Why Jigsaw Jumps When Sawing

Correct sawing technique

The main thing is to remember that it is these files that are enough for only a couple of hours of work.

And you need to handle them very carefully.

The smallest saws can only cut plywood.

If the material is harder and more dense, it means that the file must be taken of a larger size. This will also help answer the question of how to cut plywood smoothly.

They start sawing after fixing the workpiece and applying the markings. To do this, you need to turn on the jigsaw, set the maximum speed level and adjust the pendulum stroke by setting it to 1.

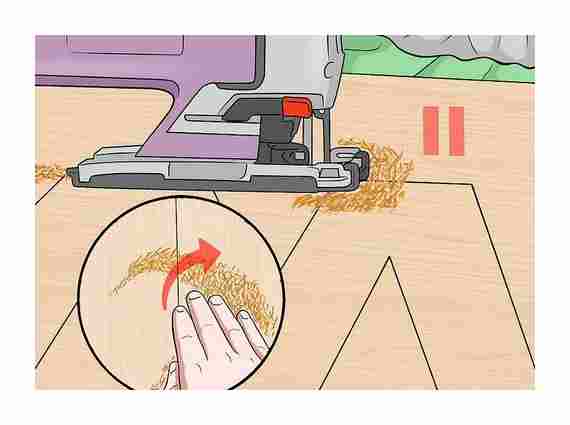

It is necessary to bring the saw to the mowing line of the marking, press the side of the platform against the guide and start working. Moving the jigsaw forward, you must monitor the location of the platform. Departure from the guide must not be allowed. When a few centimeters remain to the end of the web, you must carefully hold the free edge, avoiding a break. At this point, the process can be considered complete. So that the saw cut does not turn out to be a curve, it is worth remembering a number of nuances:

- during work, do not press hard on the electric jigsaw, otherwise the file will break;

- when cutting a steel sheet, it is necessary to choose a tool with maximum power and work at high speed. when heated, the steel softens and becomes more pliable;

- when processing plastic, laminate, organic glass or stainless steel, it is necessary to provide for additional cooling of the file and periodically take breaks so that the tool has time to cool;

- so that the plastic does not melt during processing, you must set the minimum speed with a frequency of 1000 rpm;

- the figured cut will turn out to be even when choosing a narrow file with small teeth;

- after finishing work, the electrical appliance should be cleaned of sawdust and put into a special case.

Professional builders advise to adhere to some rules to help avoid mistakes, which will not be easy to fix.

When choosing a file, you need to build on the material with which you have to work: plastic, thin or thick metal, plywood, solid wood. All additional items that may be needed in the process of sawing, marking and fastening should be prepared in advance. Particular attention should be paid to fixing the material to the surface.

It is best to try the cutting technique in advance, practice cutting with a jigsaw on unnecessary workpieces, because it will be difficult to fix a curved line. Safety precautions should not be neglected, goggles should be used, sawing with gloves.

Fastener material

In order for the line to be cut to be even, the working surface must be as stable, rigid and durable as possible. When working at home, it can be an ordinary table with reliable legs and a flat table top.

The board is fixed to the surface with clamps fixed on both sides with moderate strength. The sheet to be processed must be positioned in such a way that the tool does not rest against the surface during operation. So that no pressure is exerted on the saw during the sawing process, the protruding edge hanging from the surface can be weighted with the attached weight.

Errors when working with a jigsaw

If the technological subtleties are taken into account, and the cut line turns out to be a curve and with many chips, there may be several reasons.

The master has little experience with a jigsaw. You need to practice more and as a result, you will be able to cut properly.

The material is not fixed securely enough and when sawing moves from its place, or is fixed inconveniently for the person doing the work.

If the process is performed by a worker without experience, it is necessary to use guides, and in the manufacture of complex shapes. a special pattern. If this is not possible, the quality of the cut can be improved by reducing the speed.

The main reason why a crooked cut is obtained is a malfunction of the tool or blade. In this case, there is a high probability of chips, sawing off the side and dullness. An incorrectly selected canvas for a specific material will lead to the fact that it will break repeatedly during work and the result will be of poor quality. It is worth carefully inspecting the jigsaw and fixing the breakage.

Too much emphasis on the jigsaw leads to unnecessary pressure, which also negatively affects the final cut.

To cut the material with a jigsaw, it is not necessary to have many years of carpentry experience, it is important to listen to the advice of professionals and follow the technology of working with the tool.

Getting started

The movement of the cutting blade must be accurate so that the cut is the right one. It’s good when the frequency of movement is high. For this, a saw of the maximum width is taken (this is suitable for a tree). The main thing in this process is the use of a guide. A flat board or rail becomes the main assistant.

Clamps are indispensable. They place the workpiece and the guide. The material to be cut should be placed on a small elevation. This helps to keep the jigsaw from pushing. After that, the distance that should be cut is fixed. For this, a tape measure is used. After that, risks are applied with a pencil. Then, using any ruler, these marks are connected, and a cut line is obtained.

The movement of the cutting blade must be accurate so that the cut is the right one. It’s good when the frequency of movement is high. For this, a saw of the maximum width is taken (this is suitable for a tree). The main thing in this process is the use of a guide. A flat board or rail becomes the main assistant.

Requirements

The very first thing is to securely and firmly fix the material on which the work will be carried out. It also happens that an error occurs and the jigsaw starts to cut unevenly. It is worth finding out the reason, otherwise it will not be possible to achieve the desired cut. This is the stability of the table, as well as the reliability of fixing the material. It is not so difficult to make even cuts with such a tool, but if you choose the direction along the fibers, nothing will work. Although experienced people can handle even such a task.

The very first thing is to securely and firmly fix the material on which the work will be carried out. It also happens that an error occurs and the jigsaw starts to cut unevenly. It is worth finding out the reason, otherwise it will not be possible to achieve the desired cut. This is the stability of the table, as well as the reliability of fixing the material. It is not so difficult to make even cuts with such a tool, but if you choose the direction along the fibers, nothing will work. Although people with experience can cope even with such a task.

Learn how to use the jig-saw. Basic Construction Power Saws series

How to cut smoothly with a jigsaw? If such a need is required for a person without experience, then you need to perform the following actions. this is a parallel emphasis. To do this, on one side, attachment to the jigsaw is performed, and the other side is an emphasis on the edge of the tree. This is how it will turn out to make the cut even and without fiber residues.

Everyone can recognize the device of this unit in the instructions. When buying, managers give a lot of recommendations. Each manufacturer includes instructions, this is no less useful information, and it is worth studying. Everything should happen in stages, if questions arise, then they need to be resolved, and not continue to work “at random”.

About additional accessories

To make the cut more accurate, for example, when cutting small parts, a special sawing table is used. It is fixed on the desktop with a clamp. Cutting on such a table is the opposite. In this case, it is not the saw that moves, but the part itself. This results in more precise mowing lines.

In order for the saw to move well along the workpiece, an additional device is used. a replaceable plate. It can be made from various materials. It is attached to the support sole of the instrument. With guide rail and adapter, more precise mowing lines are cut.

When sawing some materials, they need to be cooled. For this, a container with cold liquid is intended, which is installed on the support sole.

Plastic and wood are cut from the back using a thin file. This will prevent deformation on the mowing line of the cut. When cutting metal, the cutting blade is lubricated with machine oil, and the line of the metal cut is cooled. Curvilinear sawing is performed with narrower saws. In order to cut a circle, use a special circular cutter. It needs to be installed in the center of the future circle.

The jigsaw is an indispensable tool in any home carpentry workshop. With its help, you can saw any materials, perform even and accurate sawing, saw out parts of any shape and size.

The use of plunge sawing is permissible if it is impossible to create holes of the required dimensions. For this, the jigsaw tilts forward until the file reaches the workpiece. Gradually during this process, a through hole appears.

No special effort is required to obtain maximum results. The tool can work as a stand-alone fixture without any additions. But there are parts that can increase the working capacity of a conventional jigsaw.

A special sawing table is installed if the accuracy of the work becomes especially important. Fastening is carried out with the working surface using clamps.

Replacement plates are another part of the kit. It prevents parts from slipping. The plates themselves are created from various substrates. The support soles are involved in the bracing. A guide rail and adapter will also help increase cutting precision.

Some materials are not recommended to be processed without pre-cooling. Special tanks fixed on the unit will facilitate the solution of this task. Maintenance is easy with universal lubricants.

A jigsaw is a kind of universal device that in some cases can replace a number of tools. Before starting work, it is necessary to make an external examination of the tool: make sure that the power cable is intact, check the connection to the mains.

#one. Parallel stop-compass. useful for cutting circles.

# 2. Rip fence. for straight cuts.

# 3. Guide bar. makes it easy to cut in a straight line.

#four. Removable pad for the support block. can be made of plastic or metal and is used to increase the sliding of the jigsaw on the surface of the material being processed.

#five. Anti-splinter liner. used to reduce the likelihood of chips in the process of work, especially relevant when sawing laminated lumber.

Having learned how to use a jigsaw correctly, you can proceed directly to sawing. The choice of the file and the operating mode plays a rather important role in the process of sawing material and operating the tool. If the operating mode is incorrectly selected, the jigsaw may break. Therefore, you should not neglect the recommendations described below.

Jigsaw guide rail

Not every master with straight hands will be able to make a perfectly even cut with an electric jigsaw without the use of accessories. Only the most hardened experts who masterfully own the tool will be able to get an even line “by eye”, and then, subject to its serviceability and the availability of suitable saw blades.

Of course, not everyone has the time and desire to become a straight saw with a jigsaw, and purchasing a circular or plunge-cut saw for such a task is quite expensive. If you only have a jigsaw with saws at your disposal, then a special guide rail will help you to get the desired even line.

A jigsaw guide is an elementary device at first glance, similar to a large metal ruler or rule. The main difference between the tire and the above devices is a special groove along which, like on rails, the sole moves with a jigsaw installed on it.

Most of the guides have rubberized strips that prevent sliding on the surface of the material, and as an additional fixation, they are attached with small clamps. The average length of such devices is from 1.5 to 3 meters, and can be increased by another, similar ruler, using an adapter.

Many modern manufacturers of electric jigsaws produce special guide rails that are focused on their products. Such devices have a rather low versatility, limited to working with instruments of this brand only. Fortunately for owners of non-branded machines, there is an advanced, versatile Line Master, with an adjustable sole and many useful features.

If the jigsaw cuts crookedly, and it is not advisable to buy an expensive guide, you can completely do with improvised means. Any flat edge with a thickness of 5 mm or more can become an improvised emphasis: a straight rail, as a rule, a piece of plywood and other straight surfaces of suitable dimensions. The clips of the guide to the material can be a pair of ordinary clamps.

Before installing a home-made stop, you should mark the line of the required cut in advance and retreat from it a certain distance equal to what is between the file and the edge of the tool sole. When sawing, the tool should be guided strictly along the edge of the guide so that it is parallel to the sole of the jigsaw.

To keep the line as neat and even as possible, use the optimal file for the material being cut. visual processes of making and using a homemade guide are demonstrated in the following videos.

Save this page in your social. network and return to it at a convenient time.

How to cut smoothly with a jigsaw? This question interests many, especially at a time when a person is engaged in construction. This tool helps to cope with a complex task. But what is it? In terms of external data and main purpose, it is comparable to a saw that has an electric drive. In this case, you can cut various materials:

- Wood products.

- Metal constructions.

- Plastic.

- Tiles.

And it is not so difficult to do work for any purpose. According to the masters, the main thing is to create all the conditions to make it convenient to work. How to cut smoothly with a jigsaw? The first is to use only a flat and stable surface. The material for cutting must be firmly fixed, and the saw of the desired sharpness and size is selected.

This saw is considered unique because it can work on almost all materials. In addition, it does more than just smooth mowing lines. With its help, you can create cuts curves. But before starting the process, it is worthwhile to understand which jigsaws cut smoothly and efficiently.

How to cut smoothly with a jigsaw? This tool is an electric saw. It can cut various materials:

- wood;

- metal;

- plastic;

- tiles.

Working with a jigsaw is simple, if you follow the rules: the table must be stable, the material is firmly fixed, the correct saw is selected.

The tool can cut parts, cut workpieces on a flat or circular mowing line. How to saw with a jigsaw?

Some features of the process

How to cut straight with a jigsaw? Before starting work, it is worth finding out the whole process, otherwise you will not be able to come to the desired result. Often, when working with any material, you need to create a cut with maximum accuracy. It is the electric jigsaw that will do the job.

Here’s what you need to do this:

- Material for work.

- Jigsaw.

- Guide tools.

- Clamps.

- Pencil.

- Construction tape.

Each jigsaw has a so-called support sole. It always rests on the part that needs to be cut. Thanks to this, the accuracy of work is significantly increased.

The sole can be easily rotated to make bevel cuts. Some manufacturers produce models in which the main tool is fixed only at a certain angle.

The file acts as the main cutting tool. Dilution of teeth, method of sharpening, size, shape, materials. they are literally different for each model. 75, 85 and 100 millimeters are the most suitable lengths if you need to cut low density materials. Saw step size is also becoming a fairly important parameter.

- Metal requires a pitch of 12 millimeters.

- For wooden products, it is from 2.5 to 4.

In this section, we will talk about how to properly saw round or oval elements with a jigsaw. First you need to apply markings to the material. In most cases, a hole is drilled in the workpiece, from which the product will be cut. In this case, the diameter of the drill should slightly exceed the width of the saw blade. To cut out curved elements, you must take a narrow file designed for such work.

Despite the fact that this type of work is one of the most common, with a lack of experience, difficulties may arise with how to smoothly saw off any element with a jigsaw. It is recommended to opt for a file with a wide blade, designed for straight cuts, in order to better hold the line marking.

In the process of work, you should not use excessive force to move the jigsaw forward, otherwise this will lead to failure of the file or tool mechanisms. A worn-out blade should be replaced immediately, since a blunt file causes an increased load on the electric drive. The workpiece to be sawn must be securely fastened.

For straight cuts, you can use a rip fence or a guide bar.

First, the workpiece must be marked. After that? by installing the jigsaw in a special shoe, and then the shoe in the tire, the tool is positioned along the mowing line of the cut.

First you need to choose the right file

for a jigsaw. A variety of files allows you to choose the option that will correspond to both the material of the original workpiece and the final required result.

In general, a jigsaw can be with a pendulum and with a normal stroke. In the second option, for an even cut, the blade must be moved clearly vertically, cutting the material upward. Due to the high generated speed, the blade wears out more slowly.

When working with a pendulum stroke tool, the principle is essentially the same, only the preferred material for processing is soft wood or plastic, difficulties with steel can arise.

In order to make a straight cut, it is necessary to choose a wide blade, it is better if the jigsaw has the “Smooth Start” function, which will avoid sharp movements at the initial stage.

If you need to cut a round hole, you first need to drill the original version, inside which the necessary file is inserted.

Sawing along the edge of the workpiece is allowed, but you must make sure of its initial evenness, without this the jigsaw cuts crookedly. If the edge is uneven, then only correct marking can fix it.

When working with thin wood sheets, there is a risk of chips. To prevent this, the sheet should be placed face down.

.

The names speak for themselves. In the first case, the panels are installed vertically, the beam, installed on the guides, acts as a bracket. The ability to rotate it to a right angle allows you to cut the material in any plane. The horizontal version assumes the presence of a sawing table, the mechanism itself and a carriage that ensures the movement of the saw along.

Start button

Device

The jigsaw is a tool that is suitable for working with a wide variety of materials:

- solid wood;

- Chipboard;

- plywood;

- hardboard;

- soft metal;

- PVC materials.

The versatility of this wonderful tool allows you to perform complex complex work that another tool is not able to do. Saw blades are actively involved during operation, they are exposed to considerable mechanical stress, after a period of time they fail.

The jigsaw mechanism is also under heavy stress. If such a unit is used regularly, then you should know its layout, how it works.

The principle of this unit is simple, its main blocks are:

- engine;

- reducer;

- stock.

Air cooler, speed control, swinging assembly are all auxiliary retention elements that ensure the duration and productivity of the work.

In some models, the electric jigsaw is provided with a separate start button, which can also adjust the frequency of the torque.

From the point of view of the transformation of electrical energy, the following process occurs:

- an electrical impulse entering the tool goes to the brushes (they are made of graphite), which ensures the appearance of a torque on the rotor;

- the impulse of rotation is transmitted to the gearbox. a unit that transforms the torque into a translational movement, which is directed to the stem.

In this scheme, a special role is assigned to the fastening unit, which ensures a reliable connection of the rod with the moving blade.

As you can see, the principle of the jigsaw is the same for all models. The difference is present only in the quality of assembly, fit of units, materials.

Knowing the “general outline” and the operation algorithm of the elements, it is easy to understand what breakdowns and malfunctions may occur, as well as to find out the reasons due to which they arise.

Replacing the file holder

In jigsaws, the most common malfunction is replacing the quick-detachable saw blade mount. Fixing requires a tool of a certain thickness. If its size is smaller, then the file will “play”.

There is an entrance from this situation: you can put the holder on bolts. Then the equipment will become quite versatile. To do this, cut the square reinforcement into two pieces, drill holes with a diameter of 3-4 mm in them and fasten them with M5 bolts. You will have to tinker, because the operation is quite laborious, but after that the tool will be cut for sure.

You can also reduce the movement of the file in the perpendicular motion vector. A plate is cut out of the aluminum sheet (it must correspond to the parameters of the jigsaw sole). Then a recess is cut according to the dimensions of the tool. Burrs are removed with a small file. Bevels must be made on the ledges. A blade cuts into the saw blade, it is mounted on the sole of the tool.

Holes are then drilled to install the fasteners. A piece of plexiglass is inserted into a metal plate. You only need to cut at the point where it will be based.

As a result, during operation, the blade will be limited in lateral movement at the point of the cut itself. This will create even more straightforwardness.

Frequent malfunctions

Like any mechanism, a jigsaw may experience various malfunctions:

- the tool cuts crookedly, the blade “leads” to the side at an angle that is unacceptable;

- the mounting of the cutting tool has broken, the file flies out;

- the unit does not turn on;

- the gear wheel or its teeth breaks down;

- the worm gear, which is anchored, wears out;

- the blade jumps or falls out when sawing;

- the clamp does not work, the file does not hold;

The nature of the jigsaw’s work is cutting out curves of cuts. The curvature can be different, so there are also indicators here. A large load during such work falls on the main support roller, which often becomes unusable. So that it does not go out prematurely, it is recommended to observe all operating modes.

Mechanisms often fail when mechanical microparticles hit dynamic elements. It is imperative to carry out timely preventive inspection and cleaning of the internal components of the device. It is necessary to flush the unit with a special composition WD-40. It is also useful to use a vacuum cleaner to clean the power tool: the cause of the breakdown of the gearbox can be if dust gets on it.

Stem breakage most often occurs during mechanical damage.

Breaking a tooth on the collet also happens most often due to the fault of the master. This happens if the working blade is fixed too tightly.

The worm gear cannot withstand the loads if you “drive” the tool on afterburner.

Film Theory: Jigsaw was RIGHT! (Saw Movies)

It is recommended to start work after a short warm-up of the engine at idle speed.

If you do not follow the recommendations, then such malfunctions occur:

- the bearing wears out quickly;

- the cam block is erased;

- gear wheel breaks down.

Also, a fairly frequent breakdown is the abrasion of brushes, which are easy to replace. Preventive cleaning of running units is a must. Lubrication should also be done regularly.

Another common malfunction is the breakage of the holder, which causes the blade to fall out.

Often, the attachment of the jigsaw loses its rigidity, as a result of which play appears, which affects the quality of work. Clamps are almost impossible to repair. they have to be changed.

Some unscrupulous manufacturers make bolting from fragile materials. Such cheap alloys break at the slightest load and are extremely short-lived. you have to change the “native” bolts for fasteners made of strong steel.

The more complex the design, the more often breakdowns are possible. Modern gadgets, which manufacturers “stuff” the tool with, do a disservice. They are often the cause of breakdowns in electrical appliances.

For example, the standard web feeding function (available on almost all models) greatly assists in the job by reducing stress on the worker’s hands. However, the presence of such a mechanism leads to a lot of wear and tear of individual units of the unit, such as:

- guide roller;

- bushings (especially in the stock).

Another example can be cited when too much load appears, which can be caused by the physical impact of an inexperienced worker: if the model is not too expensive, then, as a rule, the file in it can break the fragile holder.

The platter roller may suddenly “freeze”. The reasons may be as follows:

- lack of lubrication;

- bearing breakage.

To change the roller, you need to dismantle the microsaw, separate the body by unscrewing the bolts. Pull the roller out of the niche and put the “fresh” one. You can do this operation yourself. it is simple.

If a protection is triggered that protects the unit from overheating, then there may be several reasons, for example, the air duct is clogged with dust, which does not allow the engine to fully cool. You should take a brush or an old toothbrush and clean the sections of the grill. You can also use the following “tools” for cleaning:

- a needle;

- cotton rag;

- alcohol.

Thermal protection is available to protect the motor from overheating. It can be triggered due to contamination of the air intake grilles with dust and sawdust. Clean the grates, let the jigsaw cool down a little. After a while, the thermal switch will turn on automatically.

The cord may be damaged and the engine will not run. You can check the cord with a tester. If there is a defect, the readings on the device will be equal to infinity. The cord is inexpensive, it will need to be changed.

There are models that operate on portable chargers. When working with such jigsaws, the battery must not be discharged by more than 15-20%.

If this happens regularly, the battery will lose its resource, which will significantly reduce its life.

Features of jigsaw repair

- Device

- Frequent malfunctions

- Repairs

- Start button

- Replacing the file holder

- Breakdown prevention

A wide variety of power tools from different manufacturers are presented on the trading floors. There are a wide variety of models: both amateur cheap and “sophisticated” professional, which cost a lot of money.

Jigsaws occupy a special place, they are also in great demand. There are units of various sizes from domestic manufacturers and imported.

Repairs

Before you repair the instrument yourself, it is recommended to collect information, paying attention to some of the phenomena that occur in case of malfunctions:

- the case gets very hot;

- there are extraneous noises at the very beginning of the unit’s operation;

- sheaves of sparks appear when the jigsaw starts functioning.

There are two types of breakdowns that you can fix yourself:

- the electrical unit fails;

- mechanical elements break.

If the rotor or stator breaks down, then such a malfunction cannot be eliminated by yourself. the easiest way is to return the machine to a service center. This usually happens from excessive contamination of working units and the lack of preventive cleaning of the unit.

If the brushes are worn out, then you can replace them yourself. there is no difficulty here.

If the regulator, which is responsible for the speed, breaks down, then only a specialist can repair this unit. The tool is disassembled in a matter of minutes. The case can be “halved” by unscrewing the screws. Old grease should be removed first, after cleaning, apply a new one.

The easiest to repair are devices where there is a rounded stem exit. The bushing is either selected, or the cone-shaped cavity is enlarged by tapering. Such procedures remove backlash if it occurs in the mount.

For some models, special clips should be made; for their installation, copper foil is used (as a gasket). If the model has a budget, the stem is usually made of a metal plate. Manufacturers save on metal, so the thickness parameters of this plate are extremely insignificant. The plate often does not withstand loads and breaks.

In this case, the machine is disassembled, each stage is recorded, photographed with a digital camera. The part is removed (the plate has a complex configuration). The plate fragments are taken by the owner to select the correct replacement part on site. After installing a new part in place of a broken one, be sure to renew the lubricant.

It doesn’t take much skill to change the brushes. It is enough to open the body of the jigsaw and take out the worn-out brushes, gently wipe all the cavities and units of the unit with a piece of bandage. Then the new brushes should be installed in place of the old elements. It is best to use rubbing alcohol for wiping.

The advantage of modern models is that there is no need to use a soldering iron. The thermal fuse also fails, but not as often. This part is easy to replace. If sparking is observed in the unit, then this primarily indicates that the brushes are worn out or the lubricant is outdated.

Any tool requires a preventive examination. this is a prerequisite for it to serve for a long time. In this case, additional revision or material expenditures for putting it in order will not be required.

After the end of the working cycle, the power tool is de-energized. this rule is not recommended to be forgotten. For some jigsaws, the socket has an additional fuse, which may fail. this should also be remembered.

Breakdown prevention

Preventive measures always extend the life of any tool, including jigsaws. At the beginning of work, unscrew the screws, open the case. With the help of alcohol and a cotton cloth, it is necessary to clean all the units from the old grease. Then a new lubricant is applied to the desired points (in accordance with the recommendations prescribed in the instructions-memo). It is very important to process precisely the dynamic parts of the unit (current, gearbox).

There are also a number of other preventive measures:

- using only “native” parts;

- produce canvases by 70 percent and then change them;

- use canvases only those that correspond to the nature of these works;

- during operation, do not “strain” with excessive mechanical loads;

- clean the tool from accumulated dust at least once a week;

- use WD-40 lubricant;

- use a vacuum cleaner for cleaning;

- do not hit or drop the tool. this often leads to damage to the bearing rod;

- do not tighten the file too tightly in the mount;

- for too dense materials there are special devices, they must be used;

- each material has its own optimal operating mode (speed, angle of inclination, etc.);

- the base of the support roller should be treated with special technical grease at least once a week;

- you should actively use technical brushes to process the tool after finishing work;

- always monitor the ventilation grill of the instrument and clean it of mechanical microparticles.

How to repair a jigsaw with your own hands, you will learn from the video below.

Why the jigsaw cuts crooked and how to fix it

In most cases, the process of straight and figured cutting of materials requires the utmost precision of the tool. This statement is most true for an electric jigsaw. The thin saw blades used in this device can easily change the cutting angle, which can negatively affect the accuracy of the line. The clarity of the edges of the product and the evenness of the mowing line of the cut depends on the skills of the operator, the serviceability of the device and the saw. Next, we will tell you how to get the planned contour with perfectly clear edges and what to do if the jigsaw goes to the side.

Why the jigsaw saws crooked

There can be several reasons why the saw blade leaves the pre-marked mowing line. The operator may lack experience with the tool, the file may be defective, and the jigsaw stem and guide roller may seriously play. In order not to guess on the coffee grounds, it is worth starting to screen out the factors that determine the accuracy and evenness of the mowing line of the cut in your, individual case.

As usual, it’s best to start with yourself and your approach to sawing. Often, novice craftsmen rush things and, wanting to speed up the cut, put a lot of pressure on the jigsaw. The tool does not have time to evenly bite into the material and create a clear groove for the file, which begins to follow the path of least resistance and makes unpredictable movements. This problem is especially common when working with thick beams (from 40 mm) and varnished plywood of the Soviet era.

This is one of the reasons why the jigsaw is tilting to the side. What to do with this? The answer is obvious. Apply the minimum pressure just enough to guide the tool along the line and set the maximum speed (when working with wood). The pendulum mode usually does not affect the evenness of the cut if its design is in good order.

The build quality and wear of the tool parts can be a good reason for the formation of beveled lines when cutting. There are basically no complaints about devices from the budget segment (up to 2500 rubles), as well as hopes for their conscientious assembly. It’s another matter when such Fortely begin to perform original, branded instruments. Often, the cause of the crooked cut is the guide roller, jigsaw rod or its sole.

You can check the reliability of the fixation of the element by simply jerking it with your hand. Looseness of the rod or roller by more than 1 mm determines that this device is not capable of producing a perfectly straight cut. The greater the backlash of the parts, the less accurate the cutting line they form. This problem should be corrected based on the circumstances. If the part itself is worn out, it can be replaced with a similar one. It is difficult to fix a breakdown if the attachment to the mechanism is worn out. Not every modern Kulibin undertakes such repairs, and usually this problem is solved by buying a new tool.

The products of many trusted brands, unfortunately, are often counterfeited, and jigsaw files are very popular in this regard. It so happened that low-quality and counterfeit products have a rather short service life, which brings many problems to the owner. One of these problems is the cutting curve. An initially flat blade can bend due to poor-quality metal, which can deform the tooth gap, if it was present at all. In this regard, if your jigsaw cuts crookedly, replacing the saw blade can correct the situation. The process of choosing a high-quality file for a jigsaw was described in detail by us in a separate topic.

Jigsaw guide rail

A jigsaw guide is an elementary device at first glance, similar to a large metal ruler or rule. The main difference between the tire and the above devices is a special groove along which the sole with a jigsaw installed on it moves, like on rails. Most of the guides have rubberized strips that prevent sliding on the surface of the material, and as an additional fixation, they are attached with small clamps. The average length of such devices is from 1.5 to 3 meters, and can be increased by another, similar ruler, using an adapter.

DIY jigsaw guide

If the jigsaw cuts crookedly, and it is not advisable to buy an expensive guide, you can completely do with improvised means. Any flat edge with a thickness of 5 mm or more can become an improvised emphasis: a straight rail, as a rule, a piece of plywood and other straight surfaces of suitable dimensions. A pair of conventional clamps can be used as fixators of the guide to the material. If the surface condition of the opposite part of the material to be cut is not very important, the guide can be screwed onto a pair of self-tapping screws.

To keep the line as neat and even as possible, use the optimal file for the material being cut. visual processes of making and using a homemade guide are demonstrated in the following videos.