What does a joiner’s hacksaw consist of?

Elements of a hacksaw: what are the main parts

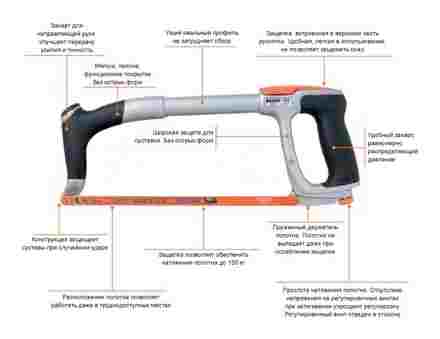

The instrument has become popular also because of its structure. Outwardly, it resembles the letter C, to the ends of which a cutting blade is fixed. This tool contains the following elements:

- A pen. Modern hand saws have handles that are made using two-component materials. This allows for a longer tool life. The shape of the handle is made so that it is very convenient to use it. Usually it is located either at the top or on the side. In the first case, the tool is used to work in places where it is difficult to get close.

- Frame. It takes on the main load. It is she who extinguishes all vibrations that arise during work. Modern hacksaw frames are made from a wide variety of materials. Very often, an element is installed on the tool that regulates the tilt of the blade, which allows you to work in places with difficult access. The frames are made in two versions. They can be solid or have the ability to move apart. It is possible to put a canvas of any length on a sliding frame.

- Canvas. To cut metal, it is made from very hard alloys. It is very thin and fragile. There are many small teeth along the entire length. The work requires special care. You need to buy a canvas that is hardened. If it is not there, then it will fail very quickly. The element with sparse teeth is more efficient. A high-quality cut can be provided only by the one in which the teeth are often located. Recently, bimetallic blades began to appear on sale.

Scope of application of the hacksaw

Tools are made not only by hand, but also electric. Their main task is to cut metal. Naturally, you can make grooves with them, as well as much more. The canvas is made of various materials, therefore, its properties may be different. A locksaw’s hacksaw is available not only for sawing metal parts. By changing the type of blade, you can cut objects made of plastic, ceramic or plexiglass. Among the entire range of hacksaws, there are three main types:

- For household use. Such models are the most common. They are ideal if you need to do something that is not very difficult. It is very easy to use them. To fix it, you need to insert it into the grooves and tighten the special screws. The main thing is to remember that the canvas should be well stretched so as not to damage it during operation. Such hacksaws are much cheaper than the others.

- Hand tools are also of a professional type. They are used when you have to work for a long time, and the cut must be clean and even. A feature of such tools is a convenient handle, as well as a quick-change mechanism for the saw element. If you need to cut something very often, then it is better to use just such models.

- Hacksaw handle. The appearance of this tool resembles a staple. They do not need to have great physical strength to work. It is used exclusively where it is simply impossible to crawl with the usual variety. Due to its design, it is permissible to install broken blades in a locksaw.

What are the main parts of a hacksaw

Any owner has a minimal set of tools. It is individual for everyone, but everyone has a hacksaw for wood and metal. Its main parts are a handle, a frame, a canvas.

Features of using a hacksaw

To work the tool comfortably, you need to stand in front of the vice with a half-side. The left leg should be in front. It is she who is the supporting one. The handle rests on the palm of the right hand, with the thumb it is held on top, and the rest is wrapped around the bottom. Place your left hand on the front end of the hacksaw.

When working with a saw, it is usually held horizontally. The movements are smooth, you should not pull. The scope of the tool is needed such that the entire length of the blade takes part in the process. As a rule, two-thirds of the length is involved in the working rhythm.

Typical hacksaw speeds are up to sixty strokes per minute. Moving is meant moving forward and backward. At the same time, when working with hard metals, the speed decreases, and soft ones are cut faster.

When the hacksaw goes forward, you should press on it, it comes back easily. Its strength should match the hardness of the metal under the saw blade. The harder it is, the more pressure is needed. Under normal conditions, 0.1 millimeter of the thickness of the web has a pressure of one kilogram. At the end of the process, when the part is almost cut, the pressure should be loosened.

Hand tools, as a rule, do not need cooling after work. To reduce friction, grease is applied to the cut.

If the blade is not tight enough, then the tool is often pulled to the side. This can negatively affect not only the evenness of the saw cut, but also the integrity of the cutting element itself. If this happens, it is best to back off and start a new cut. If you try to fix a cut that has gone to the side, it will lead to damage.

If even one of the teeth breaks, it is better to immediately change the blade, because others will break behind it. You can use the old one, but then it will need to be restored first. To do this, the nearest teeth are ground near the broken tooth. It will be enough to grind off two or three. After this procedure, you can use the canvas again.

Hacksaw for metal

A fairly common construction tool is a hacksaw for metal. It is used for a wide variety of construction work, it allows you to change the size and shape of a wide variety of materials. Many experts call this tool universal. There is a fairly large number of different hacksaws for metal, all of them are characterized by their own specific features, which we will talk about in more detail later.

Scheme of work with a hand hacksaw

Subject to certain rules, you can use a hacksaw for metal with the exception of the likelihood of damage. When considering how to properly saw with a hacksaw for metal, we note the following points:

- The body must be correctly positioned relative to the body.

- A well-fixed blade eliminates the likelihood of various vibrations at the time of work. Too strong fixation may damage the blade.

- Hold the tool with both hands when cutting. Due to this, the likelihood of displacement of the hacksaw on the metal relative to the surface to be processed is eliminated. When moving forward, you need to press the surface harder, while the opposite is true, slightly weaken the pressure, due to which the removal of chips from the cutting site is ensured.

- Before carrying out the work directly, it is recommended to fix the workpiece in a vice. This significantly improves the quality of the resulting cut.

On the Internet, you can find a drawing of a hacksaw for metal, which is used to create a homemade structure. However, do not forget that the cost of the tool is relatively low, so it is recommended to purchase it.

Types and areas of application of the tool

In the construction market, a hacksaw for metal is found in electric and manual form. The main purpose of the tool is to saw a metal product, as well as to create grooves and some other elements. When using special materials at the time of fabrication of the blade, it can also cut plastic, ceramics, organic glass and other surfaces. Conventionally, a mechanical hacksaw for metal is divided into three main groups:

- Home models. This version is very common and is optimal for solving simple tasks. It is characterized by ease of use. To fasten the working blade, a tensioning screw mechanism is installed, which greatly simplifies the process. Do not forget that if the working part has a weak tension, then there is a possibility of serious deformation. A home-type hand hacksaw is much cheaper.

- There are also professional hand tools. They are designed for continuous work and high quality cuts. Distinctive characteristics are the presence of a comfortable handle, as well as a special mechanism, due to which the process of changing the working blade is simplified. The purpose is to carry out frequent work on cutting various parts.

- A hacksaw handle belongs to a separate category. It is characterized by the fact that it has the shape of a staple. This type of tool does not require much effort. The area of use lies in the processing of hard-to-reach places. The design of a metal hacksaw allows you to install even a broken blade.

There are also electrical appliances on sale, which are characterized by increased performance. Their use is possible only if there is source of electricity.

Design features of a hacksaw for metal

The widespread use is largely determined by the device of the hacksaw for metal. It is presented in a C-shape, between the two edges of which there is a special canvas. When considering what the tool consists of, note the following:

- Lever. Today the handle of a hacksaw for metal in most cases is made of two different components, which ensure a long service life. The shape should be comfortable enough, and the element itself should be placed at the top of the structure or on the side. In most cases, the top location is used when it is necessary to process hard-to-reach places.

- Frame. It is designed to take the load, as well as damp vibration at the time of operation. Today, various materials are used in the manufacture of such tool elements. In order to carry out the processing of hard-to-reach places, the structure often has an element due to which the tilt of the web is adjusted. The frame is made in one piece or sliding, the second version of the design allows the installation of the product with different lengths.

- The canvas is represented by a hard alloy tape. This element is considered the thinnest and most fragile, represented by a combination of small teeth located relative to each other at a certain distance and angle. At the time of work, be careful, as even minor mistakes can lead to damage. When choosing, attention is paid to the fact that the surface must be hardened, since otherwise the required level of wear resistance cannot be ensured. To increase productivity, a blade with a rare tooth is selected, to increase the quality of a cut with a frequent one. Recently, bimetallic blade has become widespread.

The design features of the hacksaw for metal determine the very widespread use of the tool. The main part determines the duration of use and other points, the cutting speed and cut quality depends on the installed blade.

Tool selection criteria

Do not forget that you should choose a hacksaw for metal in accordance with the recommendations, since mistakes made can lead to the acquisition of a low-quality product. Even minor defects reduce the service life. The main criteria for choosing a tool for metal are as follows:

- The shape of the tooth is selected depending on the inclination of the cutting edge part. In most cases, a classic form is created during production, since it is a universal option.

- A rather important parameter is the pitch of the teeth. Too much will reduce productivity and improve cut quality. Many manufacturers indicate this parameter as one of the main ones, the indicator can vary in a very wide range.

- The length of the blade is selected depending on the size of the workpiece, as well as the metal tool itself. This indicator varies in the range from 300 to 700 mm. At the time of selection, attention should be paid to ensure that there are no significant defects on the surface. Even after slight bending, the product should regain its shape.

- The handle is available in a wide variety of designs. Experts do not recommend giving preference to products with a hollow handle, as it can quickly break. At the time of selection, it is recommended to take the product in hand, it should be comfortable. The handle has recently been made of two materials, due to the combination, a long service life is ensured. Corrugation on the surface reduces the likelihood of slipping during operation.

- The type of material used in the manufacture of the main part. The most commonly used alloy is characterized by increased resistance to moisture. Due to this, the operational life is significantly increased.

- The tension of the web can be done in a variety of ways. The convenience of using the device, as well as the service life of the canvas used, largely depends on the features of the mechanism used.

- When choosing, attention is also paid to functionality. As previously noted, some mechanisms allow tilting the blade or changing the length of the cutting part.

The incredible English Joiner’s Bench

The most important selection criterion is cost. It is not recommended to give preference to budget options, as they will not be able to serve for a long period.

Note that a hacksaw for metal is a basic tool. Even after the appearance of the grinder, it is very popular, since it can last for a long period and allows the processing of hard-to-reach places. It is recommended to give preference to products of well-known brands, as they will serve for a long period.

Types of hacksaws

The whole variety of hacksaws can be roughly divided into tools for:

- Works with wood surfaces. This includes both the universal saw and the garden hacksaw, and some other special varieties.

- Metal surface treatments. This group also has its own modifications for masters of different classes.

Works with aerated concrete

By structure, the instrument is:

- Standard single handle.

- Modifications with a solid frame are found.

- A specialized tool is a folding hacksaw, which is an attribute of the traveler’s tool kit.

A hacksaw. what is it, a device, what is it for, how it differs from a saw, the main types

One of the main tools for working with various materials from a home craftsman is a hacksaw. It has several varieties, which are used depending on the type of surface to be treated. It is important for each of them to be able to use correctly.

Cordless hacksaw

A special type of tool that has appeared relatively recently is a cordless reciprocating saw, which is also called an electric hacksaw. Such a device will come in handy when performing a large number of construction or garden work. The compact size allows the electric hacker to be used in confined spaces that would be difficult to handle with a conventional saw. Such a hacksaw should be selected, guided by the following characteristics:

- Battery capacity, which directly affects battery life. Professional models can last about 5 hours before changing the battery.

- Voltage affecting the power and number of movements made by the saw per unit of time.

- The ability to connect additional batteries to increase performance.

What is a hacksaw for??

Having dealt with the definition of what a hacksaw is, it is worth dwelling in more detail on the areas of its application:

- This tool is widely used in horticulture for pruning trees and shrubs, cutting knots and rough parts of wood.

- A hacksaw is used to cut wooden parts during construction and household repairs.

- She cut figures out of plywood, make curved cuts or make through holes.

- There are special varieties for sawing metal sheets and pipes, aerated concrete blocks.

- Some modifications cut grooves, spikes and recessed holes.

Hacksaw for wood

The largest number of types of hacksaws are designed for working with wood. Among them, the following are considered popular:

- Classic saw, which is also called standard or conventional. It is a standard tool with a wide blade for straight rip or cross cuts. The number and size of teeth may vary depending on the modification.

- External or narrow tool. It differs from the classic model in that the hacksaw blade is much narrower. This saw is more maneuverable. It is more convenient for it to cut sheet material along a given contour.

- The bow saw has a thin curved bracket. Such a tool is convenient for cutting tree branches and carrying out other work in the garden. Some varieties have a dedicated rod connector for working with tall branches.

- Passing saw. It is also called spike or obushkovy. It is used by carpenters or joiners to remove protruding grooves or tenons, that is, to obtain an even cut.

Hacksaw rating

- Gross Piranha 24101 is one of the best classic professional wood carving models with a comfortable grip from a German company with production in China. Cost. 20.

- Vira 800240 is a high-quality domestic saw with three-sided sharpening of teeth and their additional hardening. High quality at a modest cost of about 7.

- Stanley 1-15-122 is a frame saw with a comfortable handle. Price. 8.

- The Stayer Max Cut is a handy, foldable type of woodcutting tool that many hunters and hikers prefer to take with them. Price. 7.

- Irwin 10505549 is a specialized tool for professional bricklayers for working with aerated concrete blocks. Price. 24.

How to choose a hacksaw?

- Specialization of the model you like. It is worth carefully choosing what material to work with. Tools for aerated concrete and gardening differ significantly.

- Steel grade from which the cutting blade is made. High-speed and carbon alloys with a blade strength of 45 HRC and a cutting edge of at least 60 HRC behave best in their work.

- Sharpening the teeth affects the quality of the cut in a certain direction or work in hard-to-reach places. Universal sharpening is somewhat inferior in quality to a cut in more specialized models.

- The length of the blade differs not only among different types of models, but also differs among tools of the same category.

- Convenience of the handle. This parameter is especially important if the master will carry out a large amount of work with the tool. The more convenient the hacksaw will fit in the palm of your hand, the less hand will get tired.

“Joiner’s hacksaw, device and purpose”.

Lesson type: combined lesson

the teaching material in the lesson corresponds to its didactic tasks, goals and leading ideas. The structure of the lesson is optimal, the stages of the lesson are logically interconnected, they begin with the setting of tasks and have a clear conclusion.

View document content

“” Joiner’s hacksaw, device and purpose. ”

Feedback on the attended technology lesson.

Date: February 13, 2018

Teacher: Ilyasova Mariam Magomedovna

Grade: 5 3 Number of students on the list: 19

Attended the lesson: 19

Lesson topic: “Joiner’s hacksaw, device and purpose”.

Lesson type: combined lesson

the teaching material in the lesson corresponds to its didactic tasks, goals and leading ideas. The structure of the lesson is optimal, the stages of the lesson are logically interconnected, they begin with the setting of tasks and have a clear conclusion.

The teacher competently leads the students to the awareness of the topic, goals and objectives of the lesson; teaches to carry out educational activities according to the planned plan. At all stages of the lesson, students are motivated for effective activities, cognitive activity. The teacher observes the principles of accessibility, scientific character, practical orientation, reliance on the students’ knowledge; interdisciplinary connections with physics, drawing, the basics of life safety are carried out.

In the lesson, various forms of educational activities of students are used: frontal, individual, brigade (group). The teacher takes into account the level of development of the personal capabilities of students, including the formation of reflective thinking and their own opinion.

The teacher also works to form personal UUD. develops the ability to determine the motives and meaning of activity, take a scientific point of view, responsibly with a friend, enter into a dialogue, defend one’s opinion, taking into account the opinions of others.

When organizing the control of learning outcomes, different forms of control are used.

Differentiated homework, some optional tasks are offered, creative.

The lesson is built in accordance with the Federal State Educational Standard, information and communication technologies and a system-activity approach are used. The level of achievement of the set goals is quite high.

Deputy Director for OIA

Feedback on the attended technology lesson.

Teacher: Ilyasova Mariam Magomedovna

Grade: 5 3 Number of students on the list: 19

Hacksaw Basics: How to buy and use a hacksaw.

Attended the lesson: 19

Lesson topic: “Drilling machine device. Rules and techniques for working on a drilling machine. Practical work “Obtaining blanks with a hole”

Lesson type: combined lesson

multimedia projector, screen, educational film “Drilling machine device”;

in a carpentry workshop: workbenches, a drilling machine, hand tools, a set of drills;

textbook V.M. Kazakevich, G.A. Moleva “Technology. Technical work grade 5 ”, workbook, dictionary, reference book, technological map, task cards;

Drilling Safety Cards.

Objectives of the topic: formation of knowledge about the device of the drilling machine; creating conditions for obtaining skills to work on a drilling machine; the formation of the ability to systematize the knowledge gained; development of hard work, accuracy.

Objectives of attending the lesson: preparation for the pedagogical council “Metasubject in the educational process as the basis for the integrity of students’ education”, teacher certification

Technologies, techniques and methods (verbal, visual, explanatory-illustrative, partial-search, problematic) used by the teacher are effective for achieving interaction results at each stage of the lesson, contribute to the formation and development of UUD.

The didactic equipment of the lesson is distinguished by a variety of tasks of various types, types, various sources of information are used.

The teacher creates conditions for the formation of subject results (the ability to select material, work with a tool and on a machine, carry out technological operations) and metasubject ECD (developed the ability to determine the topic of the lesson, its goals, the purpose of the assignment, choose the most optimal means and methods of solving the problem during work) in a group (brigade), to assess the degree of goal achievement, to be aware of the level of their knowledge). The teacher also works to form personal UUD. develops the ability to determine the motives and meaning of activities, take a scientific point of view, take a responsible approach to the results of activities, understand the importance of safety rules; regulatory. teaches you to work according to plan, control your activities, analyze and evaluate your work, communicative. teaches you to interact with each other, enter into a dialogue, defend your opinion, taking into account the opinions of others.

When organizing the control of learning outcomes, different forms of control are used.

Differentiated homework, some optional tasks are offered, creative.

Self-assessment (reflection) of students’ activities based on the results of the lesson.

The teacher uses a communicatively appropriate communication style, maintains psychological comfort in the lesson when communicating with each student.

The health-preserving aspect of the lesson consists in the feasibility of completing the assignments, the correspondence of the material to the age and psychological characteristics of the fifth graders, the establishment of an atmosphere of cooperation with the students, the competent construction of the lesson, and physical minutes.

The lesson is built in accordance with the Federal State Educational Standard, information and communication technologies and a system-activity approach are used. The level of achievement of the set goals is quite high.

Municipal budgetary educational institution “Sovkhoznaya SOSH

“Joiner’s hacksaw, device and purpose” open lesson

For preschoolers and pupils of grades 1-11

Record low registration fee 25 R.

Open lesson on technology in grade 5.

The topic of the lesson is “CARPENTER HACKSAW, DEVICE AND PURPOSE”

Lesson objectives :

Lesson Objectives :

-sawing rules and safety precautions when performing work;

Lesson type : combined

Lesson method : explanatory and illustrative, practical work

Equipment and inventory : solar workbench, joiner’s hacksaw, joiner’s square, ruler, pencil.

New concepts and definitions: sawing (longitudinal, cross and mixed), saw, teeth, cutting edge, miter box.

During the classes :

Repetition of learned material (8 min.):

In the last lesson, we studied the markup rules. Without good, accurate markings, you won’t get a good product. Therefore, now we will repeat how to correctly mark out wood blanks.

Question 1: What is markup? Name the markup tool.

Question 2: What are the markup rules?

Purpose: the device and purpose of a carpenter’s hacksaw, the formation of initial knowledge about the sawing process.

To teach to determine the purpose of a hacksaw by its appearance;

Saw wood parts with a joiner’s hacksaw;

Develop practical hacksaw skills;

Learn how to select a hacksaw depending on the cut;

Master the basic safe hacksaw techniques.

Sawing of wood is carried out with various saws. Look at the picture, what different types of saws are used, each has its own purpose.

There are three main types of sawing in the direction of cutting: cross, rip and mixed sawing.

Have drunk for transverse sawing, sharp cutting edges of the tops of the teeth alternately cut the wood fibers and take out the splintered wood particles in the form of sawdust.

Have drunk for longitudinal cutting the forward cutting edges of the inclined teeth shear the wood fibers and the cut particles are chipped along the fibers, forming sawdust.

The board shows the shapes of the teeth and the schemes for cutting the fibers with longitudinal and transverse saws.

SAFETY SAFETY WHEN SAWING

When sawing with carpentry saws, hacksaws and other hand tools, consider the following:

You can use only serviceable, well-sharpened saws, with correctly set teeth. Do not use blunted saws.

It is necessary to firmly grip the workpiece when cutting. Use supports, miter boxes and other ways.

Observe the correct position and hold the instrument correctly; be attentive and accurate in work.

It should be especially taken into account that the most dangerous when cutting is the moment when the saw blade is guided along the risk with the help of the thumb or the second joint; jerks of the saw should not be allowed, especially forward, when cutting.

It is not allowed to keep the left hand close to the cut.

Place the saw on the workbench with the teeth away from you.

Do not blow off sawdust or sweep it by hand. Use only a brush.

Students record TB under the teacher’s dictation.

Consolidation of the studied material (5 minutes.).

Before we move on to independently completing the task of sawing blanks in the manufacture of various products, let’s repeat what we learned new today in the lesson (in the form of a frontal survey):

Practical work (30 min.).

Well done, you have mastered the training material well, and we are moving on to doing practical work.

You have to cut the workpiece, having previously made the markup. Look at the blueprint on the board. The teacher explains the algorithm for completing the assignment.

Open notebooks, sign the number, the topic of the practical work, the purpose, equipment and tools with which you will work, complete the drawing.

Before starting the assignment, does anyone have any questions? If there is, the teacher answers.

Next. a short briefing on the sequence of work.

The teacher informs the students that the assessment for practical work is given taking into account the correct organization of work, compliance with the safety rules.

Sequence of work:

one). Check the availability of equipment and inventory. Everything should be in good working order, clean.

2). Make markings on the workpiece, check the correctness.

3). Make a cut.

four). Clean workplace.

five). Hand over completed work to teacher.

Now you can start doing practical work.

During practical work, the teacher individually works with students on the formation of sawing skills, monitors the implementation of the safety rules.

Assessment of students’ practical work (3 min.).

Grading a lesson, including oral responses and written assignments.

Varieties

By combining the above factors, manufacturers have developed and today produce standard products with different blades, handle and tooth shape. To understand how to choose a hacksaw for wood, you first need to familiarize yourself with the existing types of saws.

Stanley 1 15 122

A model from a well-known brand that belongs to the budget segment. Her. For this money, the buyer receives a working tool for home use with a blade length of 300 mm. Hacksaw for metal Stanley 1 15 122 has a comfortable ergonomic plastic handle, 4 positions of blade tension and the ability to reinforce it up to 102 kg.

Gross 77604. locking lever for maximum blade tension Stanley 1 15 122

Types of hand saws for wood

It should be noted that, depending on the type of teeth, there are the following types of hacksaws:

- Longitudinal;

- Transverse;

- Mixed.

Longitudinal saws are designed for cutting wood along the grain. They have teeth in the form of beveled acute-angled triangles, similar to hooks. The teeth are sharpened on both sides, so they cut both when moving forward and in the reverse path of the saw.

Transverse saws are used to cut wood across the fibers and have teeth in the form of isosceles triangles, sharpened in the same way as longitudinal ones, therefore the cutting process occurs both with forward and reverse motion of the saw. They cut dry wood well, but damp wood with difficulty.

Mixed saws are suitable for cutting wood both lengthwise and crosswise. The blade has both sawtooth types arranged one behind the other, combined with notches in the circular blade for better removal of sawdust.

Currently, manufacturers produce the following types of saws:

- classic look;

- external;

- backing;

- onion;

- saws with a fence;

- saws-reward;

- folding hacksaws;

- garden.

The classic type of hacksaw is produced with a blade in the form of an elongated trapezoid, passing from the wide end into the handle. Available with different types of teeth and steel grades. They are widely used at home and at work. Convenient to operate.

Circular saws have a long and narrow blade with a comfortable pistol grip. The blade has fine, frequent teeth, often double-sided. Convenient for cutting lines of complex shapes: round, square and curved, as well as through holes. hence the name. circular.

Butt saws. have rectangular blades equipped with a stiffening rib (butt) on top, which limits the cutting depth to the width of the blade. The handle is conveniently attached to the canvas at an angle of 45 degrees.

Bow saws for wood have narrow canvases with arched or rectangular devices that pull the canvas like a bowstring, hence the name. bow. They are used for cutting curly products. Easily cope with knots and hard wood species, suitable for cutting wood both along and across.

The award saws are similar in shape to a plane and have two handles. Their main purpose is to cut out spikes and grooves in wood of any hardness. This procedure is not easy, so rewards require job skills.

Folding hacksaws are indispensable for trips to the forest or to the country house to cut branches on trees. They have a straight or arcuate folding blade with fine teeth. Compact and lightweight, they are easy to carry.

Garden hand saws are a great assistant for the gardener. Their canvases are shaped like a saber, which is perfect for pruning garden trees.

How much does a hacksaw for metal cost: an overview of popular manufacturers and models

Bahco 325. high quality at a high price

Type 2: Narrow

Its other name is circular hacksaw. It takes the name from the main application. lines of various shapes are cut out for it, moreover, it does it neatly and clearly. It is also used to cut through round, square holes. The saw blade is narrow, the teeth are frequent, can be located both on one working plane, and on both.

When working with a saw, you should be careful: if the movement is uncertain, the blade will turn in the other direction, therefore the choice of a hacksaw for wood with a narrow blade should be stopped on a product made of high-quality hard steel, which will not bend during the sawing process.

Handle shape

This part of the saw determines the convenience of work. The tool should ideally blend into the hand and be comfortable. For the manufacture of pens, various plastics are used that are pleasant to the body

An important note. the material should not slip if the hand suddenly fogs up. For this, grooves and grooves are provided in the handle body, a rubberized pad

Tooth size

This parameter affects the quality and speed of work. For the convenience of determining the size and number of teeth, the designation TPI has been introduced, indicating the number of teeth in one inch. This parameter can be seen in the description of a hand saw for wood, often the value is applied to the blade.

- A hacksaw for wood with a large tooth gives a rough cut at high speeds. It is useful for cleaning the area from branches, sawing boards for firewood and other events where you can get by with the rough ends of products and trunks. For such instruments choose the TPI tooth size 3. 6.

- For products that need to be cut accurately and evenly, a fine-toothed hacksaw with TPI 7. 9 is suitable. This is used for sawing fiberboard, chipboard, laminate, in repair work. The performance of such a tool is significantly lower than that of a coarse-toothed.

The teeth are distinguished by their shape, depending on this, the tool acquires a different purpose:

- The hacksaw for ripping is equipped with triangular teeth with oblique corners. Their appearance resembles hooks that are sharpened on both sides. Because of this, the saw slides along the grain of the wood and cuts the blade evenly, almost without chipping.

- The cross cut tool is equipped with isosceles triangle teeth. A mechanical hacksaw of this type cuts when going forward and backward, but it can only be used for processing dry wood.

- The hand saw for mixed sawing is equipped with both types of teeth alternately arranged one after the other. Long curved ones cut the material in the forward direction, the triangles in the opposite motion expand the channel for passage and catch the chips and sawdust. In modern models, the teeth alternate with voids. This allows you to use the saw on dry and freshly sawn wood, coarse unnecessary fibers are removed through the holes.