What kind of rotary hammers are better horizontal or vertical?

Straight and barrel perforators. tool comparison

The arsenal of every modern professional builder includes a large number of tools, both manual and electric. One of these is the peorator. Today there are a large number of models of perforators, some of which are designed for simple tasks and use in the home, and others. for professional activities. Differing in many of their parameters, including weight, dimensions and performance, the peorators are also divided into two subcategories according to the location of the engine. straight and barrel. In this article we discuss the main differences, advantages and disadvantages of barrel rotators, and tell you how to choose the right tool. By the way, read more about the features of the choice can be found in the article “How to choose a peorator for home and work.

Peorators have a wide range of applications that are greatly enhanced by the tool’s multiple modes of operation. Peorators have two or three of the following operating modes:

Each of these modes is designed for a specific range of work. For example, in no-impact drilling mode, the peorator can drill holes in wood, metal, plastics, and ceramics, acting as a drill. In the drilling mode it can work with hard materials. concrete, stone, brick. The geared tool efficiently breaks down material by chiseling.

I could go on and on, listing all the uses of the torch. It finds its application in any more or less significant repair work and even in performance of simple household tasks. Replacing wiring requires cutting through walls, re-planning involves the dismantling of walls, replacing door frames, windows, and even plumbing fixtures also require the use of a gator. Regardless of the base material to be worked on, the peorator is up to the task.

By design, the tools differ in the location of the motor. This is reflected in the shape of the peorators, so you can easily distinguish one type from another. Peorators that are L-shaped are called barrel-type (vertical layout of the motor), and the long drill-like tools are called straight-line peorators (horizontal layout of the motor). Many people can’t answer the question: “Is the straight torch or the barrel torch better??”. Below we will describe each type and tell you how they differ from each other.

Straight (horizontal) gimbals

Their design is similar to a drill, because the motor is located in the same way. The power unit is in the same plane as the drill axle. This allows direct transmission of torque to the nozzle, and also simplifies the design. The downside of the medal is a restriction in the force of impact. These tools are best suited for small hole diameters (5-16 mm), because they are compact, easy to use, and the rotational speed of the head is enough to perform most basic tasks.

- They are lightweight and well-balanced. The use of such a gator requires minimal effort from the operator.

- Their small size and elongated shape allow them to be used in hard-to-reach places, apertures and slots.

- Straight torches are easy to maintain and repair. Their simple design reduces the chance of breakdowns.

- The cost of straight torches is lower than that of barrel torches. You can find excellent models with good functionality on the market.

Straight torches are not without their disadvantages:

Straight torches are often chosen as the universal tool for drilling, drilling, easy dismantling and mixing. Straight peorators, like drum peorators, can be used commercially and for continuous work. The main thing is to stick to the recommended modes of operation of a particular model, not to overload it and not to forget to service.

Choosing the power of the torch

The basis for assignment of the torch to this or that power class is served by type of equipment used with it: SDS-max or SDS-plus. SDS-max peorators are tool monsters that only belong on the construction site. They do not drill through walls, but rather pierce through them. Such tools are useless for home works. As for the SDS-plus models, 400-600 watts of power output and about 3 Joules of impact energy is enough. With these characteristics the tool can successfully cope with drilling holes in concrete up to 26mm, which is more than enough for home repair. (There are also drills with diameter exceeding 26 mm, but they can be used only for work on bricks with great risk of damaging the tool).)

The classic horizontal peorator has the motor in the same plane as the working barrel. This makes the tool body longer. When upright, the motor is accordingly in an upright position in the center. There is no advantage in power or impact force, but the vertical rotary tool is more compact and convenient to work, especially in cramped conditions. The final decision you can make in a store after taking both modifications in your hands and having estimated the convenience and ergonomics of the tool.

Working modes of the torch

The vast majority of modern rotary tools can operate in three modes, which are implemented by a quick chuck change. In just one movement of the hand you can remove the SDS-plus chuck from the barrel and install a conventional 3-jaw quick-change chuck for tooling up to 13 mm in diameter.

- Drilling with impact. the essence of the torch and its main modes.

- Drilling after replacing the chuck. Keep in mind that as a drill, the torch is not capable of any serious work. the rotational speed is low and drilling turns into a tedious process. But it has plenty of power and in the drilling mode it can do all the jobs that a regular drill can’t do: mixing various construction mixtures, including heavy cement and plaster mixes. The rotational speed is not needed there, but the torque is very welcome.

- Clean blow with rotation lock. In this mode the torch can be used as a jackhammer. Chisel, chisel or spade is inserted in the chuck. Punching angle can be varied in order to find the most suitable point of impact. Again, you can’t smash walls with such hammer (this is destiny of full-featured SDS-max breakers). only light chisel jobs are available such as taking the tile off the walls, beating off the plaster or breaking a couple of bricks in the opening.

So, let’s draw a conclusion.

The main corner difference between horizontal and vertical pehorators is in the impact transfer system. In the heavy and less convenient vertical tool, this system is more reliable and can work in the impact system indefinitely. The horizontal instrument is more compact and light, but you have to pay for it by a light striking system. There is no need to use it in the impact system for more than ten, fifteen minutes. It should be periodically switched to spinning, let it get fresh oil and cool down a little.

While choosing a tool, you should take into account all the above mentioned functionalities and pieces of advice from the producers. Then your work will go much easier and faster, and the tool will last for a long time.

The vertical (barrel) peorator

This type of tool has a more complex device. the motor is located perpendicular to the axis of the drill, in the lower, vertical part of the body. Therefore, the design includes a reducer that transmits torque to the motor shaft. These devices are more powerful than straight, and are equipped with a cooling air system. Exactly these devices, like the Makita HR4013C, belong to the professional, because the mode of operation is correlated with demolition hammers.

The design includes a crank mechanism, due to which the impact performance of the device is increased. With this device you can perform heavy construction operations in hard reinforced concrete and stone structures: demolition of walls, removal of concrete floor layer, drilling large holes.

The device has also proven to be indispensable for mixing large amounts of construction mixtures. The cooling of the motor in barrel units is more efficient, so frequent interruptions do not need to be made.

To the disadvantages of such devices can be attributed their considerable weight, but in some works, the weight of the device increases the kinetic energy of destruction.

In general, the advantageous features of barrel-type tools, such as the Bosch GBH 4-32 DFR SET, are:

- The device is wear-resistant, has a long service life when chiseling (in contrast to straight);

- Achievable torque values allow to perform the function of a mixer;

- Ability to obtain holes of large diameters in hard textures;

- Impact parameters are sufficient for dismantling walls;

- Effective drilling in the vertical direction.

Curious: What is the difference between an impact drill and a peorator: 7 main criteria

So, let us conclude.

The basic cornerstone difference between horizontal and vertical pehorators is the impact transmission system. The heavy and less comfortable vertical tool has this system is more reliable and can work in the impact system indefinitely. The horizontal tool is more compact and lightweight, but at the price of a lighter impact system. You do not need to use it in the impact system for more than ten, fifteen minutes. It has to be periodically switched to rotation, let it get fresh oil and cool down a little.

When choosing a tool, consider all of the above features and advice from manufacturers. Then your work will go much easier and faster, and your tool will last for a long time.

So, let’s conclude.

The main corner difference between horizontal and vertical pehorators is in the impact transfer system. The heavier, less handy vertical tool has a more reliable system and can work in the impact system indefinitely. The horizontal instrument is more compact and light, but you have to pay for it with a lightweight striking system. You don’t have to use it in the impact system for more than ten, fifteen minutes. It should be periodically switched to spinning, let it get fresh oil and cool down a little.

When selecting your tool, consider all of the above features and the manufacturer’s advice. Then your work will go much easier and faster, and the tool will last for a long time.

Choosing Advice

Having figured out what the difference between a side peorator and a straight one, you can move on to the study of specific models. If you focus on the reviews of the owners of the tools, you can gather some important tips:

- For home needs it is better to choose the horizontal type of the tool. even though it is weaker than a barrel tool, but for household and repair tasks its power is enough. It is not worth overpaying for a powerful unit with excessive functions.

- If a serious repair of the apartment with redevelopment, demolition of partitions, replacement of electrics. it is worth thinking about a more productive model with good shock performance, the ability to work for a long time without annoying pauses for cooling the device and anti-vibration protection. These characteristics are present at the devices with vertical installation of the motor.

- The manufacturer is considered to be an important factor in your choice. Look for brands that are well known in the power tool world. This will ensure that the advertised performance is in line with the actual performance.

- Always follow the manufacturer’s instructions and recommendations.

Let’s compare a Makita HR2810 barrel drill and a Makita HR2300 straight drill for an example:

| Characteristics | Makita HR2810 | Makita HR2300 |

| Destination | professional | professional |

| Mode of operation | drilling, drilling/impact, impact | drilling, drilling/impact |

| Speed of rotation, rpm | 1100 | 1200 |

| Number of strokes/minute | 4500 | 4600 |

| Impact force, J | 2,8 | 2,3 |

| Weight, kg | 3,4 | 2,7 |

| Max. Hole diameter, mm | 28 | 23 |

| Power | 800 | 720 |

Characteristics for domestic and professional torches

Before you buy a tool, you need to know what a peorator looks like. Household appliances differ from professional ones in power and weight. However, when buying a device, you should consider the following characteristics:

For your reference! Smooth start allows you to make the hole smooth, regardless of the type of material. Makes the work safer at the same time.

Also of great importance is the power of the motor and the weight of the product. For professional purposes, devices with high power are used. The household appliance is easy to use and small in size.

Household tool has low weight

How to choose the peorator successfully

In order to understand how to choose a peorator for home purposes, it is necessary to follow the recommendations of masters. If the peorator will be used for drilling materials such as wood, or thin metal, you can use a device with a single mode of operation.

It is also necessary to carefully study the characteristics of the models, and choose the most suitable. Preference should be given to well-known brands, with a lot of positive reviews.

Important! When ordering over the Internet, you should study how much the consumables cost for the selected model.

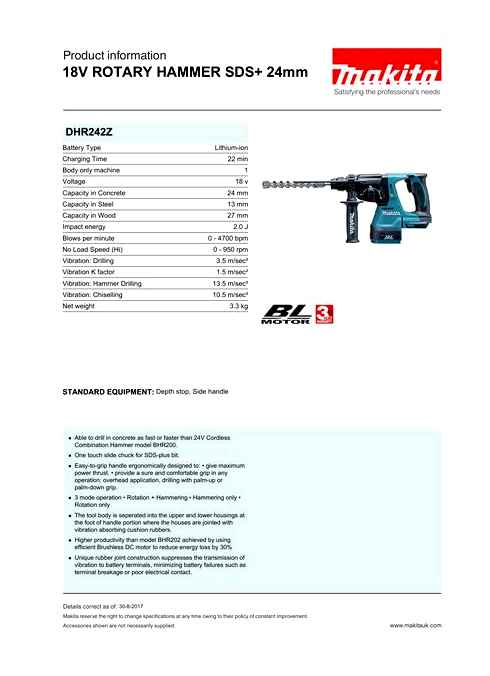

place. Makita HR2470

Makita HR2470 takes the 8th place in the top of the best torches for home in terms of value for money and quality, and will be a reliable helper for DIYers, construction workers and furniture makers. The horizontal layout of the motor makes the device lighter and more compact.

The tool can make holes in the toughest materials and hard-to-reach places: up to 32 mm in wood, 13 mm in metal, 24 mm in concrete. Core drilling rises up to 65 mm in diameter. Rubber-coated main grip prevents slipping and auxiliary handle reduces drilling stress for the user. Safety clutch prevents from injuries by sharp jamming, and the tool itself will last longer.

A good inexpensive home peorator is capable of chiseling walls to widen doorways and break down partitions. The chisel rotates through 360 degrees and can be locked in 40 positions. The device will last longer due to the absence of impact when idling, and the accuracy and quality of work improves the automatic speed control. Impact energy up to 2.4 Joules, and up to 4,500 beats per minute.

- Low noise;

- Fits perfectly in the hand;

- Very high quality and reliable;

- Repairability;

- Handy carrying case included;

- Long power cord;

- Lightweight and compact;

- Rubberized handles;

- Plenty of space for storing drills.

7 place. Makita HR2630

Popular budget concrete peorators come with a SDS Plus quick-release chuck and are powered from the mains by plugging in a 4-meter cable. The tool can be safely chosen for more assembly, disassembly and other construction work. The motor is positioned horizontally and delivers 800 watts of power, while generating 2.4 Joules and up to 4,600 beats per minute. The Makita HR2630 weighs 2.8 kg and has a modest dimensions 36.1×7.7×20.9 cm.

Comfortable use thanks to ergonomics, proper weighting and handles with rubber pads to prevent slipping. There are three modes to choose from. Drilling, percussive drilling and chiselling.

The device creates holes up to 26 mm in diameter in durable concrete, bricks and other hard materials, including natural and artificial stone. The core bits increase the drilling radius up to 68 mm. The drill jams, the unhooking clutch engages, and reverse will help pull out the jammed tool.

- The quality of construction and materials;

- Good drill bits included;

- Sturdy and large carrying case

- Effectively dampens vibrations;

- Mode switch is hidden underneath;

- Long power cord;

- Easy to work with reinforced concrete slabs;

- Powerful and reliable.

Description

Peorator is a pounding and rotary tool.

In contrast to the drill, the grinder does not drill holes in the material with a sharpened edge of the teeth of the drill, but punches them through by translational and reciprocating (rebound) motion.

In appearance and sharpness the auger resembles a chisel, because its purpose, unlike a drill, is not to cut the hole with a rotary motion of the drill bit edge, but to punch it through by pneumatic impact. The drill collides with the material at the point of contact and destroys it in a directional manner.

This is the main principle of operation of the device and explains the features of its structural elements: the motor of higher power in comparison with a drill, specially shaped drill bit made of high-density metal and others.

What is it for

As follows from the definition, the main function of the rotary tool is to chisel solid or “blind” holes in materials of different density. from “soft” plaster to stones, concrete and bricks. According to the type of work, expected depth and width of “hole”, the drilling nozzle is chosen: their diameter varies from 15 to 150 mm.

Power and directional impact force are also the main features of the device. Power is counted in Watts, and impact force in Joules. The value of these parameters determines the speed and efficiency of the torque generator during operation. The power of household appliances is 800. 1000 watts, and professional 1000. 1500 watts.

Peorator is used for the installation of electrical networks, television and Internet cables, installation of “heavy” heating and electrical equipment, arrangement of plumbing and drainage systems, drilling subsockets in concrete.

Peorators are classified according to the design features of their elements, such as: the type of drive and power supply, the location of the motor, the type of the chuck of the battering mechanism. The tool is also classified according to the ability to work in two or three modes.

According to the number of operating modes

This classification is determined based on the number of operating modes of the tool:

- Two-mode. The most common domestic models, whose functions include: drilling with a longitudinal blow and drilling holes without a blow;

- three-mode. Heavier and more powerful professional models. These models have the added function of t.н. impact mode without rotation.

Reference! The first mode is the standard function and is used for crushing concrete, bricks, stone and heavy metal, such as steel. The second is an additional mode, in which the device works as a drill, it is used for drilling holes in thin metal surfaces, wood and various plastics. The third one, the percussion mode, is used in large-scale construction work, when it is necessary to make a hole in high-density materials, including for example: pavement or metal structures poured in concrete, “sacrificing” neatness.

By drive type

The main construction detail of the torch is its power unit, which consists of a motor and a drive mechanism. Modern models are subdivided according to this classification into:

- Pneumatic. The device that powers the tool is an air compressor. Such mechanism is used in work with road pavement, sewers, mines, or other areas where, for safety reasons, the use of electricity is unacceptable;

- Fuel. The power source for the peorator is a gasoline or diesel engine, which provides high power at a lower noise level than a compressor;

- Hydraulic. To work the tool is connected to the hydraulic system of road machinery or to the pumping station through the nozzle of the distributor. It also makes less noise than an air compressor;

- Electric-powered, grid-powered. The most popular modern models, which use an electric motor powered by the mains as a drive. Used in construction and repair work, both indoors and “outdoors” if there is a power socket nearby;

- Cordless. This type of rotary drill is also driven by an electric motor, but it does not require a direct connection to the mains. The energy for operation is stored in special lithium-ion, nickel-cadmium or nickel-metal batteries. The advantages of such tools include mobility, but the disadvantages are lower power compared to other types of gears and active service life.

Important! To the first three types because of the high noise level, power and size of the engine unit mainly include professional and industrial machines. They are used on construction sites, in hydraulic engineering structures, in the mining industry, in road infrastructure construction, in the oil or gas industry, etc.д.

By motor location

In the design of domestic electric peorators, the motor can be installed:

- Vertical, i.e. perpendicular to the rotary axis of the tool. This is reflected in the shape of the device (in the form of the letter L). Due to this, the installed motor may be larger and more powerful, but it adds weight to the entire device, which makes it less mobile and ergonomic;

- Horizontally, i.e. along the axis of rotation. The motors of such tools are not powerful, but these models are easier to hold on the weight: they are ergonomic, compact and relatively light.

Horizontal rotators are most often used in domestic work, while vertical rotators are most often used on larger construction sites.

Weight

Finally, as already noted above, an important criterion for a tool is its weight. According to weight, all models of peorator devices can be subdivided into:

The latter have not only great weight, but also dimensions, and they are often used in heavy industry and road works, performing, in fact, the function of a “jackhammer”.

Important! In addition to the above, the basis for classifying the models of rotary tools is the implementation of the percussion system and the design features of the drill bit attachment. different types of chucks and drill rods (bits, chisels, drills, etc.) are used for specific jobs during repair or construction.д.).

Once you understand the working principle and functions that distinguish the peorator from other similar devices, as well as identify its areas of application, to make a choice in favor of a particular model is not difficult. It is enough to determine for yourself the scope and volume of the necessary works and by opening the website of an online store or by visiting the construction market, look at the basic design and technical characteristics.