Blade Direction on Different Saws Explained. Chain saw blade direction

Blade Direction on Different Saws Explained

A surprisingly under-discussed topic in the power tools world is the directionality of different saw blades. There are no “universal” rules here; the blade installation direction varies from one saw to the next depending on the type of blade and the type of saw.

How is the Blade Direction Specified?

The blade direction is the direction at which the sharp cutting teeth points. This is usually the path the blade moves or spins in the case of circular blades.

Manufacturers may specify the blade direction on the blade itself and/or on the power saw.

In many cases, you’ll be at a big advantage if the saw you’re replacing a blade on already has one installed that you can copy. However, that doesn’t mean that the installer before you made no mistakes!

This article isn’t a comprehensive blade installation guide, so be sure to check the saw manufacturer’s instructions for blade removal and replacement for that particular saw to be sure your new blade stays put and works as intended.

Overall, there are some clear indicators of the correct blade direction, depending on the saw type below. But essentially, the trick is to remember how the saw moves in conjunction with how the blade cuts, and this will determine the directionality of your blade for installation.

Blade Direction by Saw Type

Following are some of the most popular power saws and their blade directions for your reference.

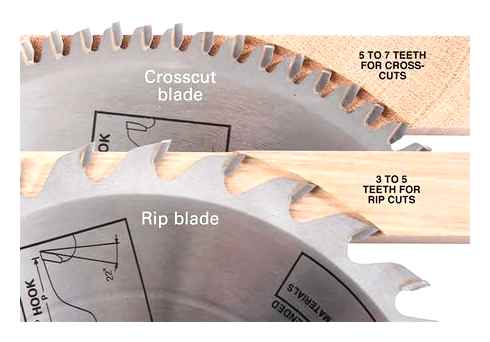

Circular Saw

Circular saws cut on the upward stroke. In many circumstances, you will find guide arrows on both the saw and the new blade, guiding the user to a successful installation. If both arrows are pointing the same way, you’ve done it!

This is an awesome “cheat code,” but if the guide arrows aren’t available in your case, keep in mind the cutting direction. You’ll want the “biting” edge of the teeth pointing upwards to match the saw’s stroke, and the dull, rounded edge facing down or backward.

Table Saw

A Table saw spins back to front, with the back of the saw being the blade guard/guide side and the sharp, biting side of the blade pointing towards you. The back of each tooth on the blade is rounded, and the front of it is sharp.

For most manufacturers, it is standard practice to print any lettering on the side of the table saw blade that will be to your left when standing at the front of the saw. So if you’ve bought a new (or used) table saw that doesn’t already have a blade installed, remember “lettering left”, and “teeth towards me,” and you’ll be good to go.

Miter Saw

Similar to the table saw, the Miter Saw spins downward to cut into the wood or other material on its deck. Therefore, the teeth should naturally face down during installation, with the rounded edge of the teeth pointing away from the rotation of the saw.

Scroll Saw

A scroll saw cuts on the downstroke, so the rake of the teeth on the blade should also then point downward during installation. The blade mount on the saw usually includes a directional indicator, and the pins must fit into the grooves or slots on the blade mount. If the blade isn’t fitting or sitting properly, it may be incorrectly installed.

Band Saw

A Band saw blade should always point towards the direction of the blade rotation. So on vertical Band saws, the teeth of the blade should be pointing downward. On a horizontal bandsaw, the teeth should be pointed toward the work as the blade is moving. If it’s helpful to you for orientation, the blade direction on a Band saw is similar to that of a scroll saw.

Concrete Saw

Concrete saws are slightly different from the others on this list as their blades are usually diamond blades. This just means that it can be somewhat more challenging to discern which is the “biting” direction, depending on the type of diamond blade you’re working with.

In any case, a concrete saw typically spins downward into the concrete, and the user then pushes it forward to cut. This means that the biting edge should face downward during installation. Some diamond blades have clearly defined teeth, so installation is easy and intuitive.

However, as with a continuous rim diamond blade that may be less clear, directionality-wise, be sure to read the manufacturer’s instructions for installation that are included with the packaging to ensure that you don’t install it upside down or backward.

Why Is My Chainsaw Cutting Uneven on a Curve?

Jigsaw

The jigsaw does most of its cutting work on the upstroke, so a standard blade has teeth pointing upward. A jigsaw is also pushed forward during use, and because the blade plunges to cut with the teeth on only one side, it is quite clear if the blade has been installed backward. Additionally, some mounts won’t properly function unless the blade is installed in the correct position, forcing the user to double-check prior to operating.

There are also reverse blades for jigsaws with teeth pointing downward (used on pre-finished materials to reduce the risk of nicks or chipping), but these would still be installed with the teeth facing out, away from the operator, and towards the work surface.

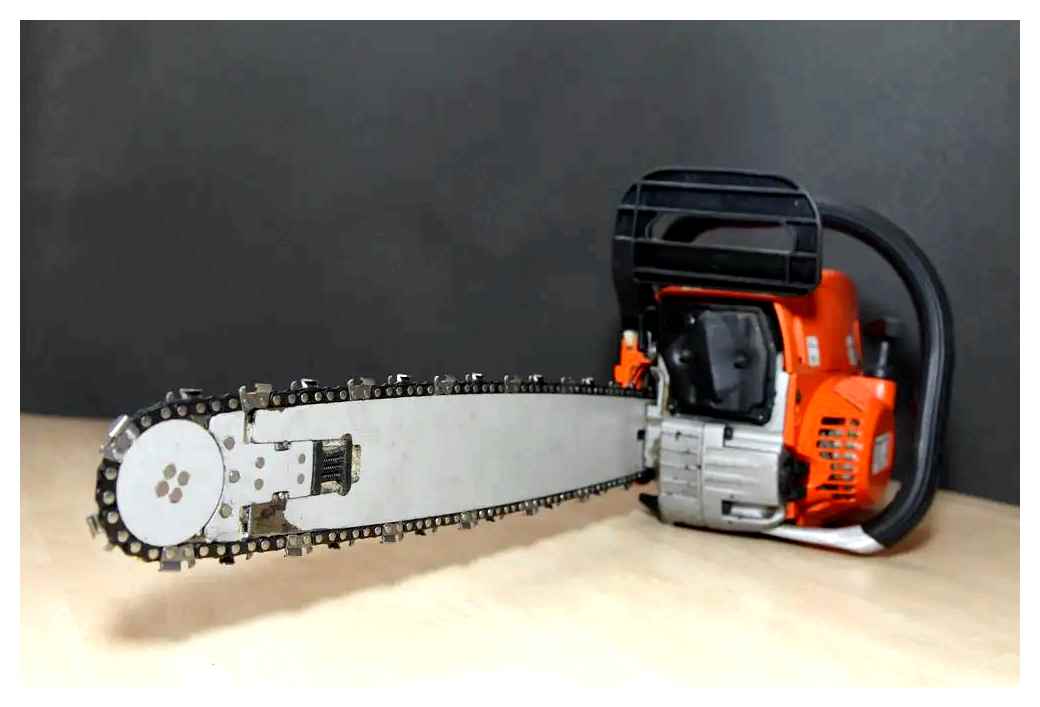

Chainsaw

A somewhat daunting task for some, switching the blade on a chainsaw is nonetheless straightforward when you take into consideration the motion of the machine. The saw is designed to cut in a clockwise rotation outward from the operator, or downward into the material in front of you when the saw is wielded from above.

Once you’ve disassembled the machine, set the saw on the surface in front of you toward your left with the bar to the right. If the “sharp parts” are moving forward, clockwise to the right, then the chain is on correctly, and the saw is ready to be put back together and put to work.

Importance of Blade Direction

Knowing which way the blade shows point can make all the difference when it comes to getting a precise, clean cut. We’ve discussed the “how,” but here are a few “why”s to supplement our above guidance:

- If a blade is installed incorrectly, it can cause a saw to “jump”. This could cause injury to not just the operator, but also to another person nearby, through no fault of their own.

- That “jump” can also damage the blade, especially if it bounces onto or off of a nearby unintended surface. For example, a wood blade isn’t intended to cut concrete or steel, so that blade could easily become damaged upon forceful (however unintentional) contact.

- Imagine spending a lot of dough on a very fine finish material, only to incorrectly install your saw blade and thus damage it. This can be frustrating at the least, but it can also cause construction and project delays if a specially ordered selection needs to be replaced.

- If a blade is installed incorrectly, the saw also may just not work at all or will work so poorly that it will put excess strain on the motor while it fights to “do its job.” Like a blender, when you ignore the “max fill” line and the little engine gets super hot and cranky, these machines are designed to work great when used correctly, but the internal components can be strained and damaged from improper use and can “burn out.”

While incredibly efficient, saws can also be dangerous tools. Be sure to “do your homework” and prepare thoroughly when doing any saw maintenance, and let us know what other topics we can cover to help you with your next project!

Chainsaw Chain Direction 2022: Get it Perfect Every Time

So you’re looking for the correct chainsaw chain direction?

If you use a chainsaw regularly, you must ensure you’re using it correctly. You’re wasting your time if you don’t have your chainsaw well-equipped, correctly aligned, and functioning as it should.

And as odd as it may seem, one of the biggest questions about having a chainsaw is the chain itself. There are millions of people who own a chainsaw but don’t quite know which way the chain itself is supposed to be set up. Does it go to the left? The right? How does it work, and what is the proper way to set it up?

I’ll walk you through what you need to know. Let’s dive in.

How To Set Your Chainsaw Chain Direction

To get it working correctly, align it this way: if the bar of your chainsaw is on the left side of the device’s engine, the chain should rotate in a counter-clockwise motion. At the same time, the cutting edges must be facing away from the engine.

When utilizing a chainsaw, it’s critical to ensure you’re going in the appropriate direction. You need a chainsaw that works, cuts, and stays sharp; if your chain isn’t set correctly, the entire device will not do that.

You won’t get the most out of the equipment if you don’t follow the proper setup. Aside from that, operating a chainsaw incorrectly is also quite dangerous for anyone using it. It could lead to serious injuries – not just to the person using the chainsaw but to people nearby. Plus, it could severely damage items, furniture, and your home.

So how do you know if the chainsaw’s chain direction is correct? It may appear daunting and complicated to someone who is new to chainsaw operation, but don’t worry, it’s not that hard.

But it must be done correctly! That must always be remembered. Because the chainsaw blade’s cutting teeth are designed to cut wood only in one way, installing or putting the chainsaw chain direction in reverse will only destroy the tool. When you put the chain in the wrong direction, it can cause a number of issues.

Wasting Oil

Whenever a chainsaw’s hawser is on the wrong side, it wastes a lot of bar oil, which causes greater injury to the chainsaw. Typically, bar oil is preserved to be utilized until a certain activity or task is done. When the chainsaw blade is positioned incorrectly, however, a significant amount of bar oil is wasted. This will make the chainsaw work worse than it should and cost you a lot of money in the long run, too, not only for the oil you’re burning through but also for the repairs needed to be done to the chainsaw.

A Broken Chain Link

The chain link is a critical component of the chainsaw; if it is impaired, the saw may not function as efficiently as it should. Keeping the link at the lowest position is critical to guarantee that it’s giving the blade ample support and enabling simple and successful propulsion. Always double-check that the drive connection has been corrected to prevent causing needless harm to yourself or your project.

If you are cutting wood, the guide bar is the most crucial portion of the chainsaw. Therefore any misalignment in terms of the chainsaw blade’s direction may cause a slew of issues. As the chain is driven into the wood, you will generally end up with a significant amount of tension on the guide bar. And because the cut would be impossible, the guide bar will be damaged.

How To Clean Your Chainsaw Without A Chain

If you have to disassemble or break down your chainsaw in order to set the chain in the right direction, you have an opportunity to make your device run better. That is because when you have taken your chainsaw apart, you can use that time to clean it, maintain it, and ensure it runs at 100% when you put it back together again. This would also be a great time to sharpen your chainsaw if needed.

Yes, cleaning your chainsaw once you take the chain off is one of the best uses of your time and will make your chainsaw last long, work better, and be safer too. Before doing anything, make sure you’re working on a stable and firm surface, like a workstation or a sturdy table. A vice is also helpful, particularly if you’re honing the chainsaw and cleaning.

To tend to your chainsaw’s bar, remove it from the powerhead by undoing the bolts holding it.

Following that, you can now clean the bar of debris and grime, especially the chain groove. You can do it with a cloth, but an air compressor will also assist you in getting the desired results and need to keep your chainsaw in excellent working order.

At the time, whenever you are replacing the chainsaw’s bar, put it back in the same sequence as when you initially got it. This will guarantee that the bar wears evenly, which will assist in increasing the bar’s life while also enhancing your chainsaw’s productivity.

Polishing and maintaining the chain is also necessary, which may be accomplished using compressed air.

Using about half a gallon of water and half a cup of common household ammonia, make a solution for the rest of the procedure. You may also use an effective cleaning product like home lye. Make sure that you remain very safe regardless of what you’re using, and do not let animals or children near the chainsaw or the products and materials you use to clean it.

Remember that something like lye or other cleaning products can be terrible to inhale. You should always wear a mask or some protection. Additionally, performing this entire procedure in a well-ventilated location and with gloves on for safety is crucial. Lastly, allowing at least 20 minutes for the chain to soak in the solution would be best.

After the soaking period has passed, clean the chain well with a hard brush. After that, thoroughly rinse it and dry it with an old towel or a clean rag.

If you wish to complete this process quickly, blow the water with compressed air to dry the chain faster. This is especially handy in humid or chilly climates, where your chain may take longer to dry.

The chain must then be lubricated. You’ll accomplish this by dipping the chain in oil. Allow the surplus oil to flow off and hang it up to allow the remaining excess oil to drain as well.

When putting everything back together, ensure the chainsaw chain direction is facing the right way!

I hope you’ve found my article on chainsaw chain direction valuable and helpful. It’s always best to put everything back together correctly, so you get the most out of your chainsaw and stay safe.

Chainsaw Larry

How to Know When to Replace a Chainsaw Chain

Chainsaws can be finicky. Its job involves spinning a barbed chain at high velocity to rip and shred through logs. Between gas, oil, tension, and general wear and tear, your chainsaw needs a fair amount of TLC. The biggest area of concern—and one that arrives frequently—involves the chain. Many chainsaw users question how to know when to replace a chainsaw chain rather than continue sharpening it.

Editor’s Note: Check out our best cordless chainsaw reviews article for our top picks.

Why a Sharp Chainsaw Chain Matters

Everyone knows the business end of your chainsaw, the chain, can quickly dull. Dull chainsaw chains are an ineffective and dangerous thing. Chains require frequent sharpening. You can’t, however, sharpen a chainsaw chain indefinitely. We hope to help you know when it’s time to give up on sharpening and start thinking about replacing a chainsaw chain.

Let’s start with making sure you understand how to tell if that chainsaw blade is dull.

How You Know You Have a Dull Chainsaw Blade or Chain

Does your chain pull itself into the wood, or do you need to force it? A dull chain won’t eat into what you need to cut as well. This forces you to apply more pressure than normal. This can cause undue stress on the engine and bar as well as further dulling out your chain.

Does the chain rattle around or bounce when cutting? Not only does this affect accuracy, but it signals that it might be time to either sharpen or replace your chainsaw chain.

If you happen to see smoke when cutting, despite the fact that you know your chainsaw oiler is working and your tension is correct, you probably have some sharpness issues.

When cutting, if your chainsaw pulls in one direction, you might need to think about replacing your chainsaw blade. This is an indication that your cutting teeth have dulled on one side of the chain, or that the cutting teeth lengths are uneven.

Check the sawdust. When making cross-cuts or split cuts, the chain should create coarse strands, not fine dust. If you see the latter, you probably have a dulled-out chain.

I Just Sharpened My Chain and It Still Seems Dull

Ah. If you recently sharpened your chain, but you still notice some or all of the above symptoms, take heed. You may have reached the end of this particular chain’s usefulness. At this point, replacing the chainsaw chain altogether seems like the wisest course of action.

Wear Markers Tell You When You Can No Longer Sharpen the Chain

Many chainsaw chains include wear markers that let you know the maximum depth to which you can sharpen the teeth. It’s no rocket science, however. You can only sharpen the teeth until the angle you sharpen at begins to cut into the rear of the tooth. This Husqvarna chain has definitely reached its limit:

STIHL also has a great image on their website that shows both the top and bottom wear marks:

You definitely want to pay attention to the bottom of your chain teeth. If you run the chain too hot (without oil or enough bar oil, for example) it can wear down to the point where the bottom of the tooth lets the rivets contact the bar. If that happens, you know it’s time to replace the chainsaw chain.

Check for Missing Teeth or Tooth Damage

Another sign that replacing a chainsaw chain makes sense, as opposed to just running a file around it, is when you notice broken, damaged, off-center, or missing teeth on the chain. You can technically use a chain that you can keep sharp if the teeth are at different wear points. However, cutting with missing teeth or damaged chain never warrants the risk.

If your chain exhibits any of these signs, go ahead and spring for a new chain. They generally aren’t crazy expensive, and your chainsaw will cut much more effectively.

Speaking of the relatively low cost of chainsaw chains, some folks even skip out on sharpening altogether, opting instead for replacing a chainsaw chain as it gets dull. We recommend picking up a file and learning how to sharpen a chain. For one thing, you could potentially save yourself a trip to the store when you’re in the middle of a long job. But also, dumping perfectly usable chainsaw chains into the landfill seems like poor stewardship of our planet.

When to Replace the Chainsaw Chain Sprocket

Sometimes premature chain wear reveals a deeper problem—like the actual chain sprocket. For example, if the depth of wear on your chain sprocket hits the 0.5mm mark (the typical wear limit), it needs to be replaced immediately. An inexpensive control gauge can tell you if the sprocket has reached that limit, but you should be able to see it with the naked eye.

Essentially, the thin drive links should fit in between the troughs of the chain sprocket so they can be driven by the motor at speed. Eventually, the constant pressure of the drive links can wear narrow grooves into the sprocket. This introduces play into the chain, damages the chain and guidebar, and reduces cutting efficiency and performance. Eventually, the entire tool can fail.

When to Replace the Chainsaw Guide Bar

Knowing when to replace the guide bar often takes a bit more knowledge—or a tool. Guide bars wear down when the rail wears away from long-term chain friction and heat. That causes a reduction in the depth of the groove in which the chain travels.

It can also wear in a way that allows the chain to lean to one side or the other. This affects its ability to cut since the sharpened chain teeth no longer bite into the wood at the proper angle.

If the bar wears down too much, the chain will “bottom out” in the groove, causing lots more heat and dramatically reduced cutting efficiency.

Diamond Blade Secrets You Should Know

Pro Tip: Flip your guide bar over peridically (we recommend every time you sharpen the chain). The chain guide bar will wear more aggressively on the bottom due to the pressure typically placed on it when cutting.

Summary on How to Know When to Replace a Chainsaw Chain

The big picture with how to know when to replace a chainsaw chain comes down to paying attention. It also helps to have a regular maintenance schedule. If you flip the bar and inspect the saw every time you sharpen the chain, you have built-in opportunities for maintenance. Keep the chain oiled and sharp and you can ensure the longest life possible from your chains.

Did we miss anything? If you have any additional tips for recognizing and knowing when it’s time to replacing a chainsaw chain, leave us a comment below.

Clint DeBoer

When he’s not playing with the latest power tool, Clint DeBoer enjoys life as a husband, father, and avid reader—especially the Bible. He loves Jesus, has a degree in recording engineering, and has been involved in multimedia and/or online publishing in one form or another since 1992.

Clint’s career has covered nearly the entire realm of audio and video production. After graduating at the top of his class with an Associates Degree in Recording Engineering, he began working for the famed Soundelux studios in 1994, one of the largest post-production companies specializing in audio for feature films television. Working on a myriad of feature films, Clint honed his skills as a dialogue editor, foley editor, and sound designer. Years later, he moved into the expanding area of video editing, where he served as the company’s senior AVID video editor for three years. Working for such clients as Universal Pictures, Hollywood Pictures, Paramount Home Entertainment, NASA, Universal Studios, Planet Hollywood, SEGA, NASCAR, and others, Clint DeBoer dealt extensively with client management as well as film video editing, color correction, and digital video MPEG compression. He also carries several THX certifications (Technician I and II, THX Video), and is ISF Level II Certified. After founding the CD Media, Inc. publishing company in 1996, he went on to help start or grow several successful online publications, including Audioholics (as Editor-in-Chief for 12 years), Audiogurus, and AV Gadgets. In 2008, Clint founded Pro Tool Reviews followed by the landscape and outdoor power equipment-focused OPE Reviews in 2017. He also heads up the Pro Tool Innovation Awards, an annual awards program honoring innovative tools and accessories across the trades. Crediting God and his excellent staff for the success of what is now the largest power tool review publication in the industry, Clint DeBoer hopes to see continued growth for the company as it rapidly expands its reach. Pro Tool Reviews critically reviews hundreds of hand tools, power tools, and accessories each year to help inform users about the best and newest products in the industry. Reaching everyone from the construction industry professional and tradesman to the serious DIYer, Pro Tool Reviews helps tool consumers shop better, work smarter, and stay aware of what tools and products can help put them at the top of their game.

Related articles

Husqvarna Spring Products Showcase

OPE Visits Husqvarna’s North Carolina HQ for an Exclusive Tour I’m not sure what it is about spring 2023, but it seems as though outdoor power tool manufacturers are especially bullish on product line development. Husqvarna is among those brands leading the pack (not surprising considering that they’ve been making various forms of equipment for […]

Solid Steal–The HART Blower Bundle

HART’s 20V 315 CFM Blower, Two Batteries, and a Charger at a Great Price Exclusive to Walmart, HART has made a name for itself within the consumer market thanks to its extensive line of tools and outdoor power equipment. And boy, do they have a deal for you with the HART Blower Bundle! Get a […]

Wisconsin Assembly Outlaws Gas Bans

Gas-powered engines scored a win in Wisconsin’s Republican-controlled Assembly. A pair of bills that conservative Wisconsin lawmakers passed on April 25 would prevent state and local governments from banning gas-fueled vehicles, snow blowers, lawn mowers, and other such equipment. The bill’s GOP sponsors targeted the passage of laws like California’s, requiring that new cars, trucks, […]

HART 40V Supercharge 21″ Self-Propelled Lawn Mower

The HART 40V Supercharge Mower Raises the Bar for Homeowners In 2022, we got our hands on HART’s 40V 21-inch Self-Propelled Lawn Mower, and we liked what we saw. But now, HART is raising the bar with a Supercharge designation, and this boosts performance while dropping recharge time. With that said, let’s put the HART […]

How To Sharpen A Chainsaw – Illustrated Guide

A chainsaw blade can be sharpened by hand using an appropriate sized round file. Each tooth needs to be filed sharp by incorporating a few different techniques for sharpening.

There are numerous ways to sharpen chainsaw teeth, but hand sharpening is the quickest and easiest method.

Learning how to sharpen a chainsaw may seem like a daunting task the first time.

But once you learn how to sharpen a chainsaw, the process can be quite rewarding.

With knowledge and practice, you may find the process of sharpening your chainsaw very satisfying. Especially when you see beautiful, efficient, effortless cuts from your blade.

Being able to harvest and prepare bowl blanks from wood that may otherwise go to waste is one of the most satisfying feelings.

A sharp chainsaw is essential for efficient bowl blank preparation.

This site is dedicated to the process and art of turning wood bowls. However, everything shared in this article applies to sharpening chainsaws for any wood cutting purpose.

There are some specific steps and practices that need to be addressed and executed to achieve a properly sharpened chainsaw blade.

This article will detail everything you need to sharpen your chainsaw blade like a pro, or perhaps even better than a pro.

Let’s dive in and get our chainsaws as sharp as new!

When to Sharpen the Chain

When is the best time to sharpen a chainsaw blade?

This may seem like an obvious question, but let’s look a little closer.

The first easy answer to this question is to sharpen when the blade is dull and not cutting very well or taking a long time to complete a cut.

There are other times when we need to stop and sharpen the blade as well.

Chainsaw Not Cutting Straight

If you are seeing the saw pull or drift as it is cutting, this is a sign the chainsaw needs sharpening.

Often, when a chainsaw is not cutting straight, the cutting teeth have been compromised in one way or another.

The most common way to cause cutting issues with a chainsaw is to allow the chain to touch the ground. Sand, dirt, or rocks will immediately damage chainsaw blade cutting teeth.

When the saw touches the ground, the damage is never balanced, and the chain, like the tires on your car, is not running true, it’s wobbling.

This lack of balance causes the blade to perform inaccurately, and the issue needs to be addressed immediately to improve performance and save the chain from further damage.

Field or Shop Chainsaw Sharpening

The chainsaw blade can be sharpened in the field or at a bench.

Sharpening a chainsaw in the field can be a bit inconvenient, but there are ways of improving the experience.

If you have a log handy, turn it upright and use a stump vise to hold the chainsaw bar steady as you sharpen.

A stump vise can be hammered into the log and provide a secure mount as you sharpen.

The thumbscrew of the stump vise holds the chainsaw bar firm and allows a steady platform to perform the sharpening.

In The Shop Sharpening

In the convenience of your shop or garage, the chainsaw blade can be sharpened right on the bench or while held in a vise.

The chainsaw blade can be left on the saw, and the chainsaw bar can be clamped in a vise to hold it in place.

Be sure only to tighten the vise enough to hold the bar steady and not crush the chainsaw bar.

Another option is to take the blade off the chainsaw and hold it in the grip of a vise.

The chain will need to be unclamped and reclaimed as you move through the teeth.

Know Your Chainsaw Blade

Almost every chainsaw blade is different.

Between the length of the chain, the size and angle of the cutting teeth, the depth of the guide links, and other factors, rarely will you find two blades the same.

Because there are so many different chainsaw blade variables, you need to know your chainsaw blade exactly.

Take the time to read your chainsaw manual and make a note of your chain size.

You can usually find your chainsaw manual online by searching your saw make and model, then adding the word “manual” with the search.

Take your saw to a professional shop if you have no idea what size blade you need. They will usually be able to help you determine the exact chainsaw blade for your model.

If you have purchased an extra blade, look at the box, and you will see the details for your blade.

Teeth Diameter

The first item you need to know for sharpening is the cutting teeth diameter and angle.

Teeth diameter is also the size of the file you will need to sharpen the teeth.

Many blades use a diameter around 5/32” (4mm) 3/16” (4.75mm) or 7/32” (5.5mm). But there again, this can be different with your blade.

The angle of the teeth can also vary from around 10° to approximately 35°.

The chainsaw tooth diameter and cutting angle are the two main factors we will need to know to sharpen the blade.

Chainsaw Sharpening Gear

You will need some equipment to sharpen your blade properly, surprisingly minimal and straightforward equipment.

If you are sharpening in the field, I recommend having a stump vise handy to hold your chainsaw bar in place as you sharpen.

You will need a file in the proper diameter to match your cutting teeth. See above to determine the diameter of your teeth.

Here are links to files for three typical chainsaw diameters; 5/32″, 3/16″, 7/32″.

If you like, use a guide handle for the file. Also, mathe the file handle to the size of your file. It will help keep the file properly positioned when sharpening.

Once, the teeth are sharp, the raker guides need to be examined and filed down. A rake depth gauge and a flat-file are necessary for this task.

That is about all you’ll need to sharpen your chainsaw.

Safety and Visual Aid

Like everything we do in woodworking, we want to be safe and protect ourselves at all times.

Because we will be moving and handling the sharp chain, it’s best to wear heavy work gloves.

Eye protection is always essential to keep metal shavings or any foreign objects from our eyes.

In addition to protecting your eyes, you may also want to wear eye magnification of some sort.

I use a flip-down magnifier to increase my vision while sharpening.

Increased vision allows for easy assessment of each cutting tooth as you sharpen your chainsaw blade.

Mark and Start

If you know the chainsaw blade has been damaged by touching the ground or another foreign object, check the teeth to find the most damaged area first.

Mark the chain in the starting area with a marker or other method, to prevent double sharpening teeth.

Set The Chain

If there is any slack in the chainsaw blade, tighten the chain before you begin to sharpen.

You want the chain to be snug and firm in the chainsaw bar track with as little wiggle room as possible.

However, you will need to have the chain just loose enough to move it along the bar groove as you progress through the sharpening process.

Proper Chainsaw Cutter Angle

Every chainsaw blade is different, but many blades use a 20°, 25°, 30°, or 35° sharpening angle. Again, check your saw manual or blade packaging.

It is crucial to maintain this same angle as you sharpen the blade.

If you use a file guide, you will see the angles marked by a line that crosses the guide. Match the proper angle and make it parallel with your saw bar.

When you sharpen freehand, without a file guide, you can make an angle guide with a piece of cardboard and place it under your blade.

You can also add the proper angle lines to the top of a vise if you are vise-clamping the chain down as you sharpen.

As you sharpen, you can look down on the file and check that it aligns with the angle below.

Built-In Angle Guide

Most blade manufacturers make a line right on the top of each cutting tooth. This line is the proper angle for the teeth.

You can freehand sharpen just by making sure your file runs parallel to the scored line on the top of each tooth.

Keep File Level

The file needs to be horizontal and perpendicular to the chainsaw bar at all times.

Do not allow the front of the file to dip down or rise as you file.

Keep the file nice and flat as you sharpen each tooth.

File Stroke Direction

OK, confession time. I used to do this step completely backward, and I thought it didn’t matter. It does matter.

The cutting teeth of a chainsaw are coated or hardened on the outer surface.

What this means is we need to sharpen from the inside out, not the outside inward.

The stroke of the file needs to go from inside out, away from the cutting tip of the teeth.

Also, the file only cuts on the push forward, not on the pull backwards. So, do not let the file touch the tooth on the way back or it will ruin the sharp edge.

File Depth on Cutter

The depth at which the file rides in the cutting tooth groove is critical.

Ideally, the file remains above the top of the cutting tooth by about 20% of the file diameter.

In other words, 4/5 of the file is down inside the cutting tooth, while 1/5 of the file sticks above the tooth.

This proportion is essential to keep the current shape of the cutting tooth.

If the file is entirely down inside the curved part of the cutting tooth, the tooth will have a hooked over appearance.

A hooked over chainsaw cutting tooth will be fragile on the top surface and prone to easy damage.

If you are having difficulty maintaining the 1/5 file above the tooth position, consider using the file guide sized to your teeth diameter.

The file guide is specifically designed to keep 1/5 of the file above the tooth as you sharpen the chain.

Chainsaw File Stroke

When you have the right size file and angle established, it’s time to start filing.

The file works on the push cut only, and you will only need to make a couple passes, in most cases, to sharpen a tooth.

Hold the file with both hands, one at each end. Place the file inline with the proper angle for the teeth and make a single stroke forward across a tooth.

As you file, add pressure back into the curve of the sawtooth, not downward.

The tendency is to apply pressure down onto the base of the tooth.

Instead, we need to apply pressure in the curve of the tooth to sharpen and remove any burrs.

There is no need to rotate or turn the file as you make each stroke. Instead, make smooth, level passes inline with the proper angle for your cutting teeth.

When each cutting stroke is complete, return the file to the starting position without touching the saw tooth on the way back.

Consistent Filing

Address the worst teeth on the chain first, then file all the remaining teeth the same amount.

If the first tooth takes five strokes to sharpen, apply five strokes to all the remaining teeth.

The reason for this practice is balance. Keeping all the teeth to similar shapes and sizes will make the chain balanced and run smoothly.

Flip and Repeat

Sharpen all the alternating teeth running in one direction on the chain until you return to the mark you made at the beginning.

Once all the teeth running in one direction are sharp, rotate the chain or the entire saw to access and sharpen the set of opposite direction teeth.

Use the same techniques to sharpen the teeth running the other way.

Chainsaw Raker Height

Between the cutting teeth are little bumps or projecting pieces of metal. These raised in-between sections are called rakers or depth guides.

The depth guides are positioned right in front of each cutting tooth and control how much wood material is allowed into the cutting tooth.

As the chainsaw blade teeth are sharpened, they are also reduced slightly in height.

To keep the same or proper amount of space between the depth guides and the cutting teeth, we also need to adjust the height of the depth guides.

Use a raker gauge to determine the proper height of each depth guide by placing the raker gauge across two cutting teeth.

The depth guide section height should be flush with the height of the raker gauge.

If a depth guide section sticks up above the gauge, use a flat-file to reduce the height of the depth guide.

I remove the raker gauge when I file because the indicator is made with hardened metal and will dull the file. Once I remove some material from the raker, I return and recheck the height.

When the top of the raker depth guide is flush with the gauge, remove the gauge and file over the front edge of the raker to assure smooth fluid movement.

Drive Link Performance

Under the chain are drive-links that ride in the bar of the chainsaw.

If you notice the chain is not moving smoothly in the chainsaw bar, there may be an issue with the drive links.

Debris or foreign objects in the chainsaw bar groove can scrape and damage the drive or guide links.

Remove the chain from the saw and inspect the drive links and look for any scratches or burrs. File any damaged areas on the links smooth.

Also, use the thin flat surface of your chainsaw tool, that looks like a screwdriver, to clear out the bar groove completely.

Use spray parts cleaner to remove fine debris from tight places.

Alternative Sharpening Methods

There are other ways to sharpen your chainsaw blade.

Probably the easiest, hands-free way to sharpen your blade is to drop it off and have a professional do it for you.

However, even if a pro sharpens your blade, you don’t have the assurance they are taking the same amount of time and attention you might.

Other options include sharpening devices that clamp to the chainsaw bar and act as a pencil sharpener, like the Timberline Chainsaw Sharpener.Timberline Chainsaw Sharpener 5/32″Timberline Chainsaw Sharpener 3/16″Timberline Chainsaw Sharpener 7/32″

Oregon makes an electric bench chainsaw blade sharpener that can be adjusted to sharpen nearly any type of chainsaw blade. This model can be useful for production or if you have several chains.

You’ll need to remove the chain from the saw to sharpen with the Oregon sharpener.

Sharpen A Chainsaw Conclusion

We all know we have to have sharp tools to get good results. The chainsaw is no exception.

Taking the time to sharpen your chainsaw might not be the most convenient thing on your to-do list. But afterward, when you watch your sharp blade drop smoothly through a log, the results are well worth the effort.

Let me know if you sharpen your own chainsaw blades and if you do anything differently. Leave me a comment below.

Happy Turning (and Cutting),Kent

Комментарии и мнения владельцев

Rich Gerhard In the field, I tend to turn my saw flat to file one side of teeth and then turn the saw on the other side, with the blade supported by a block to file the other side of teeth. I find it easy to maintain direction and the blade is well supported while filing?

Brian Sempsrott This has always been something I shied away from but I think with your very helpful information I will tackle the job. I also just turned my first bowl yesterday (12″ from Sassafras) and have been checking out your turning videos. Thank you so much for your time to share so much knowledge. Have a great day!

Kent W Brian, Thank you for writing and sharing! Yes, you can do it! Give yourself time to practice and enjoy the whole process. All the best to you and Happy Turning! Kent

John Hartmus II I really enjoy most of your articles, and they are very informative. However, this article leaves out some very important information. Some chain saw chains have chisel teeth, and do not use round files. Here is a link to an article on the Oregon website that describes them, and how to sharpen them. https://www.oregonproducts.com/en/square-filing

John Beattie I agree with the comment that file should be 1/5th above top of cutting tooth on chainsaw chain, however, some chains are bigger than for instance 7/32 file. I use 3/8 –063 chains and bars all purchased from China and excellant quality, and I can go 2/3 days without any sharpening, and wood chips are thrown out 2/3 mtrs behind me It is a shame that Files bigger than 7/32 can’t be purchased, however a good alternative is a “Diamond”grinding stone available 7/32 to fit a 240v Electric/12volt hand held grinder.

Kent W Hello John, Thanks for writing and sharing this info. Yes, a diamond grinder can work, but you need to be gentle. Another option is a sharpening system like this one from Oregon tools. Happy Turning (and sharpening), Kent

How to Tighten a Chainsaw Chain

About: We are the ULTIMATE in supplying you with replacement parts from over 60 name brands, and creating award winning How To Articles and Repair Videos. eReplacementParts.com is #1 when it comes to figuring out e… About toolrepair »

Chainsaw chains stretch and become loose during operation. This article’s maintenance steps explain how to properly tension a chainsaw chain in under a minute.

Chainsaw chains stretch during normal operation and begin to sag on a saw’s guide bar. If a chainsaw chain is allowed to become too loose, it can easily come off the bar during operation and create an unsafe situation for the user.

Chainsaw chain tension should be checked and tightened often. We explain simple steps for how to tension a chainsaw chain below.

Correct Chainsaw Chain Tension

Before explaining the tensioning steps, we should explain what proper chainsaw chain tension looks like.

A properly-tensioned chainsaw chain should still be just a little loose on the chainsaw guide bar, but the chain needs to be tight enough that you can’t pull the drive links out of the bar nose.

To determine whether or not your chainsaw’s chain tension needs to be adjusted, pull the chain away from the guide bar a little to see if the drive links remain engaged or not.

A loose chainsaw chain will look like the one pictured below when it is pulled away from the guide bar. If the chain’s drive links are disengaged from the guide bar when pulled, then it’s time to tighten it up.

Chainsaw chains can also be overtightened.

There should be at least a little play in the chain, just not enough for the drive links to leave the guide bar. Tightening a chainsaw chain too tightly risks breaking it during operation.

Steps to Tension a Chainsaw Chain

Even though tensioning a chainsaw chain is easy and takes less than a minute, it’s important to do each step carefully and correctly. Forgetting to do something like lift the guide bar nose when tightening it can seriously affect your tool.

Most chainsaws come with “scwrench” (screwdriver/wrench) that matches their side plate nut and tension adjustment screw size.

Step 1: Loosen the Nuts on the Guide Bar Side Panel

This will give the guide bar and chain the room they need to be adjusted.

The brakes of some chainsaws are attached directly to the side panel. If this is the case, make sure to unlock the brake before removing the side panel.

Step 2: Adjust the Tensioning Screw

Tightening the screw will tighten the chain, and loosening will loosen the chain. Double check the chain to see that it’s at the correct tightness before moving on.

Step 3: Tighten the Guide Bar Side Panel Nuts

It is very important to lift the nose of the chainsaw while tightening the nuts that secure the side panel and guide bar (see picture below).

It’s just that easy once the know-how is in place! Your chainsaw chain is now properly tensioned.

Keep those chainsaws and chainsaw chains running the best condition possible. Our power tool and equipment information tools and parts replacement service is here to help you get the most out of your equipment investments.

Visit our Chainsaw Chains page to our inventory of available replacement chains and other chainsaw accessories. For chainsaw repairs, type your saw’s model number in the search field at the top of this page.

eReplacementParts.com stocks thousands of parts for many major chainsaw brands, including Echo chainsaw parts.

Be the First to Share

Did you make this project? Share it with us!

For the Yard

Battery-Powered Contest

Комментарии и мнения владельцев

Hi for the life of me i cannot see the tensioning screw on this lidl petrol chainsaw. The manual points to the top inner side of the blade. It is a 50cc Star Tools Saw.

They aren’t always where that particular one is. Some are on the side where the nuts are to loosen the bar

eager beaver 18″ 35cc bt mccholloch chain will set up but very quickly loosens

I have a different issue. I get my chain set properly and when I hit the gas within 5 seconds it has tightened itself so tight it stops turning the blade and starts to bog down. what could this be?

Good info! Just got a chainsaw and pinched the chain, pulling it loose. Tried to adjust it but the manual didn’t say to loosen the two nuts holding the bar first! Hope I didn’t strip out the tensioning screw. now to go and do it properly.

I to am a Small engine tech that works at a dealer ship that sells a full line of Honda and STIHL power equipment. I could probably give you little tips about everything for everything I have seen, But by the time you check them all it would be night time and you wouldn’t want to cut wood.

Toolrepair has a good basis down for tightening your chain, Once you do a thousand of them you might develop your own technique, But until then, follow the directions put forth in your owners manual. They write them for a reason and one of the reasons is so you have a reference of how to correctly tension your chain. If you own a STIHL chainsaw and don’t have an instruction manual, you can go to your local STIHL dealer and they should be able to order you one. The book costs nothing to order (least here in Canada it doesn’t) but maybe they will charge you some shipping. Then cover basic maintenance, starting, operating and safety. If you are worried about have a cracked impulse line, or a gas tank that is vapour locking, or your unit only idles, then take it to your (enter whatever brand here) dealer and get them to check it or get a service (tune up) done on your saw every year or two. and if you’re not going to use it within 3 months drain all the gas and run the unit dry. Gas does go bad and the 2 dollars in gas that you save by nothing getting rid of it, isn’t worth the hundred dollar bill you will get for repairing your unit.

If anyone has questions. thats what the question section is for. If you want my help, feel free to question me if you really want. maybe i’ll even divulge some of my secrets