What Can Be Cut With A Miter Saw

Rent of a miter saw Miter saw for hire in Kiev Affordable price Progressive system of discounts Miter saw for rent on the Peak Company website Large selection

Miter saws for rent are popular in the following types of work:

- Installation work;

- Joinery;

- Finishing work;

- Work to create furniture.

Miter saw rental is used in agriculture or in the country. It is able to cut material or structure with an exact angle of inclination, without the slightest flaw. Such a saw serves faithfully and reliably, performs work efficiently and efficiently, in a small amount of time. If you need to cut metal, iron, or a profile, then it’s still worth renting a miter saw. The rotating disc is the main part of the saw, so you should check in what condition it is and whether it is capable of performing the job perfectly. Also, when choosing a miter saw, pay attention to the type of motor. It can be asynchronous and collector. The first type does not make a lot of noise, and the second does not need frequent checking, but serves a long time.

Renting a miter saw in Kiev is quite a convenient option for working with different materials in a short time. Thus, you kill two birds with one stone, and save time, and after the completed work you return to the company and do not spend your monetary budget as much as you would have spent when buying a tool. You don’t need a motor that is too strong to cut wood, and you can use a less powerful one. But, if the work is to be done with metal or iron, then it is not worth talking here, and it is so clear that a saw with a powerful motor will be required.

Rent of miter saws in Kiev

Renting a miter saw in Kiev will allow you to perform various operations quickly and efficiently, no matter what the slope, the result will be accurate. Such saws are very popular and no construction site can do without them. If the tool is large, then it must be equipped with clamps and built-in clamps, the quality of fixation changes the efficiency of the cut.

Miter saw BOSCH GCM 800 SJ Professional

Displaying all 6 results

Can a miter saw cut metal?

This is what our guests sometimes ask. For our regular customers, this issue has already been resolved.

Most likely, you are already aware of the ability of circular saws to cut metal, especially if you are already familiar with EVOLUTION products. Over, industrial circular saws for metal are specifically designed to cut steel or non-ferrous metals regularly. And stainless steel. Periodically. But this limitation is due to the capabilities of the discs and the features of dry cutting of chromium-nickel steels.

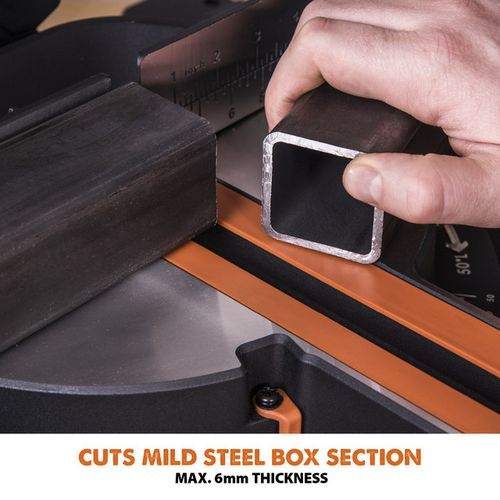

Rage professional hand-held circular saws and cut-off machines also successfully cut steel when the sheet thickness does not exceed 6 mm and the profile wall. 3 mm. However, by using the steel cut-off wheel used in the EVO 180 saw or S355CPS cut-off machine, these limitations can be surpassed without damaging the machine.

Serial cutting of steel profiles or pipes with EVOLUTION miter saws used to be ineffective. We have already covered this topic in previous articles. And nevertheless, with infrequent work with rolled steel, miter saws of this brand show themselves much better than other brands on which a disc for metal was installed. The main advantages of the EVOLUTION miter saws over competitive models:

- A robust gearbox originally designed for cutting steel

- Reduced rpm, optimized for steel discs

- Than 20 years of experience in the development, production and sale of circular saws for metal

This is without touching the carbide wheel itself on steel. Just a lot of people ask the question “Will I be able to cut steel with a miter saw for wood if I put a blade on it for metal?

What has changed in over 10 years of manufacturing EVOLUTION RAGE metal miter saws?

In 2020, the company introduced a new generation of special cutting discs. Now, the steel discs with a diameter of 185 mm are designed for speeds up to 5800 rpm. A special professional disc R185TCT-20MS is offered for the R185SMS miter saw, and for saws with a 255 mm disc. Suitable cutting disc for steel.

So in the question “is it possible to cut steel with a miter saw” there have been significant advances.

Follow these guidelines when working with steel workpieces on miter saws:

- Securely fasten the workpiece to the base, if the standard clamp is not enough, use additional devices

- Fold the saw advance to the forward position and secure with the set screw. Reduce the number of places where vibration is possible

- Do not apply significant force to the saw, let the blade cut at the expense of speed, not pressure

Miter saw: device, selection principles and discs used for work

Cutting finishing materials at an angle is, frankly, not an easy task, and almost all people have problems with its solution. Meanwhile, most of the finishing materials require just such an approach to their installation, for example, lining, skirting boards, baguettes and even metal structures assembled from a profile pipe. In general, there are many such materials, and their diagonal cutting has to be solved, sometimes even with very high accuracy. In this article, along with stroisovety.Org, we will explore a tool such as a miter saw to help you tackle the task of diagonal trimming. We will familiarize ourselves with the structure of this tool, the evaluation criteria, which will allow us to purchase a model suitable for work, and we will deal with the saw blades used with this tool.

Electric miter saw photo

Miter saw: device, purpose and capabilities

A manual miter saw has a narrow purpose, and you are unlikely to be able to unfold boards with its help. Her tasks are slightly different. She can perform extremely short cuts. With its help, you can cut the board in half, align its end or cut the end of the board at a certain angle. That, in principle, is all that she can, but, believe me, this is a lot. Other saw equipment copes with such tasks much worse. Oh yes, I completely forgot that in addition to wood, depending on the equipment used, the miter saw can work with soft metals, plastic and, if necessary, with thin sheet iron, or rather with a profile made of it.

Miter saw capabilities

The universal miter saw has a rather complex design. It consists of two main units, which are not at all simple in design. This is a bed on which a rotary table and a movable cutting head are fixed with a powerful electric motor.

- Bed with a rotary table. As a rule, these two parts cannot do without each other. There is a guide on the bed itself, which ensures a fixed position of the workpiece. The miter saw table itself can be rotated relative to the guide within 90˚ (45˚ in one direction and 45˚ in the other direction), thus providing a simple trimming of the workpiece in any direction without reinstalling the part.

- Cutting head. Installed directly on the turntable. It changes its location with it. For ease of use, a graduated scale is applied to the side of the rotary table on the bed. By aligning the table mark with a certain degree value, you can make cuts at any angle. And that’s not all. The head itself, or rather its cutting part, can tilt to the left and right, thereby providing an oblique cut. In most cases, this tilt is performed in one or two fixed positions (30˚ and 45˚ to either side). Also, some models may be equipped with a special broaching mechanism. The miter saw with a broach allows you to cut workpieces much wider than its ordinary counterpart.

What is the design of the miter saw

Electric miter saw: nuances and selection criteria

The question of how to choose a miter saw can be solved by adhering to five small rules.

- First, you must decide on its purpose and operating conditions. What do you need it for? What kind of work, and most importantly, how much do you plan to do with it? If you purchase a miter saw for home use and do not plan to perform complex operations, then it is quite possible to get by with a simple tool with a basic set of additional functions. If we are talking about the professional use of a miter saw and its daily use, then, of course, you need to choose an extended version of this tool with a full set of additional options. You can consider purchasing a so-called combined miter saw, which is equipped with an additional work table in the upper part of the cutting head, allowing it to be used as a stationary circular saw.

How to choose a miter saw

Naturally, when choosing a miter saw, it will not be superfluous to take into account the power of this tool, as well as the speed of rotation of the blade. In most cases, these values are calculated by the manufacturer and are optimal. A household tool will have a lower power than a professional one, but the rotational speed of the disk is almost always the same, which is due to the need to make a clean and even cut.

Miter saw. How to choose the right one and is it needed at all?

A miter saw can often be found in a carpentry shop. It is a very handy tool, especially when paired with a circular saw table. Today, let’s take a closer look at the miter saw and decide if you really can’t do without such a saw?

So, Miter saw Is an electric circular saw designed for cross-cutting wood blanks at a right angle or at another arbitrary angle. Has a horizontal base to which the arm with a circular saw is attached. When lowering the saw onto the workpiece, a cut occurs. The simplest models are only capable of cutting at 90 degrees. However, most modern miter cuts have the ability to cut at an angle, and most often even in two planes. When turning the base, as well as when the saw itself is tilted along the horizontal axis.

It is really very convenient to have a circular saw table and a miter saw at the same time in the workshop. On a circular machine, make a longitudinal cut of a workpiece, and a cross cut on a facing. Thus, the work goes faster, since each operation has its own machine, which is always ready for work and does not require readjustment between operations. In addition, the miter saw is quite mobile. You can easily dismantle it and take it with you to the facility, where, for example, a house is being erected using frame technology or wall cladding with wooden materials such as a lining or block house.

On sale there is a huge number of trims from different manufacturers, in a huge price range. From 2,000 to 200,000 rubles. How to choose the option that suits you? The choice should start with the basic characteristics: power, disk rotation speed, cutting depth and width. By power models are from 800 to 2500W. For operation in a small workshop, a power of about 1500-1800W is quite enough. By disk rotation speed The general rule is that the higher the speed, the cleaner the cut is. Accordingly, it is better to consider models with a rotation speed of 5000-6000 rpm.

The depth and width of the cut, in my opinion, you should start from your own needs. But the depth less than 50mm, it seems to me, is not worth considering. In width, the usual range is 80-180mm. This is largely due to the standard saw blade sizes. 10 and 12 inches (250 and 300 mm). But there are models with a much wider kerf. These are saws with horizontal movement, or, more simply, “with broach«: The saw is not only lowered onto the workpiece, but also has a certain horizontal stroke due to special guides. For saws with a broach, the cutting width increases to 270-310mm. With such a width, it is already possible to work not only with boards, but also with furniture boards. I think that if you really buy a facing, then it is with a broach, in order to have a cutting width of 300mm.

Among the additional functions, it is clear that all models have the ability to connect to a vacuum cleaner and a protective cover on the saw blade. Of the useful, in my opinion, functions are found: soft start, auto shutdown when jammed and maintaining speed under load. Also, the saw can be equipped with a laser for marking the cutting place, illuminating the working area and adjusting the speed. These functions, to me personally, seem to be secondary, but if you plan to cut plastic besides wood, the speed control may come in handy. If you plan to work with long workpieces, it is a good idea to consider a special saw stand. A table with stops on the sides (as in the picture above).

When choosing a miter saw, you should definitely pay attention to the absence of backlash in the design. If backlashes are present, then it is better to refuse such an option. After all, the main requirement for facing is an accurate cut, and with backlash this is impossible. Unfortunately, most of the budget options, and some not budget ones too, have significant backlash in the design. Be careful when choosing.

Here are examples of miter saw options from different manufacturers to consider when purchasing:

Given the cost of this tool, the question arises: does a beginner really need trimming? In short, the answer is not. The fact is that the miter saw is a rather highly specialized tool. Yes, with its help it is very easy and quick to trim workpieces, but this is more relevant for a medium-sized commercial workshop, where the speed of production of products comes to the fore. A novice master can do without it, especially having at his disposal circular sawing table. Most cross-cutting operations, including miter cuts, are part of the standard saw table operations. Yes, it might take a little longer than trimming, but it can save you money and space in your workshop.

For facing at an angle in a vertical plane on a circular table, it is enough to tilt the saw blade to the required angle.

For an accurate cut at 90 degrees, a simple carriage is used:

For cutting at other angles, you can use the standard corner stop, which comes with many circular tables. If, for some reason, you need more precision, you can consider a professional emphasis, for example Incra:

Thank you for attention! Good luck with your craft!

Read new notes before anyone else. Subscribe to the channel in Telegram!

Chat and ask questions to the author blog In contact with !

Miter saw 210mm Scheppach SX8L / HM 80L

Construction, main units and elements.

Each model consists of a wide, thick-walled aluminum base on which a turntable is mounted. A stand departs from the bed, carrying the electric motor and the saw unit, ending with a control handle.

Wood trimming with pull-through 210mm DWT KGS16-210P

Using a miter saw in a home workshop

A master who has a sufficient theoretical and practical base can use crosscutting for a number of purposes:

- Creating furniture using your own design;

- Implementation of projects to create author’s decorative elements;

- Working with floor coverings, in particular, laminate, cutting and laying them;

- Creation of racks for the construction of frame structures of varying complexity;

- Trimming lining for finishing residential buildings and premises.

In addition, various other work can be carried out in the workshop using miter saws.

Can I use a miter saw at home?

Today, home workshops have become very popular. Thanks to the development of the Internet and a large number of training materials, everyone can get the necessary knowledge base to start independent work. Of course, in order to gain experience, theoretical knowledge alone will not be enough. It needs to be supported by practice.

With the training, the master can begin to use rather complex equipment, including miter saws. With the help of this and other tools, you can create products of various complexity at home.

Miter saws, as tools for home workshop

Miter saws are a category of electric woodworking tools, without which it is impossible to imagine any professional workshop. They are designed for facing wood blanks, that is, cross-cutting. This tool finds its application in construction, renovation and joinery. Often, trimming can be found in furniture manufacturing, as well as in factories that manufacture finishing elements.

No one questions the fact that miter saws are indispensable in the professional field. However, when it comes to home use, the answer is not that obvious.

Circular saw or miter saw. Which one to choose?

Are you looking to make a nice table to match your couch but can’t decide between a miter saw and a circular saw?

Don’t worry, read our comparison guide to find out all the differences between the two saws and decide which one is the best for your task.

Some people think that one of them is better than the other, others that there is not much difference between them, and one can replace one saw with another. Nevertheless, each of them has its own characteristics and it is better to use the saw exactly for its intended purpose.

So let’s first take a quick look at the advantages and disadvantages of both types of saws.

Miter saw

What is a miter saw?

Cross-cut is a tool for precise, mainly cross-cutting, cutting of a workpiece. Most miter saws are small and portable. Unlike stationary miter saws, you can pull it out and set it on a temporary base by placing a drop mechanism (sometimes called a drip mechanism) over your workpiece. The blade sizes most commonly used for miter saws range from 8 “to 12” (20-30 cm).

What is a miter saw used for?

You can use it to create cross cuts on a workpiece in one quick motion. But more importantly, you can do it at your chosen angle. It is the best choice when you need to cut trims and moldings.

Pros

The miter saw is useful when you need precise cross-cuts in your workpieces. This saw is also a great option for miter cuts.

This is one of the main competitive advantages of this saw over other types of saws. Most importantly, the miter saw is one of the safest.

Minuses

Despite all the advantages, a miter saw is useless when you are about to cut large workpieces. While it is the best choice for cross-sections, trimming can be ineffective with long cuts (over 15 centimeters).

Miter saws are more of a luxury than a necessity.