What can be cut with a diamond blade for an angle grinder

What does the color and markings mean?

When choosing a disc, you can distinguish between different types of attachments on several grounds. First, each type of circle has a different color. So, blue means metal, green means concrete, etc. In addition to colors, on the information sticker over the attachment there may be a schematic drawing of the material or an inscription, often in English. The disc for an angle grinder also differs in the degree of softness of the material from which it is made. So, for hard materials, softer nozzles are used, and for those that are softer, on the contrary, harder.

Testing Diamond Blades for Grinder by RTC

Many also wonder how to properly install a wheel on an angle grinder. Most builders assure that, in general, there is no difference how to fix a flat disc on the device, since the manufacturer does not indicate on the information label what is the direction of rotation of the circle.

Most install flat circles with markings on the front side. With bowl-shaped discs, there is only one installation option.

What can be cut off without problems

The next type of discs is cut-off. Cut-off wheels are also not the same, they are abrasive, wood and diamond. The former are intended, for the most part, for metal, the latter, based on the name, to cut wood, and the latter for concrete, ceramics and stone. If you have to work with tiles, it is worth choosing circles with a solid coating in order to avoid chipping. Please note that when using saw blades for wood, you need to be extremely careful, since this type of nozzle is the most dangerous. When working with it, it is best to use a fixed angle grinder.

You can also clean the work surface

The last type of diamond discs is stripping or roughing. There are also several such circles: sharpening, twisted cutters and roughing. A sharpening tip is most often used for sharpening tools, however, fiber-based diamond discs do a fairly good job of removing oxidation traces and cleaning welding spots. Twisted cones consist of metal or are wire brushes, they come in different sizes, thicknesses, shapes, and differ in the speed with which they rotate.

It is mainly used for scraping off oxidation marks when working with metal or brushing when working with wood. Rough diamond discs are designed to interact with concrete or stones.

Summing up

So let’s summarize. There are several types of angle grinder wheels. The main ones are grinding, cutting, sharpening. Grinding tools are used for removing old coatings, leveling the layer, sanding, polishing surfaces. Cutoffs are generally used for slicing, cutting, sawing. Sharpeners. for sharpening elements. Please note that this type of circle, like wood saws, is one of the most dangerous. It is not recommended to use it on a loose machine.

What to look for when choosing

The second significant feature that you should pay attention to when buying a disc for a tool is the diameter of the cutting wheel. The size ranges from 115 to 400 millimeters. When choosing a disc, you need to strictly adhere to the diameter set for a specific tool, since choosing a wheel one or two larger than the allowable size, firstly, will lead to rapid wear of the angle grinder, and secondly, it can lead to serious injuries during use. The size of the angle grinder, and therefore the circle for it, should be selected depending on where you are going to use the tool. For everyday life. a smaller diameter, for professional use a larger diameter is suitable.

Diamond disc for angle grinder

One of the most respected construction tools is the angle grinder, or as it is more simply called, the angle grinder. This attitude towards the device is not surprising, because the angle grinder can perform various functions: cut, grind or clean various objects.

The main element of an angle grinder is grinding wheels. The grinding wheel is of two types: simple and diamond, knowledgeable builders opt for the second, since such wheels can cope with any material. However, when choosing a disc, it is worth considering some nuances, because they can be different in size, thickness, purpose, speed with which it rotates. So How To Choose The Right Angle Grinder Diamond Blade?

The main criteria for choosing

When choosing a diamond disc for an angle grinder, rely on several points: diameter, material to be worked with, permitted rotation speed of the disc. The diameter should be chosen in accordance with the maximum allowed on your device, otherwise you can get the following consequences: breakage of an angle grinder, insufficient power of the device to rotate the set circle, injury to the worker.

If you are going to work with several materials at once, it is, of course, easier for you to deal with a universal diamond blade. But we would advise you to purchase a specialized one for each material separately. Failure to comply with the permitted speed may result in the disc not being suitable for your instrument, causing damage to the device or injury to the user.

Wet and dry cutting with a diamond blade

Diamond cutting blades are used in two ways: dry and wet. The choice depends on the material with which to work. Usually, the manufacturers on the information label next to the type of material for which the disc is intended, which method should be used. For example, with concrete or granite, it is advisable to work with a wet method, since thanks to water, the working time will increase, and the amount of dust will significantly decrease. Also, the wet cutting method should be used when working with tiles.

For some materials, marble, ceramics, stones, both methods can be used. With dry cutting, try not to use the device continuously for more than 2 minutes, as it may overheat and the disc may be damaged.

You can cut EVERYTHING with this disc! 1 disc = 60 abrasive discs. Innovation in areas such as metal processing

Universal discs for angle grinder: ?? FREE video course on working with drywall:

This, by setting the number of revolutions of the output shaft of the angle grinder, corresponding to that indicated on the marking of the saw blade, they significantly reduce the risk of injury during operation, but do not eliminate it one hundred percent. The reason for this, in the beginning, is the material itself, or rather its structure and heterogeneity.

Even in different places of the 1st trunk, the tree has different hardness, we are not talking about inclusions of viscous resin, the probable presence of metal trapped in the thickness of the tree species: from pellets and bullets that fell into the tree during the hunt, to wire ingrown there, busy tying up branches. Do not forget about the knots, which are actually present in many species of the tree species.

Features of saw blades

General safety rules say that any tool and consumable should be used only for its intended purpose. Does this rule apply to an angle grinder in the context of its application to wood pieces? Rather not, because the developers of modern models of this tool make the designs universal, and in the assortment of nozzles, you can even find special discs for soft-bodied materials. Another question. can an angle grinder be able to cut wood as a target workpiece on a regular basis? Again, theoretically this is possible and allowed, but in practice this approach does not justify itself. Circular saws cut boards and beams more efficiently, while chain saws do a good job of cutting logs and felling trees. Therefore, an angle grinder can only be used as a one-time substitute for a profile tool for cutting wood blanks.

Choosing a saw blade that is ideal for the task facing the master is quite troublesome. There are many varieties of products of this type on the market, and therefore a beginner is unlikely to be able to immediately figure out which tool he needs. To remove at least some of the questions, in this article we tried to systematize the most important and relevant information on the operational parameters of saw blades.

It is necessary to select the cutting part of the saw very carefully.!

Benefits of using an angle grinder for woodworking

The tool has a powerful engine, which allows it to easily cope with all breeds used in domestic housing construction and production. As a rule, we are talking about working with a bar, board and chip blanks. Even a minimum power of 500-700 watts will be enough to handle standard lumber. But here another question arises: “Is it possible to saw wood as such or logs with an angle grinder?” This will depend on the size of the attachment, but it is for such tasks that a chain saw is more suitable. The angle grinder, in addition to performance, justifies itself in terms of functionality. Modern compact models weigh a little, but at the same time have a wide range of regulation, safety and equipment control systems. The operator can individually adjust the device according to the cutting depth, the number of revolutions, use a soft start and other possibilities.

Is it possible to cut wood with a diamond blade

Application of angle grinder for cutting various materials, cutting and grinding wood

If you are trying to understand how you can cut a tree with an angle grinder, then the answer to the myth is unambiguous: there is an option. But probably they will not do this, tk. people get a lot of injuries specifically from using an angle grinder as a saw for wood, which is correctly called an angle grinder.

At first this is caused by the unusually high speed of its rotation, for which most of the saw blades are simply not designed. But he directs attention to this when it is necessary to do the work, and there is, as it were, a suitable tool at hand, and an additional compensator ring of a suitable size is applied to the saw blade for wood. In addition, the protective casing is also removed for ease of operation, which is absolutely impossible to do.

However, we will not talk about injuries here, but let’s talk about how to process (including sawing) a tree with an angle grinder, but what about the difficulties of working with an angle grinder with a tree species.

Feature of diamond discs

A special place among all cutting tools is occupied by diamond discs. Their main feature is the presence of diamond dusting. The technologies for its application can be different, but the sputtering effect is almost always the same: the disk resource, cutting accuracy and cutting cleanliness increase dramatically. In addition, the list of materials on which you can work is significantly expanding.

For example, the average abrasive disc is extremely inconvenient for cutting ceramics, natural stone or good concrete. Diamond blades handle these materials well.

Basically, discs of this type are designed to work with non-metallic materials, but there are special modifications for metals. However, it should be borne in mind that cutting metal with such discs can only be “in a straight line”. Best of all, diamond blades cope with:

- ceramics;

- glass;

- all types of stone;

- brick;

- concrete and reinforced concrete.

What can be cut with a diamond blade for an angle grinder

The angle grinder (better known as the “angle grinder”) quickly became a popular tool with a very wide range of functions. Various interchangeable discs allow you to solve a wide range of tasks, from direct grinding to cutting a variety of materials.

Which angle grinder blade / disk for concrete, plastic, tiles and metal

Solid disc.

This type is great for working with ceramics or marble. Due to the solid shape of the disc, an even cut is provided, which allows you to work with decorative materials. On the one hand, a solid disc requires forced cooling (it is widely practiced cutting “in a puddle”), on the other hand, while ensuring high-quality cooling, there are no restrictions on the duration of continuous operation.

For working with particularly hard materials, it is recommended to use special discs with oblique slots (splines). They reduce lateral friction by reducing the heating of the disc and helping to remove dust.

Are they versatile?

A certain type of diamond blade is better suited for certain Spectra applications. You can, of course, try to work with them as with a universal device, but this will lead to a decrease in efficiency, accelerated wear and increase the risk of injury.

Let’s consider the main types of diamond discs:

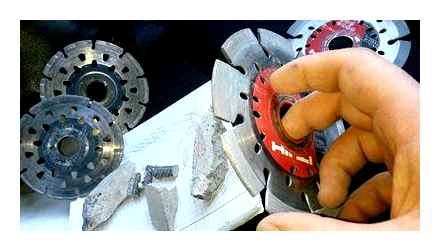

Segmented disk.

This option is ideal for dry cutting (without forced water cooling) as the blade is cooled by design features. They are good for cutting concrete, stone (including granite) or brick.

It is important to remember that continuous operation of a segmented disk should not exceed 1.5 minutes, otherwise the intensity of its wear increases dramatically.

Please note: the smaller the segment size, the slower the disk heats up. Reducing the segments also reduces the degree of vibration.

Combined disc.

Can be used to cut any non-metallic material, but ceramic tiles should be cut with water and concrete can be cut without cooling. The disadvantage of this type of disks is low efficiency compared to the above options.