Rotary harrow for power tiller with your own hands

Harrow varieties

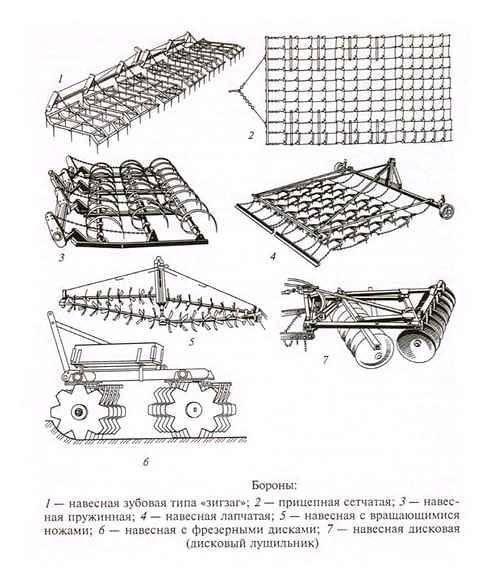

Harrows for agricultural work are divided into types:

A toothed harrow is a simple mechanism that consists of a metal frame with attached to it teeth of the desired length. The power of the power harrow affects their number and the size of the frame. Teeth are placed in the form of a zigzag or rectangle and are attached to the frame rigidly, articulated or on a spring stand.

The depth of harrowing depends on the setting of the tines. Harrow arrangement with sharp edge pointing forward increases loosening depth, with arrangement pointing backward the depth is reduced.

The disc harrow differs from the toothed harrow in its cutting tool. Instead of tines, spherical-shaped discs with a smooth or notched cutting edge are attached to the frame and placed at an angle, called the angle of attack. It varies and is 10° to 25°. In the process of treatment each disc cuts the surface layer of soil, intensively breaks the roots of weeds, mixes them with the soil and compacts the soil. When harrowing, agronomists recommend using a needle harrow. The needles dig into the soil and loosen it.

Disc mechanisms are aggregated with the motorblock by means of front or rear suspension.

Rotary harrow is better than other mechanisms suitable for the initial cultivation of the land. the depth of cutting into the ground is 7 cm, but this factor does not prevent its use for loosening virgin lands. It resembles in appearance a cultivator and disc device.

The rotary tool for the power tiller consists of 6 edges, a disc and a hub. Its working elements are sharpened plates, which are arranged at different angles.

The active rotary harrow is mounted on shafts instead of wheels or a soil tiller, which greatly increases its performance, especially on virgin and heavy soils. For quality work it is better to aggregate to power tillers of high power with gearboxes.

The working principle and the construction of the power harrow

The first harrow made by man with his own hands had the form of bound logs of spruce. They were made not very long, so that it would be possible to maneuver in the fields, but the weight of the harrow, was too great, so that it could break up the clumps of earth after plowing and keep the natural moisture in the ground.

Today this machine is used both on its own and with other kinds of devices like seeders and cultivators. The harrow copes not only with earth blocks, but also covers the soil, leaving moisture inside it. The harrow’s technical features also allow it to pick up dry plant debris and pull the roots of weeds.

It is a device that has passed the ages and has managed to be modernized to such an extent that when using it, human effort is required to a minimum. There are several types of harrows:

Technical specifications of the harrow correspond to generally accepted standards and are calculated on the basis of the weight that comes to one disc or tooth. Accordingly, based on this classification, there are heavy, medium and light harrows. And their use can be special or general.

Types of harrows for power tillers and tractors

First of all, let’s take a look at a rotary harrow for a power harrow, it is very good for removing the top layer of soil. The rotary harrow is used to till the ground after the harvesting of crops. It is also a good option for leveling the ground. Thanks to this harrow there is no need to mow grass. The working depth is set depending on the tasks to be performed. It usually ranges from 5 to 7 centimeters.

For the tractor it makes absolutely no difference what kind of harrow it will be, here more important and more valuable to take into account the dimensions required for tillage. If the field is several hundred hectares, the wider the harrow, the better.

Large harrow is made specifically for power tillers, so to make it with your own hands will not be very difficult. It is attached to the power tiller with a hitch.

Farmers have drawn the following conclusion: to work well in the field the harrow or more precisely its blades have to be oblique. The teeth should be positioned at an angle to the plane of the ground, it allows you to cut easily, and thereby level the soil.

Disc harrow

The second harrow is a disk harrow for dry land. The disc harrow performs all the same functions as the rotary harrow, only different in design: it uses discs, each standing on a separate axle. But, unfortunately, this kind of harrow breaks down more often.

The classic tooth harrow is used in places where an even and loose soil layer is required. The tines are evenly spaced in the frame and vary in length from 25 mm to 45 mm. The size of tines depends on the weight of the harrow, the heavier the weight, the bigger the tines. The disadvantages are, the speed of the efficiency of the power tiller, the power must be significantly high, and should be at least. 12-14 km / h. If you have to choose one, the rotary harrow for the tiller will suit perfectly for work in small areas.

Needle harrow

Needle harrow for power tiller is used for pre-sowing or final winter tillage. After harrowing, the surface of the cultivated area becomes flat and is not subject to drying and weathering.

Curved interchangeable plates are used as working tools on the equipment. Fastening to the power tiller is carried out by means of a rigid hitch, which has a mechanism that regulates the position of this type of attachment.

Harrow for the Neva power tiller

The Neva power tillers, one of the leaders among small agricultural equipment. The harrow for the Neva does not differ from harrows for other devices, and you can buy them everywhere.

Here’s an example of a rotary harrow for Neva and other power tillers, whose shaft diameter is 30 mm.

Rotary harrow RB-1,4 (two sections, 0,7 m each).) for the Neva motoblock.

Designed for presowing and postharvest soil treatment.

Design features of the homemade harrow

The optimum and easiest option for making it with your own hands is considered a tooth harrow. For its creation it is necessary to study carefully the drawings, which should indicate the sequence of operations in the assembly of the equipment. It is also very important that the diagrams show the dimensions of all the parts used for making the harrow.

The very design looks like a cage made of a frame, to which the tines are attached through bolts. The front of the design must be equipped with a hitch, which, in most cases, is in the form of a hitch with holes. When mounting on a single axle tractor, the hitch has to be inserted into the towbar tube and then both elements have to be secured with a pin. It is extremely important to weld a special chain between the tow bar and the hitch to make it easier to work with the equipment.

The cage of the tooth harrow should be as strong as possible, so you should use square or water pipes and corners to reinforce the joints of the structure. Each piece should be made of steel, at least 5 mm thick, otherwise the soil will tear out the tines with the pieces of metal.

The design of the manufactured grid should consist of transverse and longitudinal parts. At the same time, the best would be a cage with bars welded together at a 45 ⁰ angle with respect to the direction of the tiller. Such a homemade harrow will be much less exposed to bending loads.

To determine the size of the cells it will be necessary to first determine how the tines will be placed on the harrow. To do this, you need to draw the tines on the drawing, and on top of them finish drawing the grid on which they should be attached. The frame must be big enough so it does not interfere with the tiller arm later on. It is also extremely important to consider the dimensions of the hitch in good time. Remember that a harrow wider than 1 m will not be pulled by many tillers.

Tooth tines should preferably be made of ribbed reinforcing steel. Its diameter should be at least 18 mm, and the length of each tine should be about 15 cm. The height of the harrow does not depend on the height of the hitch, because the homemade harrow will be attached to the tiller with a chain. The thickness of the latter must be increased if the harrow is fitted with thicker tines.

Harrowing peculiarities

Harrowing is considered the most important stage of soil cultivation, which affects the condition of crops and crop yields. This horticultural measure achieves several problems at once, the main ones being weed control and soil loosening. harrowing also helps to level the soil and dramatically reduce water loss. The ripping effect is achieved through the action on the ground of the working elements mounted on a common frame and shaped like discs, teeth or hoes.

Such a device is called a harrow and has been known to mankind since ancient times. To pull a harrow was formerly the privilege of horses, but today, thanks to mechanization, this role is played by agricultural machinery.

Large farms often use mini-tractors as a harrow tractor, while dacha owners and owners of small plots more and more often give preference to power tillers.

The process of harrowing is done twice a year. First time in early spring, immediately after thawing, and the second time after the last harvest, just before the first frost.

There are several types of harrow for a power harrow: a tooth harrow, a needle harrow, a disk harrow and a rotary harrow.

Tooth model

It is the simplest type of equipment and is a reduced copy of the classical harrow, which is equipped with tractors. Structurally, it is made in the form of a wedge-shaped or rectangular frame, with metal tines of 25 to 40 mm in length. the arrangement of the tines on the frame can be different, but the most common way is zigzag, but the tines themselves can have both circular and rectangular cross-sections.

Tooth harrow is able to loosen soil by 10-14 cm, which promotes the normalization of air exchange and regulates the water balance.

A chain or rigid hitch is used to attach the harrow to the tiller; to get a better harrowing effect the rigid tines are sometimes replaced with spring tines.

The advantage of this type is its simple design, lack of complicated components and the possibility to make the device by one’s own hands.

The main working characteristics of the tooth model can be considered on the example of the common double track harrow BN-1, which is designed specifically for the power tiller “Neva”. This model is used for loosening, breaking up large clods of soil, formed as a result of plowing, and leveling the top layer of soil.

Working depth varies from 3 to 10 cm, and productivity is 0,2-0,5 ha/h. Working width is adjustable with a special handle and varies from 60 to 100 cm. Dimensions of the model. 72x67x51 cm, weight. 17 kg, and the optimal speed of harrowing. 4 km/hour.

It is attached to the tiller with a screw mechanism and universal hitch.

Needle-tooth model

Design somewhat resembles a toothed one, but differs from it in that instead of the teeth welded to the frame there are replaceable arc-shaped peorized pins. This harrow allows you to cut stubble and use it for leveling the ground to prevent it from drying out.

The machines are designed for high-powered, water-cooled implement weights of 200 kg and more.

As an example of a needle model you can consider a harrow for Zubr power tiller. The working width of this device is 1 m, and the depth of loosening reaches 14 cm.

The device is attached to the power tiller through a rigid hitch that has an adjustment mechanism. Harrow weight 30 kg.

Disk model

Available with spherical discs in smooth or perforated design. The harrow with peorized discs gives the best results, but requires constant cleaning of the working area during harrowing.

Discs are attached to the frame at different angles, which in each case is set by the motobloc operator and depends on the type of soil and its condition. The principle of operation of disc models is quite simple and is as follows: during the movement of the power harrow discs cut the top layer of soil and grind it. It everses and cuts the roots of weeds.

The disk harrow can be attached to a power tiller at the front or rear of the machine and depends on the power tiller model and the type of attachment.

The range of disc devices is wide enough, so it would be unfair to take just one model as a benchmark. Most of disc machines in the line of disc harrows are quite powerful devices. The widest models have a working width of up to 140 cm, can go down by 20 cm and weigh up to 70 kg.

Such devices are installed on medium and heavy motor blocks and attached to them by means of a rigid adjustable coupling.

Rotary or rotary models

They belong to the active class of attachments. Their difference from the previous three passive models is that they are not hitched to the tiller by means of a hitch, but are installed on the machine instead of the wheels. The working part of such devices is made in the form of sharpened plates located on discs and installed at a certain angle. Namely plates are working mechanism and carry out processing of soil.

The penetration depth of rotary models is quite small, only 7 cm, which is quite enough to cultivate the ground immediately after harvesting crops. The greatest efficiency is achieved when rotary models are installed on motor blocks with gearboxes.

Range of application of rotary devices is somewhat wider than of other types, and along with loosening and leveling the ground includes the possibility of seeding and effectively cover them. This method leads to a significant reduction of seed loss and significantly increases yields.

In addition to seed placement, the rotary harrow is also used to place mineral fertilisers at the desired depth.

As an example, you can consider a Russian-made rotary harrow for a “Neva” power tiller. The device is able to effectively flatten soil after plowing and apply mineral additives at a depth of 5 to 7 cm.

The unit travels at 4 km/h for better tillage efficiency.

This harrow has a working width of 1.4 m, a section length of 70 cm and a harrow diameter of 35 cm. Tilling depth is somewhat greater than other models of this type and reaches 10 cm. Weight of one section. 9 kg.

Traditional harrow

Classic, or as it is also called, horse harrow, is used to create an even and loose surface. This attachment also gives a good water retention and prevents soil from drying out. The harrow breaks up large clods of earth to the required size, destroys weeds and removes residual vegetation from the soil. The machine is relatively light, therefore it is used for shallow tillage, crumbling the clods and for light loosening before the sowing campaign.

MIni Paddy Field Rice Weeder/farm cultivator/rotary power tiller agricul tural

Tooth harrow for factory-made power tillers is made of special structural steel that can withstand significant loads. This equipment is also good for leveling soil after milling.

This type of equipment for harrowing is a straight or zigzag frame, which can be made with your own hands from steel strip, square tube or angle, a stand for coupling with a power tiller and teeth. Tines can be fixed to the frame by welding, or by threading them and securing them with nuts. Working tools on the frame are placed at a uniform distance from each other, and their length can be 25-45 mm. Regarding the equipment width, 500-600 mm is enough, for example, for the Neva power tiller. This video shows the toothed harrow at work.

You can also make a power tiller with your own hands according to the drawing below. In order to make such hinged equipment, it would take half a day, but it will be worth it.

In order to make such equipment for a power tiller we will need the following

- To the metal tube with a square cross-section to weld iron strips, on which, in fact, with the help of nuts will be attached to the teeth with a thread cut on one side;

- The drawbar of our attachment ends with a welded sleeve, through which with the help of a metal pin will be connected to the used power tiller;

- make a rack with a adjusting screw to adjust the lifting height of the harrowing equipment, to ensure uniform penetration of working tools into the soil.

Whether it’s purchased factory equipment or home-made harrow, to the tiller “Neva”, there is a feature of accumulation of wet soil with residues of vegetation on the working bodies, which can make land treatment ineffective. In order to easily and smoothly clean the tines with a scraper or any metal object we will use the lifting arm of the machine.

The video shows the simplest tooth harrow for a power tiller with dimensions.

Varieties and structure

There are several variants of implements for loosening the soil, which differ in design and have a number of characteristic features.

Harrows are divided into such types:

Rotary agricultural tool

If we talk about the rotary harrow for power tiller, its main advantage is the optimal removal of the top layer of soil. To level the ground with it. no problem. The depth of loosening the soil varies from 4 to 8 centimeters, it can be adjusted, taking into account the specificity of the work.

The harrow width is very important, here we take into account not only the power tiller’s capacity, but also the area of the cultivated field. As a rule, this value is equal to 800-1400 millimeters. Such parameters are explained by the ability to work comfortably while maneuvering over small areas.

The industrial made rotary harrows are made of qualitative metal alloy that gives the possibility to use the equipment actively for dozens of years (with a proper care and maintenance).

On quality farm implements the blade has an oblique configuration and the tines are at an angle to the ground, having an ideal angle of invasion for quality cutting of the soil, its leveling and elimination of weed plants.

Disc device

The disc harrow is used on dry soils, it performs the same function as the rotary harrow, but is completely different. Key components in ripping are the discs, which are similar in configuration to the stars. They stand on a single shaft at a specific inclination, ensuring maximum penetration into the soil.

Tooth harrow

Cultivation with a power tiller with such a device is practiced if it is necessary to obtain an even and scattered layer of soil. The tines are measured and can have all sorts of configurations and sizes: square, knife, round and so on. The height of the tines depends directly on the weight of the agricultural equipment: the higher the weight, the higher the tines. In general, their parameters vary from 25 to 45 millimeters.

This tooling can have several ways of aggregation with the chassis. In one variant by means of a spring stand, and in the other. articulated.

Tooth harrow is subdivided into:

Stages of manufacturing

The whole process of manufacturing units for a motor-block with their own hands can be divided into several stages. To begin with it is necessary to determine what equipment is necessary and what functions it will perform. For example, in the case of a trailer, the design can vary depending on the type of work performed. Homemade cart for power tiller can have the ability to unload loads on its own. This is very convenient if we are talking about bulk transportation of fertilizers, soil, harvested vegetables. In such cases, it is much easier to lift the body and pour everything out than to unload it by hand.

The next step is to calculate and make a drawing. At this stage, it is important that the single-axle tractor and the obtained equipment can work “in tandem”. This applies to power, dimensions, method of attachment and many other factors.

After preparing the drawing, when the necessary materials and tools are known, you can begin preparing them. The work can be done faster if everything is prepared in advance. In this case, it will not be necessary to quit work and go to the store for the missing parts.

And only when all stages of preparation are passed, you can begin the actual production. It can take a lot of time and effort to build. But the result is worth it.