The clutch on the motobloc Agro does not work

The clutch of the power tiller. Agro single axle tractor: clutch repair How to properly adjust the clutch on a motoblock

Nowadays, special equipment is quite often used in agriculture and horticulture. Here separately distinguishes such equipment as a single-axle tractor. These devices allow you to quickly and accurately process the ground. However, like any kind of equipment, such equipment can also fail. Important components of this machine. the motor and transmission. These two components work together, and the mating is done through the clutch disc for a power tiller Agro or other type of equipment. In this case, it is necessary to consider in detail how to replace and repair the clutch on a power tiller Agro.

You can repair the clutch in this motoblock by yourself

Assignment and varieties

The clutch provides inertial torque transfer from the crankshaft to the transmission gearbox, ensures smooth starting and gear shifting, regulates the contact between the gearbox and the motor of the tractor unit. If we consider the design features, clutch mechanisms can be subdivided into:

According to the operating environment, a distinction is made between wet (in a bath of oil) and dry mechanisms. According to the mode of activation, a permanently closed and a non-permanently closed device is distinguished. By the way torque is transmitted. one stream or two streams. a distinction is made between single-flow and dual-flow systems. The design of any clutch mechanism includes such elements:

The friction clutch is the most popular among farmers-owners of motor-block machinery, because it features ease of maintenance, high efficiency and long continuous operation. The principle of operation is based on the frictional forces that occur between the contact faces of driven and driven parts. The leading components work in close connection with the engine crankshaft and the driven ones. with the gearbox main shaft or (if the gearbox is missing) with the next transmission unit. The friction system elements are usually flat discs, but some models of power tillers have a different shape. chock or cone.

In the hydraulic system, the torque is transmitted through the fluid, which is pressurized by a piston. The piston is returned to its original position by the springs. The electromagnetic clutch is based on a different principle. the system elements move under the influence of electromagnetic forces.

This type refers to permanently open. The centrifugal clutch type is used in boxes that automatically change gear. Not too popular because of the rapid wear of parts and the long slipping time. Disc type, irrespective of the number of discs, is based on one principle. Reliable and smooth starting and stopping of the machine.

The belt clutch is characterized by low reliability, low efficiency and rapid wear, especially when used with high-powered motors.

Controls of a power tiller

It is a system of mechanisms that allows you to change the speed, as well as the direction of the motoblock. The controls include the steering wheel, clutch and gearshift levers, throttle position control knob and more. Since power tillers are not equipped with operator’s seat, it means that maneuvering of such machines is carried out by hands. But if you can buy a cart with a seat in a specialized store, then you will get a mini-tractor.

The clutch is an integral element of the transmission, whose task is to transmit the torque received by the crankshaft to the gearshift box, and disengage the gearbox from the engine when shifting the speed of the motoblock. It is the presence of this mechanism that allows the farm machine to move smoothly from the ground and can stop without completely shutting off the engine.

Centrifugal clutch. device and benefits

This element is worth standing out because of its reliability and durability. It is used in automatic transmissions. Its design consists of the following elements:

- Flywheel;

- Pulley

- Hubs with a locking groove and key;

- Flange;

- Sleeve;

- The shroud;

- Bearing;

- Retaining ring.

One of the most important roles is played by the differential, which is connected to the centrifugal clutch. It helps improve the maneuverability of the machinery and ensure a smooth ride in corners.

Together with the clutch, the differential regulates the rotation of the wheels of the power tiller at different speeds. over, the mechanisms that transmit power together act as wheel locks. Some models of equipment instead of a differential install a special device that blocks one of the wheels of the power tiller on the driver’s command.

modern machines are fitted with a friction clutch. It is mounted between the engine and the gearbox. In this design, the driven parts are closely connected to the transmission’s primary shaft, and the driven parts are connected to the motor’s crankshaft. In most cases. both master and slave elements are made in the form of flat round discs or cones. Just like the centrifugal clutch, the friction clutch is actuated by manipulating a separate handle.

What to do if the Ugra single axle tractor won’t start

We suggest familiarizing yourself with the reasons that affect the starting of the power unit of the power tiller “Ugra”:

- Lack of fuel: fill up the fuel tank.

- Oil ran out. refill.

- Trouble with spark plug: smoky. clean and flush in gasoline; wet. flush and dry, replace plug; burnt out. replace plug.

- No spark: adjust contact gap;

- Trouble with magneto: adjust its position if the blades are jammed; replace it if it is burned out.

- Requires repair carburetor motoblock “Ugra”: if clogged. disassemble and clean; out of service. replace.

- Filters (air and fuel) clogged: cleaning or replacement.

About the Motor Sich single axle tractor. Adjustment of clutch of power tiller

Adjustment of motor Sich clutch.

Adjustment adjustment, repair, modernization of clutch single axle tractor Motor Sich.

MB Motor Sich clutch is a continuously closed multi-disc clutch in an oil bath. Three clutch slave discs and three clutch drive discs, half clutch drive (flower), half clutch slave, three springs, pusher.

All of this you can view and find out more in the articles on this website:

In this article, I would like to show a detailed. where the owner of a Moto Sich motoblock has summarized his own experience and the experience of other owners of MB Motor Sich.

The fact that the clutch really motor Sich motoblock clutch is very reliable, there are no complaints and problems with it, but there are certain aspects that each owner of power tiller decides for himself, based on his own experience and knowledge.

READ How to adjust your STIHL 250 chain saw

Naturally, it is always better to use the experience of other owners of similar equipment, especially if it is a positive experience and all improvements lead to positive results.

For example, many owners of Motor Sich motor blocks make cuts in the clutch disks, which have a positive impact on the engagement of gears photo.

Device adjustment adjustment repair modernization of single axle tractor clutch Motor Sich.

If you have any questions or additions, please do not hesitate to write in Комментарии и мнения владельцев.

How to adjust the clutch on mtz 82. The Equipment Expert

Checking and Adjusting Transmission Mechanisms

Checking of tractor main clutch includes check of its condition and adjustment.

Checking condition. While driving the tractor on level ground at medium engine revolutions, apply the parking brakes to the tractor. If the tractor engine stalls, the clutch is functioning normally. If the engine does not stall, but only reduces the speed of the crankshaft. the clutch is slipping.

Advertising offers based on your interests:

To check the adjust-k and clutch is to measure the free play B of the release pedal (fig. 79, a) or distance A (Fig. 80, a) between the stop 8 of the release bearing and the pressure ring (or release levers), and the distance B (Fig. 80.6) between the end of the brake shoe boss and the end of the nut when the shoe is pressed against the pulley.

Measure the clearance A with a feeler gauge through the hatches specially made to access the clutch.

Check the pedal’s free stroke with a fixture or ruler. If this finds irregularities in regulation, the clutch must be adjusted.

Adjustment of main clutch of MTZ-80 tractor. Disengage the brake rod from the lever.

Release clutch pedal from spring action by tightening bolt all the way to the bracket and loosen screw to allow bracket to move. Adjust the pedal’s free play B by changing the length of the lever.

Turn the brake rods counterclockwise as far as they will go and fasten the brake rods with the screw.

Unscrew the screw until the pedal rests on the cabin floor.

Check the free play of the B pedal. When the pedal is depressed by the size of the free stroke, it should return to the starting position freely without dawdling under the influence of the spring. Check and, if necessary, adjust the compression of the spring 8.

Adjust the brake clearance by turning the lever counterclockwise as far as it will go. By changing the length of brake-link rod achieve the alignment of holes in fork of brake-link and pressed to the stop lever.

Reattach the pull rod to the lever and if it is loose with the lever, disconnect it again. Shorten by 7mm, refit, cotter pin and tighten linkage locknut.

With properly adjusted brake control, the spring 8 of the traction rod should be compressed an additional 34 mm when the clutch is released.

Clutch adjustment on tractor T-150K- If between the body (pic. If there is a gap B between the release mechanism body (Fig. 80, a) and the cup end, adjust the rod length. If there is no backlash, then due to wear of the linings of slave discs, clutch adjust the original position of the squeeze levers ring, determined by the gap A between the ring and the squeeze bearing stop.

Adjustment by changing the length of the pull rod (external adjustment). Disconnect the pneumatic chamber rod from the swivel arm.

Loosen the counter-nuts on the link and turn the link to the required clearance A, then retighten the loosened counter-nuts and check the clearance again.

Loosen the nuts fixing the pneumatic cam and, rotating rod yoke, align the hole in the yoke with the hole in the swing lever. Then finger them together so that the rod is in its rearmost position, and tighten the loose nuts securing the air chamber.

Adjustment by changing the position of the release levers (internal adjustment). Disengage the air chamber rod from the lever.

Bring one of the release levers to the hatch, loosen the screws securing the locking springs and unscrew the nut a turn and a half (turning the nut one facet changes the position of the ring release levers by 1.1 mm).

Turn the engine crankshaft 1/4 turn each time, loosen the screws, and loosen the nuts on all three clamping levers.

Loosen the locking bar nuts and set the desired slack A by changing its length.

Check the value and the uniformity of the gap between the stop and the ring when the clutch is engaged, as well as the simultaneous contact of these parts along the entire circumference when disengaging the clutch.

Lock the adjustment nuts with the locking plates, and tighten the locking spring retaining screws securely.

Loosen the nuts securing the pneumatic chamber and, turning the fork rod, align the fork holes with the lever holes. Fit them together with your finger so that the plunger is in its rearmost position.

Check the stroke of the housing release mechanism, which when fully depressed on the pedal should move by 2122 mm, and the full stroke of the pedal at the same time equal to B.

Checking and adjusting brake action. Press the pedal, fully disengage the clutch and measure the gap B (Fig. 80,6).

If the backlash B is not normal, with the clutch off (pedal depressed), turn the nut to set the backlash required by the specifications.

Adjusting the traction control. If the clutch release pedal does not return to its original position, and its lever freely passes into the hole in the cabin floor, then increase the clearance between the plunger (Fig. 80, a) and the servomotor valve.

In order to do this work, remove the tracking device from the tractor, having previously disconnected hoses from it, as well as plunger forks and rods from the levers.

After that, unscrew the crossover nut and take out the spring and the valve. Then loosen the locknut and, turning the adjusting nut, set the distance of 1.8±0.1 mm from the plug face to the valve seat face. After the adjustment, tighten the lock nut, put the valve and spring back in place, screw the adapter nut back in place. Put a tracking device on the tractor, connect it to the levers and hoses.

single axle tractor Neva MB1-C6,5 PRO deal with clutch

Not always radio amateurs sit in front of transceivers, repairing electronics or something construct, they sometimes have very other things to do.

Now I had to deal with the clutch on my Neva MB1 power tiller, t.к. The single axle tractor was always trying to go somewhere and didn’t really want to engage gears.

For agricultural work in the countryside we have a single-axle tractor Neva MB1. It’ll help you plow the land and mow the grass.

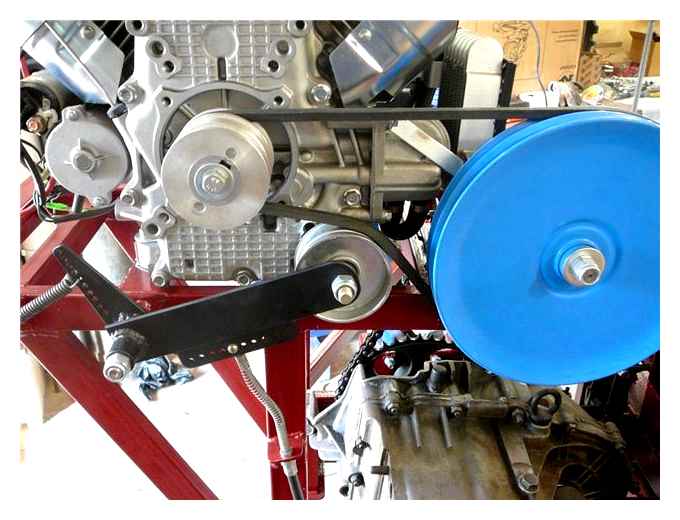

To mow the grass, we use a rotary mower ZARYA. It is fastened to the front of the power tiller, and its drive belt is put on the engine pulley, in parallel with the drive belt on the gearbox of the power tiller.

We’ve had this whole system for about 4 years now. Mower is being pulled up and down often and the drive belt is being manipulated all the time. But there was a problem with the clutch.

Description of clutch problem

Earlier, with the clutch off, switching gears on our “tractor” had no problems, but recently began to manifest itself problem. the clutch is off, but the speed does not engage, gear howling but not going in gear. No problems if engine is off, no problem, clutch engages sharply and does not pop out. The box is fine.

As it turned out, the clutch is no longer engaged and the shaft does not stop. And if the speed is on, the single axle tractor, even with the clutch off, tends to drive itself away (demonstration of the problem in the video below).

Well, this is just beyond any limits!

How a power tiller clutch works

Neva MB1-C6.5 PRO single axle tractor. How the clutch works

The clutch in power tillers does not work like in a car, but vice versa. By pushing the clutch knob, we lift the roller (1) it tightens the drive belt and the tensioned belt starts to transmit the rotational motion from the motor shaft (2) to the gearbox shaft (3). Here we go. By releasing the knob, the roller (1) is lowered, the belt is loosened and the gearbox shaft (3) should stop.

It should, but it doesn’t stop! It means that the whole primary shaft of the gearbox doesn’t stop, so the gears howl but don’t mesh and the speed won’t turn on.

Trying to solve the problem

The first thought that came to mind was to adjust the clutch pulley (1), even when released it may not loosen the belt enough. I just disconnected the roller from the cable that comes from the clutch lever, the roller lowered to the maximum, but no miracle happened, the belt kept clinging to the engine pulley and transmit the rotation.

Well, now it’s all clear, something with the belt (swollen, became too rough, I do not know). 4 years of work apparently it finished, we order a new one and that’s it, the problem is solved, well, what else can be in such a simple scheme does not work.

As it turned out to buy the belt for this model is not so simple, all under the order and basically costs money.

When the new belt came and was installed in its place, it didn’t change the situation a bit, everything was exactly the same as with the old belt, the gearbox shaft rotated like crazy, it could only be stopped by a foot.

Then the following manipulations were done:

- engine shaft and gearbox shaft pulleys were degreased and cleaned

- Checked the installation of the engine on the frame and alignment of the engine

- Installing the original pulley on the engine (we used a non-native 3-speed pulley)

- finally greasing the pulleys and the belt (then it took a long time to clean them)

The result is ZERO, the problem did not go away, there was no solution either in the manual or on the Internet

Finally a solution to the clutch problem

It was just a matter of watching the whole thing spin without stopping and in the end the solution came all by itself.

There are 2 belt limiters near the engine pulley, bottom and top, these are 2 steel tendrils that can lift and lower with a little effort. Their meaning is not described in the manual, I figured their job is to keep the belt from coming off the engine pulley, and their position is not very important.

Over time, because of the settings of the rotary mower, and in particular its drive belt, these 2 stops have moved closer to the pulley and further away, and before this had no effect on anything. But apparently this time there was a critical moment, they both bent so far away from the pulley that they stopped touching the drive belt. The belt, in turn, did not experience any braking effect and did not bend in the right way, did not lose grip on the engine pulley, even in a relaxed state.

After watching for a long time, with the clutch off, how the drive belt was spinning and how it was wobbling, I had the idea to press those limiters to the belt, and voila, the belt was a little crooked, took the right shape on the engine pulley and stood like a rocker when relaxed, and with the clutch lever depressed, the roller pulled the belt and now everything was spinning as it should.

The problem with the clutch engaging and the spontaneous motion of the power tiller was solved.

with demonstration of clutch problem and its solution

The video demonstrates a clutch problem and shows how to fix it.

I hope this article will be helpful to someone. I myself lost a total of 6 days and more than 1500 to fix the problem.

Disassembly and Reassembly

In order to disassemble and then reassemble the transmission, it is recommended that you follow these tips:

- the mechanism is disconnected beforehand, and in addition all the oil is drained from the device;

- the next step is to unscrew the oil filter and completely remove the clutch and gearbox;

- Next is the removal of the protective box, followed by disassembly of the transmission unit and the removal of gears and shafts;

- then a full flushing of the attachment with a special composition is carried out;

- Subsequently, after drying, a full assembly is performed, and in addition, the replacement of damaged elements, if necessary;

- Finally, the machine is mounted in place, and fresh oil is poured.

Finally the oil filter is mounted and it needs to be properly tightened, but before doing so, a gasket must be installed so that afterwards no grease will leak from the transmission unit.

Adjusting

Over time this mechanism will gradually wear out, so you need to make adjustments. Let’s consider in more detail how this procedure is performed:

- First of all, you should find a comfortable and spacious place;

- it is necessary to detach the catches;

- it is necessary to release the tension rope;

- then it is necessary to grease everything with a special grease;

- Then the cable is tightened and the spring is shortened;

- it is necessary to turn out a bearing in a more suitable position.

When adjusting the length of the rope so that the squeezing of the handle does not require great effort.

Important! When adjusting the clutch on your power tiller it is always necessary to lubricate the elements, otherwise there is a risk that the tensioner will break or squeeze badly again.

The device and the scheme of a power tiller, the engine

Engine scheme of a power tiller “Agro“. UMZ-341

The device, repair and adjustment of the carburetor

The diagram below shows the unit of “Agro” motoblock carburetor. model KR-45R.

Type of carburetor: float. Horizontal diffuser arrangement.

Adjustment (tuning) of the “Agro” power tiller is made only with the warmed up engine, the throttle position is regulated with the help of a special regulating screw. Idle speed should be low enough to keep the engine running and sounding smooth and even. Adjust the maximum and minimum engine speeds several times until the desired result is achieved.

Glands, anthers, bearings

- For power tillers “Agro” used bearings with inner diameter of 20 mm, outer diameter of 47 mm. Bearing width. 14 mm.

- Oil seals (oil seals) for this model: for gearbox/transmission oil seal size 2.2-30×52×1, for the primary shaft the oil seal dimensions are 20×42×10 mm

- Oil seals for Agros: universal for power tillers of 6-9 liters.с.

Clutch, transmission, flywheel

Transmission “Agros” consists of such elements:

- cone clutch. dry type, with friction clutch;

- Gear reducer;

- Differential (has a function of forced locking).

Ignition, starter, spark plugs

- Ignition of power tiller “Agro” is made with the help of contactless magneto MB-23U.

- The power tiller is started by hand starter, after starting the cord is automatically removed. Power generator capacity of the walking tractor engine is 25 watts.

Candles for this unit: type A11-3. Allowed to replace the plugs on the type A-17B (in the transition to a higher-quality gasoline, for example, AI-92).

For such a transition it is also necessary to shift the ignition advance angle by two degrees. Direction of ignition. counterclockwise.

If you own a power tiller of this model, share the link to the video of your machine in the Комментарии и мнения владельцев to this article.

Nowadays, special equipment is often used in agriculture and horticulture. Here separately identifies such equipment as a single axle tractor. These devices allow you to quickly and accurately process the ground. However, like any kind of equipment, such equipment can also fail. Important components of this machine. motor and transmission. These two components work together, with the mating is carried out through the clutch disc for the motoblock Agro or other type of equipment. In this case, it is necessary to consider in detail how to replace and repair the clutch on a motoblock Agro.

You can repair the clutch on this tiller by yourself

Clutch for a power tiller with your own hands

Regular operation of the clutch system implies a constant friction of its parts, so that even the most reliable mechanism sooner or later breaks down. After that, you can buy a new device, or try to make a homemade clutch for an agricultural machine.

Before making a clutch for a single axle tractor, you will need to prepare certain parts. For the job you will need:

- Flywheel and a primary shaft taken from a gearbox from a Soviet Moskvich;

- A steering knuckle and a functioning hub from the Tavria;

- Drive pulley, complete with two knobs;

- Crankshaft from the car GAZ-69;

- B-profile.

- First, grind the used crankshaft so that it does not touch the other internal elements of the unit;

- Next, put on the shaft on the regular hub of your motor block;

- Flatten the place in the surface of the shaft for mounting the bearing. As a result, the hub should be installed without the slightest backlash, and the pulley itself should rotate freely around its axis;

- After that, turn the crankshaft over and do the above steps on the back side of it;

- Then make 6 holes in the pulley, using a drill with a 5mm drill bit. The distance between the holes should be the same. Take into account that 10mm bolts will be screwed into the holes, so you also need to drill holes on the back side of the pulley;

- Put the pulley on top of the flywheel, and bolt the two parts together. Next, mark the places where you need to drill holes. Note that they must match the holes previously drilled in the pulley;

- Pull out the pulley and drill small holes in the flywheel;

- Flatten the surface inside the flywheel and shaft so that the parts do not touch each other;

- The mechanism should include the clutch handle on the single axle tractor. To make it, take a tube, length 30 and a diameter of about 10 mm, and fasten it to the pulley;

- The clutch cable for the power tiller can be taken from an old chainsaw, or you can buy a new cord and wrap it around the spool.

Home-made clutch is suitable for installation on Agro, Neva MB-2 and other brands of agricultural machines.

The clutch is tightly connected to the gearbox. It has a fairly important function. Namely, it transmits torque from the crankshaft to the gearbox, located in the transmission, decouples the gearbox and crankshaft (this is done during gear shifting). And also this mechanism ensures the smooth running of the motorblock from the seat. It makes it possible to stop the machine without shutting off the engine (this is possible through the clutch lever, cable and the entire system).

What types there are

Depending on the design features of the motoblock, the mechanism in question can be of the following types:

- friction

- hydraulic

- electromagnetic;

- centrifugal;

- single-disc;

- double-disc;

- multi-disc;

- belt-driven.

The centrifugal clutch has a number of applications, one of which is to make it easier to control the tiller. The clutch provides a smooth start because the clutch disc is pressed against the clutch disc automatically.

It includes the following component parts:

- Clutch cable;

- handwheel;

- release bearing;

- the trigger lever;

- a clutch lever mounted on a single axle tractor;

- The transmission’s primary shaft;

- slave disc;

- handle;

- lock washer;

- rod mushroom;

- fork disengage.

By the way, if the owner of the motoblock has no experience in locksmithing, he will not be able to make the clutch with his own hands. only replace or repair it.

Running-in

Main rules for starting, running-in and operation of Ugra:

- before the first start make sure that the single-axle tractor is ready to work. assembled, stands on a level surface, filled with oil and fuel to the recommended standard;

- after the first start-up the next 25-30 hours are the running-in period, and during this period it is allowed to load the single-axle tractor with two-thirds of the power;

- start work preferably at temperatures above zero, if the single-axle tractor is used in winter, keep it in a warm room at temperatures above zero before turning it on;

- Do not change gear without stopping the single axle tractor;

- Regular service and replacement of worn out parts on the power tiller must be carried out;

- on dense soils, the coulter must be mounted with the point toward the ground, so that the single-axle tractor can brake quickly;

- Use the “Stop” lever to stop immediately;

- Perform the first passes of dense or frozen soils on low gears;

- During the running-in period you should work with the power tiller on soils that have been previously cultivated;

- After the break-in period change the oil and top up the single axle tractor.

Please note that these rules apply to all Ugra power tillers, regardless of modification. Before starting to use, it is mandatory to study the instruction manual for the machine.

Review of motoblock Ugra, running-in in the video review:

Classification of clutch mechanisms

According to the available design features of agricultural machines, they can be equipped with clutch mechanisms of the following types:

- Friction-type clutch. this kind of mechanism is in the highest demand among buyers. Its main advantages include ease of use and self-maintenance, as well as high performance and long service life;

- Centrifugal type clutch. this mechanism is not so popular due to their tendency to prolonged slippage. The centrifugal clutch has many parts that rub against each other and are subject to increased wear and tear. That is why the centrifugal clutch is not in such high demand among farmers;

- belt-type clutch. the main disadvantages of such units include low performance and extremely low reliability. Belt clutch of a power tiller rather quickly comes into disrepair, especially if the agricultural machine is equipped with a powerful engine;

- disc-type clutch. the agricultural machine may have a single disc or multiple disc mechanism. The disk clutch on power tillers is completed with reliable spare parts, the correct placement of which ensures a smooth start of the power tiller used in the farm.

This kind of classification allows each of the buyers to pick up the optimal mechanism for his motor-block by design and characteristics.

How to choose the right spare parts for the “Agro” single axle tractor

If a single-axle tractor is constantly in active operation, most possible malfunctions still come from trivial wear and tear of parts. According to statistics, such equipment most often requires replacement of clutch mechanisms or bearings. However, no matter what part needs to be replaced, the choice of a new one always depends on the brand of the power tiller manufacturer. There should be no problems with Agro units. it is one of the popular Russian manufacturers, and the of spare parts for the Agro power tiller are much more affordable than for imported models. It is important to consider the following nuances when choosing spares:

- The manufacturer. On the manufacturer, its manufacturing policy and used materials will depend on the quality, as well as the service life of components.

- Reputation as a supplier of spare parts. It is recommended to buy this type of product only from trusted companies that have already been able to prove their integrity. Only in this case the owner can be fully assured of the originality of the spare part to the “Agro” motoblock and exact accordance with the brand of the aggregate.

- Service level. Not every owner of a power tiller is competent enough to buy the parts he needs on his own. You may need a specialist who is able to choose the most optimal configuration of parts, individually to your motoblock “Agro”.

- Cost. This issue is never left unattended. it must match the quality, but not be overpriced. On the other hand, the low price can be as unreliable part, and the counterfeit of normal quality. Here it is also important to have enough knowledge to distinguish a really good product from a cheap imitation.

Simply speaking, having enough competence in this sphere to choose and install all the necessary spare parts, to resurrect the single-axle tractor “Agro” is not very difficult. As a representative of domestic agricultural machinery, still respected by other manufacturers in its industry, well repaired “Agro” will serve you for a long time without interruption.