What wood router bits for

Groove cutter and its design parameters

Category of cutter bits that serve for selecting grooves of desired width and depth. Sampling is done in the middle of the part, as well as from the edge or toward the center. By the design of the cutter stop, the width of the resulting slot can be adjusted accordingly, and it is not necessary to install new cutters in the drive tool chuck.

Slot cutters are divided into their respective types:

- Gallettes narrow specialty nozzle for making semicircular shapes

- Tapered units used for tapping on flat surfaces

- Spiral cutters have similarities with end pieces, but their main difference is that they have a more pronounced design of the cutting part, which is on the outer side. Structurally, helical cutters are similar to drills, but they cannot drill holes

- Shaped

- T-slots are used for making grooves of corresponding shapes and types

- Devices called dovetails

- Combined

- Slotted straight type nozzles, which allow obtaining slots with rectangular cross-sections

Copy cutters, also called straight cutters, belong to the category of small bits used in hand-held milling machines. They have distinctive features in such characteristics:

The bearing plays an important role in nozzle design, as it enables the cutter to move smoothly and efficiently across the work surface, resulting in a groove with the appropriate configuration.

The head of the pebble cutters has a rounded appearance, so the resulting grooves are U-shaped. Servers are used to obtain semicircular recesses, and to provide different angles of inclination of the walls, it is necessary to use nozzles of different configurations.

How to work with a wood router. techniques, tips and examples of products

People who have no experience with woodworking machines do not understand how to work with a wood router: the techniques, tips, devices recommended by experts will help them. The knowledge will allow you to master this difficult task at home. Gradually, the young craftsman will learn how to cut patterns on the material, perform engraving, apply carving, cut straight and spiral grooves. Below you can read the information regarding what you can do with a wood router at home and the basic rules for working with the tool.

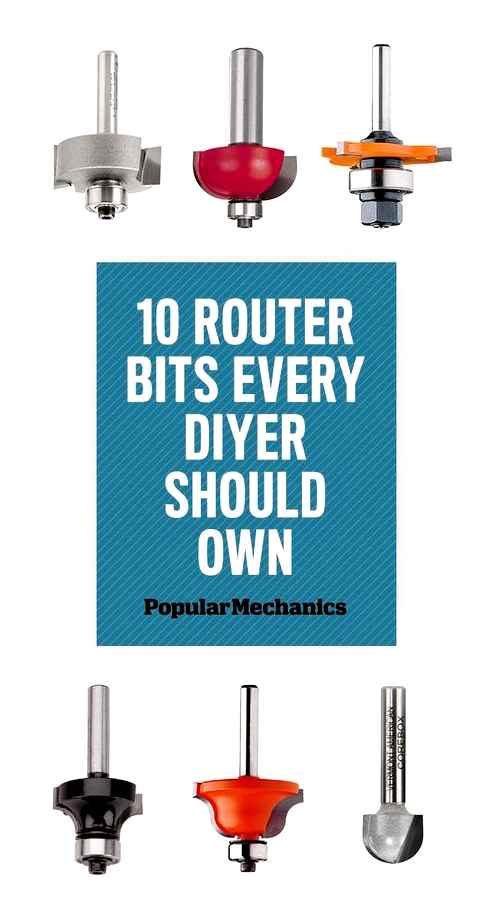

Mill bits

End milling cutters. designed for roughing the edges of products. Equipped with a bearing as a guide, allowing the cutter to make a pass at the same depth. Spiral end milling cutters also include.

Flush-face grooving. for routing a rectangular groove in the wood. Without stop, it is very difficult to work with such mill, so it is used together with a template.

V-notches. allow you to choose rounded and V-grooves along the length of the product. By adjusting the cutter position, it is possible to make grooves of different depths. V-groove cutter makes it possible to produce a groove whose walls are at right angles to each other.

V-shaped cutter with inverted cone. designed for dovetail slotting. This groove is used for reliable dovetailing of parts between each other.

Tapered. for edge banding, for decorative purposes or by virtue of its design features. Equipped with a bearing as a stop.

Cone cutter. just like a cone cutter, it is equipped with a stop and designed for processing the edges of the product, but the resulting edge has a rounded shape, and at the maximum lowering of the cutter, you can also get a straight line on the edge.

Rectangular groove milling cutters for rectangular grooves in door and window frames. In some cases, the bevel is selected in several passes, depending on the material to be milled.

Disk milling cutters are used for slotting, the working part of the cutter is not only the edge, but also its entire peripheral surface. Suitable for drilling deep and narrow grooves, e.g., under glass or organic board.

Combination cutters are used to perform two or more functions in one pass, for example, grooving and beveling.

Although these routers are made with the expectation that they will work with wood, but in principle they also allow you to work with plywood, plasterboard, oriented chipboard, particle board and some other materials.

Device

The production of manual edge trimmers (or, otherwise. trimmers) are engaged in several popular brands in this segment. DeWALT, Makita, Virutex, but the basic device of the considered power tools. the same:

- Drive collector electric motor, necessarily. with a low starting torque and the number of revolutions from 3000 6000 min.1 up to 20,000 26,000 min.1. The engine is equipped with an air-cooling system.

- The roller bearing-mounted shaft, to the end of which the edge mill is secured by a clamping sleeve, is the main type of tooling, although, in principle, some other tools are also suitable for the edge mill.

- A lifting device designed to connect and disconnect the shaft to the motor (manual grass trimmers are not equipped with a coupling, because in this case their weight would increase markedly).

- Landing base or base frame with roller guides. stable base on which the grass trimmer is supported when in use.

- A locking device that prevents the edge cutter from exceeding the permissible travel range.

- Safety guard that prevents small chips and sawdust from getting into the eyes of the worker.

- A rubberized handle, near which the tool’s electronic controls are usually mounted, providing a smooth increase and decrease of the shaft speed.

The edge router kit often also includes adapter rods for using tools with a different diameter of fit, spare brushes, dust bag, etc.д.

Household edge routers of relatively low power (up to 7501000 watts) are designed for hand holding when using, as they do not have much weight. Professional and semi-professional models (e.g. Makita rt0700cx2, DeWALT 26200 and several others) will require mandatory installation on a work table or workbench.

Working with a handheld wood router

In the presence of the milling machine really simplifies the work of cutting hinges, the formation of complex holes, recesses, wood carvings, etc.д. But this does not mean at all that it is necessary to have professional and expensive equipment: it is enough to have a simple handheld device.

The only thing you need is to know how to work with wood and use power tools. In addition, it is necessary to have a desire, otherwise there will never be a result. Those who have no desire to work, they just buy furniture or hire a handyman to, for example, install a new door and cut the locks. Any work, especially with power tools requires certain knowledge, and especially safety precautions.

Popular Manual Routers

There are a large number of models on the market for joinery work. To understand which wood router is better, you should take into account not only the prices, but also the reviews of real buyers.

The Makita RP1800F is a mid-range quality tool

Makita RP1800F hand router

Model from a well-known brand, which is not the best in the range of similar devices, but serves as the best in terms of price-quality ratio. Engine power is 1.8 kW, cutting depth up to 70 mm, spindle speed. 22000 rpm. Option of maintaining speed stability. Of the obvious advantages, users note convenient ergonomics. The disadvantages include the lack of a mount for the hood and the gradual loosening of the handles when exposed to vibration.

Review of the Makita RP1800F:

Read more on Yandex.Market: https://market.yandex.ru/productfrezer-Makita-rp1800f/13005838/reviews

Bosch GMF 1600 CE. a proven brand

Milling machine Bosch GMF 1600 CE

The model from a recognized leader in the production of equipment. It is a versatile device that can be used at home and in the workplace. Rated power 1600 watts, the speed of 10 to 25 thousand rpm., Plunge depth up to 76 mm with an adjustable precision of 0.1 mm. Has an LED backlight that provides illumination of the work area. The only drawback is the inflated cost, which is 32523 rubles.

Review of the Bosch GMF 1600 CE:

Router Bits for Beginners | Rockler Skill Builders

Read more on otzovik: https://otzovik.com/review_7572741.html

Interskol FM-40/1000E. rich functionality at a modest price

Interskol FM-40/1000E hand router for wood

From Russian manufacturers, the most popular is the company Interskol. The presented sample is a universal with a motor power of 1.1 kW, the speed of the cutter up to 10 to 25 thousand rpm., maximum depth up to 44 mm. The advantages are the additional collet, the nozzle for connecting a vacuum cleaner, the protected housing. The unit has a low price and a high level of durability.). Among the disadvantages, users include not the best build quality.

Review of the Interskol FM-40/1000E:

Read more on Yandex.Market: https://market.yandex.ru/productfrezer-interskol-fm-40-1000e/1719695924/reviews

Manual milling machine from an ordinary angle grinder: the necessary materials and tools, a similar step-by-step description of the process of making the product with their own hands, check the performance of the tool, tips and recommendations. read in the publication.

What is a mill and what it does

A cutter is called a cutting element that is installed in a special device. a router. Cutters are used for various operations, such as chamfering, grooving, recessing, and notching. Such a nozzle for the cutter rotates at very high speed, which excludes chips and wood scoring. Each cutter in the set has a different configuration and is used for a certain operation.

Important! Work with a router without some knowledge and experience should not. Because the rotational speed and power of the tool is high, it can come out of your hands and cause injury. In addition, the cutter should be guided along the workpiece, against the direction of rotation of the cutter. If you do the opposite, then at best you can spoil the workpiece, and at worst In general, use such devices should be with extreme caution.

Classification and types of routers for woodworking

Wood cutters for hand routers can be subdivided into the following varieties:

- Edge milling cutters for wood edge milling (end mills). Such tools are equipped with a guide bearing, which ensures evenness of processed edge of the product. Spiral cutters also fall into the same category.

- Shoulder end milling cutters. To use them, you will need a stop and a known practical skill, because without a template it is almost impossible to get an even, rectangular-shaped groove.

- Cutslate cutters, designed for milling out a semicircular groove in the end face of a wooden bar. Such cutters are also quite universal, because the depth at which the cutter plunges into the material determines the size of the arc of the groove. Shaft end milling cutters with bearing for the production of decorative furniture laths.

- Grooving cutters with V-shaped flank. When using them, you can get a shallow groove with the side walls tilted in relation to each other at an angle of 90 0. Increasing the insertion depth of such a milling cutter in the material will produce smooth walls of the slot.

- Reverse taper blade mill, for “dovetail” grooving. Such a tool is indispensable when performing repair work with furniture, when one fragment is removed, and the second is fixed with the base with a specified groove.

- Cone cutters. They are used to process the outer edges of the product, which, when ready, must have chamfers of a strictly defined height and slope angle. The penetration depth of such a burr into the wood can be limited by the insertion of a thrust bearing similar to that used in edge milling cutters.

- Edge milling cutters that can be used to produce rounded edges. A set of wood cutters for a hand router usually includes several sizes of such a tool, which allows you to decorate edges with different values of the radius of curvature. Installing a support bearing allows, with a deeper insertion of the tool into the wood, to get a further straight edge.

- Quarter milling cutters. They create not only vertical but also horizontal edge, that’s why they are used while making and repairing wooden window frames.

- Disc milling cutters. Also designed for slotting, but unlike slot cutters, they do not work through the face, but on the periphery of their work part. Set of such cutters with different diameters (3 6 mm) allows to obtain grooves with guaranteed depth along the whole length of the working area. Bearing is not required in this case. Disk milling cutters with increased height of the working part are sometimes called rebate milling cutters and are used to make window grooves for glass in wooden frames.

The listed versions of hand router wood routers can be used not only for wood, but also for a number of other materials, such as plasterboard, plywood, etc. п.