueling, it is necessary to use fuel with oil recommended in the instructions. If you leave the combustible mixture in the fuel tank, the oil will float and dies on the damper when starting, worsening its adjustment. The mixture can give a sediment and score fuel supply in the carburetor.

When preserving equipment for the winter, make an audit, grease the gearbox and the piston system, wrap the entire saw in the oiled rags and store in a dry place.

It is impossible, dangerous for the instrument and health of the mowing, use a metal cable instead of fishing line. It cuts more efficiently, but the load on the gearbox and the engine increases. A demolished piece of wire when separating flies at the speed of a bullet. Effective mowing can lead to a speedy wear of the piston group of the engine. Reasons for a stop if a gasoline trimmer for grass that this device is not started. For greater efficiency of the mowing, it is proposed to use the profile of the “Star” fishing line.

Mins plus pop design Ajay kumar

On gasoline trimmers, both two.stroke internal combustion engines (ICE) and four.stroke. But the ignition system in them is no different from each other, so the repair and adjustment of this fuel ignition system will be the same for different types of internal combustion engine.

The ignition system of a two-stroke ICE consists of 2 elements: flywheel and coils (magneto). The figure below shows how they look.

There is a impeller on the flywheel, which works like a engine cooling fan. There are also permanent magnets on one side of the flywheel, the figure is shown by the arrow.

When the flywheel rotates in the coil, an electric current is produced, which serves for a spark on the spark plug. The spark appears at the moment when the magnets are directly under the magneto.

Why is the ignition adjustment

In some cases, when the engine does not start, the ignition adjustment will be required. Of course, first you need to check the serviceability of a candle and a high.voltage cable with a cap.

It is necessary to adjust the ignition on a two.stroke engine in order to ensure timely ignition of fuel in the engine combustion chamber. Below is a scheme from which you can understand the principle of operation of the internal combustion engine.

The spark in the candle should appear at the time of compression of the fuel with a piston, when it does not reach the upper dead point (VMT) at least a little. Когда поршень проходит ВМТ, происходит возгорание топливной смеси, в результате чего поршень под действием энергии взрыва уходит вниз.

Therefore, if for some reason (mainly this is due to the shift of the flywheel to the shaft relative to its original position), the fuel fire occurs earlier than the piston passes, then it returns back, and the crankshaft scrolls in the opposite direction. Such a movement can damage the starter knot, cut off the launch cord, etc.D. In this case, an early ignition of fuel occurs.

There may also be a later ignition on the trimmer: the piston after compression of the fuel, which does not ignite, goes down, and at that moment a spark appears. In this case, the engine will either not start or significantly lose power and will be poorly gaining momentum.

But such problems with early or late ignition on two.stroke ICE are quite rare, since the flywheel with magnets is already established in the correct position, which is perfectly synchronized with the movement of the piston. In addition, the flywheel is fixed on the shaft using a key and nut. Therefore, the wrong installation of the part is excluded.

Basically, the ignition adjustment is to set the correct clearance between Magneto and the flywheel.

How to adjust the ignition on a trimmer for Huter grass

A rather pretty element of the site is now the lawn. But it will look great if you care for him. For this purpose, you should often water the area, feed with fertilizers and cut the grass once a week. If you neglect the last condition, then the territory will be rapidly rapidly reincarnated into dense thickets.

To increase the convenience of control, the presence of a bicycle handle is foreseen, which is being placed on our client, the necessary control buttons remain. This equipment, as customers say, is used to cut grass in personal plots. The design is durable, it is designed for saturated and long.term operation.

- vibration extinguishing system;

- strong structure;

- several years of operation;

- placement of control parts on the handle;

- Easy start.

The Huter 1900 trimmer has a rather impressive power, which is 1.9 kW. In the role of the cutting element, a knife or a fishing line for a trimmer is used. The tank capacity is 0.7 l, and the thickness of the fishing line is 3.5 mm. Before purchasing this equipment, you need to take into account that its weight is quite impressed. This is probably said by novice users. The mass of equipment is 7 kg.

The above trimmer for the grass of the gasoline “Huter” should be used taking into account the safety rules that are registered in the annotation. There you can study that the use of equipment to persons who are under the influence of alcohol or are tired at the physical level is unacceptable. Before work, you need to arm yourself with special means of protection, in the middle of them you should highlight appropriate clothes, protective glasses, gloves in other words of gloves, helmets and headphones. Equipment should not be used near flammable and explosives. This also applies to the criterion when the highest humidity remains.

How to set the ignition?

If you are indelible to purchase an electronic trimmer for Huter grass, then of course to note the model that was mentioned in the subtitle. Its price is not so high and amounts to 5,000 equipment, from the phrase of customers, is used to process the lawn in the personal plot, and in addition to processing small territories. It is possible to use a tool for mowing grass even in inaccessible places, for example, along the fence or under the shops.

The power of the unit is sufficient to perform tasks in everyday life and is 1.4 kW. The bar is collapsible, this, as customers emphasize, simplifies not only storage, and transportation. This example is an impeccable solution for ladies and pensioners, because the equipment has a slight weight. The mass is 4.5 kg.

No matter how high.quality the tool is, there are variations of the spare parts for a trimmer for grass “Huter“. About some of them and it will be below. For example, the drum for adhesion to the body will cost the consumer in 860, while the clutch hull bolt costs only 5 flexible shaft for a trimmer for grass costs 600, but the capacity for the manufacture of fuel consistency will cost a symbolic amount. 50

Repair of a trimmer for grass “Huter” and perhaps you are carried out when you need to adjust the carburetor. But first of all, you should produce a technical service of equipment, for this purpose it is washed for you, as for the motor, and after changing the spark plugs, eliminating small flaws. It is necessary to wash the foam element of the filter using warm soap water. If adjustment is carried out on a dirty filter, then after cleaning the fuel mixture will become poorer, which will lead to a bad work or breakdown of the motor. Next, you should install a trimmer head with a very huge cord, its length is suitable for standard.

How to set a ignition on a trimmer

Often, owners of gasoline cos are faced with the fact that ignition does not work on their technique. In most cases, the problem is really in this node. To fix it, you need to adjust the ignition on the trimmer. But at the same time, there are frequent cases that the ignition coil is working and a breakdown should be sought elsewhere. The ignition system is arranged equally on four.stroke and two.stroke internal combustion engines, therefore, the correction of the malfunctions of this node is carried out in a similar way. In addition, the technique of different brands has an almost identical design of this most important component of the tool, which means that the process of adjustment will be identical for both the trimmers “Soyuz” or “Prostr”, and for Huter or samples of other brands.

Ignition on the trimmer. the principle of operation and possible malfunctions

If the owner of the lawn mower wants to establish the operation of the ignition system on his own, he should understand the principle of operation of this unit. In the internal combustion engine, it consists of a flywheel and magneto (coils). In turn, the flywheel includes a impeller that performs the function of cooling the motor and a number of permanent magnets.

Operating principle

When the flywheel rotates, an electric current is generated in Magneto, which creates a spark on the spark plug at the moment when magnets pass under the coil.

The second method

If you use the tester, there is no other way to check. At the same time, it is important not to touch the cylinder electrode, otherwise the coil will be damaged.

- It is necessary to remove the cap from the spark plug. You should not unscrew the candle, as this will save compression.

- Then you need to choose a nail with a remote hat and tightly insert it into the cap.

- Further, the cap with a nail should be reliably tied to the cylinder by the dielectric. In this case, the electrode should be at a distance of 5.5-7 mm from the cylinder body, but do not touch the mass.

- Then the starter needs to simulate the start of the motor with the ignition button. In this case, it is required to carefully monitor whether the spark will appear, and try to determine its color.

Read Lawn Mushiel is in speed at idle

Important! A strong spark of white or with a blue shade indicates in favor of the serviceability of magneto. If it is weak, as well as orange or yellow, magneto is damaged.

There is one important point that needs to be taken into account when diagnostics: uninhabited magneto in any state can form a powerful spark. However, if it is faulty, then, heated, stops creating a current, and the trimmer does not start for the grass. Later, cooing, the coil again returns to the working level, the unoic tractor turns on and for some time works at idle or under load, until the magneto temperature rises again. In this case, the part needs to be changed for a new.

On a note! In a number of situations, the problem with heating does not occur due to the fault of the coil, but due to the spark plug. This means that the test must be subjected to both parts.

How to set a ignition on a trimmer

Often, owners of gasoline cos are faced with the fact that ignition does not work on their technique. In most cases, the problem is really in this node. To fix it, you need to adjust the ignition on the trimmer. But at the same time, there are frequent cases that the ignition coil is working and a breakdown should be sought elsewhere. The ignition system is arranged equally on four.stroke and two.stroke internal combustion engines, therefore, the correction of the malfunctions of this node is carried out in a similar way. In addition, the technique of different brands has an almost identical design of this most important component of the tool, which means that the process of adjustment will be identical for both the trimmers “Soyuz” or “Prostr”, and for Huter or samples of other brands.

It is necessary to adjust the ignition system so that the fuel is ignited at the right time in the combustion chamber.

Important! When the piston compresses fuel and practically reaches a dead point from above, a spark arises in. Further, when it passes the maximum upper point, the fuel is lit up, as a result of the explosion, energy forms and directs the piston down.

If the flywheel is shifted to the shaft relative to its original position, the fuel is ignited faster than the piston overcomes the upper dead point. As a result of this, the piston moves back, and the crankshaft rotates in the opposite direction. You can determine the early fire of the fuel by a broken launch cord, a broken starter node or other breakdowns.

Sometimes ignition is late. The piston compresses the irreparable fuel, and then goes down, and only then the spark forms. As a result, the engine either does not work or its power is reduced, and the speed is gaining much slower.

Typically, a flywheel with magnets is installed in an ideal position, as if coordinated with the operation of the piston, and in order to avoid displacement, it is carefully fixed. This allows us to say that an incorrect installation of a part is impossible. But if the shift of the flywheel is a confirmed fact, then it is a failure or accident. Thus, the installation of the moment of the ignition is not required, since problems with early or late ignition of fuel happen very rarely.

How to set an ignition on the trimmer Echo SRM 22 GES.

Important! It is very simple to regulate the ignition system. There is no need to calculate the ignition angle angle. The maximum that you need to do is to properly set the gap between the flywheel and the reel.

Typical malfunctions

Before starting the ignition of the trimmer for the grass, you need to cut off other probable causes of breakdown and make sure that the problem is really in this node. For this, it is necessary to carry out a number of actions in the following sequence:

- inspect the ignition coil body for damage and defects;

- make sure that there are no pollution on all nodes and elements conducting current;

- check the integrity and isolation of the wiring, contacts, the strength of the fastening, the presence of rust at the joints;

- inspect the candle cap, as it regularly breaks away from the high.voltage wire, and they try to restore it manually, and any unreliable connection lowers the power of the electric arc of the candle;

- check the candle, since the quality of modern gasoline very quickly disables this part, but there is another possible problem. the candle is wet;

- make sure the circuit switch is working.

By excluding all possible malfunctions, you can proceed to adjust the ignition of the coil.

The second method

If you use the tester, there is no other way to check. At the same time, it is important not to touch the cylinder electrode, otherwise the coil will be damaged.

- It is necessary to remove the cap from the spark plug. You should not unscrew the candle, as this will save compression.

- Then you need to choose a nail with a remote hat and tightly insert it into the cap.

- Further, the cap with a nail should be reliably tied to the cylinder by the dielectric. In this case, the electrode should be at a distance of 5.5-7 mm from the cylinder body, but do not touch the mass.

- Then the starter needs to simulate the start of the motor with the ignition button. In this case, it is required to carefully monitor whether the spark will appear, and try to determine its color.

Important! A strong spark of white or with a blue shade indicates in favor of the serviceability of magneto. If it is weak, as well as orange or yellow, magneto is damaged.

There is one important point that needs to be taken into account when diagnostics: uninhabited magneto in any state can form a powerful spark. However, if it is faulty, then, heated, stops creating a current, and the trimmer does not start for the grass. Later, cooing, the coil again returns to the working level, the unoic tractor turns on and for some time works at idle or under load, until the magneto temperature rises again. In this case, the part needs to be changed for a new.

On a note! In a number of situations, the problem with heating does not occur due to the fault of the coil, but due to the spark plug. This means that the test must be subjected to both parts.

Features of adjustment on different models of trimmers

The ignition system is arranged in a similar way on the technique of various brands, so the process of adjusting will look the same. The differences, if they are, are insignificant. They are mainly associated with the disassembly of technology. For example, removing the casing from the engine on different trimmers is performed with some differences. So, on the devices of Patriot, you must first twist the bolts and disconnect the air filter housing with a slotted screwdriver. After that, it will be very easy to remove the plastic casing. A detailed diagram and a trimmer for grass of a certain model are usually shown in the instrument operation instructions.

So, you can adjust the ignition for a gasoline trimmer for grass with your own hands. This process is simple if you know the correct procedure. But preliminarily it is necessary to exclude the likely malfunctions of other nodes and parts, for example, the spark plugs or magneto, which may cause the absorption of the motor motorcycles. However, analyzing the technique of different brands, it is necessary to take into account the likely differences in the design, which are described in detail in the user guide.

Distributor malfunctions:

- wear or breakdown of sliding coal contacts

- Weakening or breakdown of springs

- Mastery or breakdown of sliding contacts of the distributor

- cracks in the insulating part of the distributor drum and lids

The electrical strength of these parts is checked with a voltage of 12 16 kV. To check the state of the distributor, you can use the control and test stand Ki-968.

Why is the ignition adjustment

In some cases, when the engine does not start, the ignition adjustment will be required. Of course, first you need to check the serviceability of a candle and a high.voltage cable with a cap.

It is necessary to adjust the ignition on a two.stroke engine in order to ensure timely ignition of fuel in the engine combustion chamber. Below is a scheme from which you can understand the principle of operation of the internal combustion engine.

The spark in the candle should appear at the time of compression of the fuel with a piston, when it does not reach the upper dead point (VMT) at least a little. Когда поршень проходит ВМТ, происходит возгорание топливной смеси, в результате чего поршень под действием энергии взрыва уходит вниз.

Therefore, if for some reason (mainly this is due to the shift of the flywheel to the shaft relative to its original position), the fuel fire occurs earlier than the piston passes, then it returns back, and the crankshaft scrolls in the opposite direction. Such a movement can damage the starter knot, cut off the launch cord, etc.D. In this case, an early ignition of fuel occurs.

There may also be a later ignition on the trimmer: the piston after compression of the fuel, which does not ignite, goes down, and at that moment a spark appears. In this case, the engine will either not start or significantly lose power and will be poorly gaining momentum.

But such problems with early or late ignition on two.stroke ICE are quite rare, since the flywheel with magnets is already established in the correct position, which is perfectly synchronized with the movement of the piston. In addition, the flywheel is fixed on the shaft using a key and nut. Therefore, the wrong installation of the part is excluded.

Diagnostics and configuration of magneto

To carry out this procedure, you will need:

- Sandpaper (zero) and flat suprafil

- Solidol

- Cross screwdriver

- The screwdriver is flat

- Electric clamp type “crocodile” mini mini

- If necessary. a new armored vehicle (car, silicone) and a new candle A17V

- If necessary. nail polish, island

- If necessary-the new capacitor 0.17-0.25MKF

So, if Magneto’s work, details should not pay attention to: wires, candle, capacitor, contacts and coil should not pay you. You can periodically extract magneto from the stand. The first thing to start with is the inspection of the design of the magneto. Remove the lid.

Are there any accidentally damaged wires and their insulation, excessive dirt or oily in the housing, traces of crushing the metal of the device? Whether the contacts in the process of rotation are adjacent to each other, and whether the gap is formed between 0.7-1.0mm between them? You can use backlight and magnifier.

Ignition adjustment algorithm

The ignition on the trimmer is adjusted quite simply.

Coil (transformer)

As a rule, the coil is not repaired. And she, as a rule, is less likely to fail and needs to be replaced. But still the reel reel is discord! It happens that from one current is like a lightning, on the other no.

And never throw a knowingly non.working coil! There is still a lot of things from her for your motorcycle! For example, lighting! But about this. part 3.

At the very beginning of this part of the article, we got acquainted with the reel device. It has two windings: low.voltage (primarily wound on the core and has about 400 turns) and high.voltage (secondary, wound on top of the primary and has about 18,000 turns).

The main trouble of such a coil is the formation of a short circuit (short.circuited turns) in a high.voltage winding. This makes the coil unusable. Replace the coil.

Or let’s improve Magneto so that we will never face the problem of this coil again! (About this part 2).

While we will consider the version that you replaced the coil with another. Clean the copper contact of the coil with zero. Inspect the wire and rations. If required, solder. Gather magneto and again to the stand! Install all the necessary gaps we talked about. Launch! There should be a spark! Change rotation speed! Now everything should be fine, but maybe another option.

Eccentric adjustment

To configure sparking (current strength), Magneto needs to rotate the weakened eccentric (cam) regarding its shaft and achieve the greatest current power.

Stand: the drill rotates, the end of the stripped armor pipeline is brought to the magneto body at a distance of 5mm. If the current is insufficient or it is not at all. now we will start setting up a fist (he is an eccentric). Stop the drill. The fist is attached to the shaft with one screw with a puck in the center of the shaft.

Setting the gap of ignition coil.

In most modern models of chainsaws and trimmers, it is not required to set the angle of the ignition. It is set specially defined places for the protrudes on the flywheel and the shank of the crankshaft under the trench connection of these two parts. The following malfunctions often arise at the junction of these parts:

As a result, both of these parts (depending on the state) in case of malfunction will need to be replaced. The nut, holding the flywheel on the crankshaft, often led to such problems.

It is only necessary to properly set the gap between the flywheel and the ignition coil. Depending on the model of the tool, the size of the gap can be of different. It usually is 0.2-0.4 mm. Important: the gap is set up from the side of the magnets and the ignition module.

Since the flywheel is round, the usual car probe for these purposes will not work. It would be technically competent to set a gap on a special template. But it is not always possible to purchase it. Buying such an expensive template for one.time use is unreasonable.

Instead of a company template, you can use a strip from a plastic bottle of water. Cut a strip from a bottle in a place where there is no embossed embossing. You can use a plastic card (not too thick).

Further, the actions for the exhibition of Zazaor are approximately the same for both chainsaws and trimmers:

- Loosen the ignition fastening bolts.

- Suppry the magnets on the flywheel to the ignition coil

- Clutching between the flywheel and the coil, tighten the fasteners.

- Remove the strip

- Scroll the flywheel 360 degrees several times, monitoring that he does not cling to the coil anywhere.

All. The gap between the coil and the flywheel is exhibited. Take the flywheel before assembly and make sure that it does not catch anywhere.

Note: Do not use paper as a template. It does not have the proper elasticity, when tightening it is necessarily deformed and the gap will be incorrect.

The repair of the ignition coil is impossible and impractical. The following is a list of ignition coils that can be bought on our website.

Types and features of the design of the ignition coils

The ignition coil called the module is present in all modern ignition systems: contact, contactless and electronic. Its purpose is to convert a low.voltage onboard current coming from a car battery to a high.voltage. High voltage causes a spark on the electrodes of candles, which ignites the fuel-air mixture (TVS).

In general, the coil is a transformer with two windings.

Three types are distinguished depending on the features of the design:

All three types have a similar design, there are only some differences. Therefore, finding out how to check the ignition coil, you can apply this knowledge for all types. You can make a device for checking with your own hands (author of the video auto.electrician RF).

The design of the classic module includes the primary winding, inside which there is a secondary. Each of the windings has two conclusions. The primary power supply is supplied to the primary. On the secondary one, one conclusion is high.voltage and is considered the weekend, and the second is connected to the primary winding. The entire structure is placed in a sealed case, on the cover of which all conclusions are displayed.

The double module has two cores. One is internal, is in the winding, the second is external, located above the windings. If the classic coil has only one conclusion for high voltage, then two of them have two. They produce a spark for two cylinders simultaneously.

An individual coil is put on a separate candle. The main part of the module consists of turns of copper wire, taking the primary voltage and secondary circuit converting the incoming current. The winding, which is primary, is located inside the secondary converter and has a core, which is located inside it. The high voltage, which is produced in the secondary winding, is directly transmitted to the candle with the help of a tip, a clamping spring and an insulator. A high.voltage diode is intended to cut off the current.

All types of modules are characterized by resistance, which differs for different models of the mechanism. If the resistance value differs from the nominal, this indicates a malfunction of the device.

Engine problems can occur due to a power malfunction. If there is a break in the windings or closing, this removes the power unit from the working condition. All types of modules do not understand, so it is impossible to repair them. In order to make sure that the device is subject to replacement, you need to know how to check the ignition coil.

You can most accurately check the performance of the device using special equipment that is equipped with maintenance stations, such as an oscilloscope. There are two ways to check the serviceability of the ignition coil with your own hands at home.

Which line for a trimmer to choose

Before you stock up on this material for refueling in a trimmer for grass, you need to decide on the choice. After all, the usual so.called round fishing line for a trimmer is far from the only existing look. How to choose the most suitable? First you need to determine the working conditions.

Type choice. a line for a trimmer with a round section is the most common. It will suit any reels with the rarest exceptions. This type of consumable is suitable in order to mow fresh, juicy grass. But with the mowing of the so.called dryness, this kind may not cope anymore. It is pointless to mention attempts to mow shrubs and mention.

In addition to the usual type, there are others with sharp faces. Usually they are made by a “star” or “square”. The presence of sharp faces is the main feature and key difference between these threads.

It is thanks to this feature, the threads of such species are able to mow dry weeds. But the spicy threads are not devoid of disadvantages, the main of which can be called rapid wear and strength, markedly inferior to the round type.

In addition to the already mentioned types of forests, there are still interesting and often encountered varieties. Especially among them can be noted fishing lines, inside which a metal wire is stretched. Threads of this type are often used in tools working on gasoline and having an engine more powerful than one and a half horsepower.

Threads with a metal core are both with a round section and with sharp faces. Regardless of the type of cross section, such threads are the best suited to overcome hard.to.stop plants. Threads related to this type easily mow not only dry grass, but even small shrubs.

The threads with wire inside are favorably different from other types of consumables for their incredible wear resistance. But unfortunately, this feature has a more than noticeable effect on the price of this type. The cost of threads with a core significantly exceeds the cost of threads of other types.

The string is not advanced

In the coils of automatic and semi-automatic cords, the cord is served without stopping the trimmer for grass. If this does not happen, then:

The fishing line for a trimmer in the head is wound wrong, so the coil does not spin; The winding of the fishing line is made unevenly, so the cord stuck between the turns and does not go out. so that this does not happen, you need to wrap the thread carefully, preventing distortions, a turn to the turns; The ends of the cord emerging from the holes are very short, centrifugal force is not enough to extract them, so the fishing line is not served-before turning on the trimmer for the grass, it is important to control the length of the thread and slightly lengthen it, if necessary; The cord is stuck

The coil does not spin

The reasons why the coil does not spin are similar to the lack of fishing line. This is the wrong or uneven winding of the string, its sticking, as well as the short ends of the cord, emerging from the holes.

How to catch more fish?

- One.built. In the modification of such a trimmer for the grass there is only one working fishing line for a trimmer. Such an unit is used in the main thing for small work, such as ending the grass.

- Two.string. Can be both automatic and automatic. Here the equipment includes two strings. Such a trimmer is used for herbs for mowing and clearing sites.

Instructions for the correct wound of the cutting thread on the coil of the trimmer for the grass:

First of all, you need to disassemble the head. To do this, click on the latch and turn the lid to the side

Measure the right amount of cutting thread and insert it into a slot.

Win a fishing line for a trimmer in the direction of the arrow on both sides. The ends of 15 cm long should be left not wound. These ends are inserted into opposite slots. Then the ends are fixed in the hole on the head.

If necessary, then you can pull the remaining ends of the thread outward. To do this, you need to pull one end of the thread first, and then the other so that they can easily pass through the slots on the head.

Now you should assemble the grooves on the case and tighten the lid.

Then press the spool and try to twist it all the way

If a click was heard, then the spool snapped. Next, you need to stretch the free ends of the thread to the end.

How to remove and put a reel on a lawn mower!

Subscribe to the channel!And we will teach you everything)))

After the coil is removed from the head, it must be carefully disassembled. It is better to do this on a already dedicated area, because there can be a spring, which will be quite difficult to find in the highest grass in the highest grass. The electrical diagram of a trimmer for grass with half an electric trimmer for grass as you have seen. After disassembly, we will have three parts in our hands: the case (upper cover), the protective casing and the coil itself.

The gap on the trimmer between the coil and the flywheel

Gap on a trimmer between a coil and a flywheel

Spare parts for chainsaws and trimmers with mail delivery in all regions cash on delivery. SDEK, PEK, business strips on prepayment

- Spare parts for chainsaws

- Cylinder-piston groups of chainsaws

- Carburetors of the chainsaw

- Starters for chainsaws

- The ignition coils of the chainsaws

- Circus brakes of a chainsaw

- The crankshafts of the chainsaw

- Clutch of chainsaws

- Oil pumps of a chainsaw

- Flaim chainsaws

- Springs of a chainsaw

- Mufflers of the chainsaw

- Basils and gaskets of chainsaws

- The bearings of the chainsaw

- Clock tensioners

- The remaining nodes and parts of the chainsaw

- Traffic jams (lids) tanks of chainsaws

- Spare parts for trimmers

- Trimmeres cylinder-piston groups

- Carburetors for trimmers (benzos)

- Starters for trimmers (benzos)

- Trimmeres ignition coils (benzos)

- Trimmeres Clutch (Basos)

- TRAMMER FLASS (BAMS)

- Trimmer gearboxes (benzos)

- Trimmeres crankshafts (benzos)

- Elements of the bar and handle

- Basmers and gaskets

- Trimmeres silencers (gasosocos)

Trimmer for GGT-1900T grass. reviews

For the convenience of control, a bicycle handle is provided, on which all the necessary control buttons are placed. This equipment, according to the customer, is used to mow grass in the backyard. The design is durable, designed for an intensive and long service life.

- vibration extinguishing system;

- design strength;

- long life;

- the location of the governing bodies on the handle;

- Light start.

The Huter 1900 trimmer has a fairly impressive output capacity of 1.9 kW. As a cutting element, a knife or fishing line for a trimmer is used. The tank capacity is 0.7 liters, and the thickness of the braid fishing line is 2 mm. Before buying this equipment, it should be noted that its weight is quite impressive. This is confirmed by many novice users. Equipment weight. 7 kg.

Model Guide

The above gasoline trimmer for Huter grass should be used in accordance with the safety regulations set forth in the instructions. This may indicate that persons who are under the influence of Al-Kogol or physically tired cannot use equipment. Before starting work, it is necessary to provide special protective equipment, including appropriate clothes, protective glasses, gloves or gloves, helmet and headphones. Do not use equipment near flammable or explosive substances. It also applies to conditions that support high humidity.

If you want to buy an electric trimmer for Huter grass, you can look at the model specified in the subtitle. Its equipment, according to customers, can be used to process the lawn in a personal plot, as well as for processing small areas. You can use a tool for mowing grass even in hard.to.reach places, for example, along the fence or under benches.

The power of the unit is sufficient to perform tasks in everyday life and is 1.2 kW. The bar is collapsible, which, as customers note, simplifies not only storage, but also transportation. This example is an ideal solution for women and elderly people, because the equipment is easy. Weight 4.5 kg.

Prevention of the problem

Often, the breakdown of the ignition coils are associated with the closure or cliff of windings and mechanical damage to the magneto body. This is due to strong blows, fluid and oxidation, as well as overheating. If you avoid such incidents, you can not worry about the integrity of the ignition coil.

Important! To prevent regular failure, one of the most important components of the ignition system, you need to refuel high.quality fuel. Bad fuel spoils these details.

One of the nodes of Magneto, which regularly suffer when using, are high.voltage wires through which current from the ignition module enters the candles. They have a high service life, but the damage to them is caused by users by an inaccurate circulation when replacing candles, carefully pulling the wire itself, and not for the tip. Another problem that can happen to them is moisture and oxidation or damage to isolation. If you carefully pull out the candle and avoid the penetration of the liquid into the device, these problems can be avoided.

So, the repair of the ignition coil is not very complex and can be carried out by the user independently, but subject to the above procedure for disassembling and replacing the magneto or contacts of the interrupt.

Why is the ignition adjustment

In some cases, when the engine does not start, the ignition adjustment will be required. Of course, first you need to check the serviceability of a candle and a high.voltage cable with a cap.

It is necessary to adjust the ignition on a two.stroke engine in order to ensure timely ignition of fuel in the engine combustion chamber. Below is a scheme from which you can understand the principle of operation of the internal combustion engine.

The spark in the candle should appear at the time of compression of the fuel with a piston, when it does not reach the upper dead point (VMT) at least a little. Когда поршень проходит ВМТ, происходит возгорание топливной смеси, в результате чего поршень под действием энергии взрыва уходит вниз.

Therefore, if for some reason (mainly this is due to the shift of the flywheel to the shaft relative to its original position), the fuel fire occurs earlier than the piston passes, then it returns back, and the crankshaft scrolls in the opposite direction. Such a movement can damage the starter knot, cut off the launch cord, etc.D. In this case, an early ignition of fuel occurs.

There may also be a later ignition on the trimmer: the piston after compression of the fuel, which does not ignite, goes down, and at that moment a spark appears. In this case, the engine will either not start or significantly lose power and will be poorly gaining momentum.

But such problems with early or late ignition on two.stroke ICE are quite rare, since the flywheel with magnets is already established in the correct position, which is perfectly synchronized with the movement of the piston. In addition, the flywheel is fixed on the shaft using a key and nut. Therefore, the wrong installation of the part is excluded.

Basically, the ignition adjustment is to set the correct clearance between Magneto and the flywheel.