Which Discs For Angle Grinder For Wood

Types of wood nozzles

As a tool for carving wood, only an angle grinder with speed control is suitable. Since the main purpose of the angle grinder is grinding homogeneous materials, it is necessary to approach very carefully when processing the heterogeneous structure of wood materials.

The following types of wood circles can be distinguished:

- Wood Saw for Angle Grinder

- Cutting discs

- Planers

- Grinding

Each of these parts must be used for its intended purpose.

Discs. planers for angle grinder

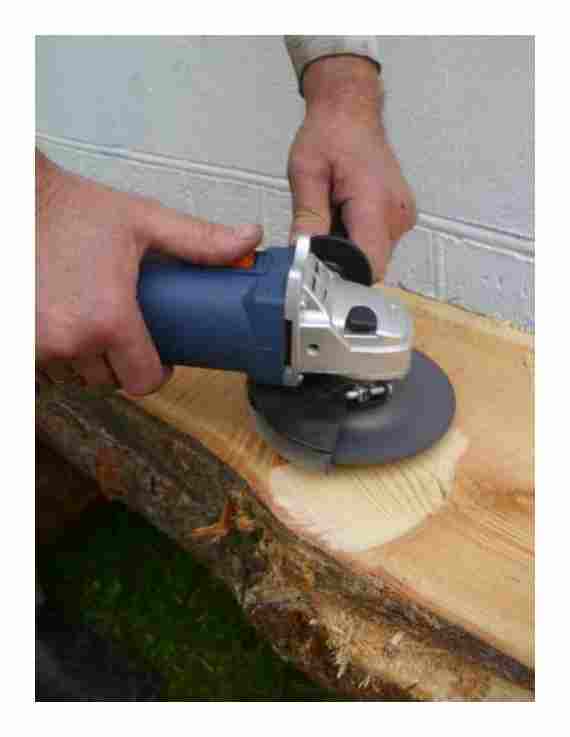

The angle grinder can be used as a planer. For this, special circles are used. planers. Working with such attachments is allowed without a protective cover, since solid discs are not destroyed. Many wheel brands can be sharpened many times. Before use, an additional handle must be installed on the angle grinder, for a more secure hold of the tool with two hands.

Grinding discs

This type of circles allows you to use the machine for its intended purpose. Various types of attachments can be used for finishing and polishing wooden surfaces:

- cord brushes;

- end circles;

- petal nozzles;

- emery wheels;

- peeling nozzles.

Rough wood processing is carried out using special cord brushes. Face discs are designed to level the edges of parts, which is often required when miter cuts of workpieces. They will perfectly replace the file.

The widest range of grinding attachments is for flap wheels. Depending on the size of the abrasive grain, the surface of the wood can be sanded with varying degrees of sanding. With a gradual transition from using a coarse-grained bit to discs with a finer grain, the effect of polishing the parts is achieved. The system of trapezoidal petals, which are overlapped by three-quarters of each other, has a rather slow wear. If the relief surface of a wooden product is complex, then flap discs with a radial arrangement of abrasive strips are used.

Using sandpaper or sandpaper on a special attachment allows you to sand fairly large areas of wood surfaces. The ability to quickly change the sanding cover makes these attachments versatile.

Peeling nozzles are often used when removing old paintwork. Typically this is a wire brush attached to a metal base. It can be located both parallel to the surface of the circle and perpendicular to it. There are options for attaching the bristles to the disc perimeter.

When working with wood, make sure it is fairly dry. If there is fungal damage on the surface of the workpiece, they must be cleaned to healthy wood.

Wood disc for angle grinder

An angle grinder is a very useful tool that can be used in various areas of production. It is thanks to its versatility that it has become widespread both at industrial facilities and at the household level.

Saw blades

The saw blade for wood for an angle grinder consists of a metal wheel with a chain attached to the edge. The construction of special sawing tools is similar to those used for chainsaws. But saw blades are made of tungsten carbide. When a disc for an angle grinder for wood hits a solid obstacle in the wood. knots, resin, metal, its base rotates without breaking the chain. With chain nozzles, you can simply clean the logs from knots and bark, give them the necessary initial shape.

Cutting discs

Various manufacturers also produce cut-off wheels for wood specifically for an angle grinder, for example, a cut-off wheel from Bosch. Their design is significantly different from the design of circular saw blades. They usually have side teeth that protect the nozzle from jamming. Cutting tools differ in the number and shape of teeth:

- beveled;

- straight;

- trapezoidal.

The first variant of the shape of the teeth is considered universal. It is suitable for all types of wood for small volumes of work. When sawing soft wood, it is quite possible to use discs for an angle grinder for wood with a straight tooth. Trapezoidal teeth are capable of processing fairly hard wood products: chipboard, DVL, OSB boards.

In addition, the cutting discs differ in diameter. The minimum size is 115×22 mm. Wheels with a diameter of 125 mm are most often used, they are universal and suitable for a wide range of works. The maximum possible size is 230 mm. But the latter option is undesirable to use when working with wood, as the likelihood of injury increases. Depending on the size chosen, the cutting depth of wood will also be different.

Universal discs for wood for angle grinder Graff Speedcutter

Wood disc for angle grinder Graff Speedcutter is a circular saw with three teeth, which is designed for high-speed angle grinders. It is used in models with a maximum rotation speed of 12.2 thousand rpm.

The three carbide teeth are made of tungsten carbide and are set at a 5 ° angle to the steel base of the tool. Thanks to this design and the special shape of each tooth, the cut surface is very clean and even. A disc for the Graff Speedcutter angle grinder is made in the size of 125×22.23×3 mm. Cutting width of wood is 3.8 mm.

Wheels Graff Speedcutter are intended for artistic wood carving, cleaning and grinding of various types of wood. They are also used for cutting and grooving in wood, its cross-cutting and ripping. It is possible to use such nozzles when processing parts made of aerated concrete and gas silicate, fiberboard, chipboard, laminate, drywall.

What are wood discs for an angle grinder and how to use them correctly?

- Is the angle grinder suitable for wood?

- Views

- How to choose?

- Recommendations for use

The angle grinder is one of the most popular tools for working on a variety of surfaces. be it metal, stone or concrete. It is also called an angle grinder. Typically, an angle grinder is used to process metal or stone workpieces. But in some cases, the angle grinder can also be used as a woodworking tool.

Is the angle grinder suitable for wood?

This question is asked by most owners of an angle grinder. Yes, the angle grinder can be used on wood surfaces. But not always. The angle grinder is not designed for woodworking purposes. Special attachments, which are recommended for wood processing work, began to be supplied to the market of carpentry tools not so long ago.

The main operations that can be performed with this tool on wood surfaces are grinding and roughing. For their implementation, it is worth using special nozzles. It is important to remember. in no case should you cut wood in a circle on metal or stone. This can lead, at best, to tool breakage, and even to injury. The saw blades can get stuck in the workpiece and the tool can simply fly out of your hand. Also, cutting wheels tend to overheat when cutting wood. In this case, the circle can fall apart and hit the face.

In general, there are three main models of cutting wheels for an angle grinder. These are saw blades, diamond blades and abrasive blades.

Diamond coated grinding wheels are designed for the processing of metal surfaces. They are characterized by high strength and durability. This type of attachment can also sharpen blunt tools. It is not recommended to cut wood with this circle. Abrasive discs are designed for grinding and have different grain sizes. Abrasive is the material that forms the basis of a circle. Quite often, electrocorundum or silicon carbide can be used as such constituent components.

Saw blades are designed for cutting and have a large classification. They can be designed for different materials. But not all of these types are recommended for cutting or processing wood materials. There are separate attachment options for wood.

Wood should be cut with an angle grinder only using specially designed metal discs that have teeth at the edges. There are some disc options that can be used to carve wood. Usually the wood is cut with a shallow grinder. For cutting large workpieces, it is better to use a circular saw that is specially designed for processing these materials. But some sander attachments allow you to cut or process small workpieces.

These attachments can differ in their purpose in the following types. cutting wheels, roughing models and discs for polishing or grinding.

Among the cutting options for circles on wood, two are worth highlighting.

- Circular circle. This nozzle is a circle with teeth. Usually these have a maximum diameter of up to 180 mm. On large circles, there are soldering. There are circles that are more compact, which have no soldering. In general, circular discs are considered a “dangerous” option for attaching a sander for trimming wood pieces. Therefore, it is advisable to choose circular discs that provide protection against jamming it in the material. This is due to the fact that the teeth on this version of the disc are slightly apart.

- Chain circles. These models are the best suited for working with an angle grinder with woody species. The risk of tool jamming in the workpiece is minimized. On the rotating base of such a nozzle, a chain is stretched, used on chain saws. In this case, the fit of the chain on the wheel is not fixed, which reduces the risk of handling the tool. That is, even if during operation the chain flies off the circle, then the circle itself will not break and fly apart, as can happen with other models.

Also worth noting are discs with a small and a large number of teeth. In this case, their number will depend on the diameter of the circle. Small diameter discs (up to 150 mm) have 3 teeth. Larger discs have 4 teeth. For woodworking, it is advisable to use discs with a small diameter, that is, with 3 teeth. Large discs are usually used by specialists to machine large workpieces. Small discs are suitable for standard household work. In general, such attachments do a very good job with cutting wood blanks.

Separately, it is necessary to talk about discs made of a special material. tungsten carbide. They are relatively new, but it is thanks to them that the angle grinder has become possible to saw wood. Externally, the nozzle is a circle divided into cutting segments. That is, the teeth themselves are absent on such a circle. The big advantage of this type of wheels is their high strength. The disc easily cuts wood of any strength, and even the presence of nails or other metal products in the workpiece will not interfere with its work. a tungsten carbide circle cuts small metal parts. The cost of such a nozzle for cutting wood is much higher than that of the previous options, but safety and high quality of work with this disc are guaranteed.

The next category of wheel models for an angle grinder is roughing. These nozzles are designed for processing on the surface of the workpiece. For example, to remove bark, remove large amounts of dirt or level the workpiece. The processing operations themselves are much safer than cutting wood. Therefore, an angle grinder for woodworking can be safely used, but do not forget about special attachments. It is customary to distinguish several types of roughing nozzles. Among them are roughing discs with spikes or abrasive grit. Abrasive cutters come in a variety of sizes. Thanks to them, you can grind the workpiece from the end or remove the top layers.

Also to the roughing options of nozzles are discs with twisted wire. They are sometimes called “cord brushes”. These attachments can be of two types. The first looks like a cup with a wire attached to it, and the second is a disc with a wire around the edges. With these devices it is convenient to remove old paint, rust, etc. from the surface of the workpiece. Also, circles with twisted wire are used to brush the surface of a tree. This is done to give the surface an antique look. By themselves, the nozzles with wire are a disk-plane, because they perform essentially the same functions.

Among the peeling nozzles, petal circles are distinguished. Such a scraper disc has several layers of sandpaper or other abrasive tape on its surface. It is important to take into account such an indicator as the grit size of the sandpaper. For roughing it is worth using wheels with coarse sandpaper. It is worth working with such a circle carefully, as you can easily damage the surface. For a more delicate and softer finish, use medium to fine sandpaper.

Also, modern manufacturers offer sticky discs on the market. This is a fairly new model of accessory used for woodworking. The essence of this circle is the presence of Velcro on it, on which you can fix a peeling tape of any grain size. This version of the nozzle is universal, because Velcro can also be used to put materials for processing metal or other surfaces.

The next category of attachments is used for polishing or sanding wood surfaces.

For sanding, the same Velcro discs or fine-grain petal attachments are perfect. For soft processing and polishing of the wood surface, use felt-coated nozzles. That is, such discs are a rotating circle on which there is densely compressed wool. Also, these models can be fine-haired, coarse-haired or universal. semi-coarse-haired.

These attachments perfectly polish wooden surfaces without leaving any damage.

The features of its use are:

- May only be used with a grinder equipped with a second auxiliary handle. For safety reasons, the angle grinder should only be held with two hands.

- It is allowed to remove the protective casing, since the body of the nozzle is one-piece, and the probability of its destruction is very small. However, protection from flying chips is required: gloves, glasses, clothing.

Wood cutters are available in a large assortment. They differ in size, position and shape of the teeth.

Cutting discs

These are the most common tips available in many types. With the help of them, you can process any material. The most popular of them are discs for metal, stone, wood.

- Metal cutting discs vary in diameter and thickness. By diameter in the trade network you can find discs with a diameter of 115. 230 mm. The thickness of the discs ranges from 1 to 3.2 mm, depending on the diameter. These dimensions also depend on the rotational speed and the load applied to them.

- Discs for stone processing differ from other types only in abrasive materials from which they are made. The rest of the parameters are the same.

- Discs for wood. The use of such discs is very dangerous, if you work carelessly, you can get injured. Such discs are essentially saws. Do not remove the protective cover from the angle grinder. It is best to use a fine-toothed wood saw blade and not use a high feed. The best option for using such an attachment for an angle grinder is the use of special devices for stationary fixation of the angle grinder.

- The diamond blade is versatile as it can cut any material. Such attachments are very popular in cutting tiles, stone, concrete and granite. For each material, you can choose your own type of disc. Some models have a cutting edge with slots, while others are solid, and they are also available with a fine or coarse diamond coating, depending on the application. For example, discs for cutting stone are solid, and for cutting concrete with transverse slots and fine dusting.

By its appearance it is difficult to determine what the disc is intended for, so when buying it is necessary to familiarize yourself with the characteristics of the disc indicated on the packaging.

Angle grinder attachments greatly increase the functionality of the grinder. angle grinder is widely used in construction and many other fields. And together with various attachments, they become universal equipment.

Roughing and Sharpening Bits for Angle Grinder

Discs are produced in different designs. Their difference is the size of the grit size of the abrasive material.

Such abrasive discs are similar to the surface structure of a hand rasp, with a difference in processing speed. If you have dexterity and acquired skills, such discs are used for finishing wood.

Polishing and Grinding

There are many types of such circles. They can be made of cloth, spongy, felt and with replaceable abrasive.

To work with them, it is necessary to use special pastes with fine abrasives, as well as various liquids. Fine abrasive wheels are used for cleaning and coarse grinding. The use of discs for grinding makes it possible to bring the surface of any material to the desired roughness. Such angle grinder attachments are used for polishing car body.

Cutters are designed for:

- Samples of various grooves.

- Cutting bowls.

- Rough edge alignment.

- Sawing small pieces of wood.

Which tool to choose

angle grinder is a very extensive range of one class of tool called an angle grinder (angle grinder). The device can have tremendous power and work with a disc of 230 millimeters or more. Or differ in compact dimensions and modest abrasives of 115 mm.

The disadvantages of a large and heavy tool are obvious: it is difficult for them to work for a long time. In addition, accurate woodworking requires serious skills and experience. It is elementary for a novice master to control a massive and powerful angle grinder. However, with a large area of processing or the need to remove a significant amount of material, such an angle grinder is very good.

The small angle grinder also has disadvantages. The ratio of the diameter of its disc to the dimensions of the body does not allow to process hard-to-reach places. In addition, it is difficult to select a large amount of material with such a tool due to low power and overheating.

Many wood craftsmen prefer an angle grinder with a disc diameter of 125 mm. This is explained quite simply:

- this class includes an angle grinder in a wide range of operating capacities;

- it is easy to choose a tool with comfortable dimensions and weight;

- there are many attachments and attachments on the market designed for the standard 125 mm disc bore.

In addition, the medium power angle grinder offers relative safety for beginners. It will not make you get tired quickly, will allow you to more accurately control your movement, reduce the likelihood of marriage on valuable parts.

Wood grinding attachments

For wood processing, in addition to cutting wheels, there are attachments specially designed for installation on an angle grinder, with which you can peel, grind, brush and milling wood surfaces.

Danger from working with an angle grinder with wood

The only operations with wood that can be performed with an angle grinder (angle grinder) without fear are sanding and roughing, and then using special attachments. Sawing wood, of course, will work, but it is very dangerous. The internet is full of shocking photographs showing what the use of an angle grinder can lead to as a cut-off tool for wood.

The main reasons that can be made against using an angle grinder for sawing are as follows.

- This machine is not designed for sawing wood.

- Since wood is soft and tough, the saw blade can jam in it. As a result, the angle grinder often pulls out of the hands, and it flies in an unpredictable direction (in the leg, arms, stomach, etc.), causing a person to deep wounds or amputation of fingers. Even fatal cases have been documented.

- When cutting wood, the saw blade heats up very quickly, which causes it to begin to lose strength. At the slightest distortion or excessive pressure, it can fly apart. Since the spindle speed of the angle grinder is large, the shards of the tool scatter at the speed of shrapnel and penetrate deeply under the human skin. The user is lucky if the fragments do not fly into the head or eyes.

- Despite the dangers of using saw blades with teeth, some angle grinder users ignore this fact and continue to install circular blades with larger teeth or advanced carbide tipped. If, when cutting wood, a hard knot or a remnant of a nail falls into it, then the tooth or soldering breaks off, clings to the next saw tooth and is thrown out at the speed of a bullet. The consequences can only be guessed at.

- Ignoring all warnings, users of the angle grinder install a circular saw with a larger diameter than the protective cover on the machine. This is the most dangerous use of an angle grinder.

Based on the foregoing, you can saw a tree with an angle grinder only at your own peril and risk, and then if this is a single or infrequent operation.

If you have to cut a tree constantly, then it is better to purchase a special machine for this purpose, or use a jigsaw. In extreme cases, an angle grinder can be used as a drive and make a circular out of it, fixing the device rigidly on the bed.

Chain saws

The saw blade, made using a chainsaw chain, reduces the risk of injury when the tool is jammed. This attachment is designed in such a way that the chain attached to the inner disc (base) has a non-fixed fit.

WOOD CARVING DISC on your angle grinder.super cheap.

In the event of a chain jam in the material being processed, the base continues to rotate and the tool does not pull out of the hand.

This angle grinder chain disc has many modifications, and can be used to cut branches in the garden, and can also be used for rough cutting of thin boards.

In addition to cutting, the chain disc can also be used as a roughing disc, for example, for removing bark, as well as for cutting out cups in logs and modeling.

Saws with few teeth

Also for the angle grinder, in order to increase the safety of working with wood, tool manufacturers produce cutting discs with a small number of teeth.

Small diameter discs can have 3 teeth, and large ones. 4, as shown in the following photo.

These discs for angle grinders are excellent for cutting wood both along the grain and across. In addition, with the help of a saw wheel, you can cut grooves, make various cuts and spikes in the workpiece. But when working with an angle grinder, one rule should be followed: you need to install a cutting disc of the same diameter on the angle grinder, for which it is designed by the manufacturer, that is, do not exceed its dimensions. Smaller circles can be used.

Grinding and polishing attachments

For sanding various surfaces, including wooden ones, there is a special attachment for an angle grinder on sale, consisting of a metal base, on which an emery grinding wheel is fixed with Velcro. The attachment is screwed onto the shaft of the angle grinder and tightened with an open-end wrench.

Often it is equipped with an adapter for fixing a drill or drilling machine in the chuck.

The grinding wheel is not used for polishing surfaces. Instead of it, felt discs are installed on the nozzle, which are attached with Velcro.

Also, a flap emery wheel is often used for sanding wood surfaces. It is called from so because it consists of many petals fixed on its plane, made of sandpaper. The granularity of the latter can be selected based on the requirements for the treated surface. Emery with a coarse grain is suitable for rough grinding, and vice versa for finishing.

What is the best way to sand wood. an angle grinder or a sander. depends on what you are going to prepare the wood surface for. If for applying ordinary paint, then you can use a grinding wheel. If for varnishing, then the grinding wheel mounted on an angle grinder cannot be used, since it will give small radial scratches on the surface of the wood, which will clearly appear after applying the varnish. In this case, a longitudinal belt sander is used for grinding (the emery belt moves longitudinally) or vibration, where the same emery wheels are used.

What are the circles for cutting wood

Despite the dangers of using an angle grinder for cutting wood, tool manufacturers still produce saw blades for it.