What do they do in the repair in the apartment. Working with tiles

Spray on Countertops | Stone Coat Epoxy

Secrets and tricks of work with an electrician

Electrician is the most affordable tool for cutting wooden blanks, in addition, it is the most compact and easy. In this regard, it is used even in cases where it is better to use the circular, tape or saber saw to solve the problem to solve the problem. Knowing some tricks of working with him, many complex cuts will be able to make a jigsaw with rather high quality.

If you need to make a spray in a hard.to.reach place, where it is impossible to turn around, for example, in the corner, then you can rearrange its saws backwards.

This will allow you to do a cut, moving in the opposite direction.

Smooth radius washed down

When trying to make a steep radius of washed down, a wide saw is not able to turn, and move smoothly along the drawn contour. In this case, the cut is uneven. However, it is quite possible to make it perfectly, if you pre.perform the cuts, as shown in the photo.

Thanks to cuts, segments will be separated with the cut, thereby releasing the file. As a result, she will not jam, and will be able to move exactly along the drawn contour.

Cutting with a plastic lining on the sole

One of the reasons for sawing a jigsaw with chips is its sole. She does not press the edge of the cut, the same makes it possible for him to break up with a return movement of a saw. This is solved by a simple plastic lining.

A lining on the sole is cut out of sheet plastic. In it you need to make a cut under a file. She just presses against the board with a clamp and saws with her. Washing overlage is glued to the sole with bilateral tape.

After that, the electrician makes it even cleaner than when using painting tape.

Cut on the notch from the knife

This is a slightly more laborious way than the previous. It implies the need to make 2 notches under the lineup 2. They are made with a millimeter indent to the sides of the marking line. That is, it is necessary to carry out with a knife so as to cut out the thin upper layer of sheet material. The gap between the two lines should correspond to the width of the cut, which makes the canvas of the jigsaw.

After that it remains to carefully make the scraps between the lines. All chips received as a result will end on notches. As a result, they will not be at all, or they will turn out to be invisible.

Choice and work by manual jigsaw

Despite the fact that the work by an electrician is more convenient, the manual version did not leave the store shelves finally. There are some explanations for this. It is much cheaper and easy to work, the file for it is very thin, so maneuverable. When working, you can make a wide range with an instrument, which better throws the chips even when sawing a thick product. The manual jigsaw is less dangerous for beginners and enables artistic sawing of small details, the electrician in this regard is not suitable, it is coarser.

However, it has a number of disadvantages, the most noticeable-a frequent break in the saw canvas due to its miniature. Also, the work with a manual jigsaw requires physical stress and more time to work. To make tiles that do not reach the edges of the workpiece, you need to remove the end of the incisor, pass it into a previously made technological hole, then fix it again. You can not cut at an angle and work with solid materials, the restriction usually ends with wood and plastic.

When buying such a tool, you should pay attention to many factors, despite external simplicity. The shape of the frame will determine the remoteness of the saw from the edge of the workpiece, and its elasticity will affect the tension of the file and the mass of the entire tool in general. A harder and elastic frame will better pull on the canvas, giving it great maneuverability and life time. It is important to pay attention to the clamps, they should be strong, comfortable and reliable. And choosing files, first take it thicker and wider, and after the work of the jigsaw is mastered, and for more detailed small works you can take more miniature files.

Teeth

Usually they are directed up for better adhesion with sawing material and pressing the workpiece to the head of the jigsaw.

There are models where the teeth are turned down, which reduces the likelihood of chips on the material. But for such work, appropriate skills are needed. There are saws with teeth in the form of a triangle that cut from all sides. The canvas can be rotated, and the cut will go with it.

Step.by.step instructions for curved sawing

If with a direct reza everything is more or less clear, then for pattern sawing you will have to “sweat” a little.

- A file is selected. When the degree of rounding is not very large, the standard version of the canvas is suitable. In the case of a sharper rounding, it is necessary to use narrower canvases. However, it is also important here to find a middle ground, because an excessively narrow canvas will resist the departure in the process of cutting.

- As mentioned earlier, the cut begins with drilling the hole under the saw.

- If the radius is small, then in the process it will be necessary to keep the reference point depending on the position of the canvas, because all sorts of points-sets can be knocked down from the required course.

- Moving along the marking, the electrician goes, turning around the axis of the part. No lateral efforts are required to make. You can’t push the tool forward. He must go calmly.

Work with metal

Speaking of metal parts is carried out using files with small cloves. The speed of the course is selected low, the pendulum course is not used at all. In the process, the metal vibrates, so it is pressed with clamps to the faner or pinched inside two sheets, forming a “sandwich”.

To reduce friction and prevent overheating of the material, in the direction of movement of the electric saw, literally a drop of oil is applied. This will improve the speed and quality of the cut, as well as facilitate the process of work.

The curved cut

The assertion that you can make a neat curved cut at home is not in a fiction. This is a little more complicated, but with proper preparation it is quite feasible. The tricks in the work are as follows:

- It is necessary to use a narrow saw canvas selected to work with specific material;

- make preliminary markings on the workpiece;

- First, you need to make a hole of a larger diameter in the workpiece than you need for a saw (drill it);

- you need to set the highest speed;

- cut out without using the function of the pendulum passage.

Note: The cut accuracy is significantly increased if you use the emphasis.

Lobzik for countertops: how to cut a circle

For convenience, it is also recommended to use compasses.

Tips

Council 1. A person is arranged so that in addition to reading, I want to hear and see with my own eyes. Then you can see how to use an electrician on

Tip 2. Get an even and clean cut, you can only work as a serviceable power tool. Hence the conclusion. before the start of the operation, it is necessary to check its performance.

Tip 3. Gently, observing safety preca. Squeezed peaks indicate the indistinguishability of the cutting tool. The work of such a file creates increased loads on the electric drive, which causes a reduction in the life of the jigsaw.

Tip 4. In the process of work, the entire plane of the sole of the electrician should come into contact with the processed product. this will contribute to the purity of the cut and the absence of vibration.

Tip 5. When processing thin sheet material, it is advisable to use a unnecessary piece of plywood as a substrate. This will avoid vibration and rattling of a metal sheet. In addition, this method will prevent product deformation.

To fully master the rules for working with an electrician and get the skills of its operation, you need to know the tool itself well, be able to set the required operating modes, apply the right file. But no theoretical knowledge will cost anything if you do not apply it in practice. therefore, practice, practice and practice again.

Noticed a mistake? Highlight it and click Ctrlenter to inform us.

Features of work with a manual tool

It is more difficult to work with a hand tool, but it is this jigsaw that will help the master perfectly in the case when it is necessary to urgently make a furniture workpiece, and there is no electricity. Manual jigsaw is quite a laborious process. The workpiece is securely fixed on the stand.

Cut the material from the center. For this, the master drilles the hole and only after that the sawing begins. Do not cut too close to the contour to prevent the appearance of chips.

Advice! The saw should be as tightly fixed in the area of fixation.

Why is the jigsaw saw crookedly

In some cases, the master may get a curve cut. A similar nuisance arises due to:

Working with too thick materials is difficult to achieve even cut.

Ways to eliminate problems

To obtain an acceptable result, you should be patient and work correctly with the tool. Do not press too much on it and push it forward. This will only worsen the quality of sawing and will cause chips on the material. It is important to apply a fishing line for a trimmer for a trim.

Sprinkle metal shields, wooden countertops and other products must be a device with a well.sharpened file.

What is the guide to the kit with the jigsaw

Almost all of the lobes in the kit attached a ruler with an emphasis on the second end. It is required to promote the screws, put the line on the desired emphasis and tighten the screws again. When the emphasis is fixed, it remains only to complete the cut.

The perfectly even saw can also be done in a different way. In this case, the presence of a flat edge does not matter. It is necessary to take a smooth emphasis and this will help the rule, a bar or a piece of a profile pipe. The main thing is to choose the corresponding length.

The prepared emphasis is fixed with clamps on the material. Then it remains only to draw a jigsaw on the board and make a cut. When accurately working with this tool, it will turn out to be quite high.quality and smoothly perform the cut.

How to install a file in an electrician

There is a special seat in the spindle to install the canvas in the spindle. If the saw is attached with screws, then you first need to loosen the mount either with a key or a special latch, insert a file, and then secure it reliably. Most modern models use a self.rearmament device for fixing equipment. To do this, raise the lock up, carefully insert the cutting canvas into the freed hole, and then return the lock to its original position.

Only clean files should be installed, on the surface of which there are no chips and other foreign particles, otherwise the shank is poorly fixed. As you wear, the saw canvas must be replaced, otherwise the cut quality worsens and the load on the engine engine increases.

What cuts can be performed with a jigsaw

Straight cut

The basic function when using an electric lobe is a direct cut. With short blanks, it is quite simple to cope. It is much more difficult to smoothly lead the tool along a long straight line. In this case, the best option will be a wide saw blade, which helps to adhere to the intended trajectory of movement.

Figure cut

For a figured saw, a special equipment is used, in the labeling of which the letter “o” stands. These are files with a narrow canvas and a small tooth, which provide a neat cut and are not clamped in corners. During figure cutting, the minimum speed of the nozzle is set. If it is necessary to cut at an angle, the position of the case is regulated relative to the sole using a special mount. In some models, this is done with a key, for others a fixer.

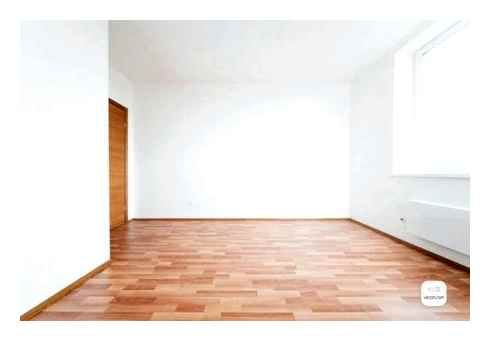

Done some repair work on a apartment floor the tiles came up