What cutters are needed for door installation

The router for mortising door locks and hinges: settings, templates and cutters, video

Determine where the door opens, see how easy it is to open. Ideally, for the convenience of the work to make corner posts for the door to hold the door on its own, it will greatly facilitate the work. Mark the door 20 cm away from the edge with a pencil, attach the hinge and mark it. Take, screw the hinge to the door, make sure the hinge has a good grip. Using construction knife we outline the outline of door hinge carefully and with little effort, as shown on the photo, then with great effort repeat the outline of door hinge and repeat the operation with the second hinge. We end up with a well-cut outline. Learn about new modern ways to quickly mortise locks and hinges using special patterns and carriages that significantly help speed up the work and improve quality. Details about tools and templates used during the installation of doors by professionals.

To cut the hinges you can use the chisel yourself by eye. You can of course do it faster with a manual cutter. Do not think that the milling machine is something, big and industrial, it is quite an acceptable tool, which will need at least a couple of diameters for different types of locks. The milling tool will make the process of mortise of door hinges easier and faster, and it helps a lot if you find knots and uneven wooden fibers.

Using a template

The considered procedure is also carried out with a special template. You can get it yourself as follows:

- To begin with, the displacement of the cutter is measured.

- To determine the dimensions of a template for plunge cuts, you can use ordinary measuring tools.

- 2 or 3 passes are made.

- At this step, the finished hole is obtained.

After obtaining the special element in question, the hinges can be mortised using various other tools.

Note that the process of mortising the hinges with the router is carried out to obtain a quality niche. Features of the tool allow you to significantly speed up the process, reduce the likelihood of serious defects. By using special attachments you can significantly expand the capabilities of the device.

Recommended steps

To make the process of embedding the hinges went without complications, you need to set the procedure and follow it.

Masters are advised to act according to the following plan:

- Prepare materials and tools.

- Decide on the direction in which the door will open and the availability of suitable hinges.

- Make a correct marking. First of all, place it on the door leaf, at a distance of 20 cm from the top and the bottom.

- Place and trace the hinge. Cut with a sharp knife and make the recess with a router or chisel and hammer.

- Dip the hinge card into the recess and fasten with screws.

- Position the leaf against the vertical bar and mark it, taking into account the upper gap of 3 mm.

- Make a similar groove for the hinges on the box.

- Hammer down the hinges and fasten with self-tapping screws.

Features of working with different types of

Installation differs depending on the type of fittings. A variety of mortise hinges:

Removable hinges are easier to install, because. к. the two parts are installed separately, and then the door is hinged. This type is used when you often have to remove the interior door, for example, when moving furniture in. They are divided into left and right. When buying them you need to take this point into account. Split hinges require precise marking, without the slightest fault.

The universal hinge is more difficult to install, because it is not always easy to remove. к. The hinge is fixed to the box after attaching the second part to the leaf. So the door has to be held vertically or has to be supported. This type is inseparable. If it is necessary to remove the door, you will have to unscrew the hinge.

Mortise hinges also include hidden hinges, according to the method of installation. They can be difficult to install for non-professionals. к. The hinge body can be inserted into the leaf. The deep placing place is made with the help of a milling cutter. The installation requires extreme precision.

Different types of routers

Worthy acquisition for tool set of every door manufacturer or craftsman-installer is another special milling cutter for mortise of locks and hinges. model designed for milling out hinge notches in door frames and the doors themselves.

With this power tool the process of adding hinges can be many times accelerated and simplified, not to mention the higher quality and accuracy of processing.

By the way, even self-made, unique templates are made possible with this tool.

Thus, the use of such a cutter becomes possible for the majority of door hinges in their widest assortment of standard sizes.

The only modification that will need to be made after using such a cutter is cutting out the corners. An ordinary chisel can be used for this purpose.

How to use the router for mortise locks and hinges

The cutter is a hand-held power tool designed for shaping edges and grooves in wooden products. Rounded edges, profiled slats, beautiful joints, mortise locks, hinge notches. all this and much more can be done by the door installation router. It is an indispensable aid in the household, but not every craftsman is familiar with it. Of course, this tool is a bit more complicated than a drill or a shape saw, but it can work wonders.

The router can be used to make different profiles with both straight and rounded edges. It all depends on the type of cutter, which is installed in it. Nowadays, it is possible to buy whole sets of cutters in the markets, each of which is designed for a certain type and shape of a groove or hole.

- plunge-cut (or vertical) routers are widely used. Their design consists of two guides, along which the working mechanism moves in a vertical direction to a given depth;

- edging (or edge). designed for processing edges or edges. This tool has low weight and power;

- combined. combine both types;

- special. dowel, lamella, grass trimmer, etc.д.

The door installation router, in turn, can be used to:

The use of a hand router for loop cutting

Adjusting the equipment

The insertion of hinges by hand router is carried out after presetting the equipment, which takes place in relation to:

The depth of the notch depends on the thickness of the hinge to be installed or. To set the desired parameter on the equipment, you must:

- Place the machine on a level hard surface;

- loosen the locking pin of the infeed pin;

- lower the router to the level of a level surface and set the number “0” on the scale;

- If a hinge cutter is used, determine the thickness of the hinge;

- raise the dowel to the required value and fix it securely.

The speed of rotation is determined by experimentation. It is necessary for the machine to work without overloading and the wood does not “burn”. To adjust the speed the switch is used.

Installation of hinges

After all the parameters have been chosen, you can proceed to the door hinge. To do this:

- The door is installed in special clamps to avoid the possibility of warping in the performance of work;

- marks out the places for mounting the hinge. It is necessary to mark not only the dimensions of the fittings, but also the places for mounting the hinge;

- the wood is excavated by the milling machine. If necessary, any deficiencies detected after the operation with electric equipment are corrected. A chisel and hammer are used to finish the notch;

When working with the cutter, it is important to choose the right direction of movement of the equipment. It is necessary that the cutting part moves against the wood fibers. Otherwise unevenness and splintering may occur.

- Drill holes to attach the hinge;

- the hardware is installed on the prepared surface and securely fixed with fixing bolts;

- the second part of the hinge is mounted on the surface of the doorframe in the same way.

To choose a milling machine, you need to determine for what purposes the device will most often be used. The use of a router can reduce the time for carpentry work and improve the quality of the result.

In order to understand how to insert the lock into internal door, one should know its construction and types.

Depending on the type of attachment the locks can be surface or mortise. Overlay models, due to the outdated design, are practically no longer used. The correct installation of such a lock is very simple, because all that is needed for its proper operation is to provide entrance to the latch in the mating plate. And the main part of the lock is outside.

It is much more difficult to insert a lock into internal door, because it is necessary to insert the mechanism into the fabric of the door.

The locking tongues can have such types of fixation:

- magnetic. the metal tab is attracted by a magnet, with a spring completely blocking its movement;

- roller locking. fixation is made by means of a moving roller and a spring;

- latch. it is the standard mechanism, which fixes the latch by means of a latch pin.

Besides, it is possible to install in the door the lock, as for an entrance door. Such lock can be: plunger, cylinder or disk lock.

Recommendations on tuning the router for mortising door locks and hinges

Before you start using the hand milling tool for mortise locks, you need to set it up. In particular, it is necessary to properly adjust the following parameters of such power tool:

The depth of the groove created during machining depends on the thickness of the door hinge material or on the geometrical parameters of the mortise lock.

To adjust the equipment to a certain depth of milling for hinges or door locks, you need to perform the following steps:

- The cutter is installed on a flat and hard surface.

- Then the threaded element, which fixes the feed pin, is loosened.

- The cutter to be used is lowered to the level of the reference surface and a zero is set on the working depth scale.

- If with the help of a cutter will be created grooves for hinges, it is necessary to determine the thickness of the material from which they are made.

- The obtained value is set on the scale of the feed pin of the router.

The mortise tool must be securely fastened to the door leaf

To get a better idea of how to adjust the depth of machining performed by a hand router, you can watch the appropriate video.

In case you plan to cut the lock with the milling cutter, which should make a groove of considerable depth in the end part of the door, the procedure is made in several steps, each of which removes a layer of wood not more than 5 mm thick.

Setting the rotational speed of the tool with which the machining will be carried out is done by experience. In this case, it is important to ensure that the cutter in the process of processing is not overloaded, and processed wood does not burn. To adjust the speed of the tool, a special regulator mounted on the body of the cutter is used.

Choosing good cutters

All cutters are divided into types according to geometry:

Also, they are subdivided according to the material to be processed:

the essential difference is the size of a shank. Most often cutters with 6mm and 8mm shanks are used, less often with 12mm shanks. There are their analogues, similar, but not identical. They are measured in 1/2 and 1/4 inches. Translated into millimeters, these are 6.35 and 12.7, but it is forbidden to use them in a collet chuck designed for shank sizes of 6 and 12 mm.

The collet chuck differs from the cam chuck in that it does not tolerate inaccuracies. Because of this, the fixation is unreliable, and during operation the cutter can fly out and injure the operator. To avoid such situations, you should use cutters for the cutter, which will help you choose a sales consultant in the store.

Buying cutters, it is worth choosing only quality products. They will last more than one day, and they will not break while working, as it happens with cheap uncertified goods. It is better if the coating of the product will be made of high-carbon stainless steel.

The procedure of work on mortising door hinges using this device.

Horizontally place the door leaf on the rib.

In order the door does not fall, I put it in a homemade support, which made in advance from scraps of wood-fiberboard door frame and pieces of OSB.

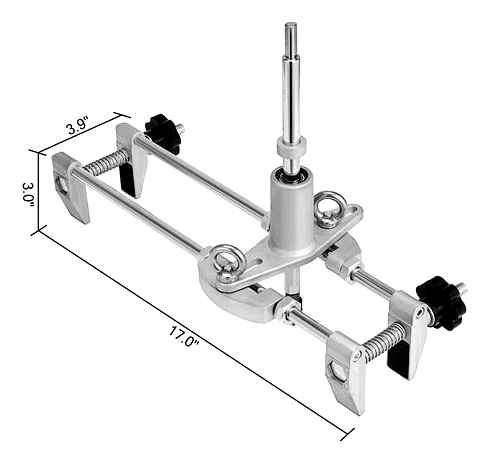

Fixing the template to the door with two screw clamps.

Advice. In order not to scratch the door, it is necessary to install pads of rubber or wood-fiber board between the clamp and the door leaf.

Also it is necessary to put a piece of wood-fiber board (2-2,5 mm) or a piece of ruler between the limit of the template and the door.

This gasket gives us in the future a gap between the door and the upper/lower transverse door frame.

The gasket is removed when transferring the template to the bow post (see carefully at the very end of the video)!

, I limit the movement of the template with two slats. The rail for the stop 50×20×580 mm. the top hinge with it The rail for the limiter 30×10×1500 mm. the bottom hinge with it.

This rail is attached to the first rail with two 25×3.5 mm screws.

To avoid having to rearrange each time, I cut all the top ones in first, and then all the bottom ones. it’s faster that way.

In principle, you can embed the hinges in a simpler way. Using this template, you only cut into the door, and on the box, simply transfer the marking and cut in the router, using the same stop that comes with the kit.

This is my practice too if you need to assemble, say, two door blocks, but if more, then only with a template.

Tip. In order to accurately set the depth of milling, I put one half (card) of the canopy between the router table and the wooden base.

After running the router we get a recess for the hinge. In the corners, I use a chisel to clean up the corners.

In this work at first glance it seems that a lot of work, but believe my little experience that this is not so. With the help of this device, I hinged 25 in a week without any pressure

door units. On this topic I am ending and will be preparing to write the next one, so subscribe to new articles. I have a lot of plans, the only thing left is to find the time to do what I have in mind.

The installation of the door leaf consists in fastening the hinges, which are the holders. To make the work and do not spoil the door, experts recommend using special templates. In addition, each door comes with a lock, the installation of which can also cause problems for inexperienced craftsman. The template for the lock can greatly facilitate the installation of. What is this equipment and how to make it yourself,

Interior door dismantling

Often the installation of the interior door is preceded by the dismantling. Disassembling is carried out in the reverse order from the assembling.

-

Décor elements. architraves and arch boards. are detached. Use a crowbar or a big screwdriver for this. Decorative elements can be reused, so there is no need to break them during dismantling. If these parts are intact, they can be painted, put on laminated film and used when installing a new door.

The architraves are removed with a crowbar or an axe

To remove the leaf from the hinges, turn it 90 degrees and lift it using the lever

Using a power tool speeds up the door dismantling several times faster

In order to speed up the door unit removal it is recommended to use angle grinder with metal cutting disc. If the old fasteners are difficult to unscrew, you can quickly separate the door frame from the walls by cutting the metal screws.

If there is no firm confidence in your abilities, of course, it is better to turn to professional installers, because the correct execution of the assembly and installation. not the only, but a prerequisite for the long life of interior doors. But if you have at least a little experience in carpentry work, and the operations described in this article do not cause you doubts about the possibility of repeating them. feel free to proceed to install the door with your own hands. You can save money and be absolutely sure of the quality of each action.

Subscribe to our channel on Yandex.Zen

Mortiser for mortising locks into interior doors

Qualitatively, it is possible to install an interior door with the help of a special cutter for mortise Every person wants his interior door to be installed beautifully and without damage, and therefore it is always worth to contact professionals, who know their business, let it be a little more expensive, but there is confidence in the quality of work.

Morter for mortising locks in interior doors: tools required

If we talk about the methods of tapping zamovki, we can distinguish 2 main approaches. This is professional, using high-precision electric tools, and artisanal, using a hammer and chisel.

Before you begin assembling the door, it is better to prepare in advance the necessary materials and tools for work

In both cases, you will need approximately the following list of tools:

- A hand router, an attachment for mortise locks;

- Hammer;

- Chisels of different sizes;

- A flathead screwdriver and a Phillips head screwdriver;

- A drill or an electric screwdriver;

- A set of feather drill bits for wood;

- A tape measure.

High revolutions of the cutter will make hollows under the lock without damaging the coating of the door. The hammer is mainly needed for the artisanal method, but can also be useful in a professional approach.

Chisels will have to cut out a place for planting a lock, but this tool can easily damage the door covering and worsen the appearance.

A flathead screwdriver and a Phillips head screwdriver are needed to tighten the self-tapping screws that hold the lock and the handle. It is recommended to use them because you screw them in with a screwdriver, there is a high probability of damaging the door covering. With a drill or an electric screwdriver you can easily, and more importantly accurately, according to the drawing, make a deep seating hole for the lock and the handle. A set of feather drill bits in wood mounted on a drill or an electric screwdriver. A tape measure is needed for measuring, so as not to make a mistake when seating the lock.

Milling machine. a device for door frames and webs, which will ensure a high accuracy of fit recesses. Nowadays there is a great number of different cutters for hand routers. All of them can be divided into 3 groups. edge, groove and phygory.

There are several varieties of cutters for mortise locks, which you can choose at your discretion

- Edge milling. used for edge milling of products, as well as for various carved elements on the material.

- Grooves. they are used to make grooves, recesses, notches, slots on wooden products.

- Finger-joints are designed to create decorative incised elements on the facades of furniture and doors.

Looking more closely, we can distinguish 9 frequently used routers. Straight groove router is designed for machining straight grooves, and in combination with a copying sleeve, can be used for shaped and straight parts according to the template. Dumbbell V-groove mills are designed for decorative threading or as a guide for moving.

Structural groove milling cutters are used for making dovetail joints or U-slots. Groove joint milling cutters are used for making dovetail joints or tongue and groove joints.

Chamfered slot drills are used for chamfering side slots in surfaces.

Straight edge phrases are used in the work, using homemade templates. Cutters with edge and disk form are used in the selection of the rebate, are highly accurate. Figured edge mills are used for processing the edges of panels, front frames and skirting boards. Cutters of the horizontal type are used to decorate milled edges.

As noted above, it is better to entrust the matter to a professional, but if you are determined to make hinges in the door by yourself, then this instruction will be relevant. For the beginning it is necessary to define, which side of a door will be the front one, and on which side the hinges will be located. It is advisable to mark the door so that you do not realize later that they are screwed to the wrong side.

In order to correctly mortise the hinges into the door with the edge router, read the detailed instructions

The latter is necessary to avoid cracks and damage to the door, which can occur during the rotation of the cutter. The most important moment is the adjustment of the plunge depth and the parallel stop on the hand router. Router the long edge from top to bottom. The top and bottom line for the contour trimmer should be processed not reaching a couple of millimeters, and then cut down with a chisel. It is necessary to avoid damaging the door.

The distances from the top and bottom edges of the door to the hinges should be 17 to 22 cm.

Then we put the hinge on and screw it down. Let’s apply the beam with letter “L”, make adjustments for the gap between the door and the frame and measure the location of the hinges. Proceed to the milling of the door frame. leave the peroral stop on the router, specify the depth of the plunge cutter and do everything exactly as for the door. After all screw the hinges with the door to the door frame.

The process of embedding the hinges can take a few hours. If you are not confident in their power and ability to use a hand milling machine, it is better to turn to professionals, or in the extreme case to call a comrade, which will help with the mortise hinges.

Templates can greatly facilitate the task of installing them. You can make these templates yourself or buy them in a construction store. Making a template will not take much time.

Additionally, it is possible to use special templates for mortise hinges and locks

- Board of thickness from 20 mm, length from 40 mm;

- Wood-fibre tiles 100×100 mm in size;

- Wooden bar of a small size;

- The rail is at least 150 mm long;

- Drill, jigsaw;

- Fasteners and bolts with thumbscrews.

On the wood-fiber board is made the necessary size cuttings, drilled 6 square parallel holes (3 on each side). Make another hole in the center with a size of 140×70. On one of the edges of the slat a bar is attached, which will be the limiter. Next, you should attach the board with a bar to the tile with self-tapping screws. Cut 3 pads from the board. one for vertical fastening and 2 of equal size for horizontal fastening. 2 parallel kerfs are made in each inlay to adjust the size of the holes. The pads are attached to the fiberboard.

The pattern is ready, but it should be made clear that all the dimensions mentioned above are arbitrary and do not have to be observed.

How to choose the right hand router

Choosing a mower, which is planned to be used for mortise locks and hinges, as well as a device for any other purpose, it is necessary to pay attention to the following parameters of such equipment.

For not too intensive and not too difficult works in the home workshop conditions, the milling machines of low and medium power are quite suitable, they can be used also for mortise in door locks. powerful devices, which are used mainly in the professional sphere, although they can cope with more complex tasks, can not provide a high rotation speed of the tool used. Besides, higher power significantly increases weight of such power tools.

Adjustable tool rotational speed

This feature allows you to choose the ideal mode for each step of the routing cutter’s operation. Among hand routers that have such an option, it is better to choose models whose speed switch is protected from external mechanical influences, contamination with wood dust and sawdust. It is also better to prefer models with switches that work according to a discrete principle.

The size of the tool’s working part protrusion above the end of the chuck

It should be borne in mind that the most important parameter is the value of the real outreach, rather than the maximum stroke length of the tool, which is indicated in the marking of each model.

Increased protrusion of the power cutter means less time required to re-drill the slot to fit the lock

To assess this parameter, you should consider several characteristics of the device, such as the weight of the cutter, its functionality, the convenience of the location of the equipment controls, the length of the electric cord. Not only user comfort, but also the quality of processing depends on how convenient it is to use a hand router.

This parameter is provided not only by the design features of the milling machine, but also by the presence of a special backlight in its equipment.

The functionality and usability of the equipment largely depend on this characteristic. That is why, when buying any milling machine (including for mortise-and-drop loops), stop at the models, equipped with various holders, additional attachments and other elements.

Choosing a milling machine, it is necessary not only to hold such a device in hand, but also to be sure to turn it on. So you can assess how freely and easily the working head of the equipment moves, test the movable elements of the cutter for backlash and misalignment, determine the level of noise produced by the device during operation.

Useful addition to the router. a tool for inserting hinges and door locks

If you follow these simple recommendations when choosing a hand router, you can buy the device that will suit you both for its technical characteristics and ease of use.

Area of application

As it was already said, you can use the usual hammer and chisel to install the hinges and locks, but you should be prepared to spend a lot of time and effort using them.

Such a device is an indispensable tool for those who professionally install doors on a daily basis.

In order to perform all the necessary actions, the blade must be secured vertically, by means of a slipway.

Be sure that the master must accurately mark the place where the installation of the lock or hinges is planned. The next step is to check. it is necessary to put the part to the marked area and see how perfectly the marking is done. On the areas of the cloth that go beyond the marking, you should cover with painter’s tape to protect against damage.

To perform the necessary actions, you should use a groove milling machine.

In any case, such tool as milling cutter for mortise locks and hinges will be relevant for any apartment or private house. The need to install the door does not arise often, but the need to replace the hinges, or align the door leaf relative to the frame, can occur frequently. If to do it on professional level. it is the milling tool that allows to fulfill the whole front of works quickly and comfortably.

Although the device is convenient to use, to work with it requires a certain experience and knowledge, why the milling machine is purchased by far not everyone.

In this article we will consider a faster method of embedding the lock into an interior door, compared to. This method greatly speeds up the work, and if you need to install a lock in several doors, it is just what you need.

We start cutting by marking out the door leaf. I put the lock to the interior door so the door handle is at 900 mm from the bottom of the door. I put the size on the door leaf.

I put the lock to the door and line up the hole for the handle with the mark, mark out the edges of the lock.

Find the middle of the door leaf thickness and run the trimmer line.

I measure the thickness of the part of the lock, which later will be hidden in the door, in my case it is 12 mm. I take a 1-2 mm bigger drill bit and drill the holes from the marking to the marking on the door. I try to make the holes one right after the other.

Then use the same drill to drill the holes in the longitudinal groove.

Smooth the mortise for the lock with a chisel. I had no 13-14 mm drill, so I had to line up at the end with a cutter to get the sufficient width of the groove for the lock. But if the drill had the right diameter, you would not have to trim anything, you would get about the same groove, only with an uneven edge.

Put the lock on and see if it fits.

If everything is all right, I mark the place of the lock on the door leaf with a knife.

Apply the latch, it should fit snugly.

I mark the holes for the handle and the latch. I put the lock on the side of the door, align it with the edge of the door and make sure that the edges are aligned with the edges of the milled groove.

Drill holes for the handle and the latch. I use a 20 mm diameter Fostner’s sleeves.Previous: How to install hinges on an interior door. Inserting the hinges with the router.

Depending on the factor of the location of the door block, the way of opening, and the total number of active webs, it is acceptable to sort the doors according to certain types. Many people are used to an exterior opening door leaf, but there are also interior-opening doors.