Why the chainsaw pulls away when sawing. Why the chain saw cuts crooked and how to solve the problem fast yourself

Why a chain saw slices crooked

If the chainsaw starts to cut crooked when working, then in addition to uneven sawing, we get a number of the following negative consequences:

- Sawyer has to exert physical effort to keep tool straight

- Fuel consumption increases due to the tool’s increased path over the material being sawed

- Increased load on the drive sprocket, which leads to its accelerated wear

- The guide bar wears out because only one side of the bar is under more strain

- Tool Performance Deteriorates

- Getting a crooked cut. If you are preparing the wood for making boards, the crooked trunks are equal to scrap. If the wood is sawn for firewood, the resulting curved log is not very convenient to chop

- Discomfort at work. the handyman quickly tires when working with a faulty tool

Why a chainsaw can cut trees crookedly? Many may think that the cause is a faulty chain saw bar, but in fact, there are four main causes:

- Incorrect or unevenly sharpened teeth

- Use of chain, guide bar, or sprocket that does not match the pitch

- Wear on the cutting attachments. this is often caused by wear on one side of the guide bar

- Untimely retightening of the chain

If this fault, such as an uneven cut in the wood, it must be corrected as quickly as possible. If you continue to operate the tool with such a malfunction, it will lead to the wear and tear of the engine, and the need to repair it.

Let’s look at each type of failure separately, and find out how to determine what causes why a chainsaw cuts sideways.

Fuel system

Faults in the fuel system are also quite often the main reason that does not allow the chainsaw to work as efficiently as possible. The first thing to do is check the quality of the fuel mixture.

If gasoline droplets occasionally appear on the chainsaw body, check the fuel tank for leaks. Over time, it can become cracked. Or the gasket is “cured” and it can no longer perform its direct function.

If full-blown gasoline streams appeared, there’s a good chance you’ll have to replace the burst hose that connects the carburetor and the fuel tank.

There are several reasons why the fuel mixture has stopped flowing into the cylinder:

- The air filter is clogged.

- The carburetor’s operating settings are off.

- The carburetor diaphragm is no longer intact.

- Channels for transporting gasoline are clogged.

In this case, you should start looking for a problem with the filter elements. in most cases, it is because of the reduced flow rate of the air and gasoline filters that the idling speed begins to “float.

If everything is okay with the filters, you should check the components of the gasoline system, and also make sure that the carburetor settings are not spontaneously changed.

In some cases, chainsaw users notice other problems, which do not significantly affect the performance of the tool.

Most often excessive smoke occurs when there is too much oil added to the fuel mixture, which does not have time to burn completely. You should also check to see if the carburetor settings are off.

In most cases, the recoil at the start signals a clamping of the decompressor. If the tool is not equipped with a decompressor, most likely, the ignition system is knocked out.

Safety precautions when working with a chainsaw

When buying such a tool, it is necessary to know how to use the chainsaw correctly. Labor safety requires that an employee must use only equipment that is in good working order. Therefore, the operation of a chainsaw requires:

- always check it before starting;

- regular checking of the condition and adjustment of the main assemblies;

- Adding oil in time and adjusting the chain tension;

- To stop working when the chain brake and other essential parts and accessories malfunction.

Do not make homemade modifications to the tool or use unsuitable spare parts for the model used. Some craftsmen tell you how to start a chainsaw without a starter motor. But they forget that its impeller is needed to cool the motor, which will begin to overheat with the threat of failure.

To use a chain saw you must wear special gloves, metal shoes, hard hat, and eye protection. Hold the tool with both hands and straight back, do not lean far forward and do not lift the saw above your shoulders. It is not recommended to have parts of the body in the plane of the saw. It is forbidden to drive with a chainsaw with a rotating cutting chain.

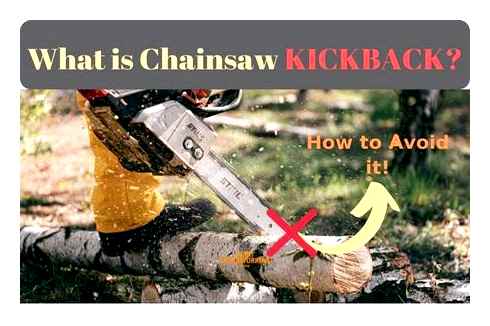

Practical work with a chainsaw when felling trees and cutting limbs requires special rules to prevent injury to the worker from falling trunks. Especially dangerous is the backstroke of a saw that has run into an obstacle. The sawyer is not allowed to:

- Felling trees in one cut;

- To cut several limbs at the same time;

- Make the cut with the end of the bar;

- be in the fall zone of a tree.

Use of unsuitable chain

It’s no secret that a chainsaw bar, like a chain, has several basic characteristics, one of which is the width of the groove to fit the chain. Groove widths can have several basic dimensions:

Let’s imagine that we take a chain with 1.1 fit width and install it on a bar with 1.3 mm groove. Initially, well tensioned it, we may not notice the difference, but as soon as the tension is slightly loose, a gap of 0.2 mm will not allow it to move evenly along the bar, it will lean to one side and we will again get a crooked material.

When you buy a spare chain for your chain saw, always quote the exact chain dimensions, not the make or model of the saw. The same chainsaw models may have different bars and therefore the chains will also be different.

Check the width of the chain can be checked with a caliper.

To correct the problem, if the chainsaw bar is not yet severely damaged and there is no uneven wear on it, you will only need to replace the chain. If it already has wear and tear, a complete new set should be installed.

Uneven sharpening

According to the instructions for sharpening chains the teeth should be ground at the same distance no matter which side they are on. This simple statement can help prevent the chainsaw from slipping when you are sawing.

Unevenly ground teeth are the most common problem with crooked sawing.

When sharpening the chain with a file it is not always possible to control the tooth length using the technique of counting the number of file movements.

This is caused by the fact that the wear of the teeth is uneven, some are more damaged and require more file movements in order to bring them back to normal, which means that the size of such teeth will be reduced significantly compared to the others.

How to avoid wrong sharpening

In order to avoid a bad cut due to uneven sharpening, the chain can be ground from time to time or if it is badly damaged, use a chain sharpening machine to dress it. Buy the machine and sharpen it yourself or have it sharpened in a workshop.

The fact is that the machine during the sharpening is adjusted by the most worn tooth, which has the smallest size of all. After sharpening, all the teeth will have the same size, which will be equal to the tooth where the sharpening was carried out.

The disadvantage of this method is that the life of the chain is considerably reduced, because. к. it is necessary to grind hard, even if the teeth are not damaged. Try to use your chain saw more carefully and watch out for nails and any other metal objects that might get caught in the sawing of old boards and other junk.

Severe saw blade wear

A guide bar lasts much longer than a chain. But that doesn’t mean you can use it forever and not have to think about changing it. Usually the guide bar is replaced after 2-3 worn chainsaws. Before replacing the chainsaw guide bar, you need to assess its technical condition. If your chainsaw is equipped with a Chinese-made tire, it can wear out faster than the chain. That’s why if you find a crooked wood cut with a chainsaw, you need to have the tire diagnosed.

To see how worn a tire is, you have to take it off and look at it. Wear is usually evident by shortening one of the flanges. Sometimes it is extremely difficult to detect this visually, so you have to use a caliper. A difference of a few tenths of a mm means the guide bar needs to be replaced. There’s also an easy way to check if the guide bar is worn out with a straight edge. To do it, put the guide bar on a flat surface with a straight edge at the side. If the upper and lower walls of the guide rail are in contact with the square, that means the part is in good condition.

Accelerated tire wear can occur due to a malfunctioning oil pump. If lubrication is intermittently applied, friction increases accordingly, and thus parts wear out more quickly. If the lube unit is working properly, it will dramatically extend the service life of not only the bar, but also of the tool as a whole.

Why a chain saw cuts crooked

Why the chain saw cuts crookedly

Working with a chainsaw, in some cases you can see how when you cut a tree trunk with a cross section of more than 30 cm the guide bar starts to go sideways a little. This is especially noticeable when large cross-section trunks need to be cut using the double-cutting technique, i.e. е. Sawing is done from the top, later on it is reversed and finished off.

IMPORTANT.Experienced electrician leaked the secret of how to pay for electricity in half, the legal way. Read more

Billets badly sawn with a chainsaw have an uneven surface, which makes it somewhat uncomfortable to split them into logs. And the introduction of such a chainsaw when building a log house, for example, for trimming beams, and is not allowed at all, ie. к. the ends will be uneven.

Using the wrong chain

It is not a secret that chain saw guide bar, as well as the chain, has several basic characteristics, one of them is the width of the slot for the chain installation. The width of the groove can have several basic dimensions:

Let’s imagine that we take a chain with 1.1 fit width and install it on a guide bar with 1.3 mm groove. and we can not even notice the difference, but as soon as you loosen the tension a little, the play of 0.2 mm will not allow it to move around the bar evenly, it will lean to one side, and we’ll get a badly sawn material again.

when buying a chain to your chain saw, ask for the exact chain size, not the make or model of the chain saw. Similar chainsaw models can have different bars and therefore the chains will be different too.

Check the width of the chain fit, you can use a caliper.

To correct the problem, if the chain saw bar is not severely damaged and there is no uneven wear on it, you will only need to replace the chain. If there is already wear on it, a completely new set must be installed.

Why a chain saw cuts crooked

Why a chain saw cuts crooked

Working with a chainsaw, in some cases, you can see how when you cut a tree trunk with a cross section of more than 30 cm, the bar begins to drift sideways a little. This is especially noticeable when you have to cut huge cross-sectional trunks using the double-cutting technique, i.e. е. First cut from above, but later turn it over and saw all the way through.

IMPORTANT. Experienced electrician leaked the secret how to pay electricity bill in half, the legal way. Read more

Chips that are crookedly sawed with a chainsaw have an uneven surface, it gives some discomfort when splitting them into logs. And the introduction of such a chainsaw when laying a log house, for example, to end beams and is not allowed at all, t. к. The ends will be jagged.

Why the chain saw is sideways

discomfort at work, reduced productivity, increased fuel consumption, crooked cuts, these are all bad consequences of this phenomenon, but what is the cause of all?

- Unevenly ground teeth;

- The introduction of a chain that does not match the characteristics of the bar or vice versa;

- Excessive wear of chain saw’s cutting equipment.

Uneven sharpening

According to the annotation on sharpening chains, toothing should be milled at a uniform distance, no matter what side it is on. Observing this common requirement can protect yourself from the trouble associated with the fact that the chainsaw when sawing takes away.

Unevenly ground teeth are the most common problem of crooked cuts.

When sharpening the chain with a rasp, it is not always possible to control the length of the tooth with the technique of counting the number of strokes of the rasp.

READ Gas Saw Needle Adjustment

It’s justified by the fact that the wear of teeth is uneven, some are more damaged and requires more movements of rathole, in order to normalize them, which means that the size of such teeth will be significantly reduced in comparison with the rest.

How to avoid a badly sharpened chain

To avoid a bad cut because of uneven sharpening, a special chain sharpening machine can be used at times or when the chain is badly damaged. Buy a sharpening machine and either sharpen it yourself or send it to a sharpening service.

The reason is that during sharpening the machine is adjusted by the most worn tooth, which has the smallest size in the middle of all. After sharpening, all teeth will be the same size as the tooth on which you sharpened them.

Why a chainsaw can cut awkwardly

The video carefully explains the reasons why a chainsaw can cut crookedly

Chainsaw is cutting left or right, the cause?

I’m wearing a mask, because the sharpening dust is everywhere!

The disadvantage of this method is that it significantly reduces the life of the chain. к. You have to grind down even the unbroken prongs. Try to use your chain saw more carefully, watch out for nails and any other metal objects that might get caught when you’re sawing old boards and other junk.

use of unsuitable chain

It is no secret that the bar of a chainsaw, as well as the chain, has several main features, one of them is the width of the groove for the installation of the chain. Groove width can have several main dimensions:

Why a sharp chain saw cuts crooked or bindes in wood.

READ Chain Spins When Chainsaw is Winding

Let’s imagine we take a chain with a 1.1 fit width and install it on a bar with a 1.3 mm groove. At the beginning, having perfectly tensioned it, we may not see any difference, but as the tension loosens a little, a gap of 0.2 mm will not allow it to move moderately on the bar, it will lean to one side and we will get a crooked material again.

Two Chainsaw Secrets | Turning a Tree into Perfect Boards

When buying a replacement chain for your chainsaw, name its exact dimensions, not the make and model of the chainsaw. On the same models of chainsaws, there may be different bars and accordingly the chains will also be different.

Check the width of the chain fit, you can use a caliper.

To fix the problem, if the chainsaw bar is not yet very damaged and there is no uneven wear on it, it will only be necessary to change the chain. If there is already wear and tear on it, it is necessary to install a hundred percent new set.

Increased wear and tear

If the chain saw slices awkwardly in the arc, it may be because the saw headset is too worn. Check can be carried out by visual inspection of their contacting surfaces. To do this, you remove the bar from the chain saw and look at its face-to-face contact with the chain, keeping it at eye level so that you can see 100% of the chain slots.

With this inspection, you can visually see the wear on the left and right sides of the guide bar in relation to the groove. Generally, edge wear should be moderate, and in this case if one side is worn down more severely, to fix the problem you must replace the defective side with a new one.

For even wear of the tire, some manufacturers suggest to rotate it from time to time. But it’s worth keeping in mind that this recommendation is not true for all headset models. к. many manufacturers indicate on the surface of the bar the direction of movement of the chain on it, and accordingly such a detail can be installed only in one position.

The picture below shows some views, the upper has the direction of the chain installation, as we are informed by the icon on the tip of the bar and the direction indicator.

Experienced chainsaw service center technicians recommend a complete diagnosis of the saw’s lubrication system if excessive wear is detected, i.e. к. If your chainsaw is properly lubricated and the chain is set to the guide bar, you should not see this as a problem, but the oil system could be faulty or out of adjustment.

If you see a crooked cut while working with a chainsaw, the first thing you should pay attention to is matching the chainsaw chain to its guide bar. If all is normal, check the sharpening of the teeth and the wear of the bar; if excessive wear is detected, check that the lubrication system is working, t. к. The problem could be it. The main thing is to remember that chainsaws are interconnected and the use of chain lubricants of inferior quality can be a cause of chain lubrication and wear at an early stage of chain-saw use.