What is the difference between Makita 2470 and 2450

A real man must be the master of the house!

Dismantling a Makita rotary hammer

DIY Makita 2450 punch repair manual

Hammers are called percussion drilling devices designed for drilling and chiselling holes in particularly durable materials.Two ideas are implemented in the puncher: the working tool rotates and simultaneously moves in the longitudinal direction, creating a shock pulse.

Hammers always work in extreme conditions.The duration of the drill depends not only on the correct operating conditions, but also on the reliability of the parts included in the product.But no matter how hard you try, over time, punchers begin to fail.

To properly repair the hammer, you need to familiarize yourself with its device.

Repairing a Makita 2470 and 2450 punch with your own hands can be done by a person who has the skills of a locksmith and knows the basics of electrical engineering.

Remember! Observe safety precautions and unplug the machine when disassembling.

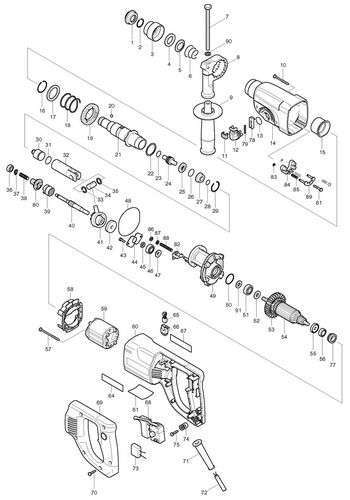

Makita 2450 and 2470 rotary hammers are assembled in almost the same way and from the same parts. Repairing them is no different.For ease of repair, the assembly diagram and catalog of parts for Makita rotary hammers are given below.

The Makita 2450 and 2470 rotary hammer circuit consists of a mechanical and electrical part.

The mechanical part provides the transmission of torque to the drill-drill, creating at the same time a translational movement that creates a shock.The mechanical part consists of a rotation drive and a percussion mechanism.

The electrical circuit of the Makita rotary hammer provides the conversion of electrical energy into kinetic energy through the rotation of the rotor.

The electric part includes an electric motor, a power button with a speed controller, a reverse switch, connecting wires.

Main makita rotary hammer malfunctionsMalfunctions of rotary hammers are divided into electrical and mechanical.

In this article, we consider all the malfunctions of the electrical part of the Makita 2470 and 2450 rotary hammers and how to solve them:

Electrical failures of the Makita 2450 and Makita 2470 rotary hammersElectrical malfunctions are manifested in the fact that when the punch is connected to the mains voltage, the tool does not turn on.The Makita rotary hammer wiring diagram is simple.

The electrical circuit of the Makita 2450 rotary hammer is a series connection of the electric motor, start button and wires. The layout of the makita 2470 rotary hammer is similar.

Through the connecting cord, pos. 72, the 220 V supply voltage is supplied through the switch pos. 68 and electric brushes through the brush holder pos. 66 to the lamellas of the rotor of the electric motor pos. 54, and through the contacts of the reverse switch pos. 60 to the stator winding pos. 59.The most common malfunction is the lack of contacts in the connections.

The procedure for determining electrical faults

Video: Makita HR 2470 disease \ 2470 puncher stopped turning on \ Burned contacts \ maintenance tool

Determination of the integrity of the electrical part of the Makita rock drill. In order to repair a Makita 2450 or Makita 2470 punch with your own hands, you need to arm yourself with devices and tools. Any tester, a set of screwdrivers, wrenches, a hammer, a wooden extension will do. It is good to have a screwdriver with a built-in phase indicator.

You need to take the tester, connect to the ends of the punch plug and press the punch switch. If the tester shows some resistance, then the power supply circuit of the punch is intact.

If the tester shows infinity, then the integrity of the circuit is broken and it is necessary to remove the back cover to control the connection cable and electric brushes of the punch.

The back cover (usually black) of the punch is easy to remove, you just need to unscrew the three screws with a screwdriver or screwdriver.

Remove the cover and use a screwdriver to disconnect the ends of the wires from the electric brushes.Using a tester or a home-made device, popularly referred to as the “arch”, determine the integrity of the lead wires and the correct operation of the switch.

A few words about a simple control device called “arcade”. The device consists of an LED or a light from a flashlight, a finger-type battery and two pieces of wire. The entire electrical circuit of the control device is a series-connected parts. Connect the battery with one end of the LED or light bulb, connect the wires to the free ends of the LED and the battery. You will get a universal device for checking the integrity of electrical circuits.

Typical malfunctions of the Makita 2450 and 2470 rotary hammerCommon failures in the electrical part of the Makita 2450 and Makita 2470 rotary hammer:

- Fracture of the supply cable at the entrance to the perforator;

- Failure of the TG813TLB-1 switch button, art.650508-0, pos. 68.;

- Wear of electric carbon brushes SV-419, art.191962-4, pos.65;

- Wear of reverse switch contacts;

- Wear of rotor bearings: bearing 609LLU, art.210060-6, item 51; bearing 607LLU, art.211021-9, item 56;

- Short circuit of a rotor 220-240 V, art.515668-8, item 54;

- Failure of the stator winding 220-240 V for HR2450, art.633488-5, pos. 59.

As a start button, the TG813TLB-1 switch, art.650508-0; pos. 68.

Replacing the brushes is done when they are completely abraded or poorly contacted. This malfunction is detected by strong heating of the points of installation of the electric brushes.

Failure to turn on the punch can be caused by abrasion of contacts on the reverse switch.It eliminates such a malfunction very simply.

Makita rotary hammer reverser repair

To repair the reverse switch, the back cover must be disconnected. Carefully disconnect the wires from the button. Carefully inspect the switch.

Further disassembly consists in removing the brush holder, having previously released the brushes themselves.Removing the brush holder, you will get to the contacts of the reverse switch.Determine its condition, replace the contacts if necessary.

Another common electrical fault is poor contact between the stator and the lower contacts of the reverse switch.

Repair contact between stator and reverse switch

To remove the stator, it is necessary to disconnect the gear housing (black) from the stator housing (green).

Remember! In the mechanical part of the rotor, the bearing is pressed by a special ring. When disassembling, do not lose it.

The stator is located in the green case.

How to disassemble the Makita HR2450 rotary hammer?

Looking in the middle, you will see two self-tapping screws 4 × 60, art. 266334-3, pos. 57, securing the stator to the housing. Unscrew them, remove the plastic stator protector for HR2450, art. 419201-3, pos. 58., Release the stator.When you get the stator, you will see the contacts on the stator and the reverse switch panel.

Thoroughly clean the contacts with sandpaper, and clean with solvent or alcohol.Before assembling, bend the contacts so that they fit tightly into each other. Lubricate the contacts with a thin layer of technical petroleum jelly.

The assembly of the electric part of the hammer is in the reverse order.

How to disassemble a Makita punch

Independent repair of the Makita hammer drill barrel with a selection of spare parts

Even very reliable Makita rotary hammers break down over time. Any breakdown is eliminated, you only need to have straight arms and perseverance.

In addition to electrical malfunctions, rotary hammers are also subject to mechanical breakdowns.

The work of rock drills with solid materials in a dusty environment shortens the life of the machine and requires user intervention to perform preventive maintenance.

Repair of the mechanical part of the Makita 2450 and 2470 puncher

Any repair of the tool begins with the determination of the nature of the malfunction and disassembly.

A Makita 2450 and 2470 rotary hammer can be repaired by a user with basic locksmithing skills and knowledge of electrical safety requirements.

This article discusses the mechanical part of the Makita puncher, the main malfunctions and how to solve them. Disassembly of the mechanical part of the Makita 2470 puncher

To get to the mechanical part of the punch, you need to remove or disassemble the cartridge.

Disassembling the quick-detachable chuck Install the hammer drill on the back of the cabinet on the surface of a table covered with a clean cloth or paper. Using tweezers or a screwdriver, remove the rubber tip 35, item 1.

Carefully loosen the annular spring, pos. 2, the clutch cover, pos. 3, the steel ring, pos. 4.

Timely punch repair: how to disassemble a Makita punch?

You will reach a steel ball with a diameter of 7 mm, pos.20.

Now you can remove the case of the mechanical part. It is black. Using a screwdriver, unscrew the four screws at the end of the case.

Holding the black case with your right hand, press the end of the shaft from which the cartridge was disassembled with your thumb. The plastic case is easy to remove.

Next, remove the gearbox shaft.

To disconnect the mechanical part from the electrical part, you must first remove the electric brushes. In the lower part of the body, the rotor is held by electric brushes, which must be removed.

After checking that the electric brushes are disconnected from the lamellas of the rotor, use a screwdriver to pry the metal case of the perforator at the border of the green plastic case.

Now we proceed to disconnect the rotor from the mechanical part of the punch. The rotor is held in the mechanical part due to helical gears of the gearbox. If you take the rotor case in one hand, and the mechanical part in the other case and pull it in different directions, swinging, you will separate these two nodes.

You get such a knot in the old grease. Next, unscrew the two M4 × 12 bolts, pos. 43, using the hexagon, item 2666273-7 with the internal hexagon head. Pull out the shaft with the intermediate spur gear 10 pos. 80, art.226399-7.

From the inner case pos. 49, art. 153687-8. Clean parts from old grease.

You get such a mountain of clean details. Now carefully review the details, immediately discard the rubber rings, picking up new ones.

Replace defective parts with new ones.

Mechanical makita 2450 and makita 2470 rock drill

Common mechanical problems with Makita rotary hammers include:

- Destruction of the quick-release cartridge;

- Bearing failure;

- Breakdown of the shock mechanism;

- Punch barrel wear;

- Wear of rubber strikers and striker;

- Gear breakage.

Repair of the perforator cartridge is done to replace the anther and rubber ring, as well as the conical spring and the steel ball, which provides clamping of the working tool (drill). What does the working tool indicate? Namely, the drill is poorly held in the cartridge.

The main reason is the wear of a steel ball 7.0 pos.20, art. 216022-2. Ball wear occurs from contamination of the barrel of the cartridge due to ingress of dust and dirt.

The general view and arrangement of the Makita rotary hammer cartridge is shown in the photo below.

Do-it-yourself makita 2450 rotary hammer cartridge repair is easy to do. The cartridge must be disassembled, freed from old grease, discard rubber parts, replace defective ones.

Complex failures require knowledge of the mechanical design of the Makita 2450 rotary hammer.

Having determined the nature of the malfunction of the Makita rotary hammer, proceed to disassemble the mechanical part called the gearbox.

Disassemble the mechanical part according to the attached. Release it from the old grease. Carefully inspect all parts, their integrity, level of wear. All rubber products during any disassembly require replacement.

Consider repairing a perforator barrel. We will analyze the mechanism completely. disassembly, lubrication and assembly of the Makita rotary hammer

Repair of parts of a shaft of the Makita 2450 puncher

Remember! In the lower part of the body, the rotor is held by electric brushes, which must be removed.

At the next stage, the rotor must be disconnected from the removed mechanism. The rotor is disconnected from the mechanism simply by pulling out, because it is held by the friction of two helical gears.

It turned out such a dirty knot.

Now you need to separate the shaft of the percussion mechanism.

Most often, rubber rings, striker poses wear out. 24, compressor spring pos. 18. And cylinder parts. Here’s how barrel parts wear out and collapse during improper use of the tool.

Consider the most difficult malfunction. Failure of the shock mechanism. The characteristic signs of failure of the impact mechanism is the absence of impact and the unpleasant noise of a working punch in the “Impact” mode.

What is the difference between Makita 2470 and 2450

Such a malfunction is typical for those perforators that during operation were pressed strongly against the work surface.

Having disassembled the gearbox, we remove debris and pieces of foreign objects. We find the defective part and clean everything from the old grease.

Very often the striker pos. 24 is destroyed, art. 324396-8, which is part of the trunk. Metal ring pos. 27. Art. 324216-6.

Discard damaged parts, replace with new ones, cover with a thin layer of grease. Parts are ready for assembly. But more on that in the next article.

Makita hr2450 punch disassembly

Than 50 models of SDS-plus Makita rotary hammers with the lowest prices. Payment upon receipt.

Weight: 2.6 kg; Vibration protection: no; Number of modes: 3; Max. Drilling diameter (wood): 32 mm; Max drilling diameter (metal): 13 mm; Power: 780 W; Impact Strength: 2.7 J; Shank Type: sds-plus; Gross Weight: 5.29 kg; Max diameter of drilling with a drill (concrete): 24 mm; Max core diameter (concrete): 50 mm; Cable length: 4 m; Spindle rotation frequency: 0-1100 rpm; Impact frequency: 0-4500 bpm; Reverse: electronic; Safety clutch: yes; Max diameter of drilling with a crown (brick): 50 mm; Speed adjustment: yes; Dimensions in the package: 480x320x100 mm; Max impact force: 2.7 J; The presence of a slotting mode: is; Complete set: suitcase / case; Drill chuck: yes;

Do-it-yourself Makita HR 2450 rotary hammer gearbox repair. The most comprehensive review

I got to my makita HR 2450 puncher, which lost a hit at the peak. There is an internal blow, but to the peak.

Dismantling the makita HR2450 rotary hammer 5 minutes before m

We repair Makita HR 2450 Replacement of the metal case Assembly of the Makita HR2450 puncher

DIY punch repair. When it is possible and necessary to repair a hammer drill

The hammer drill always works in extreme conditions. It is not surprising that over time it goes down, both consumer goods models and well-known brands. If the punch is expensive, then you can’t just throw it and run to buy another one in return, and you don’t need to. It’s better to try to repair the punch yourself, and our article will help you with this.

To be or not to be repaired

When you are faced with a choice and decide what to do with a hammer drill that doesn’t want to work at all, think: can you repair it yourself? It is worth undertaking repairs if:

- You already have experience in repairing some mechanisms;

- If your hammer drill is not one of the cheapest models. In this case, not only do not start repairs yourself, but also the masters should not be contacted. As the saying goes: “The sheepskin is not worth the mint”;

- If you know the nuances of the device of the puncher that you are going to repair, because they are very different from each other, each has its own technological features.

It is most effective to consider a concrete example, which we will do.

Repair of the Makita puncher

This rotary hammer is known for its reliability, but still someday there is a limit to its endurance.

We disassemble our tool and start with a cartridge

To find out the cause of the breakdown, you need to parse the mechanism:

- Remove the lever through which the switch. Special care is required here, otherwise the repair may result in further damage to the parts.

- If you have a Makita model 2450, then the cartridge is not removed here, so you have to disassemble it:

- We take a screwdriver flat and remove the rubber gasket. A barrier to dust from entering the perforator. Perhaps you have changed this detail more than once;

- The snap ring is next;

- Now further disassembly is prevented by the cover. We remove it and see that in the barrel of the cartridge there is a fixing unit, consisting of a ring holding the ball, a guide for the ball, a conical spring. We disassemble everything in order, starting with a metal ring.

What surprises can await you after disassembling the cartridge? Typical problems are:

- The rubber gasket has worn out and does not prevent dust from entering the punch anymore. Repair will consist in cleaning the parts from dust and replacing the boot. Dirt will also penetrate if the lid on the cartridge is deformed. This does not particularly affect the work, but the details will wear out faster;

- The retaining ring has relaxed or is completely worn out. We change it;

- The ball has worn out. The solution is simple. A replacement, but with the condition that the diameter is not even a micron less, otherwise the cartridge will fail again and already completely. Do not forget to honestly lubricate this element and fix it in the hole of the guide washer;

- Possible wear of the guide ball itself, i.E. Washers at the points where they are in contact. In case of critical wear, we make a replacement;

- A conical spring is the most resistant part, but with prolonged use it can also deform. If this happens, we carry out the replacement by deploying its smaller vertex to the gearbox;

- Now you can assemble the cartridge, but do the assembly in the reverse order and finally grease the end of the drill.

We disassemble the switch that controls the choice of operating modes

To perform this operation, a slotted screwdriver 2 mm, having a T-shaped working part:

- The main task is to pull the latch out of the handle. After inserting a screwdriver into one of the grooves on the side of the handle, carefully hook first on one wing of the latch, and then on the other and pull it out of the handle. In this case, the spring can be wrung out, and the latch pops out of the handle. We hold it to prevent this from happening;

- Now you need to take the handle to the left until the protrusions on it and the recesses on the gear housing coincide. The switch is released and we dismantle it;

- The clamp, together with the spring we take out;

- Remove the rubber seal located on the handle of the switch;

- We clean all the details and their location.

- The first thing that most likely caused the hammer to fail was the developed switch fingers, because during operation they constantly come into contact with rotating parts. In this case, the switch must be changed, but if the work cannot be interrupted to search for a new switch, then simply rotate the worn element 180 degrees. This measure is temporary and full replacement anyway can not be avoided.

- Disused seats. We change the switch.

- The round rubber gasket is deformed and grease flows out of the gearbox. The solution is obvious. We make a replacement.

- The process of the retainer broke, holding it in the gear case, which contributes to spontaneous switching of modes. You can not change the latch, if this problem does not bother you, the punch will still work.

- Failure of both wings of the retainer, which leads to popping up the switch from its seat in the housing. We change the lock and work on.

- The handle of the switch is equipped with two metal fingers. They must be lubricated, and at the same time the ring, before putting it in place.

- Next in the pen we put:

- A spring;

- Clamp;

- Latch.

3. We put a switch in the gearbox, but only partially, otherwise we will not be able to perform the following operation

4. The switch will have to be turned against the clockwork, so that it becomes as it was when we dismantled it. Now he will fully fall into place. If you feel that something is wrong, it means that you have excessively deepened the latch.

5. It remains to scroll the switch clockwise until it occupies the drilling mode, press the latch, make sure that the switch moves as it should to the selected position, and the punch repair in this part is completed. Next we deal with the gearbox.

We repair a reducer

If there is no suspicion that the engine has burned out, then the task is simplified by the fact that we will not dismantle the entire gearbox:

- From the barrel located in the perpendicular position, we extend the housing together with the needle bearing. A malfunction may occur in the fact that the bearing did not come out, and this indicates the development of a seat in the housing. Then the case is better to replace;

- Replacement of the part is also necessary when the landing of the intermediate shaft bearing is weakened;

- If you notice that there is an oil leak, then sometimes, although rarely, you have to change the seal, the place of which is the neck of the case. Often the reason is not the oil seal itself, but an excess of lubricant;

- If you have a real Makita, and not its fake. The seat for the switch is extremely rare, and if you slipped a fake, then the case will have to be changed for this reason often.

The reason was found and eliminated, now we collect, while:

- Lubricate parts, but sparingly;

- Remove metal particles from the housing;

- Make sure everything is folded correctly;

- Set the case in place.

Here the wizard parses the Makita punch in 5 minutes:

Bosch rotary hammer repair

Bosch belongs to punchers with a long service life, but sometimes even the most famous brands have to be repaired.

So, what kind of malfunctions can this puncher have:

- So as not to disassemble the tool in vain, first ring the cord, its damage may cause a stop;

- If the cord is OK, check the anchor and stator. To do this, unscrew the cover from the back and first just inspect, and then test;

- Disassembling the upper assembly, perform the work in the following sequence: rubber tip, lock washer, head, spring, ball;

- Dismantle the case and switch;

- Bosch Achilles Heel. Compressor ring and hammer, pushing drill. Most often, you yourself are to blame when you think that the harder you push, the better the tool will work. And just the opposite. You press harder and decrease the striker stroke, more frequent strikes and, as a result, the striker becomes unusable;

- If you do not lubricate the shank of the drill periodically, then the sealing rings and hammer strikes will fail more often.

The technology, in general, differs little from that used in the repair of other brands of perforators.

The subtleties of repairing a punch will convey better than any description:

DIY Makita 2450 punch repair manual

The assembly of any mechanism should begin after careful preparation. It is necessary to prepare not only parts, but also tools, a place, a lubricant.

Of the tools can not do without pliers, screwdrivers, a hammer, a brush for applying lubricant.

But what is the assembly scheme of the Makita 2450 and 2470 rotary hammer?

Do-it-yourself assembly of a Makita rotary hammer can only be carried out subject to the attached instructions.

The task of the assembly process is to replace the parts that have gone out of order with fit parts and to ensure interchangeability and operability of the tool.

Assembly order for Makita 2450 rotary hammer

Shock assemblyHow to assemble the hammer mechanism of a Makita punch?The impact mechanism is assembled from two nodes: the shaft shaft with a spur gear and the intermediate shaft with a rolling bearing.

A). A spur gear pos. 19 is put on the barrel pos. 21 and pressed by a compression spring pos. 18.For fixing, the spring is pressed by the washer 30 pos.17 and secured by the circlip 28 pos.16.B) To assemble the striker, put on the ring 9 pos. 25 on the striker shaft, tighten the rubber ring pos. 26, press down with the metal ring pos. 27.

Now go to the opposite side of the barrel pos.21. On the other hand, the inner surface of the barrel must be greased and inserted into the assembled drummer pos24.

Assembly of the intermediate shaft assembly

To assemble the intermediate shaft, it is necessary to put the rolling bearing pos. 41 on the shaft pos. 40 with teeth to the splines of the shaft, put the coupling pos. 39 on the splines of the shaft.

On the opposite side of the shaft, a helical gear 26 pos.42., A flat washer 8 pos.45, a bearing 608zz pos.46 and a snap ring 8 pos.47 are put on.The intermediate shaft is assembled.

Gearbox AssemblyThe gear unit is mounted on the inner housing, item 49.

By the way, there are cases when the axles pop out of the inner aluminum case. Both axles are pressed into the housing.

In the housing, item 49, the assembled intermediate shaft is inserted, the rolling bearing lever of which must fall into the hole of the cylinder hinge.In this case, the lever of the rolling bearing pos. 41 of the intermediate shaft must fall into the hinge of the cylinder pos. 32, and the lower bearing of the intermediate shaft in the socket in the housing. This procedure is usually carried out by rocking the structure until the parts completely get into the indicated places.

Setting the mode lever

The mode switch is designed to translate the clutch pos.39 in various positions and transmit translational motion to the shaft of the shock mechanism through the rolling bearing pos.41 to the cylinder pos.32.

Assembly of the lever of the switch of the regimes of the puncher of Makita 2450

On the axis of the inner case, put on the lever of the mode switch pos. 82, pressurizing spring pos. 88 on top, and press down with a flat washer pos. 87. Install the snap ring pos. 86. And fix.

The snap ring must be carefully fixed.Turning the intermediate shaft, it is necessary to carefully check the correct operation and free movement of the cylinder in the housing. This must be done now so that it does not become clear at the end of the assembly that the assembly was not assembled correctly.

Assembling the shaft of the percussion mechanism

First, lubricate the inside of the cylinder, pos. 32, and insert the drummer, pos. 30, into it.

It remains to put the oiled barrel assembly in pos. 49 into the inner case pos. 21 in place, putting it on the oiled cylinder pos. 32.As lubricants, it is recommended to use a special grease developed for Makita rotary hammers.

Lubricants are available in several types: Makita P-08361 and Makita 183477-5 SDS-PLUS.Makita 183477-5 SDS-PLUS grease is recommended for the gearbox. For drill shanks, Makita 196804-7 brand grease is used.

Lubricants vary in color, but have exactly the same characteristics.What lubricants are used in the Makita 2450 and 2470 rotary hammer?

And here is the assembled mechanical block.

of the general disassembly and assembly of the Makita 2450 rotary hammer

Video: Repairing Makita HR 2450 \ Replacing the metal case \ Assembling the Makita HR2450 rotary hammer

Check its performance by rotating the countershaft and controlling the movement of the piston in the percussion mechanism. All!

Now lubricate all parts of the mechanical unit with the recommended lubricant.

How to repair a Makita HR 2450 hammer drill if the shock mode is lost

Here is an example of proper lubrication on rotating surfaces.

Here is another example of a generous lubrication of a mechanical unit.

So it is also allowed to apply grease. Do not spoil the porridge with butter!

A lubricated mechanical unit must always be closed with a plastic case, item 14, in black.Having placed the housing on top of the assembly, press the housing down until the assembly is completely fixed in it.Backwardness, insert the four screws, pos. 10, into the housing and tighten.

Now it’s the turn of joining the mechanical part of the rotor of the electric motor.

The helical gear of the rotor is firmly inserted into the body of the mechanical unit and pressed.

It remains to insert four self-tapping screws m4 × 60 pos. 57. And screw them into the body of the electrical unit.

Installation of electric brushes

Remove dirt from the grooves of the brush holder and put the brushes in place, fixing them with latches.

Now is the time to check the performance of the punch. Connect the punch plug to the outlet, turn on the punch for a while in the “drilling” mode. After making sure that the tool is working, turn it off. Set the mode switch to the “punch” position. Do not insert the tool.Check the performance of the rotary hammer in this position. At the same time, you checked the operation of the mode switch.

It remains to check the installation of the speed control button, make sure the contact connections are reliable and you can proceed with the installation of the cover plate.

The cover is fastened with three self-tapping screws Mx4 of different lengths.

Connect the rotary hammer to the 220 V network and check in all modes.The Makita 2450 or 2470 rotary hammer is assembled and working properly!