Why the jigsaw juts sideways. Straight sawing technique: nuances you need to know

The jigsaw jumps

Initially it is necessary to choose the right saw blade for the jigsaw. A variety of saws allows you to choose the option that suits both the material of the initial workpiece and the final result required.

In general, the jigsaw can have a pendulum stroke and a regular stroke. In the second variant for a straight cut, the blade has to move vertically, cutting the material in an upward motion. Due to the high speed created, the blade wears more slowly.

When working with a pendulum stroke tool, the principle is essentially the same, only the preferred material for processing. soft wood or plastic, with steel can be difficult.

In order to make a straight cut, you need to choose a wide blade, it is better if the jigsaw in this case will have a function “Soft start”, which will avoid sudden movements just at the initial stage. If it is necessary to saw a round hole, you must first drill the original version, inside which the required saw is inserted.

It is allowed to saw along the edge of the workpiece, but you must always make sure that it is initially flat, without this electric jigsaw will cut crookedly. If the edge is uneven, it can only be corrected by proper marking.

When working with wooden sheets of small thicknesses, there is a risk of chipping. To prevent this, the sheet should be placed face down.

The names speak for themselves. In the first case, the panels are installed vertically, the beam installed on the rails, acts as a bracket. It can be tilted to a right angle so that the material can be cut in any plane. The horizontal version involves a table for sawing, the mechanism itself and the carriage, which ensures the movement of the saw along.

How to saw with a jigsaw straight? Before you start, it’s worth figuring out the whole process, otherwise you won’t get the result you want. Often when working with any material it is necessary to create a cut with maximum accuracy. It is the jigsaw with an electric drive that will do the job.

The jigsaw is sawed out on a stand of some kind, so that it turns out even and easy.

Before using the jigsaw, the workpiece should be marked with a pattern. It can be transferred from the special album (it is possible to search on flea markets albums with patterns for sawing of times of the USSR), or to draw independently. Another option is to print the pattern on a printer and then paste it on the workpiece.

Start sawing from the inner contours of the workpiece. This is due to the fact that plywood is a fragile material, and when sawed first the outer contour, there is a high probability of chipping the finished pattern. To start the work in the inner contours of the workpiece, it is necessary to drill a hole with a drill, in which the saw blade is inserted, after which it is fixed on the jigsaw.

In case the workpiece has more inner contours to be sawed, it is necessary to drill the required number of holes before fixing the workpiece. This will reduce operating time. When fixing the blade to the jigsaw, it should be fixed so that there is no vibration of the blade when working.

Sawing process itself is not much different from the work with a usual saw. the same forward motion. It is important when working to maintain the angle of 90 o between the workpiece and the jigsaw blade. If the cut is made at an angle, it is possible that the blade will tear. Such mistakes are often made by beginners, but there is nothing wrong with it. the blade is quickly replaced.

The guide rail for the jigsaw blade

The jigsaw guide is an elementary device, similar at first sight to a large metal ruler or rule. The main difference between the rail and the above devices is a special groove on which, as on rails, moves the soleplate with an electric jigsaw mounted on it. Most of the guides have rubberized strips that prevent slipping on the surface of the material, and as an additional fixation, they are fixed with small clamps. The average length of such devices is from 1.5 to 3 meters, and can be increased by another, similar ruler, using an adapter.

When You Only Have a Jigsaw to Make a Straight Cut

How wear and tear and quality assembly affect the crookedness of the saw

Not all workers know what to do if the jigsaw saws crooked, how to fix such a defect. So, in case a cheap tool was purchased, you should thank the manufacturer for the malfunction.

How to Use a Circular Saw. Everything you need to know. | Woodworking Basics

However, sometimes the blame lies on the shoulders of the worker, as modern manufacturers recommend using inexpensive devices for a maximum of 20-30 minutes per approach. Therefore, if a failure occurs, the fault is most likely in the actions of the owner.

A completely different situation when the defect is encountered with professional electric appliances. In this case you should not rush and run with the tool to the workshop, it is better to understand why the electric jigsaw saws crookedly and perform the repair yourself.

- Check if there is any slackness in the piston rod. When the value of its value is more than 0.9 mm, it means that the breakdown is in its design. Even the highest quality guides wear out over time, so it is necessary to monitor their condition.

- The leaf is not fixed properly. This malfunction is often associated with wear and tear of the fixing mechanism.

- The guide roller is defective. it does not hold the material and vibrates, and therefore the jigsaw does not cut evenly.

- The web is deformed. If the shape of the saw is curved, it will not be able to cut evenly.

Important! The reason of a bad cut can be dull blunt cutting edges of the blade, so make sure they are not frayed, because it is dangerous to your health to continue working in such a case.

Often the problem of a crooked cut lies in the curvature of the blade

Prevention or how to extend tool life

The effective life of a jigsaw (kerf size) depends on two factors: the quality of the tool itself and the conditions of use. Gentle use with a few simple rules.

- The jigsaw should be used for its intended purpose. Especially for short groove/slash cuts, cutting of thin boards, shape cutting (arcs, circles, ornamental cuts). Despite marketing claims that your hand held jigsaw can cut 100×100-sections of lumber, this is not a task for the jigsaw. Optimal. board thickness up to 30 mm, occasionally a little more. For sawing thick material, there are circular saws, electric chainsaws, chain saws and sawmills.

- Only high-quality, always sharp saws should be used. With bad, the tool works hard and overheats, takes longer, wears out faster.

- The electric motor must not be overheated. When working continuously for a long time, it is necessary to pause and let the jigsaw cool down.

- Store the tool in a dry room, preferably sealed to prevent dust from entering through the vents into the collector contacts (under the brushes) and other parts.

- After prolonged use, if excessive noise, dry knocks and creaks occur, the gear mechanism should be lubricated.

- If excessive sparking occurs under the brushes, the tool must not be used. Brushes must be changed immediately. Otherwise, after long hours of work with a big spark the copper plates of the collector contacts burn out and replacing the brushes will not help.

How to learn to saw straight with a jigsaw

To exclude curvilinear sawing with the jigsaw, it is necessary not only to eliminate all kinds of defects, but also to learn how to hold the tool in the hands. This will require a lot of experience and if there is no time for training, then the difficulty is solved by using a guide rail for the jigsaw.

Immediately it should be noted that even when drawing a marking it is not always possible to pass over it with a jigsaw as one would like. After all, when moving the tool, you need to control the movement of the blade, as well as pushing the device itself. When accuracy and flatness are important, then the jigsaw guide comes to help when working. This is a special metal ruler in the form of a rule or water level, along which the jigsaw moves. To take advantage of such an addition, it can be bought or made your own hands.

The jigsaw guide has a special recess along which the tool moves. The length of this jigsaw ranges from one to three to four meters. If necessary, the length of the guide can be increased by attaching a similar tool. The rail is attached to the workpiece to be sawn precisely along the cutting line. Either existing fasteners or a screw clamp are used for fastening. Approximate and higher, which depends on their length and additional functions. attachment and the presence of a rubberized base.

Uneven sharpening

According to the instructions for sharpening chains, all teeth should be sharpened at the same distance, regardless of which side they are on. Observing this simple requirement, you can protect yourself from problems associated with the fact that the chainsaw when sawing takes away.

Unevenly ground teeth are the most common problem of crooked sawing.

When sharpening a chain with a file, it is not always possible to control the tooth length using the technique of counting the number of file movements.

This is due to the fact that the wear of the teeth is uneven, some are more damaged and require more file movements to bring them back to normal, which means that the size of these teeth will be reduced significantly compared to the others.

How to avoid faulty sharpening

In order to prevent a bad cut because of uneven sharpening, you can use a special chain sharpening machine to dress the chain from time to time or when badly damaged. To buy a machine and sharpen it yourself or have it sharpened in a workshop.

The point is that the machine adjusts itself during sharpening to the most worn tooth, which has the smallest size of all. After sharpening, all teeth will be the same size, which will be equal to the tooth on which the setting was made.

The disadvantage of this method is that the life of the chain is considerably reduced, i.e. к. Even the teeth that are not damaged have to be ground very hard. Try to use your chainsaw more carefully, watch out for nails and any other metal objects that you might come across when cutting old boards and other junk.

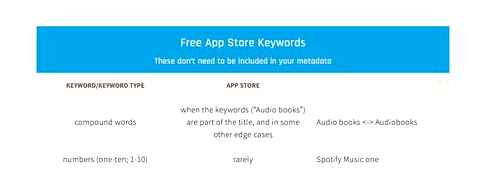

Choosing a cutting blade

Different saw blade versions have different tooth lengths. The quality of the part also depends on their frequency. Prefer a trusted brand. Depending on the configuration of the teeth, there are the following classifications of saws:

- Equal distance and one direction of the teeth is typical for standard products.

- Popularly used are variants with a skipped tooth. The defect has a favorable effect on the cutting speed, resulting in less heating of the structure. The device does not jam and works well.

- There are twin models that allow for better cutting of the workpiece.

What tools help to make a straight cut

Additional attachments can be used to make a smooth cut. The main ones are:

- trailing compasses. Serves for outlining the circumference and the fluted curve on the surface of the workpiece;

- parallel stop. It is used to form a cut parallel to one of the side edges of the workpiece;

- guide bar. Represents a metal ruler with a side stop for the jigsaw blade. It makes it possible to make a precise straight cut of the desired length;

- laser pointer. The light pointer shows the position of the saw blade. Such a fixture can be installed independently, or you can buy a model with an already available fixture;

- anti-skid pad. Made of transparent plastic or plexiglass the insert allows to fix additionally the blade and to prevent the material to be cut from splintering and burrs;

- guiding platform. Reduces the coefficient of friction, thereby allowing the jigsaw to glide effortlessly over the surface of the workpiece.

To improve the visual control of the sawing process it is recommended to maximize the lighting of the working area.

How to cut material without chipping

To avoid the appearance of such defects, it is advisable to consider the following recommendations:

- Based on the cutting drawing and the size of the selected tool, set the thrust rail. It will avoid oscillation of the cutter, which will reduce the amount of damage.

- If the work is done with a hand-held circular saw, tooth loss is minimized. As a result of the adjustment the sawing part should not protrude more than 5 mm.

- To make the edge without splitting, a special tape is glued along the line. This reduces splitting, but does not guarantee the complete absence of defects. The alternative is to wet the upper area, but because the material is moisture resistant you will not get the desired effect.

- The cutting part is brought to the place where the process starts while it is switched on, because when starting directly at the edge the teeth tear the wood fibers.

- The movement of the tool should be uniform, too much pressure creates fractures and burnt areas. If you move very slowly, the constant entries into the surface will result in marks.

The type of plywood is not unimportant. The most difficult to process laminated versions: it is possible to completely eliminate chipping only on the formatting and cutting machine, where the trimming is done from the top and bottom. Damage can be minimized by immediately selecting the front side and test sawing on a piece. This will determine the correct position of the sheet in relation to the cutting part.