Correct Sharpening Of The Chainsaw Chain On The Machine

3 ways to sharpen a chainsaw chain with your own hands Learn how to sharpen a chainsaw chain correctly at home using a file, an angle grinder and a machine. Detailed do-it-yourself sharpening process. We will show you how to work properly with tools and devices.

Sharpening the chain with an angle grinder

For the operation you will need:

- Angle grinder, preferably slightly powerful and large;

- Cutting wheel for metal of the corresponding diameter and thickness of 2-3 mm;

- Vise or clamp to firmly secure the angle grinder to the table.

The angle grinder is clamped in a vice so that the disc is located strictly vertically, without a protective casing, in the direction of the operator. Sparks must fly towards the operator, therefore protective clothing and goggles must be worn to operate. The angle grinder is turned on and, observing the angle, each link of the chainsaw chain is sharpened by eye.

Chainsaw sharpening angles and tooth configuration

- Base. The lower part of the tooth, which has holes for connection with the rest of the chain elements and during operation hides in the guide channel of the bar. It is this part that is lubricated.

- A special stop is an element of the tooth structure that allows the cutter to remove only a certain thickness of wood chips in one pass. Thanks to him, the chain does not get stuck in the fibers, and the chainsaw does not wedge.

- The so-called blade of a tooth is a cutter consisting of vertical and horizontal working surfaces that form cutting edges.

Tooth blades, or cutting edges, need to be sharpened at a specific angle, otherwise it will be difficult to achieve optimal sawing characteristics of the chain. The upper blade (horizontal) has the function of cutting the tooth into the wood and forming a groove. The side or end blade (vertical) helps to trim the fibers from the side.

The productivity of operations when sawing wood in the transverse direction increases if you increase the angle of sharpening of the chainsaw chain to the maximum possible and vice versa. Chains designed for longitudinal cutting of the tree trunk should be sharpened at an angle of approximately 10 degrees.

Under no circumstances should the depth gauge be touched once again: improper grinding can lead to vibration during tool operation. Its finishing is done according to a special template.

File types and tips for choosing

Following the rules, before choosing files for sharpening the chainsaw chain, the exact chain pitch is determined by the chain marking. Further, they adhere to the recommendations:

| Step size | File diameter, mm |

|---|---|

| 0.25 | 2×2 |

| 0.325 | 2×2.4 |

| 0.375 | 2×2.6 |

| 0.404 | 2×2.75 |

There are saw chains where it is appropriate to use round files with a cross-sectional diameter of 2×1.6 millimeters.

Do-it-yourself chainsaw sharpening

The chain tooth planes the wood like a plane, and the chip thickness is adjusted by the height of the stop.

Intense sawing will quickly dull the chain. Several sharpenings may be required within one day. The problem is aggravated by the fact that the tooth quickly dulls when it meets the ground. It is enough to hook the soil with the tire once or twice, and the work can be stopped. The shavings become fine and the saw stops going deep into the wood.

The sooner dull teeth are sharpened, the less material needs to be removed during sharpening, as a result. The service life of the saw chain is longer. Determining the moment when sharpening is already required is quite simple. An important feature is the feed force. A properly sharpened chain is pulled into the cut with just a little pressure. If, on the contrary, the chainsaw is forced to cut by increased feed force, then the teeth are dull. A dull chain can also be recognized if only small chips fly out of the cut instead of coarse, thick chips.

In this situation, the chainsaw must be sharpened urgently. Do not cut with a dull or defective saw chain. The consequence is high stress in the body, high cyclic load, poor cutting results. In addition, this means reduced productivity, high fuel consumption and increased wear on all parts of the chainsaw.

General rules for sharpening chainsaw chains

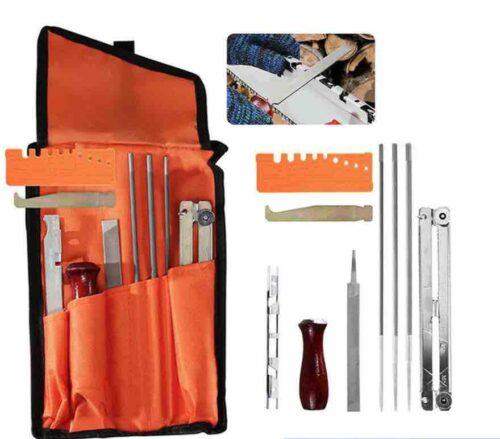

Chain sharpeners

The round file holder has a mowing line that can be correctly positioned in relation to the chain. The holder fits onto the sharpened tooth in accordance with the line orientation. In this case, the insert itself rests on the upper edge of the tooth and the depth gauge, and the file is located under the cutting edge.

The use of a holder ensures that the file will fit to the tooth at the correct height. There are different holders for different pitches of the saw chain. The correct choice of holder, combined with the correct file diameter, ensures that the file protrudes over the back of the tooth by 1/5 of its diameter. Use only special saw chain files.

Before sharpening the chainsaw chain, it is advisable to secure the bar. When sharpening, it is necessary, keeping the position of the holder and pressing the file to the sharpened edge, to make several (2-3) turning movements away from you. Do not try to press too hard on the file, the movements should be smooth and measured. Rotate the file regularly to avoid one-sided wear. All other teeth are sharpened in the same way. It is more convenient to first sharpen the teeth in one direction, then change the position and do the same with the teeth in the other direction.

When sharpening all teeth, file the same number of strokes at the same pressure. This will result in the same tooth length. All cutting teeth must be of the same length. Different tooth lengths cause uneven chain running and cracking. If the length of the teeth is not the same, all cutting teeth must be filed to the length of the shortest tooth.

After several sharpening of the cutting teeth, the depth gauge is ground. To do this, a template is superimposed on it so that the limiter falls into the slot, and the tip protruding from the slot is grinded with a flat file.

The principle of using another set for sharpening chainsaws is no different from the first, although its design is different.

A round file is also used for sharpening the cutting tooth, and for sharpening the depth gauge. Flat. A special template provides parameters for sharpening both cutting teeth and stops. In the first case, it is superimposed on the chain in such a way that it falls into its slots. The file, placed on the template and brought under the cutting edge, rests on the guide rollers. The direction of movement of the file must be parallel to the lateral edges of the template.

When sewing the stopper, the template is applied so that the stopper falls into the slot, near which it says SOFT (for soft wood) or HARD (for hard wood). As in the case of the first device, the file is seamed with smooth, even movements of the flat file away from you.

When sharpening all teeth, do the same number of strokes with the ratfil at the same pressure. This results in a uniform tooth length. All cutting teeth must be of the same length. Differing tooth lengths are a prerequisite for uneven chain running and cracking. In this I will show you how to sharpen a chainsaw chain at home. Sharpening the chain on a chainsaw is very convenient and just use a file and a vice to sharpen the chain on. If the length of the teeth is not the same, all cutting teeth must be filed to the length of the shortest tooth.

After several sharpening of the cutting teeth, the depth gauge is ground. Sharpening the chain on the bg60016 machine. Chainsaw equipment / chain sharpening correctly. To do this, a template is superimposed on it in such a way that the limiter falls into the slot, and the tip protruding from the slot is grinded with a flat ratfil.

The principle of using another set for sharpening chainsaws is no different from the first, although its design is different.

A round ratfil is also used to sharpen the cutting tooth, and a thin one is used to sharpen the depth gauge. The special template ensures the sharpening characteristics of both cutting teeth and stops. In the first case, it is superimposed on the chain in such a way that it falls into its slots. The ratfil placed on the template and brought under the cutting edge rests on the guide rollers. The direction of movement of the ratfil should be parallel to the lateral edges of the template.

When sewing the stopper, the template is applied so that the stopper falls into the slot, near which it says SOFT (for soft wood species) or HARD (for hard). As in the case of the first device, stitching is done with smooth, even movements of a flat ratfil away from you.

Correct sharpening of the chainsaw chain on the machine

Chainsaw chain sharpening machines

Stihl manufactures two versions of manual machines. The stationary FG 2 and the mobile FG 1, which is mounted directly on the tire. There are analogues of the least recognized companies, commensurate in cost with the more ordinary devices described above, for example, this

The working part of these devices structurally resembles a bow saw, into which a round long ratfil is inserted instead of the saw blade. Fg 1 and FG 2 not only sharpen the chains, but also straighten them, adjusting the length of the upper edge of all teeth to one size. According to the smallest tooth, which is taken as the control one. A rather complicated option mechanism allows you to set all the necessary characteristics. Sharpening is done in 2-3 movements, after which they proceed to the next tooth, keeping for it all the options that were made for the control tooth. This ensures similar sharpening characteristics for all teeth. When sewing the stopper, the round ratfil changes to thin.

Easy and convenient to use electronic chain sharpener for chainsaws. It has an option system that allows you to set the chain at the desired angle and bring the disc exactly to the sharpened edge. There are machines that automatically clamp the vice when the disc is lowered onto the chain.

Chainsaw sharpening angles and tooth configuration

The cutting edge of a tooth is characterized by the following parameters:

- Width;

- Thick;

- Sharpening angle.

In addition, each model of the tool has its own tooth pitch, the value of which for household and semi-professional models is associated with the power of the chainsaw, and the torque that the drive develops. For example, for rip sawing, the pitch is taken less (eg 0.325 inches). In this case, the productivity of work will decrease, but the required effort will be significantly lower. The upper values of the steps for household chainsaws are extremely rare, mainly when felling trees with a large trunk diameter. In this case, the motor power should not exceed 2500 W.

The thickness of the cutting edge for most manufacturers of chainsaws is set the same, and equal to 1.3 mm (there are also edges with a thickness of 1.1 mm, but, firstly, they are extremely difficult to sharpen at home, and, secondly, such links are extremely are of little use: they can only be used for cutting thin branches).

The height of the chain profile can be either 0.625 mm or 0.762 mm, moreover, in the vast majority of cases, it is a low profile that is used for household power tools. When sharpening the limiters, this parameter is very important, because with a decrease in the height of the above-permissible values, the vibration of the tool during operation increases, although the quality of the cut remains satisfactory. Therefore, you should not get carried away with lowering the height of the limiter when sharpening a tooth.

The sharpening angle of the chainsaw chain depends on the main purpose of the tool. For transverse or rip sawing. Since the resistance of the wood is always noticeably higher when ripping, the edge of the tooth must be very sharp. It is recommended to do it in the range of 6. 12 ° (for comparison. With the predominance of cross-cut. Up to 25. 30 °). Naturally, in the first case, sharpening should be done more often, and especially carefully, since an unacceptably small angle of inclination of the tooth contributes to its rapid chipping during the operation of the chainsaw. This is especially important for links that are made of structural alloy steels containing silicon and manganese, for example, 40KhGS or 35KhGSA.

Chainsaw chain sharpening angle. How to choose the right one?

Even the popular Stihl does not last forever: once the teeth of a chainsaw wear out, which is easy to determine by the nature of the chips formed. With a blunt cutting edge, the chips are small, because the working edge does not cut, but crumples the wood. Naturally, the effort expended by the operator increases dramatically. It’s time to sharpen the saw. How to do this correctly. Choose the optimal technology, establish what angle of sharpening the tooth should be and how to check it?

External signs of a blunt cutting edge of a chainsaw tooth

Recall that the chainsaw tooth has a complex configuration (see Fig. 1), which also depends on the direction of movement of the chain. It has two working edges: the lateral one, which is located perpendicular to the axis of movement of the links, and the upper one, located at a certain angle to the direction of the chain movement. In addition, a limiter is provided on each tooth, the parameters of which determine the height of the removed chips. Since the main cutting effort falls precisely on the working angle, then all subsequent work with the tool will depend on which angle to sharpen the tooth.

Before starting long-term work with a chainsaw, she needs to inspect and perform test sawing, as a result of which:

- Visually establish the presence (or absence) of a tapered section adjacent to the corner of the tooth, as well as radius curvature on it. The main signs of bluntness (see Fig. 2).

- Check the feed force at which the tool runs stably, with a fast cut. For sharp teeth, the initial moment of penetration of the tooth into the wood occurs quickly, and without significant material resistance.

- Find out the presence of chain vibrations during a steady cut. If they are noticeable, then the teeth must be sharpened.

- Inspect the appearance of the just cut end (especially if the tool is used for ripping). If there are rough chips and dents, the chainsaw chain must be sharpened.