What to saw Cement-bonded particleboard at home

The main technical characteristics of cement-bonded particleboard

To understand how to mount the cement-bonded particleboard on the facade of a country house and what it can be finished with, it is necessary to understand what this material is. The composition of cement-bonded particleboard consists of: cement (binder, about 65%), wood chips (24%), water (needed for hydration of the mixture) and special mineral additives. The mixture is molded at the factory by pressing and, as a result, the output is slabs of strictly defined geometry and thickness.

Among the advantages of cement-bonded particleboard, for example, as compared with OSB (oriented strand board), we should mention its fire safety (combustibility group cement-bonded particleboard G1, flammability group B1, slow-burning material). Also the cement-bonded particleboard does not spread the flame and has a low smoke-forming capacity. The cement-bonded particleboard is an environmentally friendly material.к. it does not contain phenol adhesives and harmful chemicals. cement-bonded particleboards are highly durable, do not rot, are resistant to moisture and harmful atmospheric influences.

All of the above properties open up wide possibilities for the use of this material, for example, as a sheathing for frame walls, the construction of interior partitions, flooring, creating formwork for pouring foundations, etc.д. But a change in the moisture level (even if only slight) leads to a change in the linear geometry of the board. That’s why when installing the particle board on the facade of a country house an expansion gap (4 to 8 mm) should be left between the boards.

Beginner builders also have a question if the boards will not warp when exposed to moisture. After all, cement-bonded particleboard “works” on the facade, and any compression or stretching of the boards will affect the finish coat.

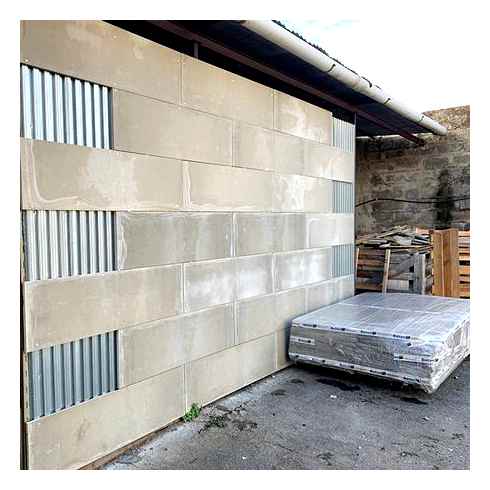

I clad the frame house with 10 mm thick cement-bonded particleboard. Measured the width of the gap between the sheets throughout the year. It hasn’t changed a millimeter. In the future, I will finish the facade under the framework with imitation of fiber-cement siding on the walls. Quite a budget option.

The moisture resistance of the cement-bonded particleboard is verified by portal member Nagel_Johansson. According to the user, he clad a frame house with cement-bonded particleboards. There was no exterior finish, and it rained on the corner of the facade for two days and got wet snow. If you run your hand over the outer surface of the board, it’s wet and seems to be soaked through. Nagel_Johansson checked the cladding from inside the house, it was dry, without any water stains and stains.

How to saw a cement-bonded particleboard at home

The structure and composition of the material impose restrictions on work with the boards.Its high mass makes it impossible to work without an assistant. Unloading should preferably be done mechanized or with 2-3 helpers.

Fragility Cement-bonded particleboard causes the board to break when accidentally dropped. Additional work and consumables are required to finish a broken sheet.

High density makes the sheets strong, but the cutting tools are not suitable for wooden products.

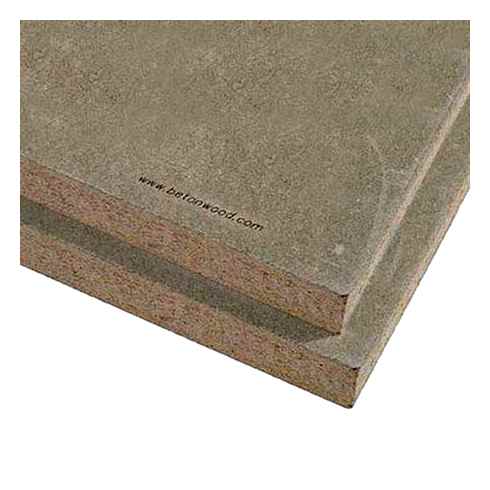

Cement Bonded Particle Board BetonWood

Lack of bending strength does not allow the use of cement-bonded particleboard in structures with lateral loads, such as making sloping walls without support.

The boards are not suitable for horizontal positioning, they may break under their own weight. Stacking products on a flat base.

Dusty sawing involves, if possible, working in an open space with the use of personal protective equipment. respirators and goggles.

High coefficient of thermal expansion forces to leave gaps at the joints and adjacencies of particle board to the walls. Cement and hard fillers are not used for caulking.

How to saw a cement-bonded particleboard at home

The structure and composition of the material impose restrictions on work with the boards.The large mass does not allow you to work without an assistant. Unloading should preferably be done mechanized or involve 2-3 helpers.

Fragility Cement-bonded particleboard leads to the destruction of the board by accidental falls. Additional work and consumables are required to finish the broken board.

High density makes the sheets strong, but the cutting tools are not suitable for wooden products.

Insufficient bending strength does not allow the use of cement-bonded particleboard in structures with lateral loads, such as making sloping walls without support.

The boards can not stand horizontally, they may break under their own weight. Products are stacked on a flat base.

Dustiness in sawing involves, if possible, work in an open space with the use of personal protective equipment. respirators and safety glasses.

High coefficient of thermal expansion forces to leave gaps at the joints and abutments Cement-bonded particleboard to the walls. Cement and hard fillers do not seal the joints.

Features of manufacturing and the main advantages of this group of products

As you can understand from the name, the basis of manufacture is cement and shavings, let’s consider the composition in a little more detail:

- High quality Portland cement of M-500 grade and above occupies 65% of the volume of the finished product. This gives the sheets the highest strength and resistance to loads, it is important to use only high-quality cement.

- About 24 percent is wood chips, which are passed through special grinders that separate them into pieces 3 to 5 millimeters wide and 20 centimeters or more in length. This component gives the product high acoustic and thermal insulation properties, in addition. wood is a renewable eco-friendly natural material.

- About 2.5% is occupied by liquid glass, which is used for timber treatment and gives it high resistance to moisture and mold. Without such a treatment the wood in the composition would soon begin to deteriorate.

- And finally, about 8.5% is water. As you know, moisture is in all materials and particleboard is no exception.

Such boards are not afraid of moisture, temperature fluctuations, mold, chemical influences and therefore are used for the widest range of works:

- Finishing of facades of frame structures. the sheets are not afraid of high humidity and low temperatures, and thus will serve as reliable protection of the building from adverse natural influences.

In the photo. cladding the house with cement-bonded particleboard allows you to work as quickly as possible

- These sheets are an excellent option for repairing old facades, constructing partitions, cladding walls and ceilings, flooring, and much more. A truly universal material that can be used almost anywhere.

Cement-bonded particleboard is an excellent substrate for any floor covering

- The material perfectly resists both low and high temperatures, so it is used for lining ventilation ducts, chimneys, various surfaces exposed to chemical influences.

Important! The material has been tested, and its safety for human health has been confirmed both at home and abroad: in the European Union, the United States, and so on.

How to saw laminated Chipboard, Laminated Chipboard without chipping? How to fix chips after sawing?

In the manufacture of furniture has to saw Laminated chipboard. Laminated chipboard doesn’t like it very much. Crumbling. Chips form around the edge. How to saw Laminated Particle Board without chipping or to fill in chips? (10)

Please tell me how to saw laminated chipboard, laminated chipboard without chips?

When making furniture, you have to saw through the edge of the Laminate Chipboard. Laminated chipboard doesn’t like it very much. Crumbles. Chipping along the edges. How to saw laminated chipboard without splitting or chipping?

Unfortunately I have never been able to edge saw the edge of the Laminate Chipboard nicely. Of course, if the laminated chipboard is planned for painting, the edge can be putty, sanded, the board itself to cover the alkyd primer, the edge of the glue with construction bandage with ingress on the laminated surface of the edge, putty with construction bandage, sanded and painted. You get a perfect edge. Read more about edging Particleboard for painting

But if you intend to use laminated chipboard in a painted finish, this is not the right method. You have to saw so there’s no chipping. It’s hard to make a chamfer-free cut without the right equipment. Not only does the circular saw crumble the edge, but it can also split the laminating surface half a meter along the board. And any other tool gives an even worse edge.

Rumor has it that Laminated chipboard can be sawn without chipping with a metal saw with a very fine tooth, or even a jigsaw with a metal saw with a very fine tooth. But I can’t do it.

I saw Laminated chipboard if I want a good edge, like this: I mark it so it doesn’t splinter. I will run a miter saw on which to saw. I put a metal ruler along the mowing line. Secure it with clamps. Using the cutter, I cut through the laminate coating along the lines I intend to cut. The cut is made quite deep and wide (a little wider than the width of a hacksaw or circular saw blade). Slide the cutter along the iron ruler several times until the coating is completely cut. I do this on both sides

It is very important to mark correctly so that the marking at the top and the marking at the bottom coincide. After that I already saw, usually, with a hand saw on wood

But already got the knack of getting into the kerf with a circular saw.

Unfortunately, the articles occasionally encounter mistakes, they are corrected, the articles are complemented, developed, new ones are prepared. Sign up for the newsletter to stay up to date.

If something is not clear, be sure to ask!Ask a question. Discussion of the article.

Why is a wood floor squeaking? My practical experience in the struggle with the creaking floor. And some advice from the old-timers. How to cut off.

Why concrete crumbles, cracks, crumbles in foundations, walkways. Poured in the summer road and the foundation. After the winter we can see serious damage, observed.

Dresser, chest of drawers with their own hands. We make, we make ourselves. Self. Making a dresser, drawer of the right size from particle board. The chest of drawers will n.

Assembling linings with their own hands. How to decorate with linings that look beautiful and professional. Practical Experience.

How to pour a foundation? Let’s make the foundation ourselves, with our own hands. Tips for pouring a foundation briefly. Planning. Marking. Pouring. Insulation.

Heating with coal, experience. Experience of coal heating. Warm, comfortable, but troublesome. The comfort and safety of coal.

Self-tapping wood, metal, chipboard, fiberboard, plastic, brick. How to fix with self-tapping screws. Screwing screws in various materials, wood, m.

Sawing methods Laminated chipboard without chips

Sawing can be done on a panel saw. But its. If you need to saw Laminated Chipboard to make a few pieces of furniture for yourself, other methods are more suitable.

Circular saw

A fine-toothed saw blade is required. Long, straight cuts are better with this method than with the jigsaw. No splintering on the side where the teeth are cut into the board. If they appear, then on the opposite side, as with the jigsaw.

The use of guides increases the accuracy of the cut. It is a good idea to secure the saw to the table when doing this.

How to saw a cement-bonded particleboard panel? If there is no desire to make holes in the cement-bonded particleboard, then the coatings should be fixed solely with self-tapping screws. In terms of strength, they are better than chipboard, but they can be worked with similar devices. Cement-bonded particleboard how to saw? As a professional treatment, you should use appliances, cutting coatings made of hard alloys. The panel can be cut to size as required by the customer in the factory. If it is necessary to cut the coating at the plant site, it is advisable to use cutting tools with carbide inserts.

Important! The extraction of dust and sawdust from the milling area must be considered in advance. Cement-bonded particleboards have a smooth and even surface, so there is no need to sand them in the factory. Furthermore, this cutting of the entire surface of the panel depicts the coating and the structure of the panel is exposed. This contributes to an increase in water absorption, and subsequently a decrease in physical and mechanical properties.

Required equipment and materials

Cement-bonded particleboard than to saw? First of all, thanks to the large weight the sound will not cause resonance of the board weighing 50-70 kg. Products are easy to break. Cutting models of great lengths would be tiring. Slabs should be cut with an angle grinder that has a cutting wheel for concrete or stone. Cement-bonded particleboard is in fact a layer of concrete, only thin and with a slight addition of wood. Often, in the form of coating the outside of the curtain-type ventilated facade insulation is used.

Sawing methods

Cement-bonded particleboard what to saw? Suitable ways of sawing cement-bonded particleboard involve the use of:

How to saw a cement-bonded particleboard board without chipping? It is important to treat the edges immediately when installing and use protection products. Installation of cement-bonded particleboards often involves a lot of holes for fixing. It is better to do these steps with a drill with a torque of the order of 220 revolutions per 60 seconds. In addition, you will need drills for working with steel or a portable drilling machine that has tungsten drills.