What is the best chain saw chain sharpening?. External signs of chain saw blunt cutting edge

How to choose the right chainsaw chain sharpening angle for longitudinal and crosscutting sawing depending on the material

The need for chain sharpening is essential in chain saws for everyday use, e.g. in the wood processing industry, but also for occasional use in gardens and orchards. Like any process associated with technology, sharpening the chain has a number of nuances, for example the sharpening angle, it is necessary to take it into account and select a certain value for a particular work.

Chain sharpening angle is an important characteristic that has a major influence on chainsaw performance. It also affects the following parameters:

- The intensity of pressing is increased, as the chain’s ability to “enter” the wood without pressing is reduced. This leads to increased stress in the human body.

- Increases fuel consumption.

- Increases the stress on the saw chain links.

- The service life of the chain saw is considerably shortened due to additional efforts on the gearbox and motor.

If the sharpening process is done in time, it is possible to increase the lifetime of the chain considerably. This is because less metal is “removed” from the tooth when sharpening is right.

There are two important rules that apply to sharpening chain saws:

- The higher the performance the higher the angle.

- By reducing the sharpening angle when sawing hardwood, vibration can be significantly reduced.

The smallest angle is 25° and the largest angle is 35°. But for longitudinal sawing chains the angle is 10°.

In this video, you can get acquainted with the sharpening process, the most popular methods and tools used for it.

A man who has a chainsaw in his household, should know how to sharpen the chain of a chainsaw with his own hands. There are several ways to do this:

- sharpen using a file (the most common method of sharpening, t.к. sharpening tool on-site at the place of sawing.)

- Sharpening with a special machine (this method is used in service centers, but can also be used in private households)

- Sharpening with an angle grinder. To sharpen with this method, certain skills are required. Not very common, t.к. It is difficult enough to sharpen with an angle grinder correctly.

1 way. with a file

The first thing that is needed in order to sharpen the chain or to dress it a little bit are special files.

File

There are two kinds of files used for sharpening and dressing saw chain. The first one is a circular file with the diameter corresponding to the rounding diameter of the working edge of the sawtooth.

For sharpening saw chains of household tools, round files with diameter of 4, 4,8 mm are used, it is conditioned by the fact that they have small tooth. For professional models more powerful chains with big tooth are used, and accordingly files with diameter of 5,2, 5,5 mm are needed.

In order to sharpen properly, it is not enough to sharpen only the cutting edges of the tooth, it is also necessary to make adjustments to the depth of cut limiter. If it is not done, the chain will not cut into material to required depth that will significantly reduce speed of work and just as in situation with dull chain it can lead to overheating of saw motor because of insufficient load on motor. This work is done with a flat file.

It is worth remembering that the use of a dull chain, can lead to overheating of the engine and the formation of scoring on the cylinder.

Process description

The first thing you need to do when dressing the saw chain is to set the tool on a flat surface or on a table. In forest conditions a big billets diameter would be good for this. Then it is necessary to examine a chain on presence of any defects, it can be cracks, completely broken off teeth. After inspecting the chain, set the brake in its working position, thus blocking its movement along the bar.

The chain must be tensioned while sharpening with a file.

It is desirable to put a support under the bar, for this purpose you can use a log, a piece of branch of a suitable diameter, or manufacturers of sharpening tools have special clamps to hold the bar during the sharpening of the chain.

STIHL chain clamp

The chain is sharpened by filing from the inside out. In doing so the file should be parallel to the special marking on the chain. This marking is applied by the chain manufacturer to indicate the standard sharpening angle.

The bar to be sharpened must be in the center of the bar, and this is necessary in order to make the sharpening operation as the chain is being pushed along the bar, making sure to always return the brake to the working position.

When sharpening the chain on a chainsaw, it is essential to use gloves made of coarse material, otherwise it is quite easy to injure yourself, i.e.к. The cutting surface of the teeth is very sharp.

Ideally, manufacturers recommend that the same number of file movements be performed on each tooth, but in practice this is not always possible, because.к. the teeth have varying degrees of damage to the working edge.

To facilitate sharpening the saw chain with a file, special holders with marked corners can be used. The markings are not only for standard cross-cutting, but also for sawing longitudinally.

Holders are also handy if you are not very experienced in sharpening. Experienced sharpeners do not use file holders for sharpening, they can only use special devices to support the file.

Another device for sharpening is the manual chain sharpening machine. As a sharpening tool it uses a regular file, which can be independently replaced. The machine is mounted directly on the bar, it also has the ability to adjust the angle of the sharpening tooth and a special stop that holds the sharpened tooth.

A hand held grinder, perfect for the novice sharper. Along with the electric models of sharpening machines, the manual one has its undeniable advantage in the form of a low price. Depending on the hand sharpening machine manufacturer their appearance may differ, but the working principle is the same for all.

The depth of cut is corrected by means of a flat file, so that there is a difference between the upper cutting edge of the tooth and the height limiter.

As can be seen in the illustration, the depth limiter is turned so as to bring the clearance to the factory setting. Check the table below for the main values of the angles and clearances for the most common chain types.

How to Sharpen a Chainsaw with Elegant Efficiency [smoother & straighter cuts]

The clearance is usually corrected by using a special die. This is inserted in the chain during sharpening, and then the depth limiter is ground.

saw design

To better understand what a chainsaw is and how it works, it is desirable to know how it is constructed.

By the way, it would be more correct to call the cutting tool of a chainsaw a saw chain.

The first saw chains were born at the beginning of the twentieth century. The designers didn’t rack their brains. they just assembled teeth on the chain that quickly lost their function. They resembled the kind found on handheld wood hacksaws. Sharpening such a chainsaw caused great difficulties. But the repeated attempts to create a perfect saw chain have been crowned with success only in 1947.

This chainsaw has links with an L-shaped cut. Modern chains are, in fact, the direct ancestors of this development.

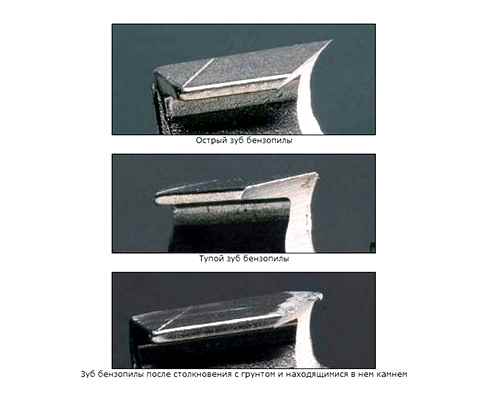

If the cutting speed begins to slacken during work and the chain starts to “wobble” in the hands of the master, it means that the saw chain has lost its performance properties, i.e. it has blunted and measures have to be taken to restore them.

Grinding angles and saw tooth configuration

As previously noted, the product in question is characterized by a rather complex configuration. Among the features of the modern versions are the following points:

- Selection of a rip saw chain is specific to the chainsaw model, because the configuration depends a great deal on power and a few other things.

- For longitudinal sawing, the blade spacing is 0.325 in. It ensures high stability at the time of operation.

- The cutting edge can have a thickness of 1,3 mm. There are also versions on sale with a thickness of about 1.1 mm, but they are difficult to sharpen at home. In addition, the low thickness allows not very thick branches to be cut.

- Attention is also paid to the profile height, which varies between 0,625 and 0,762 mm. For residential applications, a low profile design is appropriate. Low profile defines the likelihood of vibration at the time of sawing.

Chainsaw chain sharpening angle depends largely on the purpose of the tool, as some are suitable for cross-cutting, others for sawing. The longitudinal resistance of wood to sawing is very high, so the edges must be very sharp. The recommended grinding angle is 6°-12°. The difference in cutting angles is chosen depending on the task at hand, as well as some other things.

When working, do not forget that a too low sharpening angle causes a rapid shredding of the edge. This point is most important when the product is made using alloy steels, for example, grade 40KhGS.

When it is time to sharpen the saw?

The periods between two sharpening operations depend on how often the tool is used. Some use it daily, others several times a year.

You can tell when the teeth are blunt by some signs that show up during operation:

- The chain is lengthening and sagging, so the saw blade does not function accurately and “slows down” in the cut. Working with this chain requires extra effort.

- Sawing slows down, productivity declines, and you have to spend twice as much time on the job.

- The appearance of the filings changes: they become uneven, sharper, finer. Chips from a sharpened saw look different: equal pieces of even rectangular shape.

If saw loses accuracy and gets stuck in a cut it is time to have the chain teeth straightened

You should not put off repair work for a long time. The earlier you sharpen, the less material you have to grind, respectively, the longer the service life. And you don’t have to work long hours with dull tools, more wear and tear, or waste your own strength.

Two samples of chips: one from a sharpened saw and one from a blunt saw

How to Sharpen Chainsaw Chain. Ozito Tool Tips [PXCCSSS-018]

Description of sharpening process

Let’s take a closer look at how to sharpen a chainsaw chain. The first thing to do is to prepare a place to install a clamp, or if the process will take place without it, it is convenient to use an ordinary log as a support to fix the bar in the horizontal plane. The chainsaw is placed on a flat surface, a log is put under the guide bar, and the brake is on.

To avoid injury when sharpening the chain saw, always use the chain brake.

The next step is the direct sharpening of the tooth. To do this, the circular file is moved from the inside of the tooth to the outside.

It is very important at this point to keep the right angle of sharpening. The standard angle is thirty degrees from perpendicular to the plane of the file. How to position it correctly is shown in the photo below.

While sharpening the chainsaw for a nonstandard cut, for example, a longitudinal cut. Angle of sharpening is changed to a smaller angle. As a rule, it is not more than 10 °. It is in such cases, to control the angle of sharpening a holder, handheld machines or filing calibers are used.

Some manufacturers of chainsaw chains, to facilitate sharpening, as well as to indicate the maximum possible sharpening, on the upper surface of the tooth make a special mark.

By holding the file parallel to the mark, you can be sure the correct angle is being followed.

The number of operating movements of the file should be the same for each tooth. This allows all teeth to be ground evenly.

When dressing the chain, it is customary to sharpen the teeth first on one side and then on the other, this is convenient because. к. there is no need to constantly change its position in relation to the chainsaw.

After the working teeth are sharpened, it is necessary to adjust the height of the limiting tooth with a flat file. To do this, the filing caliber is placed on the chain so that the limiting tooth coincides with its slot, after which the protruding part is ground with a file. This procedure is performed on all limiting teeth.

Using a roller attachment

The sharpening fixture, which can be used to quickly and accurately correct teeth, consists of a small guiding template with two rollers.

By installing the attachment on the guide bar, you can sharpen chain saw teeth even inexperienced in chain saw sharpening.

How to know when it’s time to sharpen your chainsaw?

There are several ways to tell when it’s time to sharpen your chainsaw’s main element, as follows:

- You put a lot more effort into your chainsaw;

- The chain starts to sag;

- There is a vibration when sawing;

- the cut is jagged.

If you see any of these symptoms while working with your tool, it means you need to have your chainsaw sharpened or have the chain sharpened by yourself. People who felling or working with wood often need to sharpen their chainsaw. In some cases, a chain saw needs to be sharpened several times during the day.

Possible ways and methods to sharpen your chain

Working with a file

The best solution is simple “gadgets” for sharpening work. This set includes round and flat files, special holders, jig-calibre, hook for chip removal etc. Structurally, the “gadgets” may be different, but the functionality has a common logic.

The diameter of the circular file is directly related to the size of the chain:

- – Chains with ø 1,3. require a ø 4 mm file (used much more often);

- – Chains with ø 1.6 require a ø 5.2 mm file;

- – To sharpen the depth stop, use a flat file.

- With the chain brake “engaged”, clamp the chain saw bar firmly in a vice (a firmly clamped saw is the key to successful sharpening)

- Set the template so that the “arrow” is pointing toward the “nose” of the bar. Be sure to mark (maybe with chalk) the tooth where you started the sharpening, otherwise you may go a second round;

- Grind in the direction of the arrows. Remember, there is a special factory notch on each chain tooth. It indicates the maximum angle of sharpening.

- In addition to the cutting tooth, there are limiters on each link. They are sharpened as needed. This is necessary if the height of the tooth is reduced as a result of sharpening, and there are problems with the chainsaw’s operation. As a rule, the limiter is sharpened after 2-3 sharpening of the teeth;

“If not skilled in sharpening, it is best to start with inexpensive chains.”.

- File must not protrude over the top edge by more than 1/5 of a file’s working area. The pressure is applied with the same amount of force;

- The sharpening tool is moved to one side “away from yourself”, and the number of movements for each tooth must be equal;

- For sharpening a vertical plane, the file position should be at right angles;

- To sharpen the horizontal plane, position the file at an angle of 20-30°

- If there are teeth of different heights, the smallest is the reference.

Advantages: Possibility of “charging the saw” in the field. In this case it is cheap.

Disadvantages: Takes time and effort. It quickly “kills” the file. Speaking of files: it is better to pay a little more and get a quality product. Than to buy for 40-50 and throw it away after the first sharpening (tested by practice). And another thing, if the chain has “tilled” the ground so well that its cutting edge has changed its original shape, it is difficult and not fast at all to sharpen it with a file.

Sharpening with an angle grinder

Professionals consider this work to be primitive. There’s a risk of damaging the tire, and not only that.

Process (easy on the face of it, but tricky in reality)

- The chain also stays on the bar;

- We fix on the angle grinder a cutting disk on metal in thickness of 1,5-2 mm. It is desirable to take not new, that is, with the worn edge;

- We put a barrier in front of the chain and the tire (a chip will do);

- Sharpening at the right angle;

- When the work is done, the chain should be tightened properly.

With a professional approach and a “steady hand”, the number of sharpenings in this case can be more than 7.

“Beginner”, it is best not to “experiment” with the saw, the chain and. with your own body parts!”

Advantages of the method: Fast, cheap, and doesn’t take any effort;

Drawbacks: Requires special skills, a steady hand and an awareness of safety.

Electric sharpening machines

They are equipped with special adjustment functions that help to position the chain at a certain angle. In doing so, it is possible to accurately and precisely align the blade to the chain teeth. Machine tools are equipped with automatic vices. They are activated by bringing the disc to the edge to be sharpened. Convenience and functionality, of course high. You can find models at a “reasonable” price.

“Hand-operated” machines

The design of such a machine is similar to a bow saw. Only, where the saw blade is located, there is a round file. This machine can be used for sharpening and straightening teeth to make sure the top edges are in line with the smallest (reference) size. The mechanism allows for precise parameter setting. After adjusting the “reference” tooth, the sharpening is done in two or three strokes. And then the transition. to the next tooth.

When it is necessary to cut the limiter, change the round file for a flat one.

Advantages of the method: Allows you to qualitatively, conveniently and without much physical effort sharpen teeth, including those that have lost their original shape.

Disadvantages: The price of the tool and the distance to the possible site of the saw.

“After finishing the “sharpening procedures”, blow the chain with compressed air (from a compressor or pump) and put it in clean motor oil for a while. Of course, almost no one does such activities, but for the chain, it will only benefit.”

What to choose for sharpening, you decide. This is related to how often you use your chain saw. On the neatness of handling it. On the quality of the purchased chain. And, of course, on the possibility of spending a fair amount of money. Methods cannot be compared, because as the German proverb says, “apples must be compared to apples”.

What to sharpen with

Sharpening a chainsaw chain is not an easy process. There are three options that are used today:

Similar ways are used for sharpening knives, scissors and other cutting tools, so nothing extraordinary is invented here. But there are special devices for sharpening the PowerSharp system. They allow you to quickly sharpen the saws at home, which have a special mark indicating the peculiarities of design.

File

Using a set of files is the most common way that can be done at home. But it is not as simple as it may seem at first glance. Two types of files will be required for sharpening: round and flat. Each is used for a specific purpose.

You need to sharpen the working edge of the saw’s tooth with a round tool, because its configuration is rounded. a file with a diameter of 4-5 mm is used for home chainsaws, because the teeth of the saw have small dimensions. Professional saws are sharpened using files with a diameter of 5.2-5.5 mm.

Use a flat file to turn the depth guide. If this edge is not corrected, the chain will not cut into the wood to the required depth, which will reduce the sawing speed. This will have a direct impact on fuel consumption and overheating of the saw’s engine.

How to properly sharpen files

First of all the power tool must be prepared. put it on the flat surface, it can be a table or workbench. Tighten the chain to the maximum, put it in brake mode by turning the locking lever. Inspect the saw teeth for defects: chips, cracks, complete breakage, etc.

As for the process of sharpening chains for chainsaws with their own hands, there are several recommendations:

- sharpening file should be from the inside out;

- there is a mark on the chain, which the manufacturer puts specifically to indicate the degree of sharpening;

- The tooth to be sharpened should be in the middle of the chain for the convenience of the work;

- sharpened, removed chain from lock, advanced the next tooth to the middle, put on the brake.

Work with the saw carefully, wearing protective gloves, because the teeth of the chain are sharp enough. The number of movements along the edge plane varies depending on the damage to the teeth.

The auxiliaries

In construction stores, special holders are sold, with which it is easy to sharpen the chain of an electric or chain saw, because they clearly indicate the sharpening angle and depth of the limiter. After installing the device on the chain, you just need to stick to the configuration of the holder, not overstepping the stops. In principle, this will not work, so sharpened on the holder teeth have the required angle and depth.

Another device that makes sharpening easier is the so-called saw chain tooth straightener. The device is fixed on the chain bar with special clamps, which are included in the construction of the device. Guide is set at an angle that defines the degree of sharpening. It can be adjusted by changing the parameter.

The tooth to be sharpened is clamped in place with a stop, and a file is placed on top of the stop. The machine of this type is produced by a large number of different manufacturers. The tools may differ in appearance, but structurally they are all the same.

Note that first the teeth are ground by hand, and only then is the depth stop adjusted. Do not exceed the height difference between the tooth flange and the top level of the limiter.

PowerSharp System

It should be noted that not all types of chains can be sharpened with this device. Their chains and bars are matched to them with PowerSharp marking. The bar can easily be inserted into any saw, and it has one difference from the standard ones. an extra hole in the front.

The sharpening system comes with a plastic block in which the sharpening stone is installed. That means that the bar is inserted inside the block, on which the chain is previously slipped. It is secured there with a pin, which is slipped just through the additional hole in the tire. The block is closed with the cover. At the front of the block there is a key that acts as a lever. This should be bent, thus pressing the abrasive stone against the teeth of the chain.

Then the saw has to be set in the ground with the key and turned on at maximum speed. A few seconds, and the saw is sharpened.

Grinding machines

In service centers no one uses files anymore. Because sharpening the chain correctly means exactly adjusted tooth angle and height of the limiter.

It’s hard to do by hand and the service center guarantees a quality operation with a long service life of the electric or gasoline-powered saw.

The variety of chain sharpeners is amazing. There are both the usual uncomplicated mechanical devices and electric ones. In this case the manufacturers offer small-sized machines, which are mounted directly on the bar, table machines, in which the chain is mounted without the bar.

Ease of sharpening procedure is due to the fact that the sharpening machine has a clamping device in its design, in which the chain is fixed. It is mounted so that the chain is fixed vertically in it.

You can adjust the installation location of the fixture. quite simple to do, because the clamp can move horizontally. Angle of inclination determines the abrasive disc (disc) that is mounted on the motor shaft. In this way the sharpener is positioned at the required angle set at the factory. But it, too, can be changed depending on the desired degree of inclination.