The forwards chain saw stalls when hot. Algorithm of checking the crankcase for leaks

Why the chain saw does not start or stops: causes and remedies

Every chainsaw owner faces malfunctions on a regular basis throughout the life of the tool. As a result of various malfunctions your chain saw refuses to start or works with a noticeable dip. The troubleshooting experts can help you. However, in order to save time and money, you can try to repair the tool yourself. You don’t need expensive equipment. All you need is the tools that you can find in any garage.

Before you start the tool you should read its owner’s manual. The instructions for some models state that before starting the saw, the instantaneous chain stop inertia brake should be activated. This will start the tool in a safer way for the operator. But it is much more difficult to start the saw if the brake is on. In practice it is best to start the saw with the brake off and follow all safety rules.

To start the cold chain saw correctly, this is the procedure to follow:

- The first thing to do is to move the throttle position lever to the lowest position. Note that you can only move the lever to this position when the throttle lever is depressed. During this time the throttle of the carburettor will close. If you want to do something else, you have to keep the throttle trigger in the depressed position;

- Then sharply pull the cable of the starter a few times. This should be done until the engine starts and then stalls. Then it is necessary to move the throttle position lever one position up;

- Then pull the starter rope again sharply;

- Then briefly pull the throttle trigger and release it. The choke control lever will move back into its operating position automatically. The engine speed will drop, which will indicate that the chainsaw is ready for further work.

To start when the machine is hot you need to move the throttle control lever to the middle position and pull the starter rope lightly.

A chainsaw that starts and stops

If you have problems with the chain brake or the lubrication level of the power tool is insufficient, it could mean that the machine does not start. The first thing to do is to check the oil level. if it’s not enough, then refilling the fluid will solve the problem. But sometimes the level is in the normal range, but the engine still stalls. That means the problem might be in the oil pipe that feeds oil into the lubricator.

It might also indicate that it is the carburetor that is causing the problem. It might be necessary to adjust it according to the instruction manual of the chainsaw. But if the carburetor is badly clogged or broken it is better not to try to repair it yourself. contact a professional technician.

Sometimes the chainsaw will not start up correctly because the fuel level is too low. when you tilt the tool, the fluid drains from the suction tube.

Why the chainsaw stalls, the main causes.

Although the chainsaw is an uncomplicated device, from time to time its operation suffers from malfunctions that can only be corrected by disassembly. The following are examples of malfunctions:

- the chainsaw does not pick up speed;

- The chainsaw stops functioning in the cut;

- the chainsaw starts and stops

- The chainsaw loses its power;

- Chainsaw stalls when pressed.

Most often malfunctions are associated with interruptions in the functioning of the motor, as well as with failures of other systems and assemblies. Proper handling of this equipment is important. If all the rules of use are followed, problems are likely to be the most obvious. When searching for the cause of a problem, it is advisable to start with checking the simplest part of the chainsaw and end with the most complicated part.

What causes the chainsaw to start and stop?

Using a chainsaw makes hard work easier. But sometimes the chainsaw starts and stops, and the cause can be anything. What to do? The choice is yours: take it to a specialist workshop or try to repair it yourself.

We will try to help the reader to understand the causes of failure, methods of elimination of breakages and give tips on chainsaw operation. In turn, it will be useful for the owner to get acquainted with the factory instructions for use and design features of his chainsaw.

This information will help him properly use and professionally perform repairs on the tool.

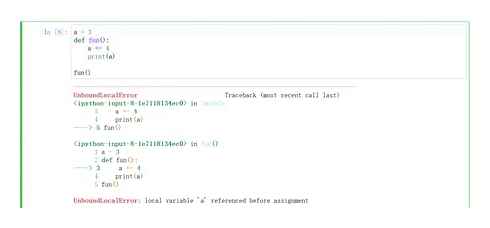

Internal Combustion Engine Characteristics of Chainsaws

The chain saw’s main malfunctions are related to engine failures. Domestic and foreign manufacturers use single-cylinder two-stroke internal combustion engines as chain drive. The engine design is simple. Ignition is normal, without the installation of capricious electronics. chainsaw engines can operate reliably in various climatic conditions. Fuel for the carburetor engine is obtained by mixing AI-92 gasoline and special oil.

As there is no oil pump, the piston and the cylinder are lubricated by a mixture of petrol and oil. The chainsaw engine develops power from 2 to 5 kW and the crankshaft speed is up to 14000 rpm. Such high RPM and loads place very high demands on the oil. Use the oil specified in the manual. Oil changes to normal engine oil greatly shortens the life of the tool.

Remember, it is strictly forbidden to fill the tank with gasoline without adding oil.

Ask Troy Live. Chainsaw Use & Maintenance

Tools and materials

Two-stroke chainsaw engine diagram.

The design of the chainsaw mechanical components is characterized by good reliability and maintainability. Virtually all parts and fittings are accessible. With the necessary equipment, they are easily removed for repair or replacement. To conduct disassembly and check the life-support systems of the chainsaw engine, you should stock up on the following tools and materials

- set of plumbing and installation tools;

- socket wrench;

- tester;

- pressure gauge to measure compression;

- feeler gauges to measure the clearances;

- needle;

- sandpaper;

- Fuel mixture (gasoline oil);

- rags.

Engine trouble shooting classification

Before you start up the chainsaw you should check the condition of the cutlery and fill the fuel and oil tanks. After checking proceed to startup. If you notice abnormalities or malfunctions in the drive system, carefully check the engine. As a result of external inspection, make sure that all units are complete and intact, there are no mechanical damages, petrol and oil leaks. Let’s point out the main malfunctions associated with poor engine performance:

- Engine won’t start.

- Starts, but chain saw soon stops.

- Is the saw unstable?

- Stops working on load.

- Loses its power.

Engine troubleshooting is conducted along the following main lines:

The chainsaw mechanisms need constant care, preventive maintenance, and repairs.

Knowing how a two-stroke gasoline engine works will help the operator determine the cause of the failure himself and quickly restore the chainsaw’s operation.

Troubleshooting by yourself

If the engine cannot be started, perform the following actions in sequence:

Location of air filter and spark plug.

- Check if there is petrol in the tank.

- Change the fuel if it has been stored for more than a month.

- Check the fuel filter. Disconnect the hose from the carburetor and watch the trickle. If gasoline flows freely, the fuel filter is not clogged. If it does not flow sufficiently, clean the filler cap hole or the filter.

- Clean the air filter. The air filter can be removed for a test run.

- Inspect and clean the muffler from cinders.

- Check that the starter is working properly. If necessary, carry out repairs to the starter (replace the pulley, spring or rope).

- Disassemble and clean clogged carburetor.

- Use a tester to test the high-voltage wire for a breakage.

- Measure the gap between the flywheel magnets and the ignition module (should be 0.2 mm).

- Unscrew plug and inspect it. Measure the gap between the electrodes with a feeler gauge (normally 0.5-0.6 mm). By the appearance of the electrodes determine the nature of the fault. If the spark plug is dry, there is no mixture. The working part filled with gasoline indicates poor carburetor adjustment or lack of spark. To check for spark, connect the high-voltage tip to the spark plug, place the skirt on the cylinder radiator and pull the starter cord. If there is no discharge between the electrodes you need to replace the spark plug. Carbon deposits on the electrodes indicate a low quality fuel mixture. The center and side electrodes should be cleaned with sandpaper.

- No compression. The reason. failure of the piston group. Measure compression. First unscrew the spark plug. Then put a pressure gauge in the cylinder bore and use the starter cord to move the piston. The condition of the cylinder-piston group is judged by the pressure in the cylinder. It should be at least 8 atm. Low readings are caused by worn cylinder, piston, piston rings.

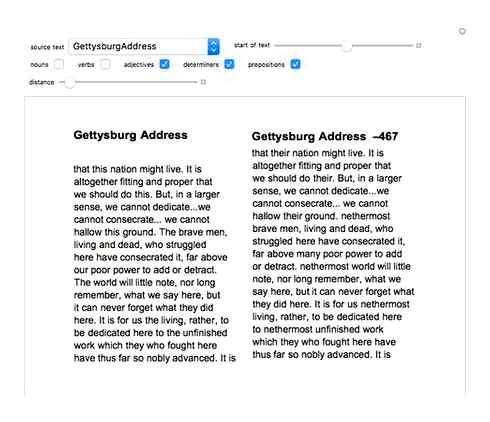

What to do if the engine stalls after it is started??

Diagram of interaction between fuel and air flow in a chainsaw carburetor.

We often see the saw not working for a long time after starting. the chainsaw almost immediately shuts down. There are several signs of this malfunction. Listed are probable causes of malfunction and remedies:

- No or insufficient fuel volume. If failure occurs when sawing in a tilted position, this indicates that the fuel intake tube is elevated above the fuel level. Check fuel level in the tank. Check the spark plug for leaks and damage to the fuel system.

- Poor fuel mixture. Adjust fuel to the exact specifications of the saw manufacturer. Completely replace the mixture.

- The breather plug is clogged. Low fuel flow to the engine. Breather. breather hole in tank lid. Clean the blockage with a needle.

- Poor contact between the spark plug and the high-voltage wire cap. In this case, the headlight insulator of the spark plug is very hot. Clean the contact and put the “cradle” tightly on the spark plug.

- Faulty spark plug. Replace with new or known good spark plug.

- Clogging of the muffler by products of combustion (exhaust gas). It is necessary to clean the muffler.

- Carburetor not adjusted. To adjust the mixture quality the carburettor has 3 screws: “L”. fine adjustment, “H”. fine adjustment of high rpm and “T”. adjustment at idle rpm. Follow the sequence of adjustment screws to achieve higher revolutions of the crankshaft.

- Clogged air filter. Air is sucked into carburetor. mixture is too weak. cause enriched mixture. Saw stalls with increasing load when cutting hardwood and large-diameter logs. Rinse filter in warm water and dry.

- Failure of piston group. Replace defective parts.

Malfunctions that lead to improper chainsaw operation

There are a number of malfunctions that must be taken into account when diagnosing, t. к. They can lead to malfunctions in the saw.

- Worn crankshaft bearings. If the crankshaft bearings are worn, runout is inevitable on the main shaft where the flywheel is mounted. Because of this, the clearance between the flywheel and ignition coil cannot be adjusted, resulting in unstable spark formation and unstable chain saw performance.

- Impulse Duct Contamination. The impulse channel serves to ensure operation of the fuel pump, respectively, its contamination leads to improper operation of the pump, which will make it impossible to work the saw (it will start and immediately glitch).

- Wear on the cylinder head. As a rule, when there is increased wear of the cylinder, there is a decrease of compression in the chainsaw engine, which will certainly affect its ability to develop revolutions.

- Fuel and air filter clogged.

Reasons why your chain saw stops when not in use

In this article of the construction site remstroisovet.The following are the main reasons why a chain saw fails to start or stops with a load.

The most common of all, are the following causes:

2005-2008 B7 Audi A4 2.0T Top 10 Common Problems

What causes the chain saw’s power to run low

The same applies to the air filter, it, if this kind of problem occurs, should be cleaned immediately. Now about the spark plug, if it is very dirty, it is also cleaned and adjusted if necessary. It is the wrong gap between the electrode of the candle on the chainsaw that can cause it to start to stall, and in general, work extremely unstable.

Why the chainsaw stalls? Causes and their elimination

What to do if the chainsaw stalls? Many chain saw owners know the weakest parts of their tool, but it may be the case that the cause can’t be found at once.This manual is also helpful for those who have recently purchased a chainsaw.

WARNING! If you haven’t found the reason in the list below, you can ask the question in Комментарии и мнения владельцев. So the chainsaw just won’t start. There can be many causes, because although the saw is not a Formula 1 race car, it is a technical device.

The main condition for a successful repair is the exact diagnosis of the fault.

It’s not a good idea to start with the disassembly of the chainsaw, but to first check the simplest possible causes of malfunction.

Here are some examples of what to look for in case of a malfunction.

(This is the second edition of this article, in which I’ll try to describe all the possible causes in as much detail as possible.)

If you don’t start your chainsaw, read more here:

Troubleshooting

If the chainsaw stalls for no apparent reason and you can’t identify even approximately possible problems, then it is worth going through all the possible causes sequentially. Sure there are some typical, standard issues we’ll talk about below, but for now, here’s a step-by-step guide!

1.Check the fuel mixture.

First, prepare it according to the manufacturer’s recommendations and using quality components. Second, deplete the tank completely or drain the fuel mixture before prolonged downtime or preservation between seasons. Read more about fuel here:

2.Clean or replace air filter.

A dirty air filter prevents the chainsaw from getting as much air as it should be able to get. That is if the carburetor that mixes air and fuel has been set to one amount of air supply, when the air filter gets dirty, the amount of air decreases and the settings remain the same and you get an enriched gas mix as a result.

3.Check the spark plug

There can be several sub-items here, too. The first step is to unscrew the chainsaw plug and check if it got wet while trying to start. This is especially common when the chainsaw is started by inexperienced users who do not follow the sequence of starting the saw in the cold.

In that case you need to dry the spark plug or install a new one and try again according to the instructions. The spark plug tip might be broken. To check this you can unscrew the spark plug and put it in the tip put it on the block and pull the starter cord a couple of times.

If there’s a spark, then the spark plug and the rest of the electrics are fine.

Another step in checking the spark plug is to check the gap and for fouling. See manufacturer’s recommendations for clearance. This is usually between 0.5 and 0.65 millimeters.Clean the soot off the spark plug by using fine sandpaper or a wire brush. Read more about spark plugs here:

Diagnose chainsaw engine by the state of the plug

4.Check the fuel filter

As with the air filter, the situation with the fuel filter leads to a change in the composition of the working mixture. Only if the air filter is clogged, the mixture becomes richer, and if the fuel filter is clogged, on the contrary, the mixture becomes poorer.

If there is not enough fuel in the mixture, the chainsaw engine will not work. Besides, when the fuel filter is clogged, the equal fuel supply to the carburetor and further to the combustion chamber is disturbed.

This is most noticeable when the chain saw cuts out when you step on the gas.

The breather valve. check valve, which is in the gasoline tank and prevents the vacuum in the tank. If it is clogged, there is no air instead of the used fuel mixture and the fuel pump cannot handle the fuel supply.

It often happens when the primer (pump for fuel pre-pumping) pumped fuel into the carburetor and the chain saw started. After the fuel in the carburetor is used up and because the breather valve is clogged the fuel does not come out. the chainsaw stops.

6.Checking the carburetor

In 50% of cases, if not more, the reason why a chainsaw stops is a wrongly adjusted or faulty carburetor.

Chainsaw starts and stops cause

Owners of chainsaws sometimes have to deal with the fact that the saw, for no apparent reason, stops working normally. To understand why the chainsaw stops working in different modes of operation, as well as to describe how you can diagnose the malfunction, we will try in our article.

The situation in which the chain saw starts in the cold, and in the process of heating can stall, familiar to many who deal with them. The main reasons for this behavior are.

- The ignition module (ignition coil) is defective. You can determine the problem by checking the spark at first on a cold engine and then on a hot one. If there is no spark on a hot engine, it is worth trying to fix the problem by replacing the ignition coil.

- The carburetor on the chain saw is not properly adjusted (fills up the spark plug when the engine is hot). You can tell if there’s a problem by the way the saw starts when cold. If you don’t need to close the choke shutter for a cold start, and the engine starts without preflash, it means that the fuel mix is formed incorrectly and after the engine warms up the fuel floods the spark plug and makes launching impossible. The problem can be solved by adjusting the carburetor.

- The spark plug is defective. in such a situation, similar to a defective ignition coil, the spark disappears when the engine heats up. You should try to replace the spark plug with a new one. If that doesn’t help, you should check the ignition coil and the gap between it and the flywheel.

You can check the ignition coil with a multimeter or replace it with a known good one. Checking the primary and secondary windings with a multimeter is carried out in the resistance measurement mode. The resistance reading of the primary winding, the working coil, is 1 kOhm. the secondary 4 kOhm.

To summarize.

Definitely every thing we buy has an expiration date and sooner or later it breaks down and how disappointing it becomes when the degree of its failure is so great that it can not be repaired. But agree that often enough we simply neglect the equipment (see “How to use the equipment”). about proper operation and how to cut a tree so that it falls in the right direction.). And when it stops working, then we try to find the possibility of elimination of breakage, addressing a huge number of services.

But remember, although the equipment breaks down, but we can extend its “life”. All that is necessary is simply to look after it, to do running-in after changing parts (read here how to do running-in chainsaws) and keep its parts in order and cleanliness. And then, undoubtedly, it will last for many years to come. It is also important to use only quality spare parts and “additives” (see more about “additives”). chainsaw nozzles). Then your machine will work flawlessly and you won’t even know what a repair is.