What Oil To Use For The Saw

What kind of oil to pour into the saw How does the chain lubrication system work, what is oil used for? What oil is better for pouring into the saw: tips for choosing, a review of manufacturers.

Consequences of a lack or excess of chain lubrication

Certain parameters must be respected for each mechanism whose operating mode is associated with lubrication based on machine oil. This primarily concerns the amount of oil required for its normal operation. Such problems can arise if not enough oil:

- Overheating of the circuit;

- Premature bluntness of cutting teeth;

- Seized or broken chain;

- Additional time spent on cutting;

- Increased wear of the sprocket;

- Failure of the tire.

For an electric chain saw, it is recommended to fill the oil tank in the following proportion: one full oil fill to a full gas tank, i.E. 1: 1. In some models, for example, Bosh, the lubrication system works in a fully automatic mode and if there is too much or too little oil on the chain, the saw itself begins to regulate its supply. However, if a malfunction occurs, and the oil starts literally pouring from the chain mechanism, then its excess can lead to the following undesirable consequences:

- Increased oil consumption;

- Excessive contamination of the tool body;

- Wide spray of oil from the chain.

Apparently to critical consequences excess lubricant does not lead, but its overrun will surely hit your pocket. Taking into account the fact that the cost of high-quality lubricating oil is quite high, it is better to use it sparingly.

Why chain lubrication is needed on the saw

Saw oil is used as a chain lubricant to reduce frictional forces and reduce heat build-up. As a result, a fast and trouble-free operation of the cutting blade is achieved. Sometimes it happens that at some stages of cutting it is necessary to exert additional efforts to obtain the required cut, and this directly indicates an insufficient amount of lubricant or its not very good quality. In this case, it is recommended to immediately check the oil level in the reservoir or simply lubricate the chain to complete the current work.

General Guidelines for Choosing Saw Lubricant

When choosing an oil for lubricating a saw, each of the users asks the question, which of the options is more profitable and acceptable. A special oil for chain mechanisms or an ordinary machine oil? If you listen to the experts, then, of course, the first option is preferable, since the chain lubrication oil was specially developed taking into account the technical characteristics of the saw.

Although conventional engine oil is cheaper than special oil, it must be taken into account that it serves completely different purposes and cannot guarantee moderate wear of working parts.. So you can win a little in price now, but then you will have to overpay for the repair of prematurely worn mechanisms.

Many experts recommend using a grade of special oil to lubricate the saw. With letter N. It is a little more expensive, but guarantees a long and trouble-free operation of the chain. Its main advantages include:

- Excellent biodegradability;

- Increased adhesive capabilities;

- The presence in the composition of special additives that protect against premature wear.

By following these recommendations, you can significantly increase the life of your electric saw chain. However, the final choice of lubricant is always up to the user.

Criterias of choice

Engine oils and their chain analogues are not interchangeable. The chain lubricant composition has a number of characteristic differences, in particular, an increased level of adhesion to the metal.

- Saw sets of all types of hand saws have the same design, therefore the chain oil for the saw is identical to the composition that is used in the sawing mechanisms of gasoline models.

- When choosing a chain lubricant for a specific model, it is recommended to give preference to the grades and grades indicated in the operating instructions. As a rule, these are proprietary developments, created taking into account many factors.

In the absence of a recommended consumable, it is better to use a well-known brand of oil. Branded products of these manufacturers are characterized by universal lubricating properties, stable operating parameters in a wide range of temperature effects.

Saw chain oil: choose and use correctly

The resource of the saw headset largely depends on the quality and correct dosage of the special lubricant supplied to the rubbing components. Saw chain oil is a mineral or organic based compound with special functional properties.

The tandem of the bar and the saw chain is operated under conditions of high static and variable loads, therefore, in parallel with the lubrication of rubbing parts, their full cooling is realized.

Disadvantages of lubricant substitutes

A household or professional chain saw, when filling the lubrication system with a cheap surrogate, may require replacing a standard headset long before its designated resource is exhausted. According to proven data, the use of substandard oil reduces the service life of the saw mechanism by an average of 35-40%.

- Used automobile oil contains microparticles of metal, combustion products and acid-base compounds, which negatively affect the wear and corrosion resistance of the metal of the sawing mechanism.

- It is also not recommended to add automotive and tractor engine oils to the chain saw. Such a filling can initiate a decrease in performance and even a breakdown of the drive of the oil pump of the lubrication system.

Only in the absence of other options, for a one-time operation, you can fill the system with a diluted to a standard density. Autol or dismeas oil

Saw chain oil

Among all consumables used for sawing tools, saw chain oil occupies the first positions, both in the frequency of use and the importance of application. A good oil not only makes it easier to work with the device, but also extends its useful life for years.

What oil to use to lubricate the saw chain

Improperly selected oil reduces the efficiency of the tool and increases its wear by 7-10 percent. Select saw chain oil based on the manufacturer’s recommendations. Russian companies claim that their saws work when lubricated with common domestic automotive oils. They are opposed by foreign manufacturers.

Finely tuned equipment works only with adapted oil formulations. So, some brands produce oils for a specific brand of saws, as evidenced by the inscription on the package. They provide ideal lubrication for saw chains and bars. At the same time, they have additional components in their composition.

To lubricate the saw chain and saw bars, oils from many manufacturers are used, the most popular are:

- Uzfam oil. For operation under any external weather conditions, well protects against wear and corrosion;

- Oleo-Mac OM Polar Lube oil. On a mineral base with a high viscosity, protects well against wear and corrosion;

- Oil Oleo-Mac ОМ Eco Lube. Does not contain mineral oils, sulfur, has high lubricating properties, antiwear with high viscosity, oxidation resistant;

- Husqvarna Chain Oil is a proprietary oil that reduces chain heating temperatures and reduces wear on chain links, teeth, and guide bar, maintains its low viscosity even at very low temperatures, performs its functions even when water gets into it;

- Al-KO oil. Used for chains of electric and chainsaws, retains its low viscosity even at very low temperatures, reduces the heating temperature of the chain as a result of friction;

- Champion oil is a universal, adhesive, used for chain and bar lubrication, provides good lubrication, while viscous additives and special additives reduce abrasion and oxidation of the saw chain metal.

How to properly lubricate the saw chain

There are models that lubricate automatically using a special built-in system. But due to their high cost, you have to resort to other methods, the saw chain and tires are lubricated with an oiler, syringe, brush or spatula for more viscous oil.

Some manufacturers recommend making an oil bath for the chains during a long break in use in order to avoid their corrosion and the appearance of rust. To do this, you will need any small container, into which a layer of oil is poured onto the bottom, covering the product. To prevent dust and debris from entering, the container is closed with a lid or foil during the conservation period.

In addition, the chain must be lubricated before each next use. It is done only when the power supply is off. The saw chain must be loosened before lubrication and lubricated afterwards. Hands will need protection (gloves), as using chain oil can cause injury from the links and blades.

Saw oil. A guarantee of its correct operation

It is hard to disagree with the fact that chain saw oil is hardly the most important consumable component for this category of power tools. After all, a high-quality lubricating product not only simplifies the operation process, facilitating the contact of the cutting blade with materials of different hardness and density, but also significantly increases its production resource by at least several years. Therefore, the question of which oil to pour into the saw to lubricate the chain is one of the central ones that each user must decide for himself, deciding to acquire a household assistant in the form of an electric hawk. All the features of this seemingly complicated process will be discussed further.

Tips for choosing oil

The fact that you need to pour oil into the saw is understandable. But another moment, which one, can also be taken by surprise. The whole variety of existing types of grease can be divided into several types:

Special, adapted specifically for saws. In its composition it contains adhesive additives, which serve for better adhesion of the liquid with the blade itself and do not allow it to drain instantly.

New environmentally friendly formulations made only from safe plant materials.

Motor and transmission oils. Can also be used as a lubricant for certain models, which is regulated by the instructions for them. However, mineral oil should be avoided. In addition to the lubricating effect, engine oil can also be used to remove residues of “biological” lubricant, which not only clogs the oil system, but can also provoke serious damage.

Incredibly, many craftsmen have learned to use waste engine oil and even regular table sunflower oil for chain lubrication. This way out of the situation, although it is economical, since it allows you to reuse the resource, but carries with it many threats to the cutting working mechanisms. So, used car oil can clog the oil filter and pump, which is generally threatened by the prospect of going to a landfill. This increases the load on the motor, often leading to overheating and damage.

Vegetable oil is generally a risky option, which categorically cannot be used for pouring into an oil tank. As a last resort, when acceptable, use to lubricate the outside of the chain.

Of the options offered, the special oil is the best. Experienced experts advise purchasing grease from the same company as the saw itself, but the price of such a product can be overstated by several orders of magnitude compared to universal chain grease, which is a serious competitor to expensive and not always affordable branded counterparts.

Features of the lubrication process

Saw chain oil is essential for the cutting blade to perform its tasks as quickly and efficiently as possible. And the fact that at a certain stage of operation it is necessary to put great efforts to make the cut is one of the main indicators of the need to either check the oil level (if possible), or manually lubricate the chain. Modern electric saws most often have a built-in system for auto-pumping oil into the chain and bar area, therefore the second option with manual chain lubrication is used only for outdated primitive designs.

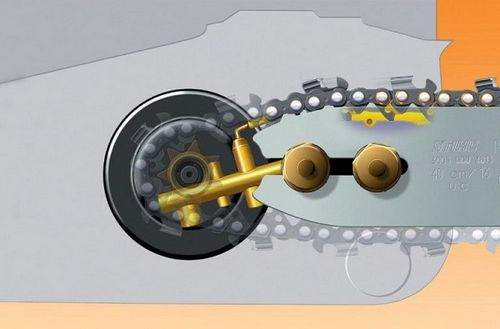

Most often, the oil for the electric chain saw comes from a special tank, where it needs to be filled periodically. Already directly from it with the help of an oil pump. A separate component of the oil supply, by converting the rotational movement of the gear to a translational rod, the chain receives oil in the volume necessary for normal functioning.

It is also very easy to monitor its level thanks to the transparent window of the container filled with oil for a convenient indication of its remainder.

Unlike the new modifications of saws, the older ones do not have such a constructive capability. But you can eliminate this defect. To do this, take a container (you can use an ordinary household bucket) and fill it with oil, into which the chain mechanism is simply immersed before operation. Such actions need to be done often, since part of the oil will go not only to lubricate the canvas, but also simply go to waste with sawdust.

Features of the lubrication process

Saw chain oil is essential for the cutting blade to perform its tasks as quickly and efficiently as possible. And the fact that at a certain stage of operation it is necessary to put great efforts to make the cut is one of the main indicators of the need to either check the oil level (if possible), or manually lubricate the chain. Modern electric saws most often have a built-in system for auto-pumping oil into the chain and bar area, therefore the second option with manual chain lubrication is used only for outdated primitive designs.

Most often, the oil for the electric chain saw comes from a special tank, where it needs to be filled periodically. Already directly from it with the help of an oil pump. A separate component of the oil supply, by converting the rotational movement of the gear to a translational rod, the chain receives oil in the volume necessary for normal functioning.

It is also very easy to monitor its level thanks to the transparent window of the container filled with oil for a convenient indication of its remainder.

Unlike the new modifications of saws, the older ones do not have such a constructive capability. But you can eliminate this defect. To do this, take a container (you can use an ordinary household bucket) and fill it with oil, into which the chain mechanism is simply immersed before operation. Such actions need to be done often, since part of the oil will go not only to lubricate the canvas, but also simply go to waste with sawdust.

Saw oil. A guarantee of its correct operation

It is hard to disagree with the fact that chain saw oil is hardly the most important consumable component for this category of power tools. After all, a high-quality lubricating product not only simplifies the operation process, facilitating the contact of the cutting blade with materials of different hardness and density, but also significantly increases its production resource by at least several years. Therefore, the question of which oil to pour into the saw to lubricate the chain is one of the central ones that each user must decide for himself, deciding to acquire a household assistant in the form of an electric hawk. All the features of this seemingly complicated process will be discussed further.

Tips for choosing oil

The fact that you need to pour oil into the saw is understandable. But another moment, which one, can also be taken by surprise. The whole variety of existing types of grease can be divided into several types:

Special, adapted specifically for saws. In its composition it contains adhesive additives, which serve for better adhesion of the liquid with the blade itself and do not allow it to drain instantly.

New environmentally friendly formulations made only from safe plant materials.

Motor and transmission oils. Can also be used as a lubricant for certain models, which is regulated by the instructions for them. However, mineral oil should be avoided. In addition to the lubricating effect, engine oil can also be used to remove residues of “biological” lubricant, which not only clogs the oil system, but can also provoke serious damage.

Incredibly, many craftsmen have learned to use waste engine oil and even regular table sunflower oil for chain lubrication. This way out of the situation, although it is economical, since it allows you to reuse the resource, but carries with it many threats to the cutting working mechanisms. So, used car oil can clog the oil filter and pump, which is generally threatened by the prospect of going to a landfill. This increases the load on the motor, often leading to overheating and damage.

Vegetable oil is generally a risky option, which categorically cannot be used for pouring into an oil tank. As a last resort, when acceptable, use to lubricate the outside of the chain.

Of the options offered, the special oil is the best. Experienced experts advise purchasing grease from the same company as the saw itself, but the price of such a product can be overstated by several orders of magnitude compared to universal chain grease, which is a serious competitor to expensive and not always affordable branded counterparts.