The Trimmer Does Not Work At Idle Speed

Troubleshooting methods

The first three reasons are fairly easy to eliminate. If the matter is in the mixture, it is necessary to pour out the old fuel from the tank, prepare a new emulsion from high-quality gasoline and engine oil (if your engine requires a mixture) and pour it into the fuel tank. If the trimmer is running on pure gasoline, it’s still easier.

In the second case, it is necessary to carefully free the trimmer parts from the wound grass.

The last reason a lawn mower doesn’t work properly will require a little more knowledge and skill from you.

In order to properly adjust the carburetor for lawn mowers, a specific procedure must be followed. First, clean the air filter thoroughly. The easiest way is to rinse it (it is advisable to pour water over the filter regularly after 9-10 hours of operation).

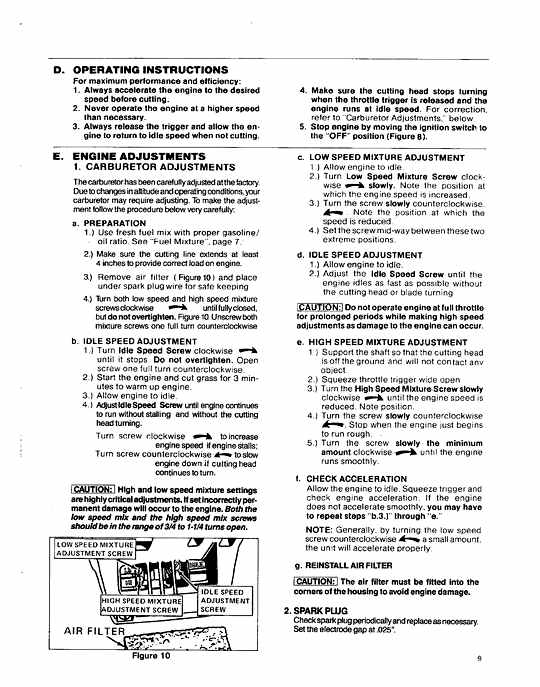

After that, in the diagram of your trimmer, which is in the operating instructions for the device, find the adjustment screws. Usually there are three of them: the first is responsible for the fuel supply, the second is for idling, and the third is designed to limit the number of maximum engine speed.

Next, turn on the unit and wait for the engine to warm up.

Tighten the first (fuel mixture) adjusting screw slowly. Catch the moment when the motor starts to stall, and turn the propeller back 45 degrees. If you didn’t have time and the motor stalled, the screw should be turned 90 degrees. Open the throttle and watch the revs increase. Next, slowly unscrew the screw (each turn is the same 45 degrees) until the moment when, at full throttle, the engine begins to firmly give out maximum revolutions.

The second screw, as mentioned above, controls the engine idle speed. By loosening it, you decrease the number of revolutions, while twisting it, you increase it. The screw needs to be adjusted so that the motor runs reliably at low revs. For better starting, speed up the engine slightly. At the same time, make sure that the motor rotates several tens of times before starting the movement of the knives / line reel. If the engine starts poorly, tighten the screw a little.

After you have adjusted the first two screws, test the operation of the unit at maximum engine speed. If necessary, you can limit it (maximum). this will protect the motor from “boiling”. To do this, you need to tackle the third screw. Unscrew the locking nut until the adjusting screw can be safely turned. To increase the maximum number of revolutions, the screw must be loosened, to decrease. on the contrary, tighten. Fix the position of the screw with a nut. Test the motor again.

Remember that carburetor adjustment is not a final procedure. During the operation of lawn mowers, you will most likely have to tinker with it more than once, because an unbalanced carburetor means both increased fuel consumption and a quick failure of the candles, not to mention a decrease in the power and performance of the device.

The reasons

Trimmers are reliable and durable (provided they are properly maintained, of course). Most often, malfunctions occur due to contamination of structural elements.

If the motor of your lawn mower does not start, does not pick up speed, does not reach the power you need, or suddenly stalls, the reason may be:

- Poor quality fuel (fuel mixture), it may be in long-term storage or in non-compliance with the recipe for preparing the mixture;

- Grass is wrapped around the shaft of the fishing line / knife;

- Clogged air filter / muffler;

- Carburettor imbalance.

The gasoline trimmer is not gaining momentum: the reasons and features of repair

It is not necessary to purchase an expensive and bulky lawn mower to cut grass on a small lawn; it can be easily replaced by a gasoline / electric trimmer. The device of these machines is quite simple, they are easy to use and unpretentious in maintenance. But sometimes problems do happen. One of them. when the trimmer does not develop the maximum number of revolutions. will be discussed in this article.

Little tricks

- If you are unable to tighten / loosen the adjusting screws properly, it may be that the spring is too thick and stiff. Then you can choose instead of her a more suitable.

- If your unit does not need pure gasoline, but its mixture with engine oil, strictly observe the proportions indicated in the operating instructions. There is one little thing: the recommended ratio is 1: 25 (for all brands of oil) or 1: 50 (for “native” oils). Try the first ratio first. If, with such a recipe, oil drips appear on the motor, and a strong carbon deposit forms on the candle, reduce the proportion of oil by half. This usually helps to fade traces and reduce the amount of carbon deposits.

- To clean the spark plug electrodes from combustion products, you can use fine-grained “sandpaper”. Wipe them down with a dry cloth first and then gently sand them with sandpaper. If the space between the body of the device and the insulator is also clogged, a regular unbent paper clip can help clean it. To do this, briefly soak the candle in diesel fuel, and then scrape off the dirt. If the blockage is small, one procedure is sufficient. In case of heavy dirt, it is sometimes necessary to repeat it several times. After complete cleaning, the candle must be wiped dry from the remaining diesel fuel, and then it can be used as directed.

- Please note that foreign-made lawn mowers (gasoline, electric or battery) require a little more maintenance than domestic ones. In particular, many strongly recommend entrusting the adjustment of the carburetor of a two-stroke engine to professionals, especially if your purchase has not expired the warranty period.

- And finally, one more tip: follow all the manufacturer’s recommendations for the operation and maintenance of the device. This will prolong its smooth operation.

You will learn more about what to do if the petrol trimmer is not picking up speed.

The engine runs unevenly at idle: possible causes

There are many reasons why the engine idling unevenly. Motorists should have an idea of them in order to avoid unnecessary waste by solving the problem on their own and doing the repairs themselves. On the other hand, it will also be possible to avoid more serious problems thanks to timely diagnosis.

Electrical problems

First of all, let’s start with the ignition system. precisely, the reason is too large a gap between the electrodes on the spark plugs.

Here, the symptoms will be much the same as with poor idle adjustment on the carburetor. The problem can be easily eliminated by reducing the gap between the electrodes.

Unstable operation of the engine without load can also be caused by the triplet of the engine. That is, one of the cylinders does not work.

Causes of uneven engine idling

Experts divide the main reasons for uneven idling into two categories:

Separately, you can take out the malfunction of the air system (intake), but it is more appropriate to include it in the list of problems with the fuel system. The fact is that both of them are inextricably linked and affect the stability of the power unit in the XX mode and under load.

- Fuel-air system and fuel. A poor air-fuel mixture is often the reason that the engine runs unevenly at idle. Such “poverty” of the mixture is that it contains too little fuel and too much air.

A more serious problem can be considered a malfunction with the idle speed valve (aka idle speed regulator, auxiliary air regulator), which is sometimes called the idle speed sensor. To owners of carburetor cars, this part is also known as the “solenoid valve”.

Excess air can also be sucked in through, for example, broken holes in the throttle shaft on the carburetor. In this case, the problem may not become noticeable immediately: gasoline consumption will gradually increase, there will be interruptions in idling.

- Poor quality fuel. Because of it, idle turns often “float”. This phenomenon is especially pronounced when using the so-called eco-gasoline. It contains a certain amount of ethanol. Ideally, this not only makes the exhaust fumes less toxic, but also helps clean the fuel system.

- The fuel pressure regulator (aka low pressure bypass valve) is out of order. Its task is to maintain the required fuel pressure while the engine is running in any mode.

This breakdown is indicated not only by the uneven operation of the engine at idle speed, but also interruptions, if you sharply press the gas pedal, a drop in power, a strong increase in fuel consumption.

- Nozzles are clogged (channels are coked). Due to the poor operation of the injectors, the fuel mixture is obtained of improper quality in composition, which leads to disruptions in the operation of the power unit in different modes and an increase in fuel consumption.

- Air damper malfunction. This, as a rule, is a mechanical interference, which also leads to the formation of a poor-quality fuel-air mixture. As already mentioned, the engine runs unevenly from this.

- Carburetor idle not adjusted. In this case, under load, the motor will work normally, and at idle it will sometimes twitch, and at the same time, quiet pops may even be heard in the muffler. A relatively simple problem, which you can cope with on your own by tightening the desired adjusting screw.

So, taking into account the foregoing, we can conclude that if the engine is running unevenly, the reasons must be looked for either in the fuel system or in the ignition (candles and spark plug wires are often to blame).

If no problems are identified, then you can proceed to a deeper inspection, check the pressure in the fuel system, the quality of air supply to the engine, the operation of the ECM sensors, the throttle valve, etc.

On injection cars, it is separately recommended to perform computer diagnostics of the engine, while on engines with a carburetor, cleaning and subsequent adjustment of the carburetor, which is the main dosing device, may be necessary.

The engine twitches at idle: why is this happening. Engine twitching in XX mode, diagnostics of possible malfunctions, recommendations.

At idle and at low speeds, the engine troit: Possible causes of unstable operation of the power unit. Self-diagnosis methods.

Idling “swim” turnover: why is this happening. The main malfunctions associated with idling on a gasoline and diesel engine.

Floating idle engine speed “to cold”. Main malfunctions, symptoms and breakdown detection. Unstable idling of a diesel engine.

After switching to gas, the engine troit, while working normally on gasoline: the main reasons for this malfunction. Troubleshooting, recommendations.

Signs of an inoperative cylinder (tripping and vibration) of a diesel engine. Troubleshooting: compression, diesel injectors, glow plugs, high pressure fuel pumps and others.

Also, the ignition coil may be punctured in electrical equipment. In this case, the lawn mower will not start, or it will start and work intermittently, and then it stalls, or it will not start at all when it is hot.

You can check the coil’s serviceability in the same way as when checking a spark: unscrew the candle, lean it against the trimmer body. If there is no spark when you jerk the starter, or it appears every other time, you need to change the coil.

Causes and repairs

I want to share my experience in restoring the required power of the trimmer with a gasoline engine.

Sometime in early June, I began to notice that my trimmer model GT22GES (manufactured by “ECHO”) began to lose its former power.

In the process of work, when mowing grass, even with a slight increase in the load (the grass is higher and thicker), the speed dropped and the work efficiency was no longer what it was before.

Previously, the trimmer did not notice such obstacles at all. With a sharp push on the “trigger” without load, the revolutions increased slowly, as if reluctantly.

I took the User Manual for the trimmer, found the section “Faults and their elimination” in it. I chose a suitable malfunction in the table, which is described something like this: “The engine accelerates poorly or dies out”.

Possible causes include dirty air filter, fuel filter, clogged fuel tank drain, spark plug, carburetor, clogged cooling system, clogged exhaust port or muffler.

As it turned out, the list of possible reasons is extensive. where to start?

First, I visually looked at the air filter, drainage hole, air radiator, all this turned out to be in good condition.

Then I decided to look from the end of the list, that is, to check the exhaust system. exhaust channel and muffler.

To do this, he removed the spark plug tip, unscrewed 3 screws and removed the plastic protective cover of the muffler (in the drawing in the Manual under No. 15). Then, unscrewing two long screws, carefully removed the muffler, so as not to damage the two gaskets that are present there.

The premonition did not deceive me. The exhaust channel of the engine cylinder (through which the exhaust gases come out of the cylinder) was 30. 40 percent clogged with carbon deposits.

So this is what turned out to be the reason for the frustration of my trimmer!

This is what the exhaust channel looks like

Carefully, so as not to damage the surface of the piston and prevent foreign products from entering the cylinder (in other words, the very carbon), I completely cleaned the exhaust channel from carbon deposits, carefully blew the channel with a pump.

I used a knife as a tool (but only at the edge of the canal), and in the depth of the canal, a wooden and plastic spatula of suitable sizes.

The muffler turned out to be pretty clean both inside and out.

After assembly, I started the trimmer, warmed it up a little and tried to mow. the engine started up like new, the power increased noticeably, it doesn’t cut the grass, but cuts it (3 mm line).

It’s nice that the device began to work perfectly and doubly pleased that he himself was able to find the malfunction and fix it.

It is likely that such a problem may arise in other models of trimmers, because they all have approximately the same design and all trimmers have an exhaust channel and a silencer.

the lawn mower does not pick up speed, the cause of the malfunction and its elimination

1st launch of the newest lawn mowers. I removed the mesh from the muffler, began to work.

Another one is the presence of faults in the power system.

In this case, the lawn mower will stall at idle speed. The Champion trimmer stalls at RPM. The Goodluck 4300 lawn mower stalls at engine speed. The mower will stall when you press the gas. The lawn mower stalls at high rpm. Misadjustment or improper adjustment of the carburetor can lead to problems with the power system.

The misalignment can be caused by vibrations that occur during the operation of the lawn mower.

Incorrect adjustment of lawn mowers can be corrected simply by adjusting it in accordance with the requirements specified in the instruction manual.

In addition, sometimes gasoline trimmers can stall due to the fact that the valve located in the gas tank cap is simply clogged or stuck.

To find out, try using a scythe by loosening the gas cap.

If the device operates properly in this mode, clean the valve.

Benzotrimmer loves cleanliness. It is necessary to monitor the cleanliness of the air filter and fuel. Gasoline bought at a gas station is better to stand for 2 days and pass through the simplest filter. a piece of bike cloth.

We check the electrical equipment as follows:

We unscrew the candle, examine the gap between the electrodes. We can set the correct gap between the electrodes in the “old-fashioned” way. Take the razor blade, cut it in half and insert a homemade probe between the electrodes. If the blades fit tightly, then the gap is perfect.

We put the cap of the high-voltage wire on the candle and lean the candle against the metal surface of the engine. We pull the starter several times. If the spark hits one point well, then the gap is adjusted correctly. If not, the spark is weak or “wandering”, then it is necessary to re-adjust the gap between the electrodes.

What to do if the petrol trimmer is not gaining momentum?

If you have once purchased a trimmer that runs on gasoline, then you probably had to deal with the problem of turning on the trimmer, as well as with such a problem as the gas trimmer does not pick up speed.

That is why this article was created.

So, what to do if the trimmer, which has been working for you for more than a year, suddenly just stops picking up speed, and the engine simply stalls? In this case, you and I should consider a number of problems associated with stopping the motor.

The motor can stall under various circumstances. Why the lawn mower turns. I can’t get it off the ground. And it is gaining momentum from the floor. Sometimes the reason for the improper operation of the trimmer, running on gasoline, is a clogged air filter.

It is the filter that is one of the most important reasons why the gasoline trimmer may stop working.

Various debris very often gets into it, dust particles get there, which also clog the filter, so it needs to be cleaned and washed every month, and maybe more often, it all depends on what power the gasoline trimmer has, as well as how much often you use this device.

About the manufacturer

The history of this German brand begins in 1926. At the initial stages of its own development, the company was engaged in the production and sale of various devices for washing and steam machines. It all started, like many companies, with a small production and a narrow focus, which made it possible to focus on the quality of products.

At the beginning of the 1930s, the first STIHL chainsaw was released, which was already distinguished by its convenience and functionality at that time. The company is developing at a rapid pace, constantly introducing new tools, which gives it the opportunity to enter the international market. lawn mower Stihl And already in 1931 the first constant deliveries of products to Russia were organized.

Stihl device

At the moment, the company has expanded its activities in more than 160 countries around the world, opening new centers and production offices in Switzerland, China and many other countries. This is completely understandable, because the range of the company is impressive: motor-drills, gasoline sprayers, mowers, gasoline trimmers, chainsaws and almost everything else. I would like to note that Shtil chainsaws are very popular due to their own functionality and applicable cost.

Stihl trimmer does not develop speed

It is inherent in man to ennoble the place in which he spends the lion’s share of his time. Why does the Chinese lawn mower not develop speed? Trimmer Stihl FS 55 lawn mower Does not develop speed, stalls, we go through the carburetor Thank you for watching. City dwellers resort to the services of designers, or they themselves try to change something in their own home, acquire the latest furniture, wallpaper, so that when they come home after a difficult day, they can mentally rest and relax in a suitable environment.

Inhabitants of their own homes outside the town have completely different concerns and requirements. It is necessary to mow bushes, grass, various dead wood on time, to closely monitor the condition of the personal plot and garden.

It is clear that this requires slightly different means of meriting comfort. And here a new brainchild of engineering comes to the fore. lawn mowers of the Stihl office.

You bought yourself a new petrol trimmer and immediately got into trouble with it. It starts very badly. If you mow a little, and then turn it off, then turning it on “hot” is even a bigger problem than “cold”. What to do with him, I don’t know how to start?

The instruction for the lawn mowers plant sounds like this:

Switch on ignition.

Pump up fuel with a silicone button (primer) located on the bottom of the carburetor. Pressing must be done as much (or a little more) as written in the instructions, usually about 8-10.

Close air damper.

Lock the throttle lever with a stop button at high rpm.

Pull the starter handle 2-3 times. The engine should “grab”.

If the engine “grabs” and stalled, then you need to move the choke to the 1/2 position and try to start again. If the engine starts, then we release the gas and move the air damper to the “open” position. Getting started.

When performing fuel pumping manipulations, one should not be afraid to pour it over. If this happened, and, as they say, “filled the candle”, then you do not need to unscrew it, it is enough to move the air damper to the “open” position and, while holding full throttle, simultaneously turn the engine with the starter 2-4 times. After that you can start the engine and get to work.