Stihl Ms 180 Chainsaw Will Not Start Reasons

Fills the spark plug

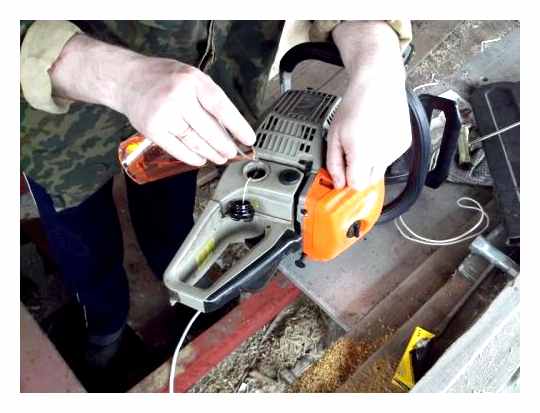

In some cases, the Stihl 180 will start and stall or not start at all. Then we check the condition of the candle, it can be flooded. There can be two reasons for this “overflow”. improper starting of the engine on a cold one and a malfunction of the carburetor. We try to solve the problem with the following actions:

Remove the spark plug;

We turn the chainsaw over the other side and wait until excess fuel flows out;

For better confidence, we jerk the starter several times, so gasoline will surely come out of the cylinder;

We return the candle to its place, install the cap and try to start the engine again with a starter.

No spark

If the chainsaw does not start, while you have not experienced any special difficulties before, the first thing to do is check the spark plug. There may simply not be a spark between its electrodes; this can be determined only after removing the candle. We check its performance, for this we stick the candle into the cap of the high-voltage wire, put the candle on the metal side of the cylinder (or other metal object). Now we do several manipulations of the starter, and if during them a spark is not observed, the problem is specifically in the spark plug.

Attention: it is imperative to make sure that the ignition is turned on, otherwise the candle will not show a spark in any case. Also, to make sure that the plug is faulty and not the ignition coil, take a similar plug and test the spark on it. If there is one, the problem is solved by a simple replacement.

Stihl 180 chainsaw will not start: reasons and repairs

And the world-famous Stihl company produces a huge range of high-quality chainsaws. For domestic purposes and simple work, the Stihl 180 chainsaw was created, which showed excellent performance and reliability. All the best practices of the German company were used here, with a weight of 3.9 kg, the chainsaw easily performed work in the garden. It is easy to cut small trees, branches with it, you can even prepare firewood. But any even the highest-quality equipment tends to break down, and it so happens that the Stihl 180 chainsaw does not start or start with great difficulty. We tried to collect all the reasons and methods of repairing the German Stihl 180.

Fuel supply to the chainsaw

If the Stihl 180 does not start, there is a spark, then first of all we check the presence of fuel in the chainsaw tank. Of course, the problem is funny, but quite common. Next, we check if fuel is entering the carburetor, for this you can disconnect the gasoline hose from the carburetor and pump in gasoline. After several manipulations, gasoline should flow from the hose, but not in a large stream, but in small jerks. If gasoline is not running or running poorly, the problem may be as follows:

Clogged fuel supply channel;

Directly connect the fuel filter.

As unusual as it may sound, even a too full fuel tank can cause it. If the pressure is high, the fuel hose may squeeze out or the required vacuum may not be created. Be sure to monitor the quality of the fuel used; for proper operation, never leave the chainsaw with gasoline for more than 2 weeks. Long storage of fuel in the tank contributes to the formation of resins and the process of polymerisation of components.

Malfunction of ignition coil

Defective crankshaft bearings

If the Stihl 180 does not start and the fuel flows correctly, you will have to look further, namely into the crankshaft. Its bearings tend to wear out, which causes backlash and attempts to shake the flywheel. The fact is that in the presence of play, the flywheel magnets are attracted to the ignition coil, or rather to its contacts.

To repair and replace bearings, it is required to disassemble the motor, so this work is performed only by craftsmen or people with experience. Do not disassemble the engine if this is your first time.

Other reasons and solutions

If the chainsaw still does not start and the reason is not in the above details, you need to look deeper. Other common problems include:

Breakdown of the fuel pump;

Absence of an impulse in the channel of the branch pipe from the engine crankcase;

There is no fuel supply from the carburetor;

Rupture of the diaphragm on the fuel pump;

The repair of the above faults can be carried out either independently, but of course it is better to give the chainsaw to the master, you can make the diagnosis yourself. Also, when diagnosing, the following indicators should be checked:

Correct operation of the carburetor;

Optimum compression in the cylinder;

Compression in the crankcase.

Compression is checked both using a special device and manually. To “by eye” make sure that there is compression, it is enough to remove the candle and insert a finger into the cylinder bore. After several times, turn the starter and if the finger pulls into the hole. there is compression.

Reduced compression

One of the frequent cases of difficult starting of a chainsaw is wear of the CPG (cylinder-piston group).

As you know, for the normal start of a chainsaw, compression must be present in its engine. It is necessary for the normal compression of the fuel mixture in the engine cylinder, it also affects the operation of the fuel pump.

The reasons for the absence of compression, or its reduction, may be natural, because. The engine wears out during operation. Also, problems can be caused by a serious breakdown, for example, a scuffed CPG, or a broken piston ring.

A sign of reduced compression is a weak resistance of the starter when starting. With reduced compression, a decrease in the power of the chainsaw is observed, which negatively affects its performance. The problem is eliminated by replacing the piston rings, or completely by the CPG.

Malfunctions in the ignition system

If, when inspecting the spark plug, it is found that it is wet and sparking on the contacts does not occur, this means that the problem should be looked for in the ignition system, inspect the coil, check the gap between the flywheel and the coil contacts. You can also check how tightly the cap of the high-voltage wire sits on the candle, and the candle itself. Try to replace it with a new one.

Chainsaw stalled and won’t start

If the tool stalled and does not start, first check the presence of fuel in the tank. Oddly enough it sounds, but many people forget about it and when a similar situation arises, they immediately try to repair the instrument, which can lead to serious damage.

In a situation where the saw has stalled, and there is still gas in the tank, you need to evaluate how the saw has worked up to this point. Maybe at the last moment there was an extraneous sound, grinding, ringing, power loss, or the instrument stopped abruptly. All this will allow a preliminary assessment of the situation.

Fuel and air filter

Contamination of the main filter elements of the chainsaw, negatively affects its operation.

For example, a dirty air filter will not fully supply air to the carburetor, which will affect the quality of the air-fuel mixture and normal engine starting. Contamination of the fuel filter will make it difficult or even cut off the supply of gas to the carburetor and make the engine impossible to operate.

Carburetor adjustment

Incorrect carburetor adjustment will cause the chainsaw to not develop full power. It will be difficult to start, or not at all. The carburetor setting directly affects the quality of the air-fuel mixture, which is necessary for normal starting and further engine operation.

An excess of gasoline in the mixture is called overflow. A characteristic sign of overflow is a wet spark plug, after several unsuccessful attempts to start the chainsaw.

Why does a chainsaw start badly

- Fuel and air filters;

- Reduced compression;

- Carburetor adjustment;

- Spark plug;

- Ignition coil;

- The gap between the ignition coil and the flywheel;

Let’s consider each reason in more detail.

Engine jammed

Quite often there is a situation when the saw worked and stalled abruptly, the cause of which was the engine jamming, which in turn occurred as a result of a break in the piston skirt, destruction of the crankshaft bearing, protrusion of the piston pin cork ring or piston ring break.

A jammed engine can be easily identified by pulling on the starter cord. In the case when the starter does not turn, most likely, it has jammed, and further repairs are possible only in a service center.

Broken fuel line

During the operation of the chainsaw, vibration occurs, which can cause damage or breakage of the fuel line of the chainsaw. In this case, the chainsaw will stall and it will be impossible to start. To diagnose a malfunction, you need to conduct an inspection and determine the presence of fuel leaks.

Fuel problems

As with the difficult hot start option, problems in the fuel system can affect a cold start or inability to start. Carburetor adjustment, fuel filter and line contamination are all reasons that cause start-up difficulties.

Diagnose the fuel system, this is the first thing you need in case of difficult cold start.

It is worth paying attention to the quality of the fuel, because When using a mixture of gasoline and oil, in which there is a small amount of water, starting can be significantly difficult or impossible.

Doesn’t get hot

Before going to the workshop and finding out possible engine malfunctions, let’s figure out in which cases the chainsaw may not start with a hot engine.

There is no spark on the Stihl 180 chainsaw

The main malfunction due to which the stihl ms 180 chainsaw does not start may be the absence of a spark between the electrodes on the spark plug. Symptoms of this malfunction can be detected by unscrewing the plug and inspecting. Having discovered during inspection that the spark plug is wet, it is necessary to start looking for the reason for the absence of a spark on the spark plug.

Chainsaw won’t start: main reasons

Before running back to the seller or taking the chainsaw to the warranty workshop, we will try to understand the main reasons why the engine does not start.

What to do if the chainsaw won’t start further?

If the initial inspection did not give anything or the defects were eliminated during the search, and the chainsaw does not start further, then you need to look for more serious reasons. It is best to identify and eliminate such breakdowns in a service center. However, with experience, you can find and eliminate them yourself. What to diagnose and check?

- Compression in the cylinder;

- Compression in the crankcase;

- Carburetor operation.

In the first case, checking the compression in the cylinder will allow you to find out the state of the cylinder-piston group (CPG) of a chainsaw that does not want to start cold. For this you need a compressometer. The device is screwed into place of the spark plug and the engine is idle. Measurement of readings allows you to judge the state of the CPG. In the absence of a compressor, the compression in the cylinder can be determined offhand as follows:

- Place your finger on the candle hole;

- Try starting your chainsaw engine.

By placing your finger on the spark plug hole and pulling the starter, you can check the compression in the cylinder

If you feel that your finger is pulling strongly into the candle channel, then the compression is all right. The absence of vacuum in the chamber indicates a malfunction. The cylinder-piston group needs a more detailed inspection, which will give an idea of the condition of the piston and cylinder, piston rings and bearings.

The chainsaw may not start on a cold one due to the lack of compression in the engine crankcase. The main reason for this is damage to the gasket placed between the cylinder and the crankcase. It is quite easy to detect the lack of compression:

- Disconnect the upper tube from the carburetor;

- Pour gasoline into a regular cork;

- We immerse the removed tube in the fuel;

- We pull the starter several times.

If the fuel from the cap is sucked in when starting the chainsaw starter, then everything is in order with the compression. If not, see the gasket.

If the fuel is drawn in, then everything is in order. the gasket is intact. Otherwise, you will have to purchase a repair kit and replace it. See how to do it. Why the Chinese chainsaw won’t start:

Starting the tool can be complicated by improper operation of the carburetor or its breakdown. It often happens that during the sawing process the fastening screws loosen and air is sucked into the cylinder. Check that the carburetor is securely attached. Inspect it for fuel leaks. There can be a lot of reasons for the malfunction. It is possible to pinpoint the malfunction, eliminate it and fine-tune the carburetor only in a service center.

After going through the step-by-step troubleshooting of the chainsaw engine, you can find the malfunction, fix it yourself and successfully start your working tool. Do not take on jobs that you are not sure about. Entrust the troubleshooting to specialists from the service center.

There is no clearance between the flywheel and the ignition module

In some cases, the absence of a spark on the spark plug is due to an incorrect gap between the contacts of the ignition module or the flywheel. It may be larger, or it may not exist at all, and then scratches will be observed on the surface of the flywheel as a result of contact with the contacts of the coil.

You can check and set the gap without a special tool. To do this, you will need to remove the starter, loosen the two screws securing the coil and lay a plate cut from a plastic bottle between the flywheel contacts and the ignition module, tighten the module fastening screws.

If, after such an adjustment of the gaps, a spark appears, everything is in order, you can continue to work with the Stihl 180 chainsaw, if not, you need to re-inspect and check whether the flywheel touches the coil contacts again. Suppose, as a result of the check, it was found that after adjusting the gap, it was gone again. So the reason is most likely in the crankshaft bearings.

Clockwork device

As with other saws, the carburetor acts as the main starting device. Considering in more detail the carburetor with which the Stihl 180 chainsaw is equipped, it should be noted that it has a single tuning screw. In other words, it is a kind of idle speed adjustment screw. In this case, the nozzle, which has a full load, is stationary all the time.

In other words, the regulation is not applicable to it. In turn, there is no way to influence the full load in any way. You also need to pay attention to the factory settings, due to which the supply of the air-fuel mixture is carried out directly to the engine. over, this principle remains regardless of the operating conditions of the tool.

Replacing the crankshaft bearings

It is better to replace the crankshaft bearings in a specialized service, since when replacing, you will need to completely disassemble the Stihl 180 chainsaw and remove all its main components.

Without some experience or at least the skills of repairing similar chainsaws, it will not work to replace the crankshaft bearings efficiently.

So, we figured out the absence of a spark, but what to do if there is a spark, and there is no answer to the question of why the Stihl 180 chainsaw does not start. The reason may be hiding in the fuel system.

Summing up.

In fact, as you can see, there are a lot of reasons for the breakdown of the Stihl 180 chainsaw, and at the same time, there are also many solutions to this problem. If you are faced with this situation, then simply follow all the above recommendations and then, undoubtedly, you can repair your device, and it will delight you with its work for many years to come.

When to adjust the Stihl 180 carburetor

To begin with, it is worth deciding why it may even be necessary to adjust and repair the stihl ms 180 carburetor. So, this must be done in the following cases:

- If the chainsaw does not idle;

- Repairs may be required if the saw does not start;

- Power loss is observed;

- Increased fuel consumption;

- Chainsaw does not reach maximum rpm.

- Stalls when accelerating.

This list can be continued for a long time, but we have identified the main reasons. Before proceeding with the adjustment, you need to know what are the main parts of the carburetor on the Stihl 180 chainsaw, and who makes it.

Record 9 comments

I had the same problem, the new saw did not start after the 2nd refueling, which I just did not find in the councils, Unscrew the muffle, look the piston, but there is no need to do this if you feel that there is compression, the starting cable stretches with effort. And it turned out to be outrageous for our client, he poured a candle and for inexperience. We drain all the gasoline from the barrel. We unscrew the candle, check the spark, then drain the rest of the gasoline from the cylinder, for this purpose, turn the cylinder down and gently pull the starting cable draining the excess about 10 times. After that, I put the saw in the same position for 5 minutes for ventilation and drying, we twist the candle. We fill the tank with gasoline and oil in the indicated proportions. I put the lever in a cool start, pulling twice smoothly with the 3rd jump, started up from the third jerk. And I was already going to take to the service.

The same problem, a brand new saw, at the 2nd gas station finished starting. I checked, overflowing the carburetor, the spark plug in gasoline, after drying, a spark appeared. After purging the cylinder, as described in the annotation, I tried to start. When the damper is in the “Cold start” position, one flash, I move the damper to the start position. it does not start. He unscrewed the candle. again in gasoline. I blew the starter one hundred times, the problem is the same. And after going to your website, after reading Oleg’s advice (with regards to blowing with a starter in an inverted saw position), I tried it, 10 grams of gasoline poured out of the cylinder and carburetor. Then, attaching the candle (without wrapping it) to the tip, put the shutter on the starting position, blew it again. Collected, refueled. started up. So thanks to Oleg for good advice. !

Distribution chamber

In the distribution chamber, as in the fuel pump, there is also a membrane that opens and regulates the fuel supply by pressing a special rocker, while raising its needle valve.

The cover of the chamber is the compensator body, which is attached to the carburetor with four screws, a gasket is installed between the body and the cover, which increases the height of the chamber and is responsible for sealing.

Similar entries. Removal and installation algorithm

In cases where it is necessary to clean the Stihl 180 carburetor or disassemble it, first you need to remove the assembly from the chainsaw. This must be done in compliance with a certain algorithm of actions:

- Put the protective cover for the chainsaw on the tire.

- Remove the top cover of the chainsaw.

- Remove the two nuts securing the air filter and carburetor.

- Remove the air filter housing.

- Disconnect the wire from the engine control lever.

- Carefully remove the lever from its seat in the housing, at the same time disconnecting the air damper rod from it.

- Pull the carburetor towards you and disconnect the fuel supply as well as the throttle rod.

To facilitate dismantling, you can additionally untwist the rear handle and disconnect the throttle rod first from it, and then only from the carburetor. This may be required, because without some experience, disconnecting the rod from the carburetor is quite problematic and it is easier to first disassemble the handle.

To install the part in place, follow the reverse order of the algorithm.

When removing and installing the chainsaw engine control lever, you should be extremely careful, because the seat on the saw body is the weak link of the saw, and very often inexperienced users break it.

Stihl 180 Chainsaw Repair Will Not Start. Chainsaw Stihl 180 Will Not Start Reasons. Stihl 180 overflows Carburetor. Communities ›Do It Yourself› Blog ›Chainsaw Stihl 180. Self Repair

Eight years ago a saw was bought and worked faithfully. And once again, I got it, chifir-chifir, but it won’t start. The first thought is to send it for repairs, and then I thought I was coping with the UAZ, I could try with a saw. I checked the spark, there is a spark. Gasoline supply is also available. He unscrewed the candle and was filled with gasoline. In short, it comes out, overflows the carburetor. I rummaged through the net, it turns out that the gasket is in the crab, it dubs, constantly presses on the needle, hence the overflow.

In principle, the most difficult thing was to find spare parts in the city. A set of carburetor gaskets were purchased, two muffler mounting studs, the nuts sour, I decided to change for one, a reinforced air filter, a new sample and a toothed stop, the plastic teeth on the saw were already worn off.

Further, simply. We remove the air filter by unscrewing two nuts by 8, they also attract the carburetor, disconnect the fuel hose, remove the rods from the carburetor and snap off the shift control shaft and remove the carburetor.

We remove the lid, look at the gasket, oak, change it and everything is in reverse order.

It is even easier to mount the muffler with studs, grind off the nuts on emery and replace 🙂

And I also put a metal stop.

The saw started up, after repairs and has already been tested in work.

After a year of use again, a little bit, stuck.

It was necessary not to save and take the original repair kit.