What Parts Does A Hacksaw Consist

Integral elements of the door structure

The classical entrance structure assumes the following components:

- Frame;

- Canvas;

- Hinges;

- Seals;

- Lock mechanism and handles.

The first part is the base, the so-called box, to which the sash is movably fixed. If the closing and opening part is metal (made of steel sheets), then the frame will be appropriate (high-strength steel). Boxes are also available in wood or PVC.

The canvas is a movable opening part of the structure. It is made of wood materials, metal, polyvinyl chloride. The front blocks have proven themselves well with a steel sash. It is shock-resistant, durable, and reliably protects your home from illegal entry. Inside it, as a rule, there is insulation.

Loops are responsible for the movable fixation of the canvas. Standard products are split, consisting of a finger, a fist, and two wings. But one-piece models are especially popular, with which the dismantling of the opening part is possible only after unscrewing the hinges from the frame or panel. Includes door and frame parts as well as hinges and bushings.

We also highlight the hidden hinges, installed in niches; corner; screw-in (in the form of two movable cylinders with holes for screws).

The modern entrance system also includes a sealing strip. Provides a high level of tightness when closing the door, made of rubber, silicone, foam or thermoplastic.

Of course, one cannot fail to mention the castle. It is mainly used in two types: lever and cylinder. The solutions are distinguished by an internal secret device. Electronic systems are only gaining popularity.

What parts does the door block consist of: main and additional components

Residential and industrial buildings are impossible to imagine doors. As you know, they are entrance and interior, differ in the material of manufacture, functional purpose, and visual component. These structures are not produced in one piece, they consist of several main parts and minor elements. Which ones?

Hardware that improves the entrance block

Additional products affecting the functionality of the structure. These include:

- Closers. Devices that automatically close the door.

- Stoppers. Compact accessories limiting the movement of the web. Floor-standing, wall-mounted or door-mounted.

- Door chains. An important addition to the locking mechanisms, they do not allow the door to open completely, thereby protecting the owner and the apartment from uninvited guests.

It is also worth adding a peephole to the list. A useful optical device that fits into a through hole in the web. With it, you can observe what is happening on the other side of the door.

Cabinet furniture parts. drawers and shelves.

With the shelves, everything is simple, their size corresponds to the size of the bottom. It is desirable to fasten it to the corners, a furniture dowel dowel or to special holders for shelves. Boxes are a kind of separate design and therefore we will devote a separate topic to them.

In this case, we have considered far from all the details of cabinet furniture, but only the main ones, which I hope will be enough to assemble furniture with our own hands for home and summer cottages.

A table is a piece of furniture that can be found in almost every home and has certain functions. They are used as a surface for cooking and dining, as well as for work or simply an elegant addition to the interior. In addition, they differ in the materials from which they are made and the type of construction.

The form

Depending on the size of the room and the purpose of the table, choose the shape for the piece of furniture. It can be round or oval, square or rectangular. The latter option is the most common. Its laconic shape allows it to be installed along the wall, saving space in the room.

Tables in the shape of a square are designed for small apartments and a small number of people sitting behind it. So, only 4 people can sit at a standard table in the shape of a square. Round and oval shapes also do not imply a large influx of guests. It is best to install them in large rooms.

Varieties of tables

A wide variety of this item can be seen in furniture showrooms today. They differ not only in design and materials, but also in functionality, type of finish, purpose and other features. Each person can choose among a huge number of models, what he will like.

The following types of tables are considered popular:

- dining;

- serving;

- dining room;

- writing;

- magazine;

- toilet;

- computer and others.

IMPORTANT. In addition to the widely used ones, there are also special products for tennis, billiards, models for a telephone, TV or computer on sale. All of them help to organize space and save space in the room.

Part of cabinet furniture. Sidewall.

The length and width of the sidewall determine the height and depth of your table, and if you can experiment with depth, an incorrectly selected table height can make it extremely uncomfortable. Of the design features, it is worth noting the need to cut the corner in the far lower corner of the sidewall, otherwise the table will rest against the plinth, which will not allow you to move the table close to the wall.

History [edit | edit code]

The first mentions of the table as a piece of furniture are found in Ancient Egypt and date back to 2650 BC. eh.

What parts does the table consist of

The table is a piece of furniture [1]. having a raised horizontal or inclined surface intended for placing objects on it and (or) for performing work, eating, playing, drawing, learning and other activities.

Beginning of the Battle for Okinawa told on top of Hacksaw Ridge

Writing or computer desk

A computer desk is usually characterized by a special shelf for the system unit, a sliding table top for placing a keyboard and disk holders. Although this design is becoming less popular today, as compact laptops have already practically supplanted desktop computers.

As a rule, in small-sized apartments there is space for only one of the tables. But in a schoolchild’s room or in the office of the father of the family, you cannot do without this piece of furniture.

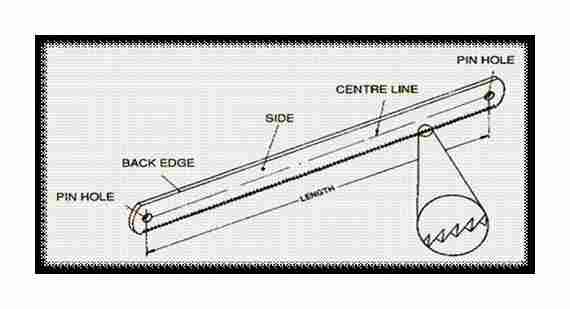

Hacksaw Blade Questions | Pdf file Notes

Style

There are a lot of stylistic and design solutions in salons today. They are all made of different materials and have different functions. Experts insist that the general concept of the design of the room is observed in this piece of furniture as well.

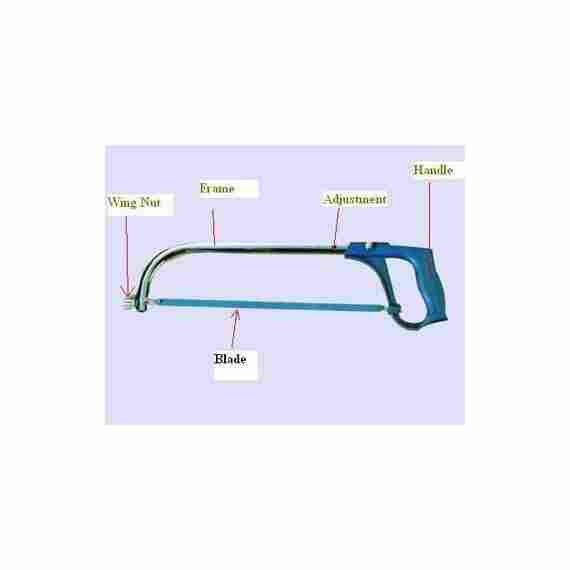

What are the main parts of a hacksaw

Any owner has a minimal set of tools. It is individual for everyone, but everyone has a hacksaw for wood and metal. Its main parts are a handle, a frame, a canvas.

Elements of a hacksaw: what are the main parts

The instrument has become popular also because of its structure. Outwardly, it resembles the letter C, to the ends of which a cutting blade is fixed. This tool contains the following elements:

- A pen. Modern hand saws have handles that are made using two-component materials. This allows for a longer tool life. The shape of the handle is made so that it is very convenient to use it. Usually it is located either at the top or on the side. In the first case, the tool is used to work in places where it is difficult to get close.

- Frame. It takes on the main load. It is she who extinguishes all vibrations that arise during work. Modern hacksaw frames are made from a wide variety of materials. Very often, an element is installed on the tool that regulates the tilt of the blade, which allows you to work in places with difficult access. The frames are made in two versions. They can be solid or have the ability to move apart. It is possible to put a canvas of any length on a sliding frame.

- Canvas. To cut metal, it is made from very hard alloys. It is very thin and fragile. There are many small teeth along the entire length. The work requires special care. You need to buy a canvas that is hardened. If it is not there, then it will fail very quickly. The element with sparse teeth is more efficient. A high-quality cut can be provided only by the one in which the teeth are often located. Recently, bimetallic blades began to appear on sale.

Scope of application of the hacksaw

Tools are made not only by hand, but also electric. Their main task is to cut metal. Naturally, you can make grooves with them, as well as much more. The canvas is made of various materials, therefore, its properties may be different. Not only metal parts can be sawed with a hacksaw. By changing the type of blade, you can cut objects made of plastic, ceramic or plexiglass. Among the entire range of hacksaws, there are three main types:

- For household use. Such models are the most common. They are ideal if you need to do something that is not very difficult. It is very easy to use them. To fix it, you need to insert it into the grooves and tighten the special screws. The main thing is to remember that the canvas should be well stretched so as not to damage it during operation. Such hacksaws are much cheaper than the others.

- Hand tools are also of a professional type. They are used when you have to work for a long time, and the cut must be clean and even. A feature of such tools is a convenient handle, as well as a quick-change mechanism for the saw element. If you need to cut something very often, then it is better to use just such models.

- Hacksaw handle. The appearance of this tool resembles a staple. They do not need to have great physical strength to work. They use it exclusively where it is simply impossible to crawl with the usual variety. Due to its design, it is permissible to install broken blades in a locksaw.

Features of using a hacksaw

To work the tool comfortably, you need to stand in front of the vice with a half-side. The left leg should be in front. It is she who is the supporting one. The handle rests on the palm of the right hand, with the thumb it is held on top, and the rest is wrapped around the bottom. Place your left hand on the front end of the hacksaw.

When working with a saw, it is usually held horizontally. The movements are smooth, you should not pull. The scope of the tool is needed such that the entire length of the blade takes part in the process. As a rule, two-thirds of the length is involved in the working rhythm.

Typical hacksaw speeds are up to sixty strokes per minute. Moving is meant moving forward and backward. At the same time, when working with hard metals, the speed decreases, and soft ones are cut faster.

When the hacksaw goes forward, it should be pressed on, it comes back easily. Its strength should match the hardness of the metal under the saw blade. The harder it is, the more pressure is needed. Under normal conditions, 0.1 millimeter of the thickness of the web has a pressure of one kilogram. At the end of the process, when the part is almost cut, the pressure should be loosened.

Hand tools, as a rule, do not need cooling after work. To reduce friction, grease is applied to the cut.

If the blade is not tight enough, the tool is often pulled to the side. This can negatively affect not only the evenness of the saw cut, but also the integrity of the cutting element itself. If this happens, it is best to back off and start a new cut. If you try to fix a cut that has gone to the side, it will lead to damage.

Incorrect hardening of the hacksaw blade contributes to tooth breakage. This can happen if the tool is pressed very hard or the metal is interspersed with harder particles.

If even one of the teeth breaks, it is better to immediately change the blade, because others will break behind it. You can use the old one, but then it will need to be restored first. To do this, the nearest teeth are ground near the broken tooth. It will be enough to grind off two or three. After this procedure, you can use the canvas again.

Motor operation

To better understand the principle of operation, you need to disassemble in detail what a car engine consists of.

The body is the cylinder block. Inside it there are channels that cool and lubricate the motor.

The piston is nothing more than a hollow metal cup, at the top of which are the grooves of the rings.

The piston rings located at the bottom are oil scraper rings, and at the top are compression rings. The latter provide good compression and compression of the air-fuel mixture. They are used both to achieve the tightness of the combustion chamber and as seals to prevent oil from entering there.

The crank mechanism is responsible for the reciprocating energy of the piston movement to the crankshaft.

So, understanding what the car consists of, in particular, its engine, let’s figure out the principle of operation. Fuel first enters the combustion chamber, mixes there with air, the spark plug (in petrol and gas versions) gives off a spark, igniting the mixture, or the mixture ignites itself (in the diesel version) under the influence of pressure and temperature. The gases formed cause the piston to move downward, transmitting motion to the crankshaft, which causes it to rotate the transmission, where the movement is transmitted to the wheels of the front, rear axle, or both, depending on the drive. A little later, we will also touch on what a car wheel consists of. But first things first.

ICE: types

Anyone understands that malfunctions in the operation of the motor can become dangerous to the health and life of people. Therefore, it is vital to know what a car engine consists of.

Translated from Latin, the motor means “driving”. In a machine, it is understood as a device that is designed to convert one type of energy into mechanical.

- gasoline;

- diesel;

- gas.

Most used petrol and diesel options.

In the first case, as the name implies, gasoline serves as fuel. After passing through a special system, it enters the intake manifold or carburetor. Then the mixture sprayed there, containing already air particles, enters the cylinders, compresses from the pistons and is ignited by the spark from the spark plugs.

Gasoline engines are of the carburetor and injection types. The first is almost never used. Injection systems of motors are, in turn, mechanical (in which mechanical levers are used as a dispenser, which can regulate the resulting mixture) and electronic (where the composition and injection of fuel is completely carried out by an ECU. an electronic control unit). Since the injector works more thoroughly, its combustion products are less harmful than carburetor ones.

For diesel engines, special diesel fuel is used. This engine does not have an ignition system: when the fuel mixture enters the cylinders, it explodes on its own due to the high temperatures and pressure obtained by the piston group.

Gas engines run on liquefied, compressed gas generator. Such fuel is stored in cylinders, from where it enters the gearbox through the evaporator and loses pressure in the process. The further process is similar to the injection motor. Sometimes, however, the evaporator is not used.

Operation of transmission parts

The clutch serves to disconnect the gearbox (GB) from the engine, then smoothly connect them when shifting gears and when starting off.

The gearbox changes the torque transmitted from the crankshaft to the propeller shaft. The gearbox block disconnects the connection of the motor with the cardan gear as much as it is necessary for the car to move in reverse.

The main function of the cardan drive is to transfer torque from the gearbox to the main gear at different angles.

The main function of the main gear is to transmit torque at an angle of ninety degrees from the propeller shaft through the differential to the drive shafts of the main wheels.

Differential rotates the drive wheels at different speeds when cornering and on uneven surfaces.

Chassis

The chassis of the car consists of a frame, front and rear axles, which are connected to the frame through the suspension. In most modern passenger cars, the frame is a monocoque body. The elements that make up the car suspension are as follows:

- springs;

- cylinder springs;

- shock absorbers;

- pneumatic cylinders.

Transmission

Above, we found out what the car consists of, and we know that the chassis includes the transmission, chassis and control mechanism.

The following elements stand out in the transmission:

- Transmission;

- clutch;

- main and cardan transmission;

- differential;

- drive shafts.

What the car consists of: diagram and description

There are drivers who drive their cars, but do not know at all what the car consists of. It may not be necessary to know all the intricacies of the complex operation of the mechanism, but the main points should still be known to everyone. After all, the life of both the driver himself and other people can depend on this. At its core, in a simplified form, machines consist of three parts:

- engine;

- chassis;

- body.

In the article, we will take a closer look at what parts the car consists of and how they affect the operation of the vehicle as a whole.

What the car consists of: diagram

The device of the car can be represented as follows.

In the overwhelming majority of cases, the machines are equipped with internal combustion engines. Since they are not ideal, developments have been and are being carried out on the invention of new motors. So, recently, cars with electric motors have been put into operation, for which a regular outlet is enough to charge. The Tesla electric car is widely known. However, it is certainly too early to talk about the wide distribution of such machines.

The chassis, in turn, consists of:

- transmission or power train;

- running gear;

- vehicle control mechanism.

The body is designed to accommodate passengers in the car and move comfortably. The main types of body today are:

- sedan;

- hatchback;

- cabriolet;

- station wagon;

- limousine;

- other.

What the automatic transmission consists of?

Torque converter. similar to the clutch in the mechanical box, but does not require direct control by the driver.

2. Planetary row. similar to a block of gears in a mechanical box and changes the relative ratio in the machine when shifting gears.

3. Brake band, rear clutch, front clutch. they serve for direct gear shifting.

4. The control device is a whole assembly consisting of a gear pump, valve box and oil sump. The valve plate (valve body) is a system of channels with valves (solenoids) and plungers that perform control and management functions, and also converts engine load, degree of accelerator depression and travel speed into hydraulic signals. Based on such signals, due to sequential switching on and out of the operating state of the friction blocks, the gear ratios are automatically changed.

Torque converter Planetary series

Brake Band Clutch Packs

Torque converter. designed to transfer torque from the engine to the automatic transmission components. It is installed in a casing located between the box and the engine, performing clutch functions. Filled with working fluid during operation, it carries high loads while rotating at a fairly high speed. By absorbing and smoothing engine vibrations and transmitting torque, it drives the oil pump, which is located in the gearbox.

The oil pump, in turn, fills the torque converter with transmission fluid, thereby creating the required pressure in the monitoring and control system. Therefore, the opinion that a car with an automatic machine can be forced to start without a starter by accelerating it to high speed is erroneous. The gear pump receives energy only from the engine; when the engine is not running, there is no pressure in the monitoring and control system, regardless of what position the gearshift lever is in. Therefore, the rotation of the propeller shaft will not forcibly force the box to work, and the engine will not start.

Planetary gear. unlike “mechanics”, where gears and parallel shafts intermeshing with each other, planetary gears are mainly used in “automatic machines”.

Components of the clutch. the piston is set in motion by oil pressure. The piston, moving under oil pressure, by means of a conical disk (dished plate) presses the packages very tightly driven to the driving discs, from which they rotate as a whole and transfer torque from the drum to the bushing. Several planetary gears, providing the required gear ratios, are located in the gearbox housing.

The transmission of torque from the engine through the planetary mechanisms directly to the wheels is carried out using friction discs, a differential and other service devices. By means of transmission fluid through the monitoring and control system, all listed devices are controlled.

Brake band. a device through which the elements of the planetary gear are locked.

Hydroblock. the most complex mechanism in an automatic box. As we wrote above, these are the brains of the transmission. Most expensive part to repair.

Automatic transmission device Video

How does automatic transmission work? Automatic transmission device | Operation and examples

This is partly true, but knowing the design features of the automatic transmission and the principle of its operation, you initially extend the life of your transmission. In this article, we would like to tell you about the basic mechanisms and principles of operation of an automatic transmission.

Types of automatic transmission | Comparison with mechanics | Advantages and disadvantages

The constant improvement in the quality of operation of a modern vehicle has inevitably led to a noticeable structural complication. The equipment of the car with an automatic gearbox had a favorable effect on the engine, speed qualities and chassis, which also made it possible to partially ease the load on the driver in motion. Due to its ease of operation and reliability, the use of this invention has found widespread use.

In our time, automatic transmissions are widely used both in passenger cars and four-wheel drive cars, and on trucks. A driver in a car with a manual gearbox, in order to move at the desired speed, needs to “jerk” the gear lever quite often, and he must independently monitor the speed and load. Using an automatic gearbox eliminates these needs.

There are clear advantages of the machine over mechanics, such as:

- The driving comfort is increased;

- Automatic gearshifts are made smoothly;

- The chassis and the engine protect against overloads;

- Both automatic and manual gear shifting possible.

Automatic transmissions used today are conventionally divided into two types. These types differ mainly in the control and management systems for the use of the transmission.

- In the first type of automatic transmission, control and monitoring is carried out by a certain hydraulic device.

- The same function in the automatic transmission of the second type is performed by an electronic device. Robotic boxes.

Here are some very specific examples:

Suppose a car is moving along a flat section of the road, a section with a steep rise. For a while, we do not touch the accelerator pedal and observe the reaction of the torque converter when driving conditions change. As the load on the drive wheels increases, the vehicle loses speed. As a result, the turbine speed drops. This affects the counteraction to the movement of working fluids inside the torque converter. From which the circulation speed increases, this automatically increases the torque on the shaft of the turbine wheel until an equilibrium occurs between it and the moment of resistance to motion.

This is exactly how the automatic machine works when starting off. Only now is the time to engage the accelerator. after that, the crankshaft speed increases and the pump wheel also increases, and the car and the turbine were stationary, but slipping inside the torque converter did not prevent the engine from idling. In this case, the torque is transformed in the maximum number of times. But once the required speed is reached, the torque conversion becomes unnecessary. With the help of an automatically acting lock, the torque converter is transformed into a link that rigidly connects the driven and driven shafts. With such a blocking, internal losses are eliminated, the value of the transfer efficiency increases, while in this driving mode, fuel consumption decreases and the efficiency of engine braking during deceleration increases.

The reactor is freed and rotated with turbine and impeller wheels to reduce all the same losses.

For what purpose is the gearbox connected to the torque converter, when it independently, depending on the loads on the driving wheels, can change the torque?

The torque converter is capable of changing the torque with a coefficient of 2-3.5 not more. And for the effective operation of the transmission, such ranges of change in the gear ratios are clearly insufficient. Also, sometimes it becomes necessary to engage reverse gear or neutral. Automatic gearboxes with gearing still differ in many ways from mechanical gearboxes, for example, they switch gears without interrupting the power flow using multi-disc friction clutches driven by hydraulics and band brakes. Depending on the speed of the car and the intensity of pressing the accelerator pedal, the desired gear is automatically selected, it then determines the intensity of acceleration.

Determines the required gear electronic and hydraulic automatic transmission control units. The driver, in addition to pressing the gas pedal, can select sports or winter modes (such automatic transmission modes have an individual gear shift algorithm), and can also select a mode that helps to move along sections of path with difficult terrain (in this mode, the machine will not be able to switch above a certain gear).

In addition to the planetary gear and the torque converter, the automatic transmission also includes a pump supplying the valve body with a torque converter with working fluid and lubricating the box, and cools the working fluid, which tends to overheat, the automatic transmission cooling radiator included in the automatic transmission.

What is automatic transmission?

An automatic gearbox is an important structural element of a vehicle transmission, which serves to change the torque, direction, and speed of the vehicle. and for long-term separation of the engine from the transmission. Distinguish between stepless (CVT), stepped (Hydro-automatic) and combined gearboxes (robotic gearboxes of the “DSG” type).

It is no secret that the transmission has a major impact on vehicle dynamics. Manufacturers are constantly testing and implementing the latest technology in our vehicles. Nevertheless, most motorists prefer to operate cars with a manual transmission, as they believe that the latter brings much less headache. This is partly true, but knowing the design features of the automatic transmission and the principle of its operation, you initially extend the life of your transmission. In this article, we would like to tell you about the basic mechanisms and principles of operation of an automatic transmission.

What is better manual transmission or automatic transmission

As a rule, our domestic motorist treats automatic transmissions with certain prejudices. Apparently the reason for this is our chronic reluctance to shift our problem onto others’ shoulders and an attempt to eliminate it on our own. For example, the Americans, and it was they who invented the automatic transmission, do not suffer from this. In America, manual gearboxes are not very popular and only 5% of American motorists out of a hundred use mechanics. The popularity of automatic transmissions in Europe is growing from year to year at an enormous pace. Of course, there are fans of the machine among our compatriots, but not everyone is able to use them correctly. According to auto mechanics, it is the untimely technical. maintenance and misuse is often the root cause of all automatic transmission malfunctions.

The turbine with the pump are as close as possible, and their wheels have a shape that provides a continuous circle of circulation of working fluids. It is due to this that the torque converter has minimal overall dimensions and minimal energy losses during fluid flow from the pump to the turbine. The engine crankshaft is connected to the impeller, and the gearbox shaft is connected to the turbine. In view of this, there is no rigid connection between the driven and driving elements in the torque converter, the streams of working fluids transfer energy from the engine to the transmission, which is thrown from the pump blades onto the turbine blades.

How does automatic transmission work?

Fluid coupling and torque converter

As a matter of fact, the fluid coupling works according to the same scheme, without transforming its value, it transmits torque. The reactor is inserted into the construction of the torque converter to change the moment. In principle, this is the same wheel with blades only rigidly mounted on the body and not rotating until a certain time. A reactor is located on the path along which the oil from the turbine returns to the pump. The blades of the reactor have a special profile, the interscapular channels gradually narrow. Due to this, the speed of the working fluids flowing through the channels of the guide vane gradually increases, and the liquid ejected in the direction of rotation of the impeller from the reactor urges and pushes it.

How does automatic transmission work??

In order to understand the principle of operation of an automatic transmission. we will conditionally divide it into three parts: hydraulic, electronic and mechanical. As you might guess, the mechanical part is directly responsible for gear shifting. The hydraulic transmits torque and creates an impact on the mechanical. Electronic. it is the brain that is responsible for switching modes (selector) and feedback to vehicle systems.

As you know, the heart of the car is the engine, in the case of a gearbox this is just as appropriate. The transmission must convert the power and torque of the engine in such a way as to provide the necessary conditions for the movement of the vehicle. Most of this heavy work is done by the torque converter (aka “donut”) and planetary gears.

The torque converter, depending on the speed of the wheels and the load, changes the torque automatically and performs the functions of a clutch (as in a manual box). In turn, the torque converter consists of a pair of vane machines. centripetal turbine and centrifugal pump, as well as between them there is a guide vane-reactor.

Differences in the device of automatic transmission of rear-wheel drive and front-wheel drive cars

There are also several differences in the design and layout of automatic transmissions for rear-wheel drive and front-wheel drive vehicles. In front-wheel drive vehicles, the automatic transmission is more compact and has a main gear compartment inside the body, i.e. a differential. Otherwise, the functions and principles of operation of all automatic transmissions are the same. To ensure movement and performance of all functions, the automatic transmission is equipped with such units as: a torque converter, a control and monitoring unit, a gearbox and a mechanism for selecting a driving mode.

Rear wheel drive vehicle Front wheel drive vehicle

The construction of a plastic window. what parts it consists of?

Very often our clients are interested in what is a PVC window made of? In this article, we will give a detailed description of the design and answer this question.

Profile

The PVC window consists primarily of a plastic profile. This is the main part of the entire structure, that is, the base where the glass unit is inserted. What parts are included in it? This element includes air chambers, which provide the required thermal insulation. The temperature inside the room is determined by the number of air chambers. The profile means the plastic frame itself, as well as PVC window sashes.

The final price depends on the brand and type of profile. Currently, the most popular are plastic profiles of the following brands: Rehau, KBE, Novotex, Salamander. When choosing, the characteristics of the premises and the financial capabilities of the client are taken into account.

Fittings

The window frame opens and closes thanks to the hardware. In this case, there are also various options, taking into account the materials used, technologies, manufacturers.

The fittings are used in the moving parts of the windows, therefore they are divided into swing and swing-out. The handles installed on the inside of the frame also belong to the hardware.

In our work, we give preference to certain brands that have proven reliability and high quality over the years.

Window sills

They consist of a window sill profile that is attached to the bottom of the frame. From the outside, an ebb is fixed to it, from the inside. a window sill.

mosquito net

It is an aluminum base on which a special anti-mosquito cloth is stretched. In regions with an abundance of flies or mosquitoes, such an accessory is necessary.

Composition

Each part included in this design, one way or another, affects the cost. Therefore, the purpose of describing the features of a glass unit is not only to determine the constituent components, but also to help in choosing.

Reinforcement

This is a special metal frame that prevents deformation and prevents crushing of the structure. The thicker the metal is used, the stronger the entire element.

Vehicle structure

But it so happened that one engine does not go far. The machine is a complex structure that can be conditionally divided into components:

- Body, replacement frame. This is the base on which all the components of the car are attached.

- Chassis or undercarriage. The chassis, as a rule, means a broader concept that includes both the transmission and even the control mechanism.

- Actually engine, which transmits movement to the chassis by burning hydrocarbons. The principle was developed a hundred and fifty years ago, but nothing has changed fundamentally since then.

- Electronics. But this is a fundamentally new part, which greatly simplifies driving and makes travel safer.

We cannot see in any way:

- Pendants.

- Shock absorbers.

- Brake system.

- Springs.

- Front and rear axle.

- Clutch.

- Cardan.

But without all of these components, no car will budge. They provide the redistribution of energy, regulate the driving process. To start, turn or brake correctly, it is necessary to act on the entire system through its individual parts. Knowing their structure and mechanism of action, you can very quickly and fairly accurately calculate the possible options and consequences of your actions.

Having traveled for at least several years and having visited a car repair shop a couple of times, willy-nilly remember what the car consists of and how it looks from the inside. In this matter, as in many others, experience is paramount.

What does a washing machine consist of??

Before considering vehicles, you should familiarize yourself with the device of a simpler technique. There is a washing machine in every home today; without it, any housewife would spend much more time on a banal wash.

The life of a modern person is simplified due to the simple details of the automatic washing machine:

- Electronic control systems.

- Powder and gel dispenser.

- Washing machine door lock.

- Rubber interlayer for tightness.

- Drum with counterweights that regulate the spinning process and prevent the “crazy machine” from getting out of control and starting to jump.

- Drum belt with fixing and supporting functions.

- Drum motor, a motor is always needed for movement. Even though it looks like a tautology.

- The tank into which water is pumped for washing.

- Pump pump and drain hose.

- Heating element.

The number of components depends on the model and year of production, the list is not complete just above. But the main mechanisms, without which the operation of the washing machine would be impossible, are given.

What does a car engine consist of??

And now we come close to discussing motor transport. The heart of any car, and any other means of transportation, is its engine.

Engine structure

Principle of operation

Combustion chamber, nozzles and pipes.

Fuel enters the chamber on one side, and air on the other. Under the influence of a spark, this mixture ignites, micro-explosions occur.

Due to the energy released during the explosions, it performs translational movements, transferring energy to the connecting rod mechanism.

Serves to transfer energy even further. to the crankshaft, and then to the transmission.

In addition, the engine includes many cylinders, the main task of which is to create the engine frame, provide all working parts with lubricant and the proper level of cooling. You may not know much about the function of piston rings and other little things, only the main thing is that they prevent depressurization of the combustion chamber, protect it from the ingress of engine oil.

What is a dishwasher made of??

The dishwasher is even simpler:

- The front wall, which we will open to lay or get the dishes.

- Control system in the form of an electronic unit. It is mounted on the front wall and allows you to set and change the washing program with a couple of keystrokes.

- The air path provides a constant flow of air, which is necessary for drying dishes that have already been washed. Without exposure to air, in sealed conditions, serious problems can arise with this process.

- Dish baskets. Their number and size depend on the volume of the dishwasher.

- Rocker arms through which water is supplied for washing.

- Discharge pump that acts on the pressure inside the machine and ensures optimal water atomization.

- Heating element that maintains the temperature at the required level.

- Drainage pump.

- Special filter.

- Ion exchanger.

The history of the car

For thousands of years, people moved exclusively with the help of manpower. either on their own or on horseback. In this regard, cars have become a real revolution, it is because of them that the traditions of cavalry, cabbies in carriages and stables in every country house have sunk into oblivion. If in the century before last all this was an integral part of culture, then today the horse has become an “exotic” animal. Her appearance on the streets of the city causes surprise and bewilderment.

The first cars were preceded by steam locomotives, which largely determined the direction of transport development. Some of the inventors have a question: “If a steam locomotive can travel thousands of kilometers on the road, why not try to make miniature versions that can travel on roads.?”. And everyone rushed to implement the idea.

Collection of answers to your questions

- The history of the car

- What does a washing machine consist of??

- What is a dishwasher made of??

- What does a car engine consist of??

- Vehicle structure

- Video about the main components of the car

It is not necessary to be perfectly technical and know what a car is made of to learn to drive. In fact, it is very useful to understand the essence of the processes taking place under the hood, but all this information may be needed only in emergency and extraordinary situations. During ordinary city trips, not every driver will think about the role of the transmission in the transmission of energy and rotation.