When to change the bar on a chain saw. Bar sizes

When the bar on your chainsaw needs to be replaced. Tire for a chainsaw. how to choose, what tires are and how they are operated

A chainsaw can be used for quite a lot of work. The main cutting element of such a tool is represented by a chain with various blades. Modern designs are characterized by the fact that they can maintain themselves. The cutting edge wears out quickly if you cut for too long or don’t follow the basic recommendations. That’s why it is necessary to remove and sharpen the chain and then install it. Such a procedure is characterized by quite a lot of features, which we will talk about in more detail below.

When considering how to correctly put the chain on the chainsaw, let us note the point that the modern version of the tool has a special setting wheel. It significantly simplifies the procedure. Among its features we will note the following points:

- Considering how to properly put the chain on the chainsaw, we note that first you should prepare a flat surface. This prevents the tool from being damaged. After that, the main part of the tool, the bar and the chain are laid out separately.

- The next step is to remove the guard, which is intended to protect the sprocket. In most cases it is secured with a simple wing nut.

- On the bar, the tensioning sprocket is turned to the right until it stops. This is the position in which the tool is set up.

- The chain is then gradually slipped onto the securing element. Quite a common question can be called what is put which side of this element. Installation begins at the top, the chain is rotated so that the bar is over. Wear only thick gloves that can withstand the cutting edge. The cutter should be facing forwards on the end face.

- Both elements are put on the sprocket.

- The next step is to reattach the chain sprocket cover. Make sure the pins are aligned with the holes. If the chain is not clamped correctly, it may rattle or cause other problems.

- Care must be taken to keep the guides in the special groove.

- Check visually the condition of the chain after it has been fixed.

The next step is to directly check whether the chain has not been overtightened. To do this, release the chain brake and pull it away from the drive line. Check with special gloves only.

In general, we can say that the procedure under consideration is quite simple to perform and does not require special tools. However, the maintenance of not all chainsaws is as simple as the above.

How to determine if a tire is broken

If there is a problem with this part of the saw, it is quite easy to spot it:

- The bar does not do what it should do, is not at the proper tensioning or lubrication level.

- The saw’s guide bar is either too tight or too loose. In the place where the blade is fastened there is not a characteristic backlash.

All of these are clear signs that it is time to change the guide bar.

To extend the life of a chainsaw guide bar, it is necessary to clean it after each work session. Carefully clean dirt and sawdust in the grooves where the chain is located and in other attachment points.

Almost all chainsaw manufacturers recommend that you change your sawblade after changing three chainsaws. Because even if the bar looks perfectly normal and functional, constant chain rotation causes the groove to expand and the chain in the bar to become slack. That can be very dangerous for the tool and the operator.

What you need to know when selecting a circuit

If you defined that it is time to change saw headset, it is necessary to define how to choose it correctly. The easiest way to do this is to consult your manual which has recommendations on the subject. There is a big range of chains for chainsaws of different brands at fdfmoto.

The other way is to use the markings on the old chain to find the same size.

In order not to make a mistake when buying, it is necessary to know the following data:

All chains are divided by size based on pitch, which is measured in inches. There are 0,325 for home saws, 3/8 or 0,375 for semi-professional and professional tools, and 0,404 for professional tools.

Thickness of driving link. This size is determined by the width of the chain groove in the bar of the tool. Their difference also depends on the class of chainsaw the more professional the tool the higher the number.

This knowledge is enough to orient oneself in the range offered by the market.

Of course not everyone has the opportunity to buy new, although it is still a question of what is better, whether it is new or proven old. Well, how not to get a “cat”. Everything is clear with the chain, there by the longitudinal length of the tooth, the longer, the newer. In the bar, look and measure the depth of the groove where the chain goes. If the chain walks on the “bottom” it’s dead. If it is 3-4 mm longer than the guide tooth, it will still work.And the width of the groove.

The chainsaw guide bar is the guide and locking element of the bar. The blade itself, the drive sprocket and the fasteners are consumables.

It is very dangerous to work with a defective bar because at high RPM it can be torn from the body and injure the operator, or because of the bad fixation on such a bar the chain can jump off and injure the operator.

Chain Saw Bar Length

often than not, the wear and tear of this element of the chainsaw occurs naturally, due to prolonged use. Because it carries the brunt of the sawing work. But there are situations when a guide bar breaks because of improper work with the tool. Excessive loads that do not correspond to the tool’s specifications.

Or a lack of proper maintenance of the chainsaw. It also happens that a professional or semi-professional guide bar is used on a light-duty machine or that a professional or universal chainsaw is fitted with guide bars meant for home use.

First of all, tires differ from each other in length. Thus, 11 and 13 inch bars are suitable for home saws, 14. 16 inches for universal and professional saws. Also the elements differ in design features. There are flat and narrow blades, there are two-piece blades with polyamide joints, and finally blades with a detachable head.

The last two types are used on semi-professional and professional saws. In the online store FDFmoto there is a large selection of tires, fasteners and other accessories for chain saws. https://fdfmoto.com/en/catalog/shinyi-dlya-benzopil

Executive Summary

A well-balanced chainsaw, chain and carefully chosen guide bar will allow you to work effectively and calmly without spending too much physical and material resources. And it should always be understood that the choice of components of the chainsawing process, including the choice of guide bar, depends on the type of wood to be processed, working conditions, professional skills of the master. all this is purely individual and comes with experience.

How to Buy Correct Chainsaw Chain Replacement (Chain/Bar Numbers Explained) The Repair Specialist

Domestic, semi-professional and professional hand-held chainsaws, regardless of cost and performance characteristics, have an identical design. The cutting set, which includes the chainsaw bar and saw chain, falls into the category of replaceable equipment.

The decision which guide bar to put on the chainsaw is made by the owner, taking into account many factors. First of all it is the compatibility of the seat and the channels for the lubricant supply to the working area, the engine power, the specifics of the work to be done.

The advice of experienced specialists or information from the instruction manual can be of great help when choosing a guide bar on your own.

Long saw headsets, in particular, are preferred for felling and sawing large diameter trees, short saw headsets are preferred for crowning trees and preparing construction timber for installation.

Signs of chain wear

The natural wear of the chainrings is not the only reason for changing the chain.

- Damage to the chain elements means that this headset can no longer be used. They can be detected by visual inspection.

- Deformation of rivets and connecting links, cracks are caused by excessive tension in the chain and can lead to loose chain and need for replacement.

These signs indicate that the cutting attachments are in a bad condition and must be replaced. It is absolutely forbidden to use a damaged chain. Because it can suddenly break off and severely injure.

Why does the chain come off?

Many chain saw users, even the most experienced ones, have had to deal with the problem of the chain jumping off the guide bar as they worked. The most common reason is insufficient tensioning or wear of the chain.

In 80% of the cases, the stretched chain links slip off the teeth of the drive sprocket and the chain is flung off the guide bar by centrifugal force. Sometimes the problem is caused by wrong sprocket position in relation to rotation axis or chain saw bar not firmly fixed on the chain saw.

There are now many chain saw models on the market. First you need to know what size is right for your chainsaw so you don’t make a mistake when buying. The second step is to install it correctly on the chain saw. This is a somewhat labor-intensive process, but if you know how to dress and adjust the chain on the saw bar yourself, then the radical owner should have no problems. We have tried to describe in detail how to install the sawblade on your chainsaw.

We hope that after reading this article you will get it right the first time. But to minimize the occurrence of problems with the chainsaw and the chain in the future, do not forget the 3 basic rules:

- If the chain is worn and sagged. replace it with a new one;

- If there is a vibration when sawing and the cut is bad. watch the chain tension on the chainsaw;

- Never use defective or repaired by dubious specialists saw blades, your health and the health of those around you are much more important than a small savings on the purchase of a new and reliable chain.

The chain for a chainsaw is a very important part of it, if for some reason it is faulty the work of the tool is not possible. There are many reasons why it needs to be replaced. Let’s try to understand in what cases replacement is necessary, as well as consider how to choose the right saw chain for a chainsaw. Let’s start with the most important thing: the choice of the bar.

Manufacturers of chainsaws, for each specific model recommend using a saw bar of a certain size and technical parameters. To have the right choice, you need to consider these parameters, and then no problems will arise.

Basic settings

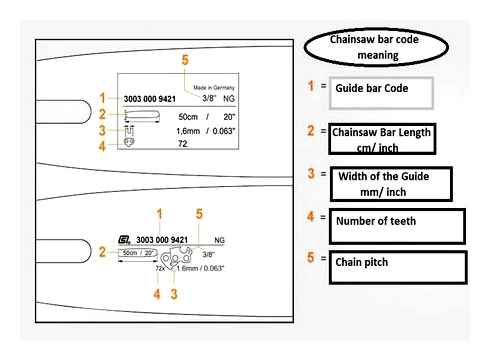

When choosing, take into account the five basic parameters, these are:

- Length.

- Width of guide slot.

- Tire sprocket pitch.

- Number of links in the chain intended for it.

- the type of shank and which chainsaw models are allowed to use it.

Depending on the power of the chainsaw it is allowed to install a headset of different length, which allows you to adjust the performance and load on the saw. The length can be specified by manufacturers both in centimeters and in inches, and, as a rule, it is not the entire length of the bar, but only a characteristic of the length of its working part. Choosing the right chainsaw guide bar should begin with reading the chainsaw manual and finding out the permissible length for a particular model. For the STIHL MS 180 chain saw for example, the recommended lengths are 14″ or 15″.

Do not go too far with the manual when choosing a fitting and use a longer set length, i.e.к. this can put too much strain on the engine and cause premature engine wear.

If you have a chain on the bar, the guide bar width and chain sprocket pitch must match the chain width and pitch to fit the guide bar, it will not fit the chain on the bar. The groove width for residential models of chainsaws is 1.1 и 1.3 mm for the pro models 1.5. The most common sprocket pitch sizes are 0.325 and 3/8 inch.

When selecting, remember that the chain sprocket pitch should be the same as the chainsaw drive sprocket pitch, so when replacing the bar and drive sprocket in the set, you can pick up these parameters as you wish.

Depending on the type of shank, the bar can only be installed on certain chainsaws. This is because the chain lubrication hole on the bars for certain chainsaw brands may be located in different places. For example, a STIHL bar cannot be fitted to a Hussquarna chainsaw, or vice versa, so be sure to take this into account when making your choice.

See the qualitative video description of the selection process below. In this video the expert of sales department of the gasoline-instrument, tells about the basic characteristics of a saw set its types and sizes.

Chainsaw bar hitch

The bar and its mounting hardware are consumables. Wear of this component occurs both under operating loads and as a result of improper operation. You can determine at a glance if there are any malfunctions. The bar will not provide proper tensioning, lubrication, or running of the chain, and the fastener. axis of the cut in relation to the body of the tool.

It is not safe to operate a chainsaw with a defective guide bar. That’s why at the first sign of trouble you need to turn the engine off and find out what’s wrong. Knowing what’s wrong with your chainsaw and how the guide bar is mounted on it, can help you troubleshoot the problem.

The bar determines the axis and length of the cut, guiding the chain. But the basis of the mechanism is still the attachment. The bar is fastened in the groove between the inner plate on the motor housing and the outer plate on the chain cover. Tire and shroud are bolted together. This part of the attachment is called the “engine node”, and its shape and design depend on the chainsaw model. The bar and drive sprocket are locked with a separate cover.

The drive links of the saw chain are fitted in the guide groove on the bar edge and engage with the drive sprocket that is connected to the universal joint shaft. If the locking bolts are loose, the guide bar can move. Chain tension can be adjusted manually or, as on professional chainsaws, automatically. Finally, at the front of the bar mount there is a stop. It is used to keep the saw axle firmly in place when the moving chain hits the wood.

A good bar should allow the chain to be tightened properly. To check it, release the chain brake and pull the chain in the direction of movement with your hand. If the chain will not move, the fastener is too tight. This should be slightly released, and then you can check again for free movement of the chain.

How to start the saw correctly?

If you want to sharpen the chain indoors, clamp the bar in a vice (this will not hurt the bar). If you don’t have a vice, you can buy a clamp.

If the number of links on the chain is not divided by 4, it is better to start sharpening the chain with two links in a row, otherwise you have to count the sharpened teeth).

Choose a tooth that is bent away from you. The holder needs to be set at right angles to the guide bar. The 30° ridge should be parallel to the bar. Make two or three movements from yourself with the file. Then turn the saw over and sharpen the second part. To evenly wear the file, remember to rotate it periodically and clean off chips. The chain pitch and the diameter of a suitable file are indicated on the holder. Don’t forget to make sure that the notch of file doesn’t run over the mounts, otherwise it will simply tear them off.