Safety when working on grinding machines

§ 14. Safety requirements when working on grinding machines.

When working on grinding and sharpening machines, the main danger is the rupture of the grinding wheel. In addition, it is possible to damage the skin and eyes of the worker with small glowing particles of the grinding wheel, as well as the seizure of the worker’s clothes and hair by unshielded rotating parts of the machine.

In case of insufficiently secure fastening, the parts to be ground can break off and injure the worker. To avoid rupture during operation, the grinding wheel is tested for mechanical strength on a special machine before installing it on the machine. Usually, the grinding wheel is installed on the machine by an experienced fitter, who must check whether the preliminary balancing of the wheel assembly with the faceplate has been carried out and whether there is a certificate of its strength test.

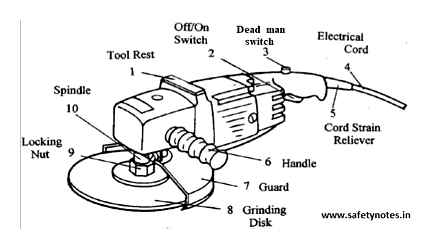

Safety Time | Angle Grinder Safety

When working on a grinding or sharpening machine, the worker should stand on the side and not against the wheel. When dry sanding, wear protective goggles. Protect the grinding wheel from impacts. Contact with the workpiece should be smooth, without unnecessary pressure. Do not work on the grinding wheel if vibration is present.

When processing small parts with manual feed, the worker must put on leather or rubber fingertips on his hands to protect his fingers from injury and use a handcuff. When stopping the machine, do not brake the grinding wheel with your hands. It is also not allowed to brake the rotating circle by pressing on it with any object. Dressing the abrasive wheel with a chisel or other impact tool is not permitted. Editing is done only by the installer.

Before installing the part on the machine, inspect the grinding wheel for visible cracks and dents, whether there is a gasket between the clamping flanges and the wheel, if the nuts clamping the flanges are loose.

Only tried and tested wheels can be installed on the machine. Wheels are tested on special testing machines by trained workers.

Grinding Safety in hindi | Grinding hazards & precautions in hindi | HSE STUDY GUIDE

The grinding wheel, mounted on the machine, must be covered with a guard and subjected to a short idle rotation at operating speed. Then you should check the centering of the wheel and the spindle (no runout); check if the grinding headstock, tailstock and quill can move easily.

Loose nuts, lock nuts, bolts must be tightened; it is necessary to check how the corresponding bolted connections of the machine, auxiliary and safety devices and devices are cottered.

When installing and securing the workpiece on a surface grinder, the part should be fastened only with special thrust and clamping strips, placing them at equal distances from each other; put all stop strips below the surface to be processed so that the circle can freely pass over them; place the fastening bolts as close as possible to the place where the part is pressed, and the fastening strips. at right angles to the part (the thread of the fastening bolts must be intact); for fastening parts, do not use random, unsuitable strips and gaskets; when installing the part, check the correctness of its position (whether the part touches the protruding parts of the machine when moving) by manually moving the table, and if this is not possible (for large parts). using the scale ruler.

Tables of surface grinding machines (including tables with an electromagnetic plate) must be equipped with guards. If the work is carried out on a machine with a magnetic plate or chucks, then first turn on the electric machine converter, and then the machine.

Machines with electromagnetic plates must have blocking devices that turn off the movement of the table and the rotation of the grinding wheel when the power supply to the electromagnetic plate is cut off.

When working on machines with a moving table, the following rules must be observed: do not allow the installation of any objects from the ends of the machine so that people are not pressed against them by the moving table; do not allow people to enter the dangerous “departure” area of the table, require its fencing (in the form of an overlap under the machine table); for high-speed machines of high power with a moving table, monitor the working order of the engagement mechanism; do not touch the moving workpiece and the grinding wheel until they come to a complete stop.

Safety precautions when working on a grinding machine

Working on machines of various types requires compliance with safety measures in order to avoid injury to the worker himself and others. When working on a grinding machine, there are rules for working, as well as for storing components.

Features of storage of grinding wheels and their installation

The storage of grinding wheels should be carried out in a dry place on a flat, stable surface. Do not allow moisture to enter the surface of the circle, as well as the likelihood of its fall and the formation of cracks as a result.

Grinding wheel safety

Before installing the grinding wheel on the grinding machine, make sure that it is free of cracks. To do this, you should knock on it with a wooden hammer: in the presence of cracks, the blows will produce a different sound than in a whole circle. In addition, it is important to secure the circle well and carefully check the reliability of the fastening.

The grinding wheel is fastened using special end gaskets. Their presence compensates for minor deviations from the correct shape, as well as possible temperature deformations during operation. When installing the wheel, consider the direction of its rotation, taking into account the direction of the thread of the threaded elements. The latter, in turn, must be carefully countered.

Safety rules when working on a grinding machine

When the machine is put into working condition, it is required to observe the appropriate safety precautions, which is expressed in the following rules:

- Do not allow the grinding wheel to get wet while the machine is running. this can lead to imbalance.

- Requires a cover to cover the circle. This is especially true for machines with a wheel speed of 60 m / s and above.

- It is necessary to stop the machine immediately if even slight vibrations appear. Restarting is possible only when the vibrations and the reasons that caused them are eliminated.

- When working with vitrified bonded grinding wheels, it is very important to keep coolant out of the non-rotating wheel.

- It is forbidden for the grinder to stay in the circle of rotation during the operation of the machine and during dressing of the wheel.

- Do not bring the workpiece to the circle with jerks, sharp movements. this can lead to a rupture of the circle, in which it splits into small parts, scattering around the room under the influence of centrifugal force. The work on the machine should be smooth, without pressure.