What is the sharpening angle for circular saws?. Tooth sharpening angles

How to correctly and at what angle to sharpen a circular saw blade

Circular saw blades differ in number of teeth and configuration. Blades are available:

- Monolithic or solid blades;

- with a hard coating in the working area;

- with soldered carbide plates;

- Without teeth, such as a continuous rim;

- With wide and thin protrusions;

- With negative and positive front angles;

- universal discs.

This variety is confusing when choosing the right saw blade. Let’s look at.

Number of teeth

Discs with fewer teeth make a coarse cut. The advantage of fewer teeth is a higher cutting speed. A 24-tooth blade with 180 mm diameter is enough for construction work. Thin slotted blade is good for cutting hardwoods and trimming where a clean edge is required. For a circular saw 180-190 mm, a blade with 40 teeth or more will ensure a clean cut.

Why I Don’t Sharpen My Own Table Saw Blades / Saw Blade Sharpening Facts

Efficiency of sawdust removal

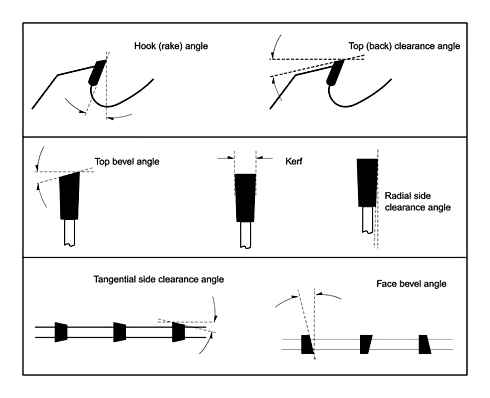

The position of the tooth where it faces down toward the surface of the wood and forms a positive angle results in fast but rough sawing. There is a large gap and recess between them, which promotes better sawdust clearance. Picture Positive tooth angle. Negative tooth angle cuts less aggressively, doesn’t remove less waste as quickly, but the cut is smoother. On the disk, the angle is marked: 5 neg. 5 degrees negative, 10 pos. positive 10 degrees.

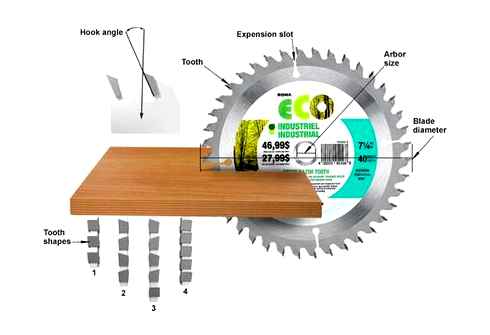

Types of teeth by shape and sharpening angle

This distinguishing factor of a saw blade is the angle of the tooth across or perpendicular to the rotation of the blade. The higher the bevel angle, the cleaner and smoother the cut. Some blades have very large bevel angles for cutting composite material such as plastics or others that are prone to tearing/chipping when the tooth exits. Bevels can be flat (no angle), alternating, heavily alternating, or another configuration, which we will discuss below.

setting

This is the width of the tooth at its widest point and therefore the width of the cut. If it is greater than the tooth thickness, the set is normal. If it is not, then the setting is done by the experts using the following methods:

- 1 through 2 teeth are set in the opposite direction;

- each tooth is alternately set to the same distance from the plane of the blade;

- the same, but with different distances within 0.3 to 0.7 mm.

A thin kerf produces less cutting resistance and is therefore better suited for low-powered saws. Thin blades originally vibrated or wobbled, causing problems when cutting wood. New blade technology with a vibration-reducing design has made some improvements in the thin-cutting blade segment, increasing demand for cordless circular saw users.

The rules

As with chain saw chain sharpening, sharpening by yourself is also a good idea.

- Watch closely for even metal removal along the profile of the saw blade teeth;

- Never press the saw blade firmly against the grinding wheel. If the circular saw blade sharpening machine is in close contact with the wheel to be sharpened, it will overheat and deform the material;

- Watch for the preservation of the height and profile of the sharpening at the end of machining operations;

- Use coolant when sharpening discs. This is also recommended for those who sharpen chainsaws;

- Beware of the formation of burrs when sharpening the saw blade;

- When sharpening edges, follow the following rule of thumb. It is necessary to sharpen only the front side, or the front and back side of the tooth. Although in practice, many craftsmen with their own hands prefer to sharpen from the back side of the saw wheels, considering this method more comfortable;

- Pobedite products can be sharpened with diamond sharpening tools. Only such tools can really perfectly restore the cutting characteristics of this tool. It is possible to use an ordinary ratchet grinder, but it will not have the desired effect.

Chainsaw sharpening school.Your saw will cut faster after this video

Basic sharpening methods

The circular saw is sharpened with a fine-grained abrasive wheel, along the planes that form the main working cutting angle:

For combined edge restoration, the front corner is sharpened first. In this case the disk can be resharpened 25. 30 times in the process.

Removing a thin layer from the back of the tooth leads to a quicker reduction in blade diameter and wear on the saw.

You can sharpen circular saws with your own hands at home. It is enough to use an ossele to correct a tool with pobedite tips. For high volume applications, an angle grinder or router is useful.

Sharpening circular saws with carbide inserts requires more force and is carried out on special machines and a device with an abrasive wheel.

Manual method

Manual method of grinding on a flat grinding wheel.

- Clamp the angle grinder with the wheel securely.

- Make a support for the circular saw blade. Its plane should be flush with the axis of the sharpening wheel.

- Bring the tooth side up to contact over the entire area to be sharpened.

- Place 2 clamps on the table support on the right and left. They will help you align the plane to be sharpened quickly, without adjusting each tooth.

- Set the trough against the left fixture and turn it all the way to the right fixture after each rotation of the wheel by one increment.

It is necessary to remove 0.12-0.15 mm from the cutting plate in one sharpening.

To sharpen the circular saw on the back plane, turn it around and change the position of the clamps.

angle grinder for sharpening circular saw blades

Using machines

In mass production it is necessary to sharpen circular saw blades regularly. For this purpose special machines with wheels are available in the workshop. Each of them has a fixture that aligns the tooth relative to the wheel at the desired angle and allows the tool to move progressively.

In special automatic equipment, the disc makes only a rotary movement to the size of the set pitch. The rotating abrasive wheel drives up after each turn and grinds the next plane.

It is possible to sharpen the carbide disc manually, using an arbor, but the effect will be poor. Without special devices it is impossible to maintain the angle and remove an even layer from all planes.

Sharpening circular saw blades properly and accurately Theory Part 1

Methods of sharpening circular saw blades

Machine for sharpening circular saws with tips

Any sharpening machine can be used to form a new cutting edge. It is important to choose the right emery wheel at the beginning and sharpen the edge with it. Corundum or diamond models should be used for this.

The best option is to use special equipment designed for this work. But because of its high cost in many cases its purchase is inexpedient. An alternative way is to use a sharpening machine with the ability to change the angle of the corundum disc.

Under no circumstances should you sharpen by hand by yourself. Firstly, it takes a very long time. Second. the result will not meet the standards. In case there is no possibility to perform sharpening of wood saw blade by yourself, it is recommended to use the services of specialized companies.

Professional sharpening of circular saws with your own hands is performed according to the following rules:

- The main deformation occurs on the upper edge of the tooth. There is a rounding of edges from 0.1 to 0.3 mm. This is where you should start sharpening;

- The sharpening is performed along the leading and trailing edges. This will ensure that the procedure can be repeated up to 25 times;

- The value of removal should not exceed the value of 0.05-0.15 mm;

- The level of finish on the leading and trailing edges should be the same.

After sharpening wood discs it is recommended to finish sharpening with fine sandpaper. This can be done manually or with a special machine.

Specialists advise using special corundum discs, the end surface of which has a specially shaped groove. It will make the procedure easier.

Resharpening circular saws with carbide tips

Angles of sharpening for carbide-tipped circular saws are difficult to maintain because the tooth is tamed. This alloy is fixed by soldering. The geometry of the cutting part is complex, and sharpening parameters must be precisely aligned.

The work is carried out by smoothing the cutting edge to a radius of 0,3 mm. A higher value should not be allowed.

- Grinding is performed on the front and rear tooth planes. If done correctly, the total number of sharpenings before the blade is completely worn will be 30 times.

- Start with the front face.

- The hardfaced part of the tooth must rest flush against the grinding wheel.

- Turning time of 3 to 5 seconds. No longer possible. This causes unnecessary heating of the metal. It is re-hardened and tempered with a decrease in hardness.

- Thickness of the material to be sharpened is in the region of 0.15 m.

Block: 5/7 | Number of characters: 906

Tools needed

You can sharpen circular saw blades with your own hands only if you have special tools. There is also a machine that allows you to automate the process, making it more efficient.

You can use the tools below to do the job of sharpening the disc with your own hands:

You can also use a circular saw sharpener that does not need the tools above.

When it is necessary to work on the restoration of circular saws?

Quite an important issue can be called determining when to sharpen circular saws. Severe wear and tear can lead to an inability to perform this type of work. Three clear signals can be identified that determine whether it is necessary to sharpen the circular saw blade:

- Occurrence of smoke, heating of the protective hood. The machine usually has a special guard, which can become hot if the circular saw blade becomes blunt. It should also be noted that in special cases there is smoke due to the intense heating of the cutting zone.

- Also with mechanical feed, when pressure is adjusted by hand, great pressure must be applied to obtain the desired result.

- When machining wood or other material, soot residue and a corresponding odor appear in the cutting zone.

In the above situations, it is recommended that the circular saw blade be sharpened.

Equipment for saws with diamond dusting

Such machines must have a design supplemented by a cast reliable base. This ensures the high machining accuracy of the discs, which are made of materials with special strength. There is also a high inclination locking device. the base is fitted with special rubber elements that reduce vibrations, which can impair the quality of the work carried out. This addition lowers the noise level of the sharpening process. The adjustment of the equipment is done manually, and the diamond-coated blades used for grinding the saws increase the quality of the result and extend the life of the tool.

The principle of the sharpening disc has its own special characteristics, as well as its structural design. Its materials are based on nitrogen and boron compounds, which not only increase machining precision, but also increase resistance to the high temperatures that characterize the process itself. It is necessary to take into account that the wheels have different diameters and are suitable for different tools and types of materials, so you need to carefully select the appropriate model according to the available tool to be processed.

Chainsaws for longitudinal sawing

A modern chain for longitudinal sawing is represented by a rather complex design, which is made by using high quality steel characterized by high wear resistance and corrosion resistance. Among the features are the following:

- The design is represented by individual links that are connected in a special way. This results in a high level of flexibility, the slitting chain can follow the complex shape of a guide bar.

- There are several different slats in terms of intended use: cutting, guiding and connecting. Cutting blades perform direct material removal.

The natural process of use is the reason why the cutting inserts wear out. In addition, violations of the operating recommendations can also lead to a similar result, for example, if the cutting zone has been hit by soil.

That is why all owners of such a tool should pay attention to exactly how the sharpening.

How to properly sharpen a circular saw!

The circular saw blade needs to be sharpened on its leading and trailing edge! Below in the picture we have shown the tooth of the new saw (far left). In the process of sawing wood, the sharp cutting edge of the tooth gets blunt, and if we look at it under a magnification of several times we can see that the leading edge has a rounded shape. To make it flat again, we need to grind one of the tooth edges: grind this circle, and the edge will be sharp again.

We can sharpen it only on the front face of the tooth (which is not right) and we have to grind a lot, or we can distribute the amount of grinding evenly. on the front face of the circular saw tooth and on the back face of the circular saw tooth. That is, it is recommended to sharpen the circular saw along the front and back edge of the tooth

As a result we, sharpening circular saws on the front and the back of the tooth we can greatly increase the life of tool: we can sharpen it more times, which means that it will work longer and pay back the money invested in it when bought. And often, circular saws of large diameters for multi-rip saws and log saws are very expensive, and you don’t buy them one at a time.

The circular saw must be sharpened on a special sharpening machine, preferably with CNC, which has a high precision. Sharpening is done in several steps:

- First it is absolutely necessary to clear the saw of wood resins, for this you need to use special demineralizing technical liquids (alkali with sodium).

- Then the circular saw is sharpened on the front edge. The saw is sharpened in several passes with a small amount of grinding in one pass. The saw can be sharpened in 2 to 3 rounds, as determined by an experienced operator.

- The third step is sharpening the circular saw blade along the back edge of the tooth. Also in several passes.

We strongly recommend that circular saws be sharpened at specialized service centers that use CNC machines.

In this case, the operator can set all necessary angles of sharpening of the circular saw tooth on the control panel:

- Angle of sharpening of the front edge,

- sharpening angle of the trailing edge, if the trailing edge has a variable bevel. this can also be set on the control panel.

- Trapezoid tooth corners, etc.п.

Quality tool sharpening is the life of a circular saw. If you were able to provide a quality sharpening, the saw will not lose its original qualities, and will work like new.