Replace the starter on the trimmer Huter. REDUTOR Repair

How to remove a coil from a trimmer for Huter grass

One of the popular options is the STIHL FSE-81 Elekhil. This is one of the most powerful trimmers for the lawn. This device includes the Autocut C5-2 coser, designed to work in small areas. It is convenient to mow it next to the flower beds, borders. She clears the territory near shrubs and trees well, and also carefully processes paths.

This braid for grass has a number of advantages that are that it regulates the revolutions using electronics. The design allows you to save the trees from damage. The circular handle allows you to perform efficient work, maneuver, and also mow in hard.to.reach places. It is easy to transport.

There are other options that have established themselves in work in horticultural plots.

Self.manufacture of bobbin

Quite often, a trimmer for grass is operated in the distance from places where you can purchase spare parts for a spitt with its breakdown. In this case, instead of a broken mechanism, you can install a simple coil made in design made by yourself. To do this, you need a sheet of plywood (textolite, metal, etc.), eyes, screws or screws. The process includes several stages.

- A disk is cut out of the plywood sheet, which corresponds to the failed spool with a diameter.

- A hole is drilled in the center of the disk, which matches the diameter with a shaft of a trimmer for grass.

- Small eyes are attached to the opposite sides of the disk, which will serve to refuel the fishing line.

- Through the eyes, pass the fishing line for the trimmer and fix it with ordinary screws or screws. The coil is ready for work.

- Clutching the made bobbin between the two washers, it is attached to the shaft of the trimmer for the grass with a nut.

Ремонт китайской мотокосы. Замена стартера

To replace the fishing line on a home.made bobin, you will have to release fixing screws, insert a new section of the string and tighten the fasteners again. It is not necessary to remove the coil from the shaft of the trimmer for grass, however, it is necessary to exclude the possibility of spontaneous launch of the motor.

So, above was step.by.step with the pictures described methods of repairing the string head. As you can see, the process is not complicated. And most of the breakdowns are directly related to the inaccurate refueling of the string and its unsatisfactory quality. You can clearly see all the stages of the process on the video.

Repair of the launch mechanism

When examining the disassembled starter, it is necessary to inspect the following parts (nodes) for their damage:

- Drive pulley. The pulleys subject to high axial and radial loads should not have cracks and damage on the back. If there are such, it is required to replace it with a new part.

- Starter spring. The main loads when starting the chainsaw are experienced by the spring. Made of high.quality carbon steel and passed special heat treatment, it loses its properties over time. If cracks or impulses are found, you will need to install a new spring.

- The launch rope. Made of synthetic wear.resistant materials, the starter cord wear out over time. With its gusts, it is necessary to install a new rope on the pulley.

The purchased spare parts must comply with the regulations of a specific chainsaw model.

After the repair work done, it is necessary to collect the launch mechanism in the reverse order. The pulley with a ratchet is installed on top of the spring. Before the final fixation of the chainsaw starter cover, it is necessary to wrap the rope and make several trial jerks.

It must be remembered that the launch cord is previously tied through the hole in the lid.

The main breakdown of the starter of the lawn mower

Two main malfunctions of the starter of the gasoline trimmer for grass are currently spreading:

In practice, there are cases when for some reason there is damage to the starter case and a ragged cord is wound on the engine shaft, which certainly leads to a fragment of the spring and cracks on the case. In the current situation, the local repair of the starter of the lawn mower will be impossible and a complete replacement of the engine start.up unit will be required. In other cases, the elimination of malfunctions will be reduced to the replacement of the spring or cord.

Diagnostics and elimination of breakdowns

To diagnose the starter mechanism, with the aim of the subsequent repair of it, the node must be disassembled. It is easy to do this, only a screwdriver is required. But during this operation, you need to be neat. with careless movements, the spring can fly out and injure the user.

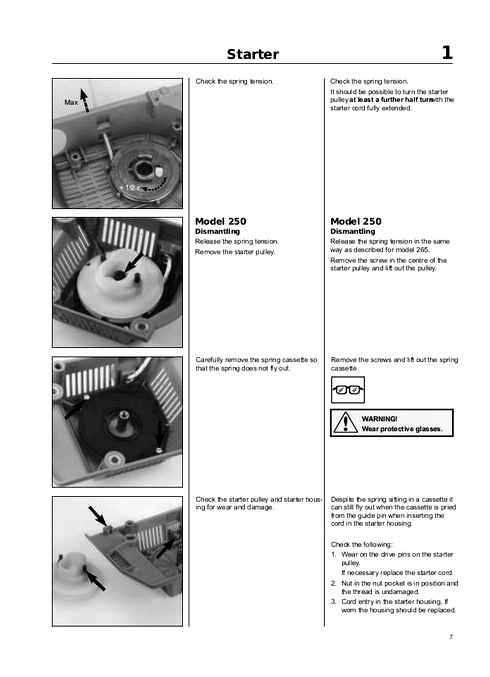

Removal and analysis of the node

The procedure for disassembling the starter is to perform a certain sequence of actions:

First you need to find a screw connecting the starter cover with the pulley, and unscrew it; Then you need to remove the spring, antennae and washers; Then you should carefully remove the pulley, holding the structure away from the face, so that the bounced spring does not injure the user; Next, it is required to inspect the spring: if it is damaged, then you need to put a new one (the cost of such parts is low), and if it jumped out of the hook, it is necessary to return it to its original place, having previously made bends if they have broken off.

Sprinking spring

Spring winding is not an easy procedure. Not everyone gets to install the part on the place the first time, so you should not be upset if it is failure. It is necessary to repeat attempts until the actions are not crowned with success. If you wish, you can watch a video on the Internet, where people’s craftsmen tell in detail and show how to easily and quickly perform this operation.

Important! When winding and installing the spring, you need to remember that it is suppressed, which means that it can burst if you make too much effort. A new part is inexpensive, but you will have to spend time on its search, which means that work on the beard of herbs will move back for an indefinite period

To wind the spring, you need to place the bend in the groove, and then, turning the coil, carefully lay the part along the inner diameter of the bobbin. In this case, the spring must be constantly held with your hands. if it is not fixed, the part slips and pops out, then the winding has to be re.performed. When everything is done correctly, the spring holds tightly in its seat.

Replacement of the cord

A torn trimmer cord for grass must be changed to a rope, you can linen, but without fail suitable in thickness and length. Buying a lanier for the starter of the lawn mower in this case is optional to buy in a specialized store.

To replace the element, in the coil you need to find a hole for it, through which to skip the cord, and then tie the knot. Then you need to take a reel with a spring, having performed several revolutions.

On a note! The exact number of turns can be found by watching the instructions for using a trimmer for grass, or manually. To do this, you need to measure the length of the rope and calculate how many times it can be wrapped around the coil.

For example, if the cord turns around the circle six times, then to pull the spring, you need to turn the coil by the clock six times. After that, it remains only to go through the rope through the hole and fix the handle on the cord.

Other malfunctions

Sometimes after the repair, the spring still flies. You can eliminate such a malfunction with two solutions:

- So that the bend of the spring does not pop out of the groove, you need to insert a small fragment of the metal plate between the bend and the wall of the seat. This will provide a denser fixation of the spring.

- Home.made fastening also helps to keep the spring in the groove. It is necessary to drill holes in the reel on each side of the groove, place the spring bend in them and fix it with a piece of wire. These actions should be performed so that the wire does not touch the starter cover and does not slow down the movement of the pulley.

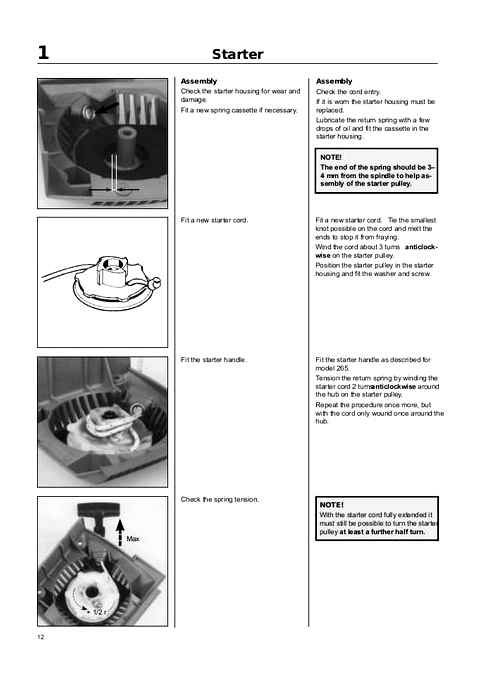

Collection and installation to the starter place

To assemble a starter and install it on its original place, you need:

- Turn the pulley with the spring down and place the housing into the case so that the spring bend falls exactly into the groove of the case;

- install the puck, then the spring, on top of it. the second washer;

- Place a cup of antennae on top of the puck and screw the screw.

When assembly, both goals should be put, otherwise the plastic cup will be damaged by a spring after a while, and when tightening the cord, the user will notice that it was jammed. It will look like a spring has flown. To eliminate such a breakdown, you will need to install a larger screw or another puck. If you find the required details it is not possible, it is enough to loosen a little, after which the starter will stop jamming. However, you need to understand that these are temporary measures, and the malfunction should be fixed as soon as possible.

The device of the chainsaw starter

Almost all leading manufacturers of chainsaws complete their products with starters of a similar principle of action. It is no coincidence that specialized stores offer universal designs of starters that are equally successful for both Stihl, Husqvarna, Makita chainsaws, and for Chinese semi.official fakes under the named brands. Only starters of domestic production (forester, Urals and a number of others) have some features only.

The principle of operation of the starter for the chainsaw is as follows. A handle is installed in the groove of the case, through which the cable is missed. If the handle is sharply lifted, the cable is stretched, and introduces the drum of a ratchet that transfers the movement to the drum with the slots provided for the shaft. In this case, the crankshaft makes several revolutions, and the working mixture in the space between the piston and the cylinder head is compressed. Accordingly, when lowering the handle, the contact between the ratchet and the slots is lost, and the shaft stops.

With an increase in the volume of the engine, the required amount of fuel-air mixture required for its subsequent ignition is also growing, so the number of jerks for the starting cable for large power saws increases. Therefore, in order to accelerate the return of the drum, baked return springs made of steels with high elastic properties are used.

The relief of the launch of the chainsaw is realized in the following ways:

- Preliminary enrichment of the working mixture, for which there is a special damper in the design of the carburetor.

- By installing an automatic decompression valve, which provides a decrease in the working pressure in the chainsaw cylinder.

- By installing an additional spring, which during the movement of the cable facilitates the spinning of the crankshaft.

- The presence in the design of some chainsaws (for example, Partner S, Maxcut, etc.) the primer. the pump that provides preliminary pumping of the fuel.

This is interesting: malfunctions of chainsaws and how to repair the tire with your own hands

How to repair a starter on a trimmer

Repair of the starter of a gasoline trimmer for grass may be required at the most inopportune moment. With all this, you can solve the case with 2 methods: change the broken part or change the entire node. The latter option will cost more. To repair the device with your own hands almost always useful from the tools only a screwdriver with a suitable tip. Repair work will not take much time and do not require special knowledge. It is enough to know the device, the mechanism of work, aspects of the assembly-disassembly of the starter on the trimmer to achieve a good good result.

Spring tension

After installing the spring, it should be pulled. For this they make subsequent deeds:

- Remove the handle from the starter cord;

- Then the rope is inserted into the coil groove;

- create a stretch of the spring, rotating the coil in the direction of the back of the clockwise (views);

- make the required number of revolutions indicated in the operating annotation to the used trimmer model for the grass and the corresponding length of the cord used;

- At the very end, the rope is threaded into the hole created for this, located in the starter cover;

- put the handle in place, fixing it with a node.

If after the repair the spring continues to fly, then you can get rid of this by subsequent methods:

- Squeeze the suitable piece of the plate into the groove at the location of the spring hook;

- drill holes from the 2nd sides of the groove in the coil, into which stick the sprout hook and fix it with a wire.

Starter assembly

The assembly of the starting node is carried out in a row of steps:

The coil is turned over, installing it so that the spring bend will definitely stand in the groove of the case, as in the photo below;

When making the stated manipulations, you must definitely lay two goals. If this is not done, then the spring over time damage the plastic cup, and when it is pulled, the jerking off will begin. Because of this, there is a feeling that the spring has flown away. In order to remove such a defect, it is necessary to install this part of a larger length or an additional goal.

When such spare parts are absent, you can just unscrew the screw a little, and the starting node will begin to work without shaken. But such an option is temporary. it is better to repair excellently as a razor as possible.

Parsing the starting node

The start.up mechanism is disassembled in order to establish new details of the incorporation broken in the subsequent sequence:

- spin a screw with a screwdriver, fixing the pulley with a starter lid;

- take out a spring and antennae;

- Remove the pulley neatly (it is necessary to unscrew your head or work with all this, putting on your glasses and gloves earlier);

- determine why the starting mechanism has broken;

- If the spring was actually destroyed by one hundred percent, then it is replaced;

- When the spring exits from the hook, it is installed in the original place, bending the antennae before that (the photo shows the styling process);

After the spring plate is installed inside the groove, carefully make it twisting. To change the spring, you should work intently and carefully: it can, under the influence of the effort caused by the installation of it in place, to break through

Even if you carefully remove the video, then the spring strip flies very rapidly from the coil and can injure the hand with its sharpened edges

Even if you carefully remove the video, then the spring strip flies very rapidly from the coil and can injure the hand with its sharpened edges

To change the spring, you should work intently and carefully: it can, under the influence of the effort caused by the installation of it in place, to break through

Even if you carefully remove the video, then the spring strip flies very rapidly from the coil and can injure the hand with its sharpened edges

Repair of the starter of the chainsaw Patriot

Chainsaw is an indispensable tool not only for a summer resident, but also during construction work. If you need to stock up on firewood for the winter, then going to the forest without a chainsaw does not make sense at all. With the proper operation of the tool, it can last a long time, but in any case, sooner or later various types of malfunctions will occur. One of such malfunctions is the starter breakdown, as a result of which the engine starts to start. In this situation, it is advisable to repair the starter of the chainsaw starter with your own hands. How to do this, we will find out in the material.

Typical breakdowns and repair of the chainsaw starter

Before carrying out repairs, it is necessary to find out the reasons for the breakdown. Since the product is constantly subjected to dynamic and other types of loads, its failure is not excluded. Frequent causes of starter breakdowns are: rupture of the cable, abrasion or painting several shits of the rattle drum, damage to the spring, a crack of the pulley and others. To determine why the saw does not start, you will need to conduct an appropriate revision of the starting mechanism. Consider the main types of malfunctions, and also find out how to properly repair the product.

Бензокоса замена сцепления. Сам за 10 минут

Repair of the launch mechanism

When examining the disassembled starter, it is necessary to inspect the following parts (nodes) for their damage:

- Drive pulley. The pulleys subject to high axial and radial loads should not have cracks and damage on the back. If there are such, it is required to replace it with a new part.

- Starter spring. The main loads when starting the chainsaw are experienced by the spring. Made of high.quality carbon steel and passed special heat treatment, it loses its properties over time. If cracks or impulses are found, you will need to install a new spring.

- The launch rope. Made of synthetic wear.resistant materials, the starter cord wear out over time. With its gusts, it is necessary to install a new rope on the pulley.

The purchased spare parts must comply with the regulations of a specific chainsaw model.

After the repair work done, it is necessary to collect the launch mechanism in the reverse order. The pulley with a ratchet is installed on top of the spring. Before the final fixation of the chainsaw starter cover, it is necessary to wrap the rope and make several trial jerks.

It must be remembered that the launch cord is previously tied through the hole in the lid.

Diagnostics and elimination of breakdowns

To diagnose the starter mechanism for the purpose of its further repair, the unit must be disassembled. This is not difficult to do; You only need a screwdriver. But during this operation you need to be careful. With careless movements, the spring can fly out and harm the user.

Collection and installation to the starter place

To collect the starter and install it in the original place, you need:

- Return the pulley with the spring down and place the housing so that the spring bend falls exactly into the groove of the body;

- Install puck, then a spring, on top of it. Second washer;

- Place a cup of antennas on the puck and screw the screw.

During installation, be sure to put both goals, otherwise the plastic cup will be damaged by the spring after a while, and when stretching the cord, the user will notice that it jammed. It will be similar to the fact that spring has taken off. To eliminate such damage, you will need to install a larger screw or other puck. If there is no way to find the necessary details, just unscrew the screw, after which the starter will stop jamming. However, you need to understand that these are temporary measures, and the malfunction should be eliminated as soon as possible.

Other malfunctions

Sometimes after repair, spring still flies. You can solve this problem with two solutions:

- So that the spring bend does not jump out of the groove, you need to insert a small fragment of the metal plate between the bend and the seat wall. This will ensure a more tight fit to spring.

- Homemade fastening also helps save the spring in the groove. It is necessary to drill holes in the coil on each side of the groove, place a spring bend in them and fix it with a piece of wire. These steps should be performed so that the wire does not touch the starter cover and does not slow down the movement of the pulley.

Trimmer starter. device and principle of operation

In order to fix the starter of the lawn mower on your own, you need to understand the principle of its work and know its device. Today, manual and automatic starters are installed on trimmers, while the former are most often found.

The part is a plastic case in which a pulley with a cord wound on it is placed to start the engine. So that the lace is independently twisted after the tool factory, on the inside of the pulley there is a strip spring made of alloy steel. On the front of the pulley, a ratchet is installed that creates a starter’s engagement with a drive engine shaft of the tool.

On a note! Depending on the model and the brand that released a trimmer for grass (Huter, Husqvarna and other brands), a pulley with a ratchet can be a single whole or two separate components.

The principle of the manual starter is the same on the gas troops of Chinese, European and domestic production, whether it be Hitachi, Patriot or another manufacturer. To start the engine, the owner of the device abruptly pulls the cord. The pulley turns from this movement, and the ledges located on it are hooked with dogs located on the flywheel. Further with the pulley, the flywheel and the crankshaft begins to rotate. After starting the engine under the influence of centrifugal force, the protrusions and dogs diverge in different directions. And the starter cord after the user releases it, wound on the pulley using a return spring.

Important! With intensive use of the drive cord, it breaks off over time, and the strip spring wear out. These details are easy to replace with your own hands

How to install a starter on a trimmer for grass

One of the key parts of the Kustorez is a starter designed to facilitate the start of the device engine. Like other parts, it breaks periodically. In this case, there are two solutions to the problem: to repair a trimmer for the starter’s grass or replace it completely. The second option is simpler, but more expensive. In addition, on sale you must first find the necessary part, since different models of lawn mowers use different starters. If you have free time and a screwdriver with an appropriate tip, you can restore the performance of this device, if you know how it works, what defects are characteristic of it and how to fix it. All this is in this material.

Three.dimensional starter. device and principle of action

In order to independently fix the gasoline starter, you need to understand the principle of its operation and know its device. To date, trimmers for grass have manual and automatic starters, and the first. the most common.

Part is a plastic case in which a pulley with a cord wound on it is placed to start the engine. In order for the cord to be wound independently after winding the tool, the steel belt is located inside the pulley. A rattle is installed on the front of the pulley, which blocks the starter on the drive shaft of the tool motor.

The note! Depending on the model and brand from which a trimmer for grass is made (Huter, Husqvarna and other brands), the ratchet can consist of one or two separate components.

The principle of the manual starter is the same for Chinese, European and domestic manufacturers of gas trimmers, whether it be Hitachi, Patriot or another manufacturer. To start the engine, the owner of the device abruptly pulls by the cord. The pulley rotates from this movement, and the protrusions located on it enter into the hook with dogs located on the flywheel. Then the flywheel and crankshaft begin to rotate the pulley. After starting the engine under the influence of the centrifugal force, the crests and dogs diverge in different directions. And after the user releases it, the starter cord is wound on the pulley using a return spring.

Important! With intensive use of the drive cord, it breaks over time, and the spring wears out. These details are easy to replace with your own hands

Signs and reasons for the failure of the starter

In rare cases, the executive mechanism breaks when the tool is inaccurate. The consequences can be unpleasant: the deformed cord is wound on the flywheel of a working engine, a pulmonary pulley and a spring break. But these are isolated cases, a complete replacement of the starter is rarely required.

Diagnostics and elimination of malfunctions

To diagnose the starter mechanism for the purpose of its further repair, it is necessary to disassemble the assembly. It’s not difficult to do, just a screwdriver is needed. But during this operation you need to be careful. With careless movements, the spring can fly and harm the user.

Dismantling, disassembling the starter of a trimmer for grass, replacing parts

First of all, the repair process begins with the removal from the trimmer for the grass of the entire starter. This process is inherently not difficult and will only require twisting several screws with a suitable locksmith tool. It should be noted that when dismantling the mechanism of launching the lawn mower, it is necessary to observe safety precautions, since the strip spring in a compressed state has sufficient energy to injure a person.

Parsing the starter motorcycles

This stage allows the master to establish the reasons for the failure of the launch unit, as well as to defect individual parts. The disassembly work should be performed in the following sequence:

Eliminated spring from a starter coil

Many experts note that the first time the installation of the spring is quite difficult, because the owner when repairing the starter of the trimmer for the grass will need not only the basic skills of the locksmith, but also patience.

The sequence of assembly of the starter of the trimmer for grass

Although the process of assembling the launch unit of the lawn mower is carried out in the reverse analysis of the order, there are several nuances that should be paid special attention to:

- The coil with the spring installed must be turned and mounted in the groove of the starter case so that all the protrusions become in their original place.

Installation of a trimmer coil for grass in the starter case

When assembling the starter, pay attention to the compression spring, which on both sides should be limited by steel springs. If this is not done, then after the first season it will rub the grooves in the pulley case

Recommendations for stretching the strip spring

After installing the starter, it is necessary to dismantle the rope handle and insert it into the groove of the coil. Further, against the move of the pulley when starting, it is necessary to make a certain number of revolutions specified in the operation of the gasoline trimmer for the grass. It is worth noting that on how to put the spring on the trimmer and how the tension will make the tension and further performance of the node depend. At the final stage, we spread the rope into a special hole and fix it with a handle.

Replacing the rope of the starter of the trimmer for grass

At the very beginning, it is necessary to extract a broken cord, select a suitable length depending on the trimmer model for the grass. We extend through a special hole in the pulley and at the other end we tie a knot in order to prevent jumping out the rope from the trimmer starting mechanism for grass. Next, we build a strip spring to the required number of revolutions and mount the handle.

Repair of the starter of a gasoline trimmer for grass may be required at the most inopportune moment. In this case, you can solve the problem in two ways: replace the broken part or change the entire node. The latter option will cost more. To repair the device with your own hands in most cases, you need only a screwdriver with an appropriate tip from the tools. Repair work will not take much time and do not require special knowledge. It is enough to know the device, the principle of operation, the nuances of the assembly-disassembly of the starter on the trimmer in order to achieve the desired positive result.

Diagnostics and elimination of breakdowns

To diagnose the starter mechanism, with the aim of the subsequent repair of it, the node must be disassembled. It is easy to do this, only a screwdriver is required. But during this operation, you need to be neat. with careless movements, the spring can fly out and injure the user.

Removal and analysis of the node

The procedure for disassembling the starter is to perform a certain sequence of actions:

First you need to find a screw connecting the starter cover with the pulley, and unscrew it; Then you need to remove the spring, antennae and washers; Then you should carefully remove the pulley, holding the structure away from the face, so that the bounced spring does not injure the user; Next, it is required to inspect the spring: if it is damaged, then you need to put a new one (the cost of such parts is low), and if it jumped out of the hook, it is necessary to return it to its original place, having previously made bends if they have broken off.

Sprinking spring

Spring winding is not an easy procedure. Not everyone gets to install the part on the place the first time, so you should not be upset if it is failure. It is necessary to repeat attempts until the actions are not crowned with success. If you wish, you can watch a video on the Internet, where people’s craftsmen tell in detail and show how to easily and quickly perform this operation.

To wind the spring, you need to place the bend in the groove, and then, turning the coil, carefully lay the part along the inner diameter of the bobbin. In this case, the spring must be constantly held with your hands. if it is not fixed, the part slips and pops out, then the winding has to be re.performed. When everything is done correctly, the spring holds tightly in its seat.

Replacement of the cord

A torn trimmer cord for grass must be changed to a rope, you can linen, but without fail suitable in thickness and length. Buying a lanier for the starter of the lawn mower in this case is optional to buy in a specialized store.

To replace the element, in the coil you need to find a hole for it, through which to skip the cord, and then tie the knot. Then you need to take a reel with a spring, having performed several revolutions.

For example, if the cord turns around the circle six times, then to pull the spring, you need to turn the coil by the clock six times. After that, it remains only to go through the rope through the hole and fix the handle on the cord.

Other malfunctions

Sometimes after the repair, the spring still flies. You can eliminate such a malfunction with two solutions:

- So that the bend of the spring does not pop out of the groove, you need to insert a small fragment of the metal plate between the bend and the wall of the seat. This will provide a denser fixation of the spring.

- Home.made fastening also helps to keep the spring in the groove. It is necessary to drill holes in the reel on each side of the groove, place the spring bend in them and fix it with a piece of wire. These actions should be performed so that the wire does not touch the starter cover and does not slow down the movement of the pulley.

Collection and installation to the starter place

To assemble a starter and install it on its original place, you need:

- Turn the pulley with the spring down and place the housing into the case so that the spring bend falls exactly into the groove of the case;

- install the puck, then the spring, on top of it. the second washer;

- Place a cup of antennae on top of the puck and screw the screw.

When assembly, both goals should be put, otherwise the plastic cup will be damaged by a spring after a while, and when tightening the cord, the user will notice that it was jammed. It will look like a spring has flown. To eliminate such a breakdown, you will need to install a larger screw or another puck. If you find the required details it is not possible, it is enough to loosen a little, after which the starter will stop jamming. However, you need to understand that these are temporary measures, and the malfunction should be fixed as soon as possible.

Chainsaw device. the design of a modern tool

Each chainsaw consists of a number of important mechanisms.

- gasoline 2-stroke engine-consists of a cylinder-piston group, cooling system, air filter. There is also a four.stroke chainsaw on sale. It is designed to carry out complex work in construction, as well as on the harvesting of the forest. Often manufacturers produce saws with electric engines. Such an electrical appliance is good for the home. He does not throw away harmful waste gases, so it can be used directly in the room;

- The transfer node of the rotational moment from the motor to the cutting circuit. As a rule, the drive consists of a gearbox that guides the asterisk;

- Corps. this element serves to protect the internal elements of the saw from damage and dust. It can be made of multi.layer plastic or aluminum. Inside the case, free access to fuel and oil tanks is provided, as well as to filters and other frequently replaced details. This makes it possible to carry out the repair of the tool and install new spare parts instead of faulty;

- Working handles. as a rule, for their production, manufacturers use steel or forged metal. The handles are also covered with a rubberized coating, which prevents the slipping of the operator’s hands;

- saw a headset. consists of a chain and tire. To tension the chain, most manufacturers use a side screw. this makes it possible to adjust the chain without using tools. A separate oil pump is responsible for lubrication of the headset.

The device of each model for a garden or forest also includes controls. They are represented by a gas lever, the throttle position button, the inertial brake switch and the ignition button.

how to wind the starter’s spring trimmer for grass

So I wrap the springs of the starter of the chainstermers, but the springs of the starters drank and the walk.behind tractors are wrapped in.

How to install a spring in a hand starter for a benzo-trimer? At home it is possible to do it. to me.

Repair the broken spring of the starter of the benzotrimer. Model and brand trimer are not indicated since the starter.

The video clearly shows how to make a quick repair of the starter with a smooth start.Repair of Starter Trimmer.

How to make a starter on a chainsaw yourself? How to bend a spring at a chainsaw starter? How to wind a spring.

how to independently assemble a starter of a trimmer for grass. bend and wind the spring. and also wind the launch rope.

Step.by.step description of the assembly process of sarter, motorcycles, walk.behind tract.

DIY chainsaw repair. replacing the spring starter springs.

Removal of the starter of the starter of the lawn mower with your own hands. Often the spring fails. which is easy.

Device for installing the spring mowing starter spring.

How to replace the starting mechanism on a gas tank sign up on the channel, like it.

Replacing the starter dog on the motorcyclate Husqvarna 325r. Oda Husqvarna Huskvarnia again.

A detailed description of the repair of the starter of the trimmer for grass for the example of Hammerflex.

Repair of a manual starter more detailed information on the Generator-Tomsk website. Maintenance.

Prevention of breakdowns

To avoid breakdowns and subsequent expensive repairs, it is recommended to comply with a number of simple rules for the operation of a trimmer for grass and servicing the gearbox.

- Lubricate this garden tool immediately after purchasing. before starting operation. Usually or huter) applies only a small amount of lubricant, which is enough only for running.

- At the end of the season or before a long.term storage of a trimmer for the grass, you should disassemble the gearbox, check the condition of the bearings and gears, grease the knot.

- It is required to add grease after the tool works from twenty to forty hours. With intensive loads, this time is reduced to twenty hours.

- Change grease to a new one is necessary when repairing a structure or before the start of the season.

- Когда редуктор перегревается или издает сильный шум, нужно проверить наличие смазки. If it is present in sufficient quantities, it is recommended to replace it completely with another.

So, you can carry out repair and lubrication of the gearbox Motokosa yourself at home. The addition of lubricants will not be difficult, a detailed description of this process and recommendations for the choice of a suitable substance can be found in the instrument operation instructions or on the video, which many are presented on the Internet. Most of the breakdowns of gearboxes are typical for trimmers of different brands, it is quite easy to eliminate them if you know the correct procedure for actions. And in order to avoid their appearance, it is enough to observe simple operating rules and conduct timely maintenance of a trimmer gearbox for grass.

The reducer lubrication algorithm

To lubricate the gear mechanism of the gearbox, there is no need to disassemble the node. for this, a special hole is provided in the upper part of the case. In addition to the gear, it is necessary to carefully lubricate the elements such as the bearing node. The wear of its compacted walls leads to the fact that the lubricant comes out of the seat and the vibration of the technique begins. This problem is relevant for Chinese trimmers. The decision would be to replace the “native” bearings with high.quality details. The flywheel is also subject to lubrication. during operation, the part is covered with fragments of grass, creating additional resistance during kosbe.

Solid lubricant or oil are placed inside through a hole protected by a screw. At the same time, the following actions are performed:

- The gearbox body is carefully cleaned from contaminants, especially next to the plug to eliminate garbage entering the node;

- A special device is supplied with a motorcycle, it is extracted by a cork;

- From a tube or with a syringe, a lubricant is inserted into the hole, smoothly turning the cutting node so that the substance is evenly distributed along the gears of the gear;

- Return to the same cork.

The lubrication of the gearbox is required to be carried out annually, and with intensive operation, this procedure should be performed every 20 hours of operation of the tool. If signs of breakage appear, the lubrication site should be treated in the very near future.