Tiller Diesel Valve Adjustment

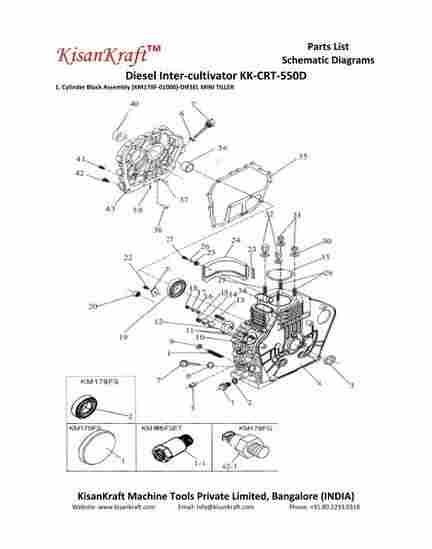

How to set up Agro on the tiller

The valves on the Agro tiller are adjusted as follows:

- We warm up the engine, after which we give it some time to cool down.

- Remove the oil bath of the air filter.

- Next, you need to unscrew the flywheel casing, mounted on 6 bolts.

- The flywheel has marks. 0 (top dead center), 5, 10 and 20 (fuel injection). We compare the dead center of the flywheel with the mark located on the cylinder so that they are opposite each other.

- Next, remove the valve cover.

- There are two valves under it. Loosen the lock nut, then insert the razor blade under the valve. The blade must pass freely between the piston and the valve.

- Having achieved this, we tighten the nut back. Then we put back the valve cover and flywheel housing.

It is worth noting that identical adjustment steps are carried out to adjust the valves on the Patriot tiller. tiller Agros and its valve adjustment also correlates with the tiller mb 1.

So, if necessary, you can use the identical scheme.

Step-by-step instructions for different models

Carburetor Tiller

As for the carburetor, it is part of the engine power system. It acts as a kind of mixer that mixes liquid fuel with air to obtain a fuel mixture, which then enters the engine cylinders. Structurally, it looks like this:

- float chamber;

- diffuser;

- spray;

- throttle and air dampers;

- mixing chamber;

- jet, etc.

This is a description of the standard carburetor, but different tiller models such as Huter, Profi, Plowman, Champion, Carver, Husqvarna may use different carburetors, respectively, and the adjustment will be different.

Cascade

Adjusting the valves on the cascade tiller:

- Remove the cover from the flywheel.

- Remove the valve cover.

- We turn the flywheel until the inlet valve is pressed in. Accordingly, the exhaust valve will be depressed.

- Next, you need to achieve the correct clearance for each of the valves. According to the instructions, for the inlet this parameter is 0.15 mm, and for the outlet. 0.20 mm.

- We check with a dipstick the existing gap between the valve and the piston. If the probe slips strongly, or it does not pass between them at all, then we need adjustment. If the dipstick is not available, you can use a razor blade, the thickness of which is 0.1 mm.

- To adjust, we loosen the fastening nut, then insert the dipstick into the gap under the valve. Its optimal position will be quite tight walking between the piston and the valve, without slipping.

- If everything worked out, we tighten the nuts back, after which we put the valve cover and the casing in place.

It is also worth approaching the adjustment of the valves on the Ural tiller based on the above instructions.

The scheme of work is arranged in an identical way, so you can use one algorithm of action, exactly the same as for adjusting the valves on the popular centaur tiller.

Lifan 6.5

Adjusting the valves on the Lifan 6.5 tiller consists in setting the correct clearance under the valves. The sequence of actions will be as follows:

- Remove the cover to get to the flywheel.

- Remove the valve cover. There are two valves under it. intake and exhaust.

- To check the inlet valve clearance, a 0.15 mm dipstick is required, for the exhaust valve. 0.2 mm. If adjusted correctly, the dipstick should pass freely under the valve.

- To adjust, loosen the fastening nuts with a wrench. We insert the dipstick between the valve and the piston in such a way that it does not slip, but is tight enough in this position. We wrap the nut.

- We put in place the valve cover and flywheel housing.

Valve Adjustment

How to adjust the valves on the tiller: adjusting and adjusting the diesel Lifan and Neva MB-2 with an American engine

Tillery as a means for plowing land has been known to many since Soviet times. This means of small-scale mechanization perfectly copes with this task, greatly simplifying the work of a person.

If we consider that additional attachments can be installed on this unit, then in fact all the work on the site is within his power.

However, in order for the tiller to work optimally, without failures, it needs constant care, which consists in timely maintenance.

In addition, the adjustment of the various components that are responsible for performance plays an important role. In particular, we are talking about adjusting the carburetor valves, on the correctness of which the stability of the engine will depend.

Required tools

To adjust the carburetor valves, a minimum list of handy tools is required:

- razor blade or dipstick;

- minus screwdriver;

- box wrench.

With these simple tools, you can adjust most carburetors.

People have invented snowmobiles that allow you to drive on snowy roads as quickly as possible without much effort. Ermak snowmobiles are quality, speed and reliability.

Gardening, caring for plants and trees have always been considered one of the most difficult types of work, as they required considerable time and effort. Sprayer Morolex. the perfect solution for your garden.

Time-consuming gardening work can now be done with a tiller. Learn how to plant potatoes with a tiller here.

It is important to understand that adjusting the valves means setting the optimal clearance, which is directly spelled out in the operating instructions for each specific model.

How to properly adjust the Tiller Zip valve

What is the order of adjusting the valves on the popular zip tiller:

- Opening the flywheel.

- Unscrew the valve cover clockwise.

- Check the gap with a probe in the same way as described above.

- With a wrench, we turn between the nuts and loosen them a little.

- We close the system and conduct testing.

Clearance adjustment

The steps to adjust the clearances are as follows:

- before starting any action, check the engine: it must be cold;

- then disconnect the oil bath cup from the air filter and filter element;

- using a wrench, unscrew the four bolts from the protective casing;

- after these actions, it is necessary to remove the starter and the flywheel protective cover;

- then fix the dead point on the flywheel. It needs to match the zero mark;

- with careful movements, remove the valve cover with a paronite gasket, before that you need to unscrew the three bolts;

- it is important to check the clearances. Remember that the inlet valve is located near the filter and the outlet valve is located near the muffler. To check the intervals, you need to insert a dipstick between the rocker arm and the valve. If the distance deviates from the permissible, you need to adjust these elements with a spanner wrench or a screwdriver;

- after which it is necessary to wipe all connections with a clean rag, completely assemble the structure and turn on the tiller to check its working condition.

With correct valve adjustment, the engine will run quietly, without any jerking or malfunctioning.

Using the proposed algorithm of actions, you can correctly adjust the valves on the tiller, while ensuring the effective operation of the device.!

Setting gaps

Adjusting the engine valves means setting optimum clearances. Their norm is indicated in the technical passport of the tiller. Each model has its own permissible parameters, which depend on the brand and type of machine motor.

The permissible valve clearance on the chiller for a standard unit is as follows:

- for the inlet valve. 0.10-0.15 mm;

- for output. 0.15-0.20 mm.

To configure them, you need the following tools:

- spanners;

- styli for 0.10 mm, 0.15 mm and 0.20 mm;

- flat screwdriver.

The algorithm of actions for setting the optimal clearances is as follows:

- The engine must be cold during operation.

- Disconnect the oil bath cup from the air filter and filter element.

- Take the key, unscrew the 4 bolts around the protective casing.

- Remove the starter, then the tiller flywheel guard.

- Fix the “dead center” on the end of the flywheel. The mark on the rib of the cylinder blowing must correspond to the zero mark of the flywheel.

- Carefully remove the valve cover with a paronite gasket, having previously unscrewed 3 bolts.

- Check the clearances:

- there is an inlet valve near the filter;

- near the muffler. day off.

To check the interval, insert a feeler gauge between the rocker arm and the valve. If the distance is greater or less than the permissible, using a spanner wrench and a screwdriver, adjust the elements.

If the valves are correctly adjusted, the engine will run without noise, jerking or malfunction.

Adjusting the unit valves.

Without proper adjustment of the valves and other important components of the engine of the mechanism, normal operation is impossible.To carry out adjustment work, tools such as are required:

- a set of various wrenches;

- a set of different screwdrivers;

- special shaped probe and other tools that may be needed in the process of work.

The concept of valve adjustment means the establishment of the most optimal clearance between the valve and the cylinder wall. The size of the gap, as a rule, is indicated in the instructions attached to the unit.

It may differ in different designs of the tiller engine. The sequence of work of the valve adjustment process is as follows:

- the engine of the unit is freed from the casing;

- the valve cover is dismantled;

- the valves are being adjusted;

- the valve cover is replaced;

- the power plant is covered with a casing.

The procedure for performing work on adjusting the valves may differ slightly, depending on the brand and engine power of the unit. The size of the gap must be checked with a feeler gauge.

In the intake valves of the power plant, the clearance should be.0.15 mm, for exhaust valves, it should be 0.2 mm. With a properly adjusted gap, a special dipstick should fit freely under the valve itself.

For adjustment, it is necessary to slightly loosen the nuts, then insert the dipstick. At the end of the adjustment process, the nuts must be tightened. It does not hurt to carefully check the gap again, and then close the valve with a cap. Final action. the engine is covered with a casing.

After correct valve adjustment, the operation of the power plant will be much more efficient, and its operating period will also increase.

What to do if the engine breaks down

Basically, there are two of the most common causes of engine failure. This is when the engine, in principle, does not work and when it is still functioning, but unsatisfactory.

If you study the first reason, then you need to proceed as follows: first you need to turn on the ignition, check the amount of fuel in the tank, open the fuel cock and the state of the carburetor air damper, and then the flow of fuel into the carburetor. Also remove and clean the nozzle, thus removing the blockage. Another reason may be a weak fuel injection pressure, which can be corrected using the instructions attached to this technique.

If the engine turns over too quickly or easily by the starter, then the problem is either in the valve or in the piston rings. In the first case, you just need to remove this valve and rinse it, and in the second, if the piston rings are worn out, then they are replaced with new, serviceable.

Why does a diesel tiller start badly?

Here are some reasons and solutions:

- a dirty air filter must be disassembled and cleaned;

- combustion products can clog the muffler, it also just needs to be cleaned;

- an incorrectly installed carburetor, then it is necessary to reinstall it;

- malfunction of the cylinder-piston group;

- also a problem can be the use of summer fuel in winter. After all, the remains of summer fuel turn into a viscous mass, which cannot be supplied by a pump to the engine. Here you just need to warm up the fuel by driving the tiller into a warm environment.

As you can see, it’s not difficult to fix everything yourself, the main thing is to follow the specified rules and instructions, because taking care of any device prolongs its life.

How to adjust the valves on a tiller engine

A vehicle called a tiller is a vehicle that, when equipped with various attachments, can perform various agricultural work.

Step-by-step instructions for different models

Preparing for valve adjustment

Install a heavy diesel tiller (Foreman, Centaur, Aurora, Bison, Scout) with the engine down, so that the oil flows into the crankcase from the cylinder head cover, which will be removed:

Heavy diesel tiller installed engine down

To adjust the valves, you need a 16 wrench (applicable to GT 100 RDK engine, others may have different ratings), a flat screwdriver, a set of calibration probes and an operation manual. In the instruction manual, find the recommended clearance sizes for your Chinese tiller.

Setting the clearances between the valve levers and the valve stems of the heavy tiller is carried out on a cold engine.

The size of the recommended clearances for the diesel tiller Prorab GT 100 RDK:

- for the inlet valve. 0.20-0.30 mm with a cold engine;

- for the exhaust valve. 0.25-0.35 mm with a cold engine.

Diesel Tiller Valve Adjustment

Adjusting the valves of a heavy diesel Chinese tiller. Setting clearances between valve levers and valve ends. Foreman, Centaur, Aurora, Bison, Scout and others.

Tiller Valve Adjustment

Unscrew the retaining nut and remove the cylinder head cover. This is the cover in which the decompressor lever is built:

Diesel Tiller Cylinder Head Cover

Under the cylinder head cover there are valves and valve levers, the gap between which needs to be adjusted:

Diesel Tiller Inlet and Exhaust Valves

The intake valve is located on the side of the air filter, the exhaust valve is on the side of the muffler.

The numbers in the image indicate:

- The place of contact between the intake valve stem and the valve lever, the gap between which should be adjusted on a cold engine.

- Locking nut.

- Adjusting screw.

Turn the engine flywheel until both valves are closed (springs are fully extended). Stop the handwheel approximately midway between the closing of one valve and the opening of the other.

Check the gaps with a feeler gauge and, if they do not correspond to the recommended ones, proceed with the adjustment.

Start the adjustment at the inlet valve located on the side of the air filter. Loosen the lock nut, insert a feeler gauge of the recommended thickness between the valve stem and the valve arm. Tighten the adjusting screw until you feel the dipstick begin to tighten. Loosen the adjusting screw so that the dipstick moves freely in the gap. Check the gap with a feeler gauge 0.05mm thicker. If it does not fit into the gap or forcibly, tighten the lock nut while holding the adjusting screw with a screwdriver. Recheck the gap with two feelers in turn.

Repeat step 4 to adjust the exhaust valve located on the muffler side.

After completing the valve adjustment, reinstall the gasket and cylinder head cover. Screw on the fixing nut. When tightening it, do not use excessive force so that the lid does not burst, as this sometimes happens.

Necessary components

To assemble or disassemble the tiller engine, you need a flat, well-lit area where nothing will interfere with your work. They are looking for the same place for repairs. The installation kit for both imported and domestic tiller includes:

- nozzles;

- block heads;

- radiators;

- carburetors.

Functional failures

Quite often, among the malfunctions of the tiller engine, its unstable action appears. If the engine at idle runs in jerks, and when trying to add gas stops altogether, the reason is rooted in a lack of fuel. Clean the screens of the fuel tank, carburetor and pipeline valve. And when problems arise even at idle speed, it is advisable to check the centrifugal regulator. Traction often sticks there.

Suppose the tiller is simply slowing down without jerking. In many cases, this is due to the use of incorrectly tuned, unsuitable or simply badly worn motors. But replacing the power plant is not always wise. Installing a better quality spark plug can help. It is also worth assuming the appearance of malfunctions in the operation of the carburetor float in the high-voltage wire.

If the tiller engine knocks, it is necessary to inspect the camshafts and crankshafts. It is there that the sources of extraneous sounds are mainly located.

In all these situations, there is no particular need to carry out major repairs. High-quality troubleshooting is very important. It is pointless to try to increase the compression in all modern engines, anyway the decompressor will not allow you to do this.

How does it work?

To understand breakdowns and fix them, it is important to understand how everything works in a normal situation. For the sake of simplicity, let us dwell only on models with an internal combustion engine. Previously, there were two-stroke tillers, but now they are increasingly superseded by four-stroke analogues. Diesel devices are also gaining popularity. As for the transmission, it can be performed in three different versions.

The traditional approach is to use a gear transmission. Despite a decent level of reliability, this device takes up a lot of space. Power transmission takes place using either a cone or a cylinder. Light tillers are mainly equipped with a worm gear transmission. A typical operating principle of a tiller regulator contains:

- a device that monitors the number of revolutions;

- the rod connecting this device with the throttle valve;

- spring.

The control unit operates on the basis of a pneumatic or mechanical connection. “Pneumatics” means the presence of a kind of wing that responds to the speed of the air flow. Centrifugal options involve placing a special camshaft inside the crankcase. It is complemented by small weights and an easy-to-move stem. The pull is made from wire, and the spring sensitivity determines how accurately the rpm values will be maintained.

Replacement and adjustment

Quite often, unfortunately, it becomes necessary to completely change the motor on the tiller. When choosing a replacement device, it is recommended to give preference to products from well-known companies. Traditional prejudices about the products of Chinese factories have long since become irrelevant. To avoid overpaying funds, you need to carefully analyze how productive the power plant should be. Buying too powerful a unit is simply irrational.

Even if there is no talk of a complete replacement, it is important to know how to adjust the engine of agricultural machinery. It is advisable to start disassembly only after flushing the engine and removing oil from it. The lubricant is poured out only when the engine is warmed up after a short operation. Then it’s time to remove the fuel tank. Sequentially remove:

- fuel supply hose;

- air filter;

- cylinder screen.

Then remove the crankshaft pulley. Following the pulley, it is required to remove the fan, reflectors, insulating flywheel casings. Unscrew the cover, removing the rings and coupling housings. When the washer is removed, you can press out the flywheel using a wooden block.

Now, having dealt with the flywheel, remove the cylinder cover, camshaft and pusher. Once access to the connecting rod is obtained, remove the oil spray and locknut. Having repaired and changed the damaged parts, the engine is assembled in the reverse order. You should familiarize yourself with the diagram in advance, then there will be no errors.

Replacement of damaged valves for a gasoline tiller occurs after removal:

- gasoline tank;

- the head of the cylinder block;

- carburetor;

- muffler;

- boxes.

It is often necessary to replace the rings. But this should be done only in the process of more serious repairs. An isolated change of rings is in itself irrational both economically and technically. In addition, a high quality ring group usually has the same service life as the cylinder. Change them at the same time.

Installation on an elastic band is advisable if a Chinese motor is installed on domestic tillers. Rubber cushions are often used as a platform. Parts of the front shock absorber from a car of a classic scheme are suitable as them. Along with the need to rearrange individual parts of the tiller engine, many people have a need to install the electric starter themselves. This starter will have to be correctly connected to the battery.

The crown is attached only to the removed flywheels. Pre-remove all interfering parts of the motor. To remove the flywheel, in many cases, you cannot do without a special key. A generator and its magnets are placed in the flywheel assembly. When the terminals and contacts of the battery are aligned, a test run of the tiller should be performed.

Troubleshoot startup problems

Often, repair of a tiller engine is needed due to the fact that this engine does not start. If this problem occurs after winter storage, you might suspect:

- clogging of fuel or oil with water;

- oxidation of electrical contacts;

- insulation damage;

- solid debris in the carburetor.

To prevent these violations, it is required to carefully inspect any connections before each launch. Noticing the slightest clamp of the cable, especially its twisting, you cannot start the engine.

How To Set Valve Lash On A Diesel Engine

Even before the very first start, it is necessary to assess whether there is enough oil in the crankcase. With a lack of it, rapid destruction of the piston group is likely. Burrs in less than a second.

In this case, very serious repairs will be required, and sometimes even replacement of damaged parts. Sometimes instability in the functioning of the apparatus is provoked by leaving the lubricant composition for the winter. If this is the reason, for the first few moments after launch, clouds of white smoke will pour out of the exhaust pipe. Immediately after this, the power plant will stall.

Diesel Tillers may also not start due to lack of oil. Only a few models are equipped with systems that prevent the lubricant level from falling. Most people will have to monitor the health of the tiller on their own. It is also worth considering that failures occur due to the systematic use of unsuitable fuel. If the usual recommendations do not give much effect, you need to remove the candle and see if there are any oil stains.

Oil, especially carbon deposits, should be carefully cleaned off. Then the candle must be dried. The cylinder is also required to dry. A very simple technique is used as “drying”: repeated sharp pulling out of the starter cable. The question often arises: what to do if the tiller does not start, while it smokes black smoke.

This usually indicates that the engine is overfilled with gasoline. It is also worth fearing damage to the piston group. If both assumptions turned out to be incorrect, you should contact the service center. Further attempts to fix the problem yourself may lead to an aggravation of the breakdown.

When violations are related to the lack of fuel in the working chamber, the candle will be dry.

You can deal with such a problem if:

- pour out the old fuel;

- thoroughly wash the gasoline or diesel tank;

- clean the air filter;

- clean the fuel hose and jets with a jet of compressed air;

- add fresh fuel;

- after opening the fuel line, blow out the channel located in the fuel tank cap.

In some cases, the failure is due to the fact that gasoline has entered the oil sump. It is necessary to check if this problem exists after any adjustment, carburetor settings.

If the lubricant is clogged with fuel constantly, you need to look at the carburetor needle. It is likely that this particular node has become a weak point. It is worth noting that sometimes the tiller motor also shoots at the muffler, and, perhaps, even with a flame.

The most likely reason is incomplete fuel combustion. She is provoked by:

- passes in the ignition system;

- excessively saturated fuel mixture;

- unjustified heating of this mixture.

When the tiller also does not want to act, interruptions in the ignition system must be looked for thoughtfully and consistently. Examining magneto, caps, candles and high-voltage wires.

Searching for even minor contaminants is of paramount importance. If everything is clean, it is required to inspect the contacts of the ignition wires. Next, the stability of the electrodes is checked, the distances between them are measured using a special probe.

Tiller engine repair

- How does it work?

- Necessary components

- Troubleshoot startup problems

- Functional failures

- Replacement and adjustment

- Advice

tillers are generally reliable and stable devices. But with active use, they still break down periodically. Even elaborate motors can be malfunctioning.

Advice

To repair and adjust the tiller less often, it is required to protect the motor from falling. This is especially true for products with four-stroke motors. Their maximum slope during operation cannot exceed 25 degrees. For a long time, the unit cannot be tilted by more than 15 degrees. Otherwise, you can be afraid that part of the engine will be deprived of lubrication. She’ll be out of order soon.

For the same reason, prolonged idle operation of the tiller is not recommended. Always check that there is enough fuel and lubricating oil before starting work. It is only necessary to change these fluids and even add them when the motor is off.

Do not start the tiller when the levers associated with the wheel drive are locked. A cold engine is started only after setting the air dampers of the carburetors to the closed position; always use the strictly recommended fuel.

The valves are adjusted using:

- universal wrenches;

- probes of various sizes;

- flat blade screwdrivers.

About the intricacies of repairing the Subaru ex21 engine for the “Neva” tiller, see below.