The chainsaw starts and immediately stalls the reason

Chainsaw stalls under load

If the chainsaw stalls under load, this may be due to the fuel system or a dirty air filter. Changing the fuel with the correct gasoline / oil ratio or cleaning the air filter are universal solutions to this problem. An improperly prepared mixture of low-quality gasoline and, for example, engine oil is the main reason for the malfunctioning of a chainsaw, including in the case when it heats up and stalls.

The chainsaw starts and stalls. Why?

There are several simple rules for the operation and maintenance of a chainsaw, the observance of which will maximize its service life. Preparing the correct fuel mixture, regularly cleaning filters and periodically replacing parts will save you from having to repair your tool for a long time. If it was not possible to avoid the breakdown, then you can figure out its cause completely independently. This applies to any brands of chainsaws, from the more complex Husqvarna and Stihl models to the simplest Makita and Patriot models.

Chainsaw stalls when tilted

With the horizontal position of the chainsaw, the fuel pipe lies at the bottom of the gas tank, but when the tool is tilted, the pipe is above the fuel mixture, i.e. in the air. This is precisely the reason that the chainsaw stalls on its side.

Top Reasons Chainsaw Starts, Then Stalls — Chainsaw Troubleshooting

The chainsaw stalls immediately

What to do if the chainsaw stalls immediately after starting? First you need to check the presence of fuel in the gas tank. If its level is not enough, then you need to prepare the fuel mixture in strict accordance with the ratio of gasoline and oil prescribed in the operating instructions. Gasoline must have the highest possible octane number, and the required brand of oil, as a rule, is indicated in the data sheet of the chainsaw.

Next, we check the spark plug, as well as the contact of its tip with the high-voltage wire. The gap between them should be no more than 0.5 mm. If necessary, the candle is cleaned of carbon deposits and dried. It is recommended to occasionally change the candle to a completely new one. The reasons for the tool stalling when you press the gas lie in the fuel filter or carburetor jet. Cleaning the gas filter will not take much time and effort, but it is better to entrust the disassembly and cleaning of the carburetor to the specialists of the service center.

Chainsaw stalls at idle speed

Cases are common when the chainsaw stalls at idle. First of all, you need to check the muffler, and, if it is dirty, clean it from exhaust tar deposits. Also on the carburetors of some models, etc., there are bolts with the inscriptions H and L. respectively, rough and fine tuning. By adjusting the bolt L during the operation of the chainsaw in such a way that its speed increases (turn the bolt just half a turn), it is possible to eliminate this problem. Adjusting the carburetor requires the mandatory presence of an electronic tachometer and is a rather time-consuming process. That is why in such cases it is better to turn to professionals.

Chainsaw stalls at high revs

In the event that the tool stalls at high rpm, there are three parts to check: the air filter, the fuel pump, and the gasoline filter. The air filter must be cleaned, you can even wash it under water and dry it thoroughly. Then it is enough to disconnect the fuel hose from the carburetor and see if fuel flows out of it or not. If it flows with a full stream, the petrol filter need not be checked. If, on the contrary, the fault has been found. The breather can be cleaned with a regular needle, and the filter can be carefully disconnected from the suction hose, cleaned or replaced with a new one. The gasoline pump is checked for wear: if fuel does not seep through it, then everything is fine with it. If the problem that your tool stalls at full speed is due to some damage to the pump, then this part just needs to be replaced with a new one.

- Blog

- About the service center

- Serviced brands

- Diagnostics and repair prices

- Delivery

- Spare parts

- Contacts

Repair and service of garden equipment.

Specialized service center “Agrotechservice”. comprehensive warranty and post-warranty maintenance of garden and municipal equipment from world manufacturers! We sell spare parts with delivery throughout Russia!

Why does the chainsaw start and immediately stall

The chainsaw starts up and immediately stalls, the reason for this behavior may be hidden in the carburetor. A malfunctioning fuel pump or malfunctioning of the main fuel jet can cause this saw to behave like this. The inability to operate the chainsaw after starting, requires a full diagnosis at the service center.

All of the above options for engine malfunction have similar causes, which, depending on their neglect, can have different manifestations. For example, with a slight intake of air into the crankcase of the engine, its work will not change much, the engine power will drop slightly, its maximum speed will increase, and it will be able to heat up a little more. In the middle stages of air leakage, the engine will stop idling and will get very hot during operation. Strong air suction, will make it impossible for the saw to work, it will start and immediately stall.

In parallel with the visible manifestations of malfunctions, for example, the inoperability of the chainsaw after starting, processes will take place inside the engine at the time of its malfunctioning, which irreversibly lead the saw to the most serious consequences, for example, melting the piston, jamming the crankshaft.

The power unit stalls at high speeds due to a mismatch with the declared performance requirements of the electronic unit. Failure is more typical for budget chainsaws made in China.

The reason for the refusal may be:

- lack of fuel mixture in the float chamber due to valve sticking;

- clogged fuel filter or the breather in the fuel tank cap.

The power unit also stalls at high speeds due to a dirty air intake filter. The same signs are typical for a situation when the chainsaw starts up in standard mode and stalls during the warm-up phase.

How to start a chainsaw correctly?

Before starting the tool, you need to read its instruction manual. The instructions for some models indicate that the inertia brake must be applied to the chain to stop immediately before starting the saw. Thus, starting the tool will be safer for the operator. However, starting the saw will be much more difficult with the brake engaged. In practice, it is best to start the saw with the brake released, while adhering to the safety rules.

To properly start a cold chainsaw, you need to follow this procedure:

- The first step is to move the throttle adjustment lever to the lowest position. It should be noted that the lever can only be moved to this position when the throttle lever is pressed. This will close the carburetor throttle valve. To perform further actions, the throttle lever must be fixed in the pressed position;

- Then you will need to sharply pull the standard starter rope several times. This must be done until the saw motor starts, and after that it stalls. Next, the flap position lever must be moved one position up;

- After that, you need to sharply pull the starter rope again;

- Then you need to quickly press the throttle lever and release it. This will automatically move the flap adjustment lever to its operating position. The engine speed will drop, which will indicate the readiness of the chainsaw for further work.

To start the tool hot, you will need to move the throttle control lever to the middle position and rarely pull on the starter cable.

Checking the spark on the spark plug and eliminating the causes.

The first step in finding the reasons why the gasoline saw won’t start is to check the spark on the spark plug. There are many factors that affect the performance of this element. However, the main ones at the initial stage of instrument troubleshooting are:

- Incorrect carburetor adjustment;

- The presence of more than it should be, the amount of oil in gasoline;

- Clogged air filter.

All of them contribute to the formation of carbon deposits on the spark plug electrodes. In 50 cases out of 100, the saws do not start on a cold one due to the absence of a spark due to carbon deposits on the electrodes and their corrosion. As a result, the gap either decreases or increases.

Checking the spark plug with an idle chainsaw

It is quite easy to check for a spark. This will require:

- Remove the tip of the high-voltage wire;

- Unscrew the candle;

- Put the tip back on;

- Lean the candle with a skirt against the cylinder;

- Start with a starter.

If a good spark is observed between the electrodes at the time of starting the engine of the chainsaw, then everything is in order with the ignition unit. If it is not there, then it is worth cleaning the element itself and checking the gap of the electrodes. If necessary, use a special probe to adjust the distance between the contacts.

For candles from different manufacturers, the distance between the electrodes may fluctuate. For some, it may be equal to 0.5 mm. Others have 0.2 mm. Therefore, carefully study the manufacturer’s recommendations.

There may be no spark on the spark plug for other reasons. Of the main faults affecting the poor start of the chainsaw and the unstable operation of the internal combustion engine at idle, from which the tool can stall, the following can be attributed:

- Overflow of the spark plug channel with fuel;

- Lack of contact between the high-voltage cradle and the tip of the candle;

- Failure of the ignition unit.

How to start a cold chainsaw if the spark plug channel is constantly flooding with gasoline? To eliminate the problem while starting the tool, you can use the following algorithm:

- Unscrew the candle with a special key;

- Wipe it with a clean and dry cloth;

- Dry for 20. 30 minutes;

- Remove carbon deposits with a file and adjust the gap between the electrodes;

- Drain the remaining fuel from the spark plug channel and dry it;

- Collect everything and try to start the mechanism.

As a rule, these measures are enough to start the chainsaw and get the job done. However, this extreme measure does not eliminate the main reason why the engine does not start or stalls. improper operation of the carburetor, which needs fine adjustment.

If there is no spark and poor contact of the high-voltage cradle with the spark plug tip, check the connection. The check can be done using a conventional tester. If a defect is found and it is eliminated, the chainsaw should start without any problems.

If the check showed that the contact is reliable, and the saw does not start further, look for the cause in the ignition unit. As a rule, a faulty unit cannot be repaired and restored. A complete replacement is required here.

Checking the breather and cleaning it.

The breather is another element, from the improper operation of which the chainsaw may not start or stall during the sawing process. This element is located on the fuel tank cap in the area of the air hole. This is a kind of valve that does not allow gasoline to flow out and equalizes the air pressure required for the free flow of fuel into the carburetor.

If the breather is dirty, the working chainsaw stalls, and when started, it refuses to start. The thing is that air stops flowing through the hole. As a result, a negative pressure (vacuum) is created inside the fuel tank, preventing the flow of gasoline to the carburetor.

Defining the problem is pretty straightforward. Disconnect the fuel hose from the carburetor and see what happens to the gasoline. If it flows freely in a good trickle, then everything is in order with the breather. If it is absent or it flows weakly and intermittently, then the reason is identified. the breather is clogged with dirt. You can solve the problem by cleaning the air hole with a regular needle or a powerful jet of compressed air.

Chainsaw outlet check.

One of the reasons that a chainsaw does not start well may be a clogged exhaust channel or its muffler. At the same time, a drop in power is noted in the process of sawing sawn timber and logs. This is most often due to resinous deposits on the spark arrestor or muffler channel, which are formed during the combustion of a poor-quality mixture of gasoline and oil, which impede the removal of exhaust gases.

Resonator clogged with carbon deposits can cause poor starting of the gasoline saw.

Eliminate the reason for the poor start of the chainsaw, in this case, you can remove the accumulated combustion products. To do this, perform a number of manipulations:

- Remove the muffler by unscrewing the screws;

- Remove the cooling panel and gasket;

- Remove the spark arrestor;

- Disassemble the resonator housing;

- Wash all elements from carbon deposits with a detergent;

- Let them dry completely;

- Collect everything in reverse order;

To prevent dust and sand from entering the cylinder when cleaning the muffler, cover the outlet of the chainsaw engine with a clean rag.

Identifying and eliminating obvious chainsaw malfunctions.

To determine the reason why the chainsaw does not start or stalls when starting, it is necessary to troubleshoot the tool. The essence of the procedure is to consistently inspect the condition and operation of the main working elements of the saw motor. At this stage, we check:

- Spark plug present;

- Fuel supply;

- Filter status;

- The operation of the breather of the stalling unit built into the fuel cap;

- Discharge duct function.

The main causes of chainsaw breakdown

Although all possible breakdowns in some specific parts of the chainsaw system have been described, their solution may not be enough. It is necessary to dwell on some aspects of problem solving in more detail.

Determine the availability of fuel and its supply.

First you need to make sure that there is a fuel mixture in the tank of a chainsaw that does not want to start, and it regularly enters the carburetor. With a full tank, we check how the mixture is fed through the gas line. Disconnect the fuel system pipe from the carburetor and try to pump it up. In the case of a complete order, when pumping up, gasoline will be supplied in jerks in accordance with the norms set by the manufacturer. Poor or no fuel supply may result from:

- The fuel supply channel is clogged;

- Debris-clogged fuel filter.

Often the reason for a poor start of the chainsaw can be a tank that is too full. In this case, you should pay attention to the presence of smudges under the saw case cover. If present, see the connection of the gasoline feed pipe to the carburetor. Most often, it is squeezed out by pressure when the tank cap is screwed on, which is filled under the very neck, which prevents the engine from starting.

The quality of the fuel mixture can also be one of the reasons why the chainsaw does not start. If, after completing the work, the remaining gasoline is not drained, and the tool is left for long-term storage (more than 2 weeks), then the processes of resin formation and polymerization of the components will begin to occur inside the tank. What can cause carbon deposits on the piston, rings and cylinder liner. Therefore, always prepare the mixture only in the required amount before work.

Why the chainsaw starts and stalls

If the saw does start, but stalls at the first attempts to do the job, the reason may be different. The reason is chain jam due to lack of lubrication or problems with the chain brake, which makes further work impossible. In this case, check the oil level in the container. If everything is in order, the reason may lie in the tube leading the fluid to the lubrication mechanism. It can clog, break, stopping oil flow, or burst, causing oil to leak out without reaching its destination.

The reason is problems with the carburetor. Parts of it may have deteriorated and require cleaning or adjustment. It is quite difficult to determine the breakdown in this case. Cleaning the carburetor is a rather difficult and monotonous task that not everyone can do. The same applies to checking the condition of its parts. It is better to entrust such an operation to professionals. The only thing you can do at home (but only for some models) is to customize it. All instructions on how to do this are in the accompanying documentation.

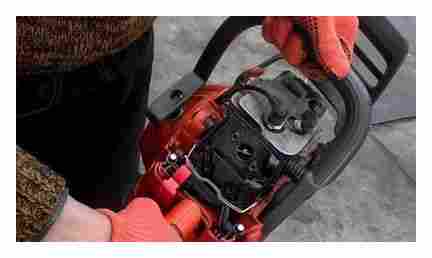

Chainsaw carburetor

The last reason is trivial. the low level of the fuel mixture in the tank. It manifests itself when the chainsaw stalls when tilted. The mystery lies in the fact that when the fuel runs out when tilted, it accumulates in a certain part of the tank. When tilted, the suction tube may end up in the airy part, which stops fuel flow into the chamber.

Why chainsaw stalls: reasons and solutions

If the chainsaw starts up badly and stalls, the performance of the simplest sawing work is out of the question. Not only budget-class instruments are subject to spontaneous failures, but also quite prestigious models of leading manufacturers.

The chainsaw starts and stalls. the reason

If the chainsaw starts and stalls at the first attempts to do the job, then the reason may be problems with the chain brake or its jamming due to lack of lubrication. In this case, the oil level is measured. If the amount of lubricant is sufficient, then the cause may be in the tube that leads it to the lubricating mechanism.

Another reason may be a broken carburetor. If he only needs adjustment, it can be done independently in accordance with the instructions. If the carburetor needs cleaning or repair, then you cannot do without the help of professionals.

Another possible cause of this malfunction is a low fuel level in the tank. In this case, the saw stalls when tilted, since the remaining fuel mixture ends up in the part of the tank opposite to the place where the suction tube is located.

An easy way to determine the quality of a mixture

The easiest and most affordable way to check the quality of the mixture is the spark plug center insulator. Brown color of any intensity indicates correct carburetor adjustment.

The consequence of working on a rich mixture is the formation of black carbon deposits on the insulator, a poor mixture manifests itself as a pure insulator of white or light gray color.

If, after normal start-up and warm-up, the saw, fueled with fuel, periodically stalls during operation, it is recommended to eliminate the vacuum in the gas tank by cleaning the breather. The reason for the unstable operation of the engine may be condensate water that has got into the carburetor float chamber.

Why the chainsaw doesn’t pick up speed and stalls

If the saw cannot gain speed or stalls when you press the gas, then most likely this is caused not by the tightness of the carburetor or engine crankcase. This problem is eliminated by checking for leaks and adjusting the carburetor.

In addition, this malfunction may be associated with a defect in the fuel tank breather. Due to the formation of a vacuum in the fuel tank during the operation of the chain saw, the required volume of the fuel mixture does not enter the engine, as a result of which it cannot gain speed or stalls. If you stop the chain saw, open and close the fuel tank and turn it on again, it will work normally for about five minutes, and then it will stop picking up speed again or stall.

Another possible reason that the saw is not able to pick up speed may be excess carbon deposits in the muffler, which makes it difficult for exhaust gases to escape, which reduces the power and engine speed.

Determining the nature of the malfunction

The main part of the failures of chainsaws of any class falls on fuel equipment. For the ignition system, this figure is an order of magnitude less. Stopping the chainsaw due to mechanical malfunctions in the practice of domestic and professional sawing works is even less common.

Add comment Cancel reply

To post a comment, you need to log in.