Which way should the trimmer turn

Which Way To Turn The Trimmer

Step-by-step instructions on how to wind the line on the trimmer spool

With the arrival of spring, you often spend your time in the country or in your garden. The trimmer will protect you from problems such as grass and weeds. This tool easily trims and mows grass in difficult terrain, where a conventional lawnmower cannot do it. Trimmer. a very effective and convenient tool for mowing grass along fences, flower beds, houses and garden aisles. Several types of garden trimmer have been invented (gasoline, electric and battery). It would seem that everything is fine, it is eating in your arsenal

is such a wonderful helper, but over time, the cutting element wears out and it becomes necessary to replace the finished line. And how to fill the line in the trimmer, not everyone knows. We suggest using step-by-step instructions with attached photos.

Instructions on how to wind the line on the trimmer spool

- 1. First you need to disassemble the trimmer head. Press the latch on the product body and turn the cover clockwise. Removing the bobbin.

- Now we have to figure out how to wind the line on the trimmer reel. We measure out about 6-7m of fishing line and insert its end into the hole of the bobbin.

- We reel the fishing line from both sides. The winding direction is always indicated by an arrow on the bobbin.

- Leave the ends of the 15 cm long cutter free. Do not wind too much line. Leave 6mm between the outer edge of the bobbin and the line.

- Insert the remaining two ends of the line into opposite holes in the bobbin.

- We fix both ends in the grooves on the head body.

- The spring is carefully placed back into the bobbin guides and into the head body.

- In order to thread the line into the trimmer correctly, it is necessary that the bobbin goes back into the head body (press it lightly). Pull the loose ends of the line out, if necessary. Pull the ends of the cutting element sharply one by one so that they come out of the grooves in the bobbin and pass freely through the holes on the head.

- So, we figured out how to wind the line on the trimmer reel. It remains only to align all the grooves on the head body and close the lid. Then we press on the bobbin and begin to rotate it counterclockwise until it stops. While holding the bobbin, turn it slightly clockwise and release it. If there was a clicking sound, then it snapped into the head. If this did not happen, then you need to repeat the action again.

- Pull out the loose ends of the line until they stop.

How to wind the line around the trimmer cutter head or lawn mowers

The video shows in detail how to wind the line on a trimmer reel or lawn mowers. Refueling with mowing line.

A Few Tips

How to start a petrol trimmer

The process of putting lawn mowers into operation, whether you bought it now or got it after winter storage, the rules listed below will allow you to avoid basic mistakes that can damage the tool.

Let’s say you just bought a petrol trimmer. Take the instructions out of the box and see if you have all the parts listed for the lawn mower. After that you can start building.

Fuel mixture and refueling

For the convenience of preparing the fuel mixture, it is better to have a special canister. where one part contains gasoline and the other 2-stroke oil. We recommend getting one like this, it is very convenient to use https://ru-sad.ru/prinadlezhnosti-dlya-sadovoy-tehniki/dlya-benzopil/kanistryi/

Next, take a measuring container with a scale applied to it, with its help you can prepare the mixture as accurately and quickly as possible. Look in the instructions what brand of gasoline and 2-stroke oil https://ru-sad.ru/prinadlezhnosti-dlya-sadovoy-tehniki/masla-i-smazki/ are recommended by the manufacturer of your lawn mowers. Pour gasoline and oil into the container for preparing the fuel mixture, according to the proportions indicated in the instructions. Then carefully pour the prepared mixture through a funnel into the trimmer fuel tank. The ratio of gasoline and oil should be exactly as indicated in the instructions. This is a very important point.!

Starting a warm engine

It’s very simple. Move the switch to the working position and pull the cord before starting. If you do everything according to the instructions, then there should be no problems with starting a working lawn mower.

Starting lawn mowers with cold engine

To start the lawn mower for the first time, locate the choke lever and place it in the closed position. Turn on the ignition on the handle. If your model has a manual fuel pump, popularly called suction, then press it 3-5 times until you see the fuel mixture inside the primer. The tool is now ready to run. Lay the trimmer on a flat surface to ensure a stable position. Pull the starter rope gently until you feel its resistance, and then pull the rope towards you 3-5 times with a sharp movement.

If the engine starts after 5 jerks, open the choke. If this does not happen, open the air damper anyway (if the damper is open and you continue trying to start the engine, the fuel will flood the spark plug and have to dry it, and this is a waste of time).

If the engine does not start when the throttle is open, close it and continue pulling the cord. The first launch can be quite difficult and require up to 15 jerks. After the engine has started to work, press the throttle lever once, so you engage idle speed. Now let the engine run and warm up. After that, it can be stopped by clicking on the “Stop” button.

Basic startup errors

Let’s list the main mistakes that beginners make when starting a gasoline trimmer:

- starting the engine with the ignition off;

- starting with a closed damper with the number of jerks more than 5 times;

- improper fuel mixture.

How to put the knife on the trimmer

With the arrival of summer, many owners of personal plots are worried about the question of how to put the knife on the trimmer. No less relevant are the questions of why and when it is advisable to replace the line on a lawn mower with a more durable cutting element. In our article we will try to disassemble all this and give useful recommendations to summer residents.

Why you need to put the knife on the trimmer

A trimmer with a knife mounted on it is most convenient to use for more comfortable mowing of tall and coarse grass in the country. The line on the lawn mower in such cases does not cope. Thin tears very quickly. Using 2.3mm thick cord or homemade rods with cables causes the vegetation to wrap around the spool. This increases the load on the engine. As a result, the piston group and other moving parts of the unit wear out very quickly.

If the weeds are mowed with an electric trimmer without a knife, only a fishing line, even a thick one with a curly section, will not solve the problem. There is always a risk of overheating the motor and damaging the flexible shaft. And it’s all about the large torque of the electric motor. Grass wrapped around the spindle creates a strong resistance to the shaft, which resembles a speedometer cable, which does not withstand and twists.

In order to protect the equipment from premature wear, manufacturers have provided for the possibility of installing special knives on the trimmers. The design and shape of the existing cutting elements allows you to easily cope not only with coarse and overgrown grass, but also successfully deal with young shrub growth.

What knives to put on an electric and lawn mower

Before buying and putting a knife on a lawn mower, let’s find out what they are and in what cases they are used. Today manufacturers offer the consumer a large number of types of these consumables. In general, all cutting tools designed for mowing grass can be classified:

- By the type of material from which it is made;

- By the shape of its cutting blades.

The main material for the manufacture of trimmer knives can be plastic or metal. The use of such consumables largely depends on two parameters:

- Lawn mowers type;

- Mowing areas.

For safety reasons, manufacturers do not recommend putting steel knives on electric trimmers. Almost all electric and battery powered lawn mowers are equipped with plastic blades. Depending on the manufacturer, they can be of a solid disc-shaped design, with several blades or in the form of a special mowing head providing for the installation of removable plastic blades.

Straight bar for petrol trimmer and curved for electric

To put a metal knife on an electric trimmer is not allowed by its design features.

- The curved bar of the machine reduces the distance from its working part to the mower’s feet. In the event of a collision of the blades with a stone or other solid object, the scythe is thrown to the feet.

- The high torque we mentioned above, in the event of a metal blade hitting a hard object, transfers a large load to the trimmer flex shaft and its motor. What causes them to fail prematurely.

- The handle of the electric scythe most often does not have a limiting bar acting as a stop. Which does not exclude injury to the legs.

It is these features that make it possible to use exclusively plastic knives on trimmers with electric motors. When hitting an obstacle, the blades are destroyed, thereby protecting the mower’s legs from possible injury.

Plastic knives do a good job on overgrown and dry grass. They can mow nettles and burdock stalks.

The use of metal knives only on gasoline trimmers is also due to design features.

- Straight bar design increases leg clearance for complete safety.

- Comfortable U-shaped and J-shaped handles provide a firm grip. D-shaped handles of lawn mowers are equipped with a limiter that rests on the leg of the mower, which does not allow the head to come close to the feet when the cutting disc meets a solid obstacle.

- The clutch of the gasoline engine allows for smooth acceleration to the optimum level. And when the blade hits a hard surface, it is able to extinguish part of the impact.

Thus, gasoline trimmers with a metal blade installed are best used in large areas. They will successfully cope not only with high coarse grass, weeds, burdocks and nettles, but also shrubs, as well as young trees.

The shape of the blades of the disc supplied to the trimmer in no way affects the quality of the work performed. Speed does not depend on them either. Triangular, trapezoidal, rectangular shapes are all the marketing ploy of manufacturers.

If you plan on making hay, it is best to use knives with a large number of blades on the mower. Note the discs with eight teeth, or discs with four large blades and four additional blades. Two and three bladed knives will chop the grass hard.

How to put a knife on the trimmer correctly

Putting the knife on the trimmer is not that difficult. The manufacturer completes its tools with a special pin that allows you to block the gearbox and a wrench with which the spool and fishing line are unscrewed. The most important thing is to observe safety precautions and the sequence of assembly and disassembly when changing cutting elements.

The algorithm for setting the knife to the trimmer is as follows:

- Remove the protective cover;

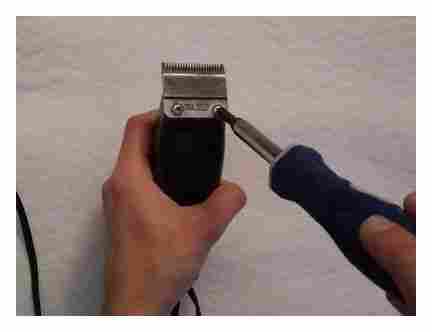

- We block the drive. To do this, it is necessary to align two holes. in the shaft hub and in the gearbox cup. After combining them, insert a pin into the holes;

- We unscrew the spool with line or the fastening nut holding the boot (if the trimmer has not been used yet) from the hub clockwise;

- Next, we install the cutting knife, so that the slots on the hub washer coincide with the recesses in the hole of the cutting disc;

- Install the boot;

- We tighten the fastening nut (counterclockwise) while holding the locking pin;

- We tighten it using a tubular wrench;

- Putting back the protective cover.

As you can see, there is nothing complicated. Now you can safely start mowing weeds on the site.

Counterclockwise reverse direction features

During the creation of a manicure, the cutter can be rotated in two modes: forward (clockwise) and reverse (counterclockwise). Switching the direction of movement is carried out on the device itself or on its handle.

It is important that when changing direction, rotation is completely stopped, after which the rotation can be resumed. Otherwise, there is a high probability of equipment failure. It is also not recommended to use metal nozzles when working in this mode, since they often have notches on only one side. Of course, there are exceptions, you can determine this directly by the cutter.

Counterclockwise reverse rotation is used in nail service in order to create more comfortable conditions when working with a cutter in the right direction.

In the absence of a reverse mode on the device, the masters rotate the client’s hand 180 degrees.

Unlike the usual mode, when the movement is clockwise, when rotating against it, the master moves the cutter to the right.

For people who find it more convenient to work with the left hand, switching modes is carried out in the opposite of the recommendations that were described above, while maintaining the principle of rotation of the cutter so that the nozzle does not touch the skin and side rollers of the client during operation.

How does reverse work in a nail cutter

What is reverse and why is it needed in a manicure cutter In which direction the cutter should turn when removing gel polish, so that the procedure is less traumatic and comfortable for the visitor.

At the moment, it is difficult to meet a girl who would not be worried about the appearance of her hands. A great way to give them an elegant and attractive look is with a manicure. For its implementation, a number of specialized equipment is used, one of which is a milling cutter. It is a device designed for the treatment of nails and cuticles. The nail art industry does not stand still and offers experienced craftsmen devices with new functions that greatly simplify the process of caring for the nail plate and save the client’s time. The complete set of the cutter for manicure with the reverse mode is the key to fast, comfortable, and high-quality processing of the most difficult areas. In order for the use of the counterclockwise direction of the apparatus to be as effective as possible, each master must understand the device and understand the principle of reverse operation.

Using the reverse in the router when removing varnish

In order to remove gel polish, you can work in both modes. So that the master has resistance and the cutter rotates in the opposite direction from the direction of the hand, the reverse and forward modes are switched depending on the position of the client. If you drive the cutter to the left, you should turn on the forward, and if to the right, then the reverse.

Almost all the varnish from the nail plate can be removed in the forward position, however, a thin strip of coating near the cuticle and side rollers on the right working side of the master, when the hand is with the nails down, must be removed in reverse mode.

The use of several directions of the cutter makes it possible not to turn the client’s hand, processing the left zone on the forward, and on the reverse. the right one. By moving the attachment against rotation, you create the necessary resistance, which ensures maximum comfort for the master and the client. With the help of the reverse mode, working in the direction from the side rollers, the varnish is removed without running into the skin or injuring it.

The presence of a counterclockwise reverse direction greatly simplifies the process of using the device, it makes the procedure less traumatic and comfortable, both for the master and for the visitor of the manicure room.

Trimmer carburetor. How to properly adjust the trimmer carburetor.

On trimmers, in addition to electric motors, gasoline internal combustion engines are installed. This mechanism requires special attention to itself, since if it is incorrectly configured, it will either refuse to work, or will work intermittently and loss of power. Basically, engine tuning is about adjusting the fuel flow, and this is done using the carburetor trimmer.

The standard design of any gasoline trimmer necessarily includes a fuel system, the basis of which is the action of a regular carburetor. Its design and initial principle of operation are almost the same for all lawn mowers, regardless of their design features and purpose.

The lawn mowers carburetor consists of an all-metal aluminum body that protects the internal components of the unit from moisture, small debris and dust. In the lower part of the body there is a built-in diffuser, the second name of which is “Venturi nozzle”. The main function of this standard part is to supply air in the amount required by the fuel unit to enrich the fuel. A diffuser works according to a simple principle: the smaller its diameter becomes, the more intensively the air is sucked in. This is due to the fact that in the area of the smallest diameter, the level of air vacuum becomes maximum.

The upper part of the built-in factory diffuser is pre-equipped with fuel pipes, through which, under the influence of air, the fuel mixture is drawn in. The rest of the carburetor parts: standard adjusting screws and a fuel pump, can be located both inside and outside the carburetor.

The device of the carburetor of lawn mowers includes a throttle valve, the main task of which is to regulate the volume of intake air. The larger the amount of air, the higher the rated power of the trimmer power unit. Another function of the damper is to facilitate cold starting of the engine. If this is the first time the mower is started after a long period of inactivity, the shutter must be closed. Immediately after starting the engine, the part must be opened, otherwise the internal combustion engine will stall.

The carburetor for the trimmer is equipped with an impulse channel that connects the internal cavity of the engine crankcase with the impulse chamber of the pump. The piston located in the engine cylinder creates reciprocating movements, which leads to gradual changes in pressure inside the crankcase. At the same time, the membrane is set in motion. Thus, the action of the pump is fully synchronized with the operation of the power unit.

The diaphragm of the standard carburetor takes an active part in the suction of fuel. It enters the fuel unit through the fitting. The fuel then passes through the integrated inlet and outlet valves, then through the strainer and fuel pipe. The fuel then flows next to the needle and gradually fills the chamber equipped with the control diaphragm.

The standard carburetor trim valve is connected to the diaphragm using a lever. Below the built-in membrane there is a cavity into which air is sucked in through a special opening.

The lawn mower carburetor works on this principle in stages. This ensures continuous operation of the fuel unit and uninterrupted fuel supply to the cylinder of the standard power unit.

When is the carburetor setting of the household trimmer required? Adjust the built-in trimmer carburetor when:

- running in a new engine, during which 4 to 5 liters of fuel mixture were used;

- sudden changes in the weather;

- changes in the air pressure. for example, when the lawn mower is often used in mountainous areas;

- long-term simple trimmer;

- intensive growth of loads on the power unit of lawn mowers;

- arbitrary unscrewing of the built-in adjusting screws of the carburetor. this causes increased vibration of the internal combustion engine;

- changes in the quality of the components of the fuel mixture;

- pouring fuel with a carburetor, resulting in an increase in fuel consumption;

- the regular appearance of a thick layer of resinous deposits and carbon deposits on the surface of the electrodes of a standard trimmer spark plug;

- starting the engine and its arbitrary shutdown or a slow set of revolutions;

- lack of fuel flow into the cylinder of the power unit;

- an increase in the volume of emitted waste gases.

The lack of timely adjustment of the carburetor threatens with a serious breakdown of the trimmer, up to the complete failure of its factory engine.

Do-it-yourself lawn mowers carburetor adjustment. Periodic adjustment of the trimmer carburetor should be performed on a serviced and fully serviceable power unit. Before starting the procedure, the operator must thoroughly rinse the internal combustion engine parts and inspect its CPG for burrs or other defects. In addition, you will need to clean or change the spark plug, as well as rinse the filter elements in the lawn mowers structure.

The lawn mower engine must be running under a certain load when adjusting the carburetor. It is best to install a cord of the appropriate diameter or cutting knives on the trimmer.

After installing the cutting elements, the operator should start the engine of the trimmer and leave it to work for about 10 minutes. If, during the operation of the power unit at idle, it was noticed that the cord or knife rotated, then it is necessary to reduce the speed generated by the motor. To do this, turn the lower adjuster, often marked with the letter “T”, to the left, until the installed cutter comes to a complete stop. Further configuration of the fuel assembly is as follows:

- The “L” regulator, located on the right, is responsible for enriching the fuel mixture with air when the engine is running at low revs. The position of this screw must be adjusted first. To do this, the operator will need to achieve maximum engine speed when idling. to do this, turn the screw “L” one by one to the right or left. As soon as the maximum speed is reached, the screw will need to be turned 1/2 turn to the left;

- The screw “T” or “LA” is required to adjust the idle speed. While turning it to the left, the speed of the power unit will decrease, and when turning to the right, accordingly, it will increase;

- The regulator “H”, provided on the left, is responsible for enriching the fuel mixture with air when the internal combustion engine trimmer is running at high rpm. This screw is also needed to adjust the engine power and the amount of fuel consumed. Its position is adjusted by turning the screw to the right or left side until the maximum permissible engine speed is reached. After that, the screw “H” will need to be turned 1/2 turn to the left.

Common carburetor malfunctions. Failure of the trimmer carburetor occurs due to the use of poor quality gasoline, a damaged air filter and the accumulation of dirt in the chamber of this unit. Most often, it is quite possible to repair the carburetor with your own hands. Listed below are typical lawn mowers carburetor malfunctions.

Fuel pump problems. A common malfunction that “pursues” the fuel pump is the deformation of the pump membrane. For this reason, it does not fit properly and the pump passages are not sealed.

The reasons for membrane deformation can be the following:

- long work of the trimmer;

- use of unsuitable fuel;

- ingress of gases into the impulse channel.

As a result, diaphragm damage reduces pump performance and, as a result:

- depletion of the combustible mixture occurs;

- it is difficult to start the engine;

- there are interruptions in the operation of the motor;

- the piston is damaged.

Also, the above-described consequences for the motor can cause clogging of the pump cavity on the impulse side. In this case, dirt enters the membrane through the impulse channel.

To remove the blockage, you will have to disassemble the carburetor and clean the membrane.

Clogged strainer

The strainer can become dirty if contaminated fuel enters through a fuel hose or a defective pickup head. In the photo below you can see what a clean filter looks like and a dirty one (parts are separated by a line).

Correcting the malfunction will require thorough cleaning and rinsing of the strainer. It is also recommended to blow compressed air through all holes in the carburetor trimmer housing.

Adjustment lever defective

This breakage occurs when the contact surface of the lever wears out.

The abrasion of the contact surface occurs due to the presence of abrasive particles in the gasoline or due to strong vibration of the engine during operation. This defect in the adjusting lever causes problems with the intake, as well as improper idling of the engine.

Intake needle wear

The inlet needle fails, as a rule, due to the presence of abrasive particles in the fuel fluid.

- the tightness of the inlet needle seat is disrupted;

- there is a leakage of a combustible mixture;

- there are malfunctions in the engine, associated with re-enrichment of the fuel mixture.

Also, the inlet needle may just jam.

A jammed inlet needle can cause dirt in the fuel or a long idle time.

Clogged control cavity

If dirt accumulates in the adjustment cavity, the inlet needle cannot close the hole tightly and a lot of fuel pours into the chamber.

This causes over-enrichment of the fuel and the engine starts to malfunction. It is necessary to disassemble the carburetor and clean the cavity of the control membrane.

Deformation of the control diaphragm

The membrane can undergo deformation during prolonged operation of the unit and when using aggressive fuels.

Failure of normal adjustment due to a defect leads to:

- damage to the piston;

- difficulties when starting up;

- depletion of fuel;

- improper engine operation.

Intake Adjustment Lever Problem

This problem can occur if the adjusting arm is not properly installed or if it bends before installing. As a result, the contact surface takes the wrong position, which disrupts the additional fuel supply.

Damper wear

The throttle and choke valves are mainly subject to wear due to the presence of abrasive particles in the air. Defective dampers look like they have been sandblasted.

As a result of valve wear, engine performance decreases, malfunctions appear in its operation, piston rings, piston and cylinder coating wear out.

Throttle and choke shaft wear

The air and throttle shaft can wear out for the following reasons:

- insufficient and improper maintenance of the air filter;

- the air filter is damaged;

- the air filter is not suitable for this unit.

Due to the ingress of poorly cleaned air, the shaft wears out and can break. Broken shaft parts can enter the combustion chamber or crankcase and cause serious damage to the entire piston system.

To eliminate problems with air purification, it is necessary to replace the defective filter or flush the existing (serviceable) one. The filter must be washed in soapy water and dried.

How to properly adjust

Before you start adjusting the carburetor trimmer, do the following:

- flush the engine;

- replace or clean the spark plug;

- change to a new one or clean the air filter (it is recommended to wash it in warm, soapy water, wring it out and let it dry well).

It is also necessary to install a cord of a suitable diameter in the trimmer coil or install knives. this is done so that during the tuning process the engine has at least some kind of load. After installing the cutting tool and starting the gasoline engine, let it warm up for 10 minutes.

If at idle speed of the engine you notice that the cutting tool rotates, then it is necessary to reduce the engine speed. This is done using the lower idle speed control, often marked with the letter “T”. But, for example, on the Stihl trimmer, this screw may be marked “LA”.

So, turn the idle speed control to the left until the trimmer head comes to a complete stop.

To adjust the carburetor, 3 regulators (screws) are used.

- The right L regulator adjusts the enrichment level of the combustible mixture at low revs. It needs to be regulated first. Achieve maximum idle speed. This is done with the L knob by turning it left and right. After finding the point of maximum speed, return the regulator half a turn to the left (counter-clockwise).

- The lower T (LA) adjuster is used to adjust the idle speed. Turning it to the left, the engine speed will begin to decrease, and when turning the regulator to the right, the engine speed will increase.

- The left regulator H is responsible for enriching the fuel mixture at high speeds. The enrichment setting completes the carburetor adjustment. Also, using this regulator, you can adjust the maximum speed, fuel consumption and engine power.

Important! If the engine is allowed to run at full speed for more than 10 seconds, then it may fail.

To eliminate this nuisance, adjustment will be required. With the engine running, give full throttle, then turn the regulator “H” to the right until the speed starts to decrease. After that, the regulator “H” must be slowly scrolled to the left until you hear the uneven operation of the engine. Then you should turn the knob “H” to the right until you hear the smooth operation of the motor.

After carrying out the above steps, the carburetor setting can be considered complete. After correct adjustment, the engine should confidently pick up speed, a little quarter at maximum speed, and when idling, the cutting tool should not turn. This manual is suitable for adjusting carburettors on Huter, Patriot and other lawn mowers.

There are also carburetors without a screw, which is responsible for enriching the combustible mixture at low speeds. That is, they have only 2 adjusting screws: an idle speed regulator and a fuel mixture quality regulator at high speeds.

Why is all this necessary and who is the owner of the initiative to transfer time?

The time shift, according to the experts, should provide the inhabitants of the Earth with more natural light and control the decrease in the use of artificial sources to save energy.

For the first time, Benjamin Franklin spoke about the need to translate the clock hands in 1784. But in practice, this was applied during the First World War in 1916 by several European countries. The first to switch to daylight saving time were the Germans in 1916, followed by the British and changed their clocks a few days after Germany. According to the astronomical observatory “Amiral Vasile Urseanu”, Belgium, Denmark, France, Italy, Luxembourg, the Netherlands, Norway, Portugal, Sweden, Turkey and Tasmania also introduced a similar practice.

Where to turn the clock hands?

We have been switching to summer and winter time for many years in a row, but each time we think. forward or backward. A simple rule “BB-OO” will help to remember this. According to him, in the spring we move the clock hands forward (BB. forward in spring), and in the fall. one hour back (OO. back in autumn). Remembering this rule, you will never be confused and worried about the risk of being late for work.

When the time is changed in 2018 and in which direction to turn the clock hands

The transition to winter and summer time has been practiced in European countries for many years. And nevertheless, every autumn and every winter, many people get confused, but where to turn the clock hands and on what days it usually happens. Joinfo.com will help you figure out the answers to these questions.

When the time is changed in 2018?

Every year, on the last Sunday in October, Europe switches to winter time. In 2018, the clock hands should be set back one hour from Saturday October 27 to Sunday October 28. Thus, we will sleep one hour longer on this day, and October 28 will be the longest day of the year.

It is worth noting that the changeover of clocks to winter time will not occur in all countries at the same time. Everything will depend on the time zones in which different states live.

Clock transfer can be canceled

Recently, more and more experts claim that it no longer makes sense to switch clocks to winter and summer time. In pursuit of economy, the authorities of some countries, without knowing it, kill millions of their citizens. It is no secret that the lion’s share of the population, such as old people, children, pregnant women, meteorological people and patients with chronic diseases, experience the most difficulties in time shifting.

In this regard, a large-scale survey was conducted in Europe in the summer of 2018, during which it turned out that the majority of Europeans believe that the directive on the translation of the clock hands should be canceled.

As a result, the European Commission announced in early September 2018 that each EU member state will have to decide by the end of April 2019 whether or not to keep changing times twice a year. If the calendar proposed by Brussels is respected, the time change on March 31, 2019 will be the last mandatory daylight saving time. Countries that want to live according to winter time will have the opportunity to reset their clocks again on October 27, 2019. After the decision is made, the seasonal change of time will not be possible.

But that’s all. business for the future. In the meantime, it’s worth learning how to survive the transition to winter time while maintaining health, mood and well-being. Many of us will have to implement all this in life tomorrow, October 28.

lawn mower or trimmer

A trimmer is a broader concept than a lawn mower (lawn mower), as it can also be electric. A petrol trimmer and a lawn mower are one and the same.

Some authors claim that the trimmer is a weaker tool than a more powerful lawn mower, which can be used for mowing shrubs. Personally, I have a tool with a maximum power of 1.7 kW and capable, as stated in the instructions, to mow small shrubs up to 10 mm thick. The user’s manual is called “Petrol trimmer.”.

Fuel supply adjustment

Start slowly turning the fuel mixture adjustment screw until the engine starts to stall or stalls if you do not have time to catch the moment. After that, unscrew the screw a quarter of a turn if the engine did not stall, or half a turn if it stalled. Start the stalled engine. Check by opening the throttle as the engine picks up speed. Continue to unscrew the screw a quarter of a turn until the engine starts to accelerate steadily during gas blowing. This will be the moment of the most economical stable engine operation. For the PRORAB-8406 petrol trimmer, the adjusting screws are turned clockwise, unscrewed. against, for some other brands the lawn mower can be the other way around.

Spring may interfere

My first attempt to adjust the carburetor of the lawn mowers did not work, as the spring of the screw for adjusting the fuel mixture interfered with. The factory spring turned out to be too thick in the compressed state and did not make it possible to reduce the fuel supply to the required level. I had to pick up another spring and continue adjusting after replacing it.

Fuel mixture adjusting screw with spring

In the photo above the factory spring, below the adjusting screw with the matched spring. I am writing about this because I’m not sure if this is an isolated case, and someone else may face the same situation.

Maximum speed limitation

After adjusting the fuel mixture and low speed, check how the lawn mower engine will run at maximum speed. If necessary, limit the maximum speed to the required level using the hollow screw. Loosen the fixing nut and screw in the screw to decrease the maximum speed or turn it back to increase it. Tighten the nut after adjustment. The maximum RPM setting is necessary to protect the trimmer motor from overheating and to be able to use the start key lock to reduce right hand fatigue.

In the future, it may be necessary to readjust the trimmer carburetor. For example, if the engine starts to rev poorly when running at full load, loosen the screw another quarter turn. If starting is difficult, increase idle speed. Both weather conditions and the quality of the fuel mixture can affect the operation of lawn mowers. Vibration can cause the adjusting screws themselves to turn.

Adjusting the carburetor lawn mowers, trimmer

Increased fuel consumption and the rapid formation of carbon deposits on the spark plug when using a properly prepared fuel mixture indicate the need to adjust the carburetor. Here’s how to tune trims with carburettors with one fuel adjusting screw.

From personal experience

Carburetor adjustment

Flush the air filter before adjusting the carburetor. It is recommended to rinse it after every 10 hours of operation. After that, you can start adjusting. The photo shows the PRORAB-8406 petrol trimmer carburetor as an example. The numbers indicate the adjusting screws that we will use.

PRORAB-8406 petrol trimmer carburetor adjusting screws

The purpose of the adjusting screws:

- Fuel mixture adjustment screw.

- Idle adjustment screw.

- Maximum speed limiting screw.

Start a lawn mower and wait for it to warm up.

Fuel ratio

I read somewhere that if different mixing ratios are indicated in the operator’s manual for the lawn mowers and on the oil canister, the proportion indicated in the manual should be used.

For a long time he did this. excess oil flowed from the engine onto the gas tank and carbon deposits were constantly formed on the candle, since the manual indicated the proportion for the run-in engine 1:25, and on the canister. 1:50. After switching to a ratio of 1:50, the appearance of oil drips stopped. The candle continued to burn, but at a lower intensity (the carburetor was not yet adjusted).

Until now, some users of gasoline-powered tools determine the proportion of the fuel mixture “by eye”. If during the preparation of the mixture the amount of oil is underestimated, after a while an extraneous sound may appear immediately after starting the engine, gradually disappearing during warming up, and the engine stops with a sharp jerk. Continued use of the trimmer in this mode will lead to its failure.

Types of anchors for guitar

There are many different types of truss rods: single truss rod, non-adjustable truss rod, dual action truss rod and double truss rod.

- Single anchor (compression anchor). It can be tightened, thereby giving the neck back deflection and straightening the neck. You can often find re-releases of 50s. 70s guitars, as well as on other guitars made according to old (vintage) specifications. (By the way, an interesting fact is that the very first Fender Telecaster, nee Esquire, had no truss rod at all.)

- The non-adjustable truss rod fits into some guitars (although not as common) and only provides a stronger neck.

- A double-acting truss rod can be used to give the neck a back deflection, but it can also be used to flex the neck straight (upward). Fits on many modern guitars.

- A double truss is when there are two truss rods in the neck. Thus, more force can be given by the anchor rods. This truss rod is used in guitars with strong string tension, such as 5-string bass or 12-string guitars.

Deflection or relief of the neck of the guitar

If you take a guitar and pull, for example, the sixth string (lower Mi (E)), you can see that the maximum vibration amplitude will be approximately in the middle of the string.

How to Use a String Trimmer. 10 Skills to Master

And since the amplitude in the middle is maximum, then it is in this place that the string does not touch the frets during vibrations and there is no nasty bounce when playing, it is necessary that the neck has a slight deflection. This neck deflection is also called “relief”. Below are diagrams, exaggerated for clarity, showing what is meant.

In this example, the truss rod is too loose. And the neck deflection is too strong, and the distance between the strings and frets is too great. This can make it difficult to play the strings at certain frets. Naturally, such deflection needs to be adjusted and the truss rod adjusted so that the neck is straighter.

This is an example of an over-tightened anchor bar (reverse deflection). Usually, such a deflection is not observed in nature, but theoretically it is possible. This means that even open strings will cling to the frets, causing bounce and they will not sound accordingly. Need to regulate.

Here we have a normal deflection (or relief) of the neck. And now, finally, let’s look at how to achieve this very normal neck deflection.?

Neck deflection and truss adjustment

Do you want to watch ads? Register!

After the first part of the opus “How to tune (rebuild) the guitar”, as usual, the second goes. Today we will try to answer the very question that newcomers love to ask on guitar forums.

Yes, yes, exactly about “which way to turn the truss rod”, well, or about adjusting the neck deflection and setting the truss rod, if you like.

What is an anchor rod and why is it needed?

Before proceeding directly to the adjustment, let’s figure out what this anchor rod is and why is it needed.

There is a metal rod in the neck of the guitar. It is called an “anchor rod” (or simply “anchor”). The truss rod strengthens the neck and compensates for the tension of the strings that are trying to bend the neck, but the truss does not allow you to do this.

Because wood is not a very stable material, then the neck mushroom of a guitar is not a constant value. Due to seasonal fluctuations in humidity and temperature, it tends to change slightly. Or, let’s say you jumped on a plane with your guitar and, from a dry, hotly heated January apartment, moved to even hotter and more humid Thai beaches. So, in this case, the deflection can also change.

What’s the weather! It’s trite, they changed the strings to a thicker caliber and that’s it. the deflection has changed, tk. the strength with which the strings pull the neck has also changed. This, by the way, is the most common reason for the need to adjust the anchor.

So, in order to somehow control this process of changing the neck deflection, an truss rod was invented, which is installed in the guitar and allows this very neck deflection to be tuned.

Anchor rods are different and look something like this:

The picture below. Loose anchor. He is under the number 1. He, as it is not difficult to see, is straight.

The tension on the strings pulls the neck of the guitar up. Those. the strings twist the neck. Unclear? Well, imagine the bow that Robin Hood was shooting from. So the bow itself is our neck, and the bowstring is the strings.

Tightening the truss nut causes deflection in the opposite direction to the natural deflection of the neck of the guitar. This allows you to compensate for the strength of the strings pulling the neck up. If we take the same analogy with a small bow, then with the help of an anchor we are trying to make the bow itself more even. That is why in this figure the anchor 2 with the tightened nut is bent upwards. The nut turned clockwise.

Anchor 3, all from the same pattern, further increases the deflection of the neck. The nut turned counterclockwise.

Neck deflection and truss adjustment

For starters, there is no such thing as perfect deflection or neck relief. There are just recommendations to listen to. In any case, you will choose your ideal deflection for yourself, because it is individual and depends on many factors: on the strings, the tuning of the guitar, on the guitar itself, the style and manner of playing the guitarist, on his individual preferences, in the end.

Before twisting the truss rod, you need to assess the deflection of the neck. You can clamp the strings at the 1st fret and at the fret where the neck is attached to the body. On the example of my guitar, this place is shown by an arrow.

While holding these two frets, you need to check the distance between the string and the top of the 7th fret, where the neck deflection should be greatest.

This is the quickest and easiest way to check neck deflection. If the string is on the 7th fret and there is no gap, then you have a perfectly straight neck or reverse neck deflection. This means that you need to adjust the truss rod.

There is also another, but similar way.

In order to measure the correct deflection of the neck, you can use a half-meter or whiter steel straight strip or ruler, placing it in the center of the neck along its length. In this case, the guitar should be tuned, and straighten you on your lap, as if you are going to play. If you do this procedure with a guitar lying on the back, the neck will be in an unnatural state. Gravity and possibly a sloping headstock will cause a slightly different deflection, confusing the measurements you are trying to take.

Make sure one end of the ruler touches the center of the first fret and the other touches the last.

Now measure the gap between the ruler and the 7th fret. If it is less than 0.15. 0.2 mm, you will have to turn the truss rod nut counterclockwise, thereby weakening the anchor and increasing the deflection.

Loosen the strings before twisting the anchor. The nut should be rolled slowly and carefully no more than 1/4 turn at a time (i.e. 90 degrees). Before checking the deflection again, you need to re-tune the guitar.

Each time you turn the nut, leave the guitar alone for a while (15-20 minutes). Because the tree has inertia, the changes in the deflection may not be visible immediately, for this it is worth pause. Some, in general, recommend waiting for several hours, or even a day.

If your check showed that the gap at the 7th fret is more than 0.4-0.5 mm, then you need to tighten the truss rod by turning the nut as described above, but clockwise. Remember to twist gently no more than 1/4 turn at a time, with the strings loosened.

Although, again, the clearance is given as an example, the correct neck deflection will depend on your personal habits and preferences.

Below are pictures of the most common truss nut locations on guitar.

This picture shows the most common truss rod adjustment tools: an Allen key on the left and a box key on the right. If you are adjusting the deflection of the neck with an anchor “as on the old Strats”, then you will need a flat screwdriver.

Generally speaking, it is not recommended to adjust the truss rod unless you are clearly not sure you know what you are doing. I would advise you to entrust this to professionals. However, if the head is on the shoulders, and the arms grow from the right place, then this is not difficult.

And in conclusion, a good video with illustrative pictures of an anchor in a guitar.

Please note: Electric guitars, acoustic and bass guitars. Akademicheskaya metro station, large selection

Do you want to watch ads? Register!

How to remove the spool from the trimmer and remove the line

Initially, remove the line from the trimmer spool before threading it into the trimmer spool. A reel or aiming device is a device that sits inside the mowing head, bobbin or drum. There are different types of heads (depending on the manufacturer), but the principle of replacing the line on the reel is the same for everyone. First of all, we will figure out how to remove the head from the tool, as well as how to get the drum and fishing line out of it.

The instruction on how to unscrew the manual head on the trimmer is as follows:

- Turn the tool upside down and, if necessary, clean it from dirt. With two fingers of one hand, grip the cover latches (on the mowing head), which are symmetrically positioned to each other. After lightly pressing them inward, remove the protective cover from the drum

- Next, remove the line spool from the drum shaft. It is mounted on a shaft without fasteners, therefore it can be removed with one hand.

- The main part of the drum is fixed with a screw, which must be unscrewed with a screwdriver with an appropriate tip or bit

- To unscrew it, hold the drum base with one hand, and unscrew it counterclockwise with a screwdriver with the other.

- After that, you can start dismantling. To do this, you do not need to pull it with all your strength, but by slightly shaking it to the sides, slowly disengage it from the metal shaft on which the drum is seated.

- When reinstalling, fit the head into the square slots

This process is not difficult, and as you know, there is no need to dismantle the entire head if you know how the replacement is performed. When dismantling, consider the following nuances:

- It is recommended to remove the head periodically to prevent corrosion of the threaded connection. If you never unscrew the screw, then if necessary, it will be difficult and even impossible to do this.

- If the screw has a four-sided bore of the head, then for unscrewing it is necessary to select a screwdriver or bits of a suitable size in order to exclude the licking of the edges on the head

- When assembling the unit, treat the threaded seat with lubricants, for example, grease or machine oil.

- If the edges on the screw are licked, then special clamping pliers can be used to unscrew it.

- There are drums that do not require preliminary disassembly. To dismantle them, grab it and rotate in the opposite direction of the clockwise direction

Knowing how to disassemble the drum, you should continue to figure out how to replace the trimmer line. The video below shows a detailed process on how to open the trimmer coil and disassemble it.

Learning to properly wind the line on the trimmer reel and lawn mowers installation instructions

Private home owners know how essential a trimmer tool is. It can be gasoline and electric, and they differ in the design of power units. For cutting grass in areas where there are stones, trees and other obstructing objects, a fishing line is used as a cutting device. This consumable wears out during use, so how to wind the trimmer coil, we will consider in detail in the material.

Step-by-step instructions on how to wind the trimmer reel and lawn mowers

In order not to be mistaken with the choice of a suitable fishing line for your tool, you should first disassemble the head and look at the side wall of the reel. This information is usually presented on a tip, which will not allow you to make mistakes with the use of the appropriate equipment.

If there is information on the reel about the diameter of the line you can fill in, then this information can be clarified in the instructions. Having decided on the thickness or diameter of the rig, it remains to figure out how to charge it. There are two ways to do this, but not all of them are applicable. We will consider both methods in detail, and depending on which models of lawn mowers and trimmers you use, you decide on your own which option is suitable.

Method 1. how to properly wind the line or put it on a reel and choose the required length

To implement this method, you will need to first prepare a fishing line of the required length (usually up to 4 meters). It all depends on the thickness of the equipment used, as well as the design of the coil. There is an easy way to find out how much line you need to refuel to charge the reel. To do this, wind the rig inside the coil until it is level with the side protrusions. In this case, the rigging should not go beyond these extreme protrusions.

The thicker the equipment used, the shorter its length will be needed and vice versa, the thinner, the longer the segment will be needed.

The instruction on how to properly tuck the equipment into the trimmer or lawn mowers is as follows:

- To begin with, a piece of fishing line that was prepared to be installed in a reel must be folded in half. In this case, one edge should protrude more than the second by 10-15 cm

- After that, take the second end from the other side, and fold it in half. Move to it so that the measured protrusion of 15 cm is preserved

- There is a slot in the inner baffle of the coil, into which the resulting loop should be inserted. The cut in the wall is shown in the photo below.

- Next, we find out the direction of winding the line. If you wind the rig in the wrong direction, then it will not function correctly, and you will need to redo the work. To insert the line and wind it in the correct direction, inspect the surface of the spool. It should indicate the direction of winding (in 99% of cases, this direction is indicated). What the direction indicator on the coil looks like is shown in the photo below.

- This arrow-shaped pointer can also have the designation, as in the example above “WIND LINE”, which means the direction of winding. If the pointer is missing on the reel, then you need to look at the head. There is a direction of its rotation on the head, and in order to properly wind the fishing line, wind it on the drum in the opposite direction to the indication of the arrow indicator. So, if the arrow is on the tip, then you need to wind in the indicated direction, and if it is not there, then you should wind against the direction of the arrow on the surface of the head

- Having decided on the direction of rotation, you should start winding. Each end should be guided in its own groove. If there is no separator, then the equipment must be laid in the appropriate distribution order.

- When almost all the fishing line is wound on a reel, you will need to do the following. place a short part in the hole of the side wall of the pickup, the protrusion of which should be up to 10-15 cm, and then similarly do the procedure with the other end, placing it in the hole on the parallel side

- We insert the coil into the head, first passing the ends of the fishing line into the holes of the drum

- We put the drum in place and, pulling the ends of the line, disengage them from the temporary clamps in the wall of the reel. After that, you can put on the cover until the latch engages.

- At this point, the process of how to replace the fishing line on the trimmer is completed, and if necessary, you can only trim the ends (if their length does not suit), and install the assembled drum on the tool

With how to put the drum in place, no difficulties arise. There is also a second way, how to charge the mowing equipment in the lawn mower. What is the difference, and how is the second method of threading the line on the reel of lawn mowers carried out, we will find out in detail.

What you need to know about trimmer line

A fishing line is a consumable made of nylon that serves as a cutting device. By means of this equipment, the grass is cut, which is ensured by rotating the tool head at a high frequency. This material has a different thickness, which depends on its use on the corresponding tools, low-power electric (from 1 to 1.6 mm), electric from 500 W (2 to 2.4 mm) and gasoline trimmers with lawn mowers (from 2.4 to 3. 2 mm).

The more powerful the tool, the correspondingly thicker the cutting equipment should be. This affects not only the quality of the grass cut, but also the service life of the material. If you are wondering how to wind the trimmer coil, then it is time to change and reload the tool. With the onset of spring, this question is becoming more and more popular, so it’s time to figure out the step-by-step instructions for replacing the line in the trimmer reel.

Method 2. how to properly put the line on the reel of lawn mowers with photo description and video

The second method differs from the first in that it is not a single piece of equipment that is charged into the coil, but segments from two parts. This method is used by manufacturers, and it is also suitable for those who have leftover material. The principle of how to insert two lengths of line into a lawn mower’s line is the same as with the first method, and to make sure of this, below are detailed instructions:

- There are two equal length pieces of material that you can use.

- One piece is taken, and the edge is bent in the form of a clamping bracket or hook, with which the fishing line will be secured

- Inside the coil there are holes in the form of a bracket for fixing, which are there for a reason. If they are not there, then the second option will not work. The appearance of these brackets is shown in the photo below. Each bracket is in its own half

- The brace of the fishing line should be hooked on the bracket, and wind it in observing the direction of the arrow

- The rig is wound until a 10-15 cm segment remains, which is fixed in the corresponding hole on the side of the guide

- Manipulations with the second end of the fishing line are carried out in the same way.

- The protrusions are inserted into the holes of the head, and then, removing the equipment from the temporary fasteners in the coil, the cover with the latches is installed

The above instructions on how to install a fishing line in the lawnmower will help not only correctly, but also quickly make the replacement procedure. Assembling the trimmer coil, as mentioned above, can be done without removing the head, but in this case, you will need to conveniently fix the tool. Video instruction is presented below.

How does a line head work on a lawn mower why you need to know how it works

Depending on the manufacturer, the heads differ structurally not only externally, but also internally. Most drums have a pressure spring inside (semi-automatic and automatic). Above is an instruction on how to disassemble the trimmer head without a spring, i.e. on the head of the manual type. The principle of dismantling a semi-automatic head with a spring inside is almost identical to the instructions described above.

The principle of operation of the semi-automatic trimmer coil is as follows:

- Inside the head there is a coil, which is fitted on the slots, which prevent its free movement.

- A spring acts on the coil, which presses it against the slots in the cover structure

- A fishing line is wound on the tip, the length of which depends on the tool itself. Typically this length is between 1 and 4 meters.

- During the performance of work, if it is necessary to increase the length of the line, the protruding part of the drum is pressed, whereby it disengages from the splines. In this case, the line is unwound from the drum, increasing in length

- After releasing the required amount of fishing line, release the pressure and continue cutting the grass

The advantage of a tool with a line is that this consumable does not require sharpening, compared to metal discs. In addition, if a stone or a tree comes across on the way, the line simply breaks off, without adversely affecting the gearbox and engine of the tool, as is the case with metal cutting discs.

Knowing the design and device of the types of mowing or trimmer heads, it is necessary to go on to consider the process of threading the line into the trimmer spool. After all, it is this moment that causes difficulties for most owners of special tools.