Cut the laminated wood-brown stove with an electrician at home. Saw disk. How to choose it?

How to cut a laminated wood-brown plate with a jigsaw without chips

In general, I have already considered this in a review article, which was devoted to the cutting of a laminated wood-brown stove without chips without the use of a format-stringing machine.

Today I decided to dwell in more detail on the method available to most homemade drivers. this is a sawing by an electrician, since this tool is very widely common. In this lesson, I used Skill 4581la household electric. By the way, a very good machine.

For the highest quality cut, the following conditions must be met

In addition, for the greater purity of the cut, we will use such a modification as sawing “on scratches”. Its essence lies in the fact that the laminate is scratched to the entire depth and its pieces pulled out by the teeth of the files, the scratches do not go abroad. For clarity, I will give several photos.

It is necessary to scratch the ruler (any sharp object-I used a drill-perca, or at least a self-tapping screw.) So that the ruler does not shift during the scratch, I additionally fixed it with a clamp. you can a couple.

Scratch to the entire depth of the laminate, that is, before the appearance of sawdust in the scratch.

Then we take the jigsaw, and we lead it so that the saw goes as close as possible to the edge of the scratch, while without leaving, beyond this border.

Thus, chips are formed only on the unnecessary side, without going beyond our marginal fishing line for a trimmer

Once again, the same cut at its completion. It can be seen that the minimum chips still remained, although they can be on professional equipment. But the evenness of the cut leaves much to be desired.

Of course, there are unique ones that can saw an electrician quite evenly. I don’t belong to this. Of course, the class of the tool itself also plays a significant role. As a rule, in inexpensive tools, the saw is not as stable as in professional models. Due to this, it takes it towards the sawing.

In general, this method has the right to exist, but I would not advise putting it on a stream.

How to use it correctly. tips for beginners

The use of an electrician does not require special professional skills that are being developed over the years. At the first sawdrops, the master studies the possibilities of this instrument in speed of sawing, the behavior of the file, weight, power, etc.D. Further, everything you need to work is to hold the tool and accurately direct the file along the cut line.

You can not rush and put pressure on the file before she did it drank on the current section. The saw should have time to drink the site, completely throw the sawdust from the cut and only then move on. Therefore, the electrician should be moved smoothly and calmly, without reducing the speed of the electric motor.

To facilitate the cut in a straight line, on most models there is a “pendulum course” mode or swing. When it is turned on, the saw walks not only up and down, but also back and forth, which facilitates and accelerates the cut.

The regime of the pendulum passage is included only at straight sawdust, when speed is required and the gusts and chips of the material at the edges of the cut are not important.

We also recommend reading a useful article-breeding about how to cut an electrician correctly, it describes all possible and necessary situations when working with this tool, and also analyzed safety precautions.

What work can be done

This tool does not need to do what it does worse than other tools: stationary and hand disk saws, endings, chain and strip saws. Although no one prohibits this. In the absence of another tool, you can, for example, cut a small meter of the review and a jigsaw. But it is more rational to use it in their special capabilities, which are not given by other sawing tools.

- clipping ornaments on panels, platbands;

- cutting holes, ovals in size of more than 50 mm;

- washed out spikes, grooves, samples, etc.D;

- rounding of straight angles on the ends of the blanks;

- Cream of thin sheets of plywood, wood.fiber slab, etc.P.

Electrolobzik, as a rule, is much easier than a disc saw and work with large areas of a large area can be more convenient for them.

In addition, the use of special files allows you to use an electrolobian for work on the following materials:

Cutting wood and wood.containing materials

Listen wood.containers include materials based on chips, sawdust, wood fibers, compressed and glued with various adhesives and tar according to different technologies. This is a wood-fiber plate (wood-fiber plate), wood-bruise (wood-bearing plate), laminated woody plate (laminated woody plate), etc.P.

For their cutting, special files with appropriate marking are used. For example:

Many pieces are universal, they can be sawed by both wood and leaf materials based on wood.

- for a quick rough cut (large tooth);

- for pure cut (smaller tooth);

- for cutting without gusts of laminate, plywood (small tooth with specially oriented inclination and sharpening).

Artistic thread on wood and faner

In such processing, an electrician is indispensable. Some work can be done with a manual jigsaw, and then not all. At a hand.lobby, the saw is attached on both sides. It cannot be introduced, for example, into a hole with a diameter of 8 or 12 mm to continue sawing along long lines. With a file of an electrician you can start sawing with a hole anywhere in the workpiece.

Electrolobsik saws fast enough. You can saw several layers of thin blanks at the same time, for example, from plywood, so that several blanks are made at once in one pass.

We also recommend reading an interesting article about cutting a jigsaw.

Crinoline cuts

To cut out curved profiles, use files with a small tooth and the highest possible canvas. A wide canvas maneuvers worse with steep turns to drink, sometimes they just can’t do it in a narrow radius.

With such a thread, it is important to quickly and accurately mark the markings. Unique products are marked according to their own drawings and sketches. For non.monitor, you can use ready.made patterns. Also, one pattern can be marked with repeated elements.

With a curved thread, files break more often due to turns. Therefore, crooked lines saw more slowly and more accurately. Better to have several spare pieces.

Riding a circle

In the kit of most models, there is a compass for cutting along the radius (in a circle). This is a bar (rod or plate), one end of which is fixed on the electric electrolobian case. And the second due to the acute tip is installed in the center of the circle. Separately, you can buy both the same simple and more complex device with linear marking.

By the same principle, you can cut a semicircle. Ovals, ellipses and other figures cut out by preliminary marking with a pencil, marker, sharp tip, etc.D.

The holes of a small diameter are sometimes easier to drill, in the presence of a drill or crown of the desired diameter.

Work with metals

For cutting metal, special files are used on non.ferrous or ferrous metals. But an electrician for cutting metal is ineffective. Other tools are better handled by other tools. “monkey” (corner grinder) with metal disk, gas cutter, rapid saws, metal scissors, etc.D.

There are cases when the use of an electrician for cutting metal is justified. For example, when cutting thin metal, when there is no other tool. Also, an electrician can be indispensable when you need to cut a round or curved hole in the middle of the workpiece. You can also cut a small corner, channel or pipe with a good file with a good file.

When sawing thick metal, it is advisable to lubricate the file with any machine oil. On machines for these purposes, a water.oil emulsion is used. It not only lubricates, but also cools the file.

We also recommend reading an interesting article about the work of an electrician with metals.

How to saw plastic

Plastics are very different from each other in their properties. These are polypropylene, polyethylene of high and low pressure, polystyrene foam, etc.D. All of them saw in different ways.

Solid but fragile materials can crack under the influence of a file. Too soft. to knit in the teeth and clog them, which makes sawing it impossible. However, many plastics are well sawed in the jigsaw. You can saw specific plastic with an electrician or not, is determined by trial saws. At the same time, the correct selection of saws is important.

The rest of the plastics is drunk with the same techniques as other materials.

Cutting laminated coatings

When cutting an electrician of any materials with a laminated coating, the main problem is chips and decorative ruptures. Sometimes this is permissible if the cut is hidden when assembling the product is hidden. But in many cases, such damage spoil the workpiece.

The laminate is sawn with a jigsaw with a file on the laminate “pure cut” or metal. The pendulum move is not used.

Sawing techniques depending on the material

We will analyze in more detail, the main types of work performed by a hand.lobbye, depending on the type of sawed material. Also, each paragraph will give its own nuances and features of working with specific material.

How to cut a countertop under the sink at home with an electric jigsaw

The saw and the speed of sawing are selected based on the material of the countertop (laminated woody plate, wood-fiber slab, wood, etc.e). A cut is made under the round shells using a circul, which can be included in the kit or made on its own. As an example,

There are jigsaws with grooves for parallel emphasis in the front of the platform. For them, you can make a compass from a metal strip, for example, skewer.

Working with a complete compass

Under the square shells with rounded corners, a marking of the sink is applied to the material, and a cutout is made on it.

Working with plywood

Pendulum move (rocking) when cutting plywood do not use. In the swing mode, the edges drank more torn more, chips are formed. Start to saw from maximum speed. If the material begins to burn (blacken) from severe friction, the turns are reduced to optimal through the sample.

How to cut a plywood without chips

There are many ways to avoid chips along the cut line, the most popular: gluing the line drank with a painting ribbon, using anti.ski sole, lining of the second layer of plywood, etc.D. All of them have disadvantages. require consumables, protect only one side, laborious.

The most effective way is the selection of the right file.

The smallest files for metal, Metal, T118G, (tooth step 0.7 mm) practically do not tear plywood. Their minus. they saw slowly, yet they are not intended for plywood.

Well combine the speed and cleanliness of the cut of wood for wood and plywood with the labeling Wood (tree) T101AO. HCS steel. The tooth is much larger than that of the file for metal, so it saws faster. It does not tear the plywood either at the bottom or above, due to the direct location of the teeth, not under the slope up or down, but strictly perpendicular to the canvas (straight.toothed saw).

What can be cut out of plywood

From plywood, you can cut out elements of any complexity. ornaments, platbands, patterns, parts for machines, models, furniture, etc.

As an example, a photo of a figure element

Bent legs for the table, simpler curved parts to cut even easier.

How to cut boards

An electrician can do such a job if the meter drank a small. But it is convenient for them to make short rectangular cuts in the board for the connection of the groove/spike, in a quarter, “in half a core”. It is also indispensable for an electrician when it is necessary to make a curved cut of the boards, cut an oval or a large hole, etc.D.

Electrician is poorly suitable for long cuts along the board. Dissolve the board on the beam, cut the spouse is better on stationary, in extreme cases, manual circular.

The board saws in the usual ways. A file for soft (Wood) or solid (Hard Wood) woods of suitable length is selected.

The most popular soft species of wood: linden, alder, aspen, all coniferous rocks.

Hard rocks: oak, beech, dry birch, ash, maple, pear.

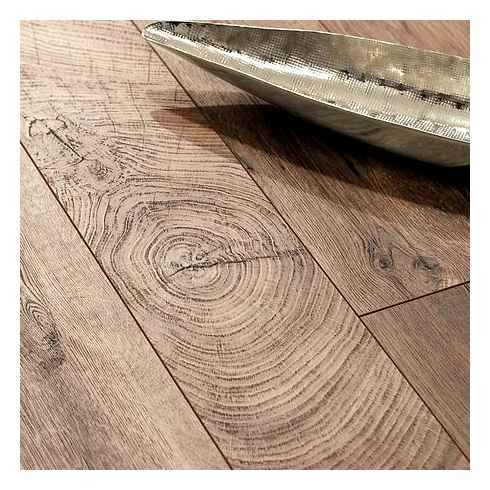

How to saw wood-brown slab and laminated wood-bearing plate without chips

The leaf material is most pulled out from below. There, the saw passes over the void, and the particles of the material have no support and support, like at the top. To reduce chips from below, sometimes use a file with a reverse tilt of teeth, by the acor. Such a saw takes the sawdust up and pulls the lower side less.

Note! Also used files with a straight tooth for pure cut. For example, with T101AOF marking from bimetal (BIM). She can cut a solid tree, because she has a marking hard wood. If chips remain, select a canvas with a smaller tooth.

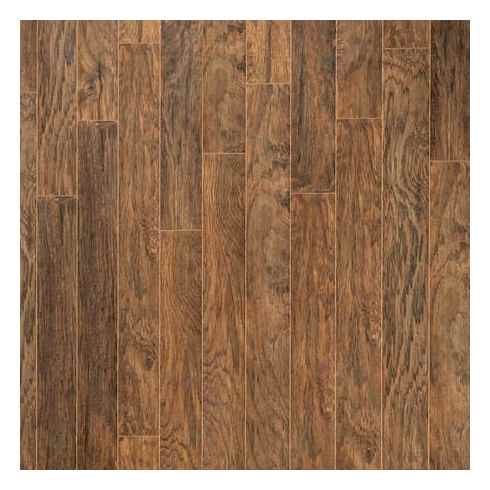

In the photo below, an example of drank laminated woody stove.

In addition to the correct selection of files, other techniques are used:

- The laminate on the laminated wood-brown slab is pre-cut out along the cut line with a mounting knife, one or two stripes in the thickness of the saw out;

- A painting tape is glued along the cut line;

- An anti.skilled platform made of thin plastic is attached to the lobby platform.

It completely closes the workspace, only a narrow strip under the file remains. The platform during cutting presses on the material and does not allow particles to break out of the array. Protects only from chips from above. effective with the use of a file with a reverse tooth inclination (upside down).

We also recommend reading an interesting article on how to properly saw lamine and other laminated materials with an electrician.

Is it possible to cut off the tile, porcelain tile

For cutting these materials, another effective tool is most often used: tile cutters, cutting machines, corner grinder with special disks. But, sometimes it is required to cut the tile along the curve line, cut a semicircle, etc.D. For this, an average and high.power electrolobesis with a special file is well suited (Special marking). Such a saw has diamond spraying and can saw ceramics and porcelain tiles.

Plexiglass

These materials are sawn in the same ways and techniques as any sheet material. The most important thing is the correct selection of a file.

The difficulty is that under the general name “Orgshydlo” there can be a variety of materials. transparent acrylic, monolithic polycarbonate, various types of plastic and hard polyethylene, and even leaf micneys for fireplace screens, etc.D.

All of them have different plasticity, flexibility, strength, density and saw in different ways.

Note! As a base, you can recommend a file mPS3108. Although it has a Wood marking (tree), black color means universality, application for different materials. The canvas only on wood or on wood and metal of other colors. It has an average step size and a back tooth tilt, with a tip up, because it pulls out the material from below less.

What devices to use in the work for straight cuts

Long straight cuts can be made along the marking line or with the help of guides. For example, with self.tapping or clamps, a bar or corner is attached to the material. Electricity is moved by pressing it with the side of the platform to the guide. With this method, the marking is made, given the position of the file (where there is really a cut) and a parallel stop.

Can be sawed with a parallel stop, which is included in the kit. It is inserted into the front of the platform. The support bar is set on the flat side of the workpiece. It is not always applied, only with the flat side of the workpiece and suitable width, because the emphasis may not reach the edge of the workpiece.

Sometimes a guide tire is used, which holds an electrician not on one, but two sides.

Cut on a home.made guide tire

As a result, an electrician is a universal tool with wide possibilities. They cannot be overestimated, it is necessary to really take into account the power and performance of this tool, especially in the thickness of the workpieces, the length of the sawdust, the strength of the materials. But all the possibilities of an electrician as an auxiliary and sometimes the main tool are useful to know and use.

Materials and tools

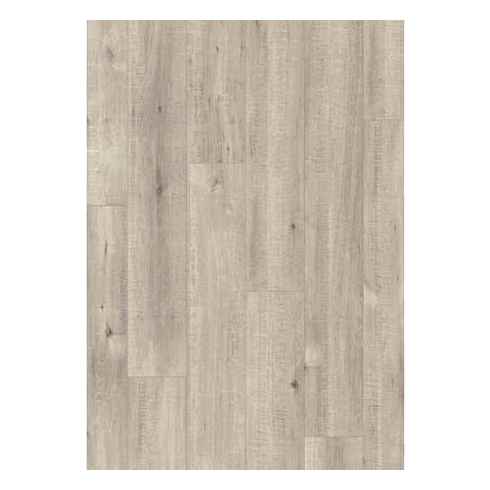

In the conditions of a woodworking enterprise, a special equipment is used for sawing a sheet of laminated woody plate, which is called a format-sprinkle machine. Some private furniture workshops acquire such a machine, but it is hardly advisable to install it at home due to a high cost. Homemade power tools will be able to replace such equipment-sawing a wood-and-steering plate can be made with a disk saw or hacksaw. The process of sawing will take a lot of time and effort, but from an economic point of view it will be quite justified.

Electric jigsaw

In order to perform a flat drink without damage to the laminated layer, you will need to take a file for a jigsaw, in which the size of the cloves will be the most minimal. It is advisable to use an electrician for sawing small in size of the plots of laminated wood-based slab. Jerks and excess pressure during work should be avoided. The speed of feeding the cutting canvas from the tool should be chosen by the minimum.

This device is quite capable of performing an even and high.quality cut without chips of a laminated surface.

Manual hacksaw

This manual tool is used in combination with the canvas for metal, since it has the smallest cloves. Before working at the cut site, it is necessary to stick a paper sticky tape that protects the layer of lamination from damage. The canvas of a hand hacksaw must be kept at an angle of 30–35 °, this position reduces the likelihood of chipping on the material. The movements of the hacksaw should be smooth, without pressure on the canvas.

After the cut is made, the edges of the cut are required to be treated with a file and fine.grained sandpaper paper.

Circular saw

This power tool consists of a small desktop and a rotating gear. The disk saw makes a slice on the wood-based panel much faster and better than an electric jigsaw. Performing the cutting process, the saw is included at small speeds. In this case, chips can appear on the opposite side of the saws of the saw.

To prevent this situation, before starting sawing into place the cut, glue a paper adhesive tape.

Electrofreing

This is a manual type of power tool that is used for sawing and drilling woody plate. Before starting work in a laminated wood-based slab, a small cut is made using a manual jigsaw, retreating from the marking circuit by 3-4 mm. In the process of sawing, several cutters knives and its bearing device are used, which regulates the depth of cut. It is not so simple to use the cutter, so for cutting the slab you need to have a certain skill of working with this tool. The movement of the cutter is quite fast, and there is a chance to make an uneven saw.

But with the help of a milling cutter you can get a perfectly smooth section of the material. the appearance of chips and cracks when using this device can be very rare.

The use of manual tools is advisable in the manufacture of single products from laminated woody stove. For mass production, it is advisable to purchase format-sprinkle equipment.

How to cut it correctly?

To cut a laminated wood-brown stove without chips at home is quite possible with your own hands. Significantly simplifies the task of preliminary creation by an sharp object of the groove in the area of the saw. Once in this place, the canvas of the cutting tool goes along a given path and it turns out to be much easier. Right-in-law cuts on a laminated wood-based slab are much easier to make than cut a sheet of figure.

It is extremely difficult to perform curved configurations using home devices, this can only be done using an electrophresis. This tool performs a quality cut and has a lot of additional functions.

The price of the electrophrease depends on the manufacturer, so you can choose a budget model with good technical parameters.

For cutting a leaf of a laminated wood-based slab using an electrophrease, the following actions must be performed:

- On the surface of a conventional wood and steering plate, all contours of the future workpiece are marked;

- Using an electric jigsaw, the workpiece is cut, retreating from the intended circuit by 1-2 mm;

- The finished sawn template is cleaned with a file or sandpaper;

- A prepared stencil is applied to the laminated wood-based stove and fix it with carpentry clamps so that it is in a stationary position;

- along the contour of the stencil with an electrophreze equipped with a bearing mechanism, the blank contours are cut, cutting off the edge exactly along the intended line;

- After the work, the end sides are cleaned and treated with a decorative edge.

The use of electrophrease allows you to perform a figured cut of laminated wood-bearing plate without chips and cracking of the material.

Electrophrees knives should completely capture the entire thickness of the workpiece material. the only way you can get a quality product.

How to cut a wood-piece stove without chips

In order to saw off at home evenly and without chips, a wood-brown slab, you need to know some tricks. Without any doubt, it is better if you will cut it with an electrician. Of course, you can also cut a hacksaw, but the result is unlikely to please you, although the wood-bearing plate is possible for various needs, where the quality of the saw does not play any role. And so, we need even and beautiful saw. To do this, we take an electrician, ruler, roulette and a square for a right angle (if it is necessary), an awl or an acute item of which can be drawn for a trimmer on a laminate on a wood-based stove. We measure the part that we will saw off with a margin of 1-2 mm for subsequent fitting and apply a ruler, we draw a fishing line for a trimmer for a trimmer for a trimmer, try to press the laminate to cut out, and sawing along the line not along the line, but namely Along, only touching it with the edge of the file.

Then, with coarse.grained sandpaper, bring the edges of our sawing to the desired state and, if the quality of the sawed end did not satisfy you, we take a wax crayon of the desired color.e. In the color of the wood-brown plate and grind chips. We’ll talk about the jigsaw files, I personally use Boschevsky.

If you need to saw off without chips on one side, then you can use the files as a tooth up and down, I use small files with a straight tooth, they have a bit less and saw off both sides is quite a decent. It will be more convenient to drop the cut end of sandpaper if you pull it on an even bar. You can buy furniture wax crayons and markers in furniture stores, where they trade in fittings. If you have not found a chalk of the color you need. It doesn’t matter how it can be made of several others, mixing like paints. Just melt the shallows with a candle and drip on the plate, one color on it is another, then roll it into one and rub the edges with chips, remove the excess with a ruler or knife and polish with a cloth gently, do not need to crush much.

Methods of minimizing chips

An additional reason for the formation of chips may be the divorce of the teeth of the files. Therefore, first of all, you need to take care of purchasing a tool with a direct reza (often it is BOSH files). However, it should be noted that with prolonged work, such files overheat and may even bend during the cutting process. In view of what needs to be made in work to cool the cutting tool.

However, one file replacement is not enough and in order to cut a laminated wood-bearing plate (laminate) with an electrolobian without chips, it is necessary to perform a small refinement of the power tool. Namely, make sure that when the file is moving against the tilt of the tooth, the material does not break out. Why is it enough to make a stubborn platform. You can come to such a conclusion by trying to cut out two sheets of laminated wood-based slab at the same time. So there will be practically no chips on the lower element.

In order to make a stubborn platform for an electrolobian, it is enough to cut a rectangle in size from the identical dimensions of the sole of the power tool from the laminate (for example, from the laminate).

Then, on the larger axial line, it should be made and fixed and fix the resulting equipment to the sole of the electrician using an insulating tape or double.sided tape. All revision is ready and you can perform finishing work in compliance with certain recommendations.

Firstly, as mentioned above, you should use a file for an electrician with a direct cut.

Secondly, in order to more qualitatively control the cutting process, the marginal fishing line for a trimmer is justified on both sides laminated wood-bearing plate and check the accuracy of processing from above and below.

Well, thirdly, make constant breaks in work to cool the cutting equipment.

Sometimes, the solution in this issue can be a simple cutting of the lemmian layer of the material using a mounting knife, and the subsequent work with a jigsaw will no longer cause large defects in the form of chips. However, this work requires a certain experience and accuracy from the contractor.

How to cut a laminated woody stove

Laminated wood-bearing plate can be sawn with a hand saw with a small tooth, an electrician, a disk saw. The cut place is glued with masking tape and cut out along the cut line with a sharp knife. The knife cuts out the laminated coating and the upper wood fibers under it. Further, when passing with a saw with a saw, a laminated wood-bearing plate will not be cooked. The finish of the end under the C-shaped overhead kant in the manufacture of furniture, this method is quite suitable. And it is better to use a different way under a melamine self.adhesive tape.

Electrolobsik or disk saw saw a laminated wood-brown stove with a margin of 2-3 mm. From the cut line. I sawed an electrician on the guide. As a guide, you can use any even rail or rule. In my case, fiberglass 150 mm wide. The thickness is 4 mm. As described above, chips were formed on a laminated wood-based stove. Next, set the guide exactly along the cutting line and with a manual milling milling milling cutter we remove these 2-3 mm. which we left for stock. The design of the bromic milling cutter has on the shank bearing equal to the diameter of the cutter itself.As a result, we get a perfectly even edge, to which you can easily glue a self.adhesive melamine tape. Also, when cutting curved cuts, you can not do without the use of the milling cutter. We make a guide with the desired radii with an electrician and also pass the end of the bromatic milling cutter. The method of cutting laminated wood-bruise without chips is also suitable for cutting laminated plywood and wood-fiber slab.

||electrician house fitting||✍✍

Everyone knows that the laminated wood-brown slab is our wood-brown plate, which is covered with paper-smoke film. The lamination process is in special conditions: pressure 25-28 MPa, temperature 140-210 ° C. The surface is strong, even, beautiful. Coating laminated woody plate is very resistant to mechanical influences and to thermal. Due to these qualities, the laminated wood-based plate has become simply necessary for furniture production and for decoration of premises inside.

Some masters love to make furniture on their own. They acquire laminated wood-based wood-boring plate from manufacturers or in special construction stores. Since the color scheme of the laminated wood-bearing plate is very rich, you can choose the right material without any difficulty. The surface of the laminated woody stove also has a wide variety of structure, since it is smooth, imitate a tree of different rocks or stone.

In order to make special furniture or a unique interior with your own hands, it is not enough just to buy a laminated wood-brown stove and draw it on details. The coating laminated woody plate is very thin, its structure is fragile. If you cut the laminated woody boat slab roughly and incorrectly, the incision will turn out ugly, torn, and shells form on the edges. To be able to cut the laminated wood-brown slab correctly and not get chips and cracks, you need to know some small “tricks” of the work.

How to cut a laminated wood-bruise plate without chips

Here, I collected a sufficient amount of material and decided to roll another analytical note. This time the topic is a sawing laminated wood-bruise without chips.

There is a fairly fair opinion that it is possible to clean the laminated wood-based stove only on professional equipment (that is, a format-risk machine).

The whole highlight of this machine is that there are two saw disks located strictly on one axis. The first cuts the laminated woody stove, the second cuts through it through.

(of course, there is more expensive))). For an amateur, it is not very acceptable.

Of course, if you decide to make a wardrobe with your own hands, it is better to order a sheet cut (five square meters) in the workshop, and then it is calm. But what to do if you were bent in the calculations and you need to cut off the piece. I don’t want to drag in the workshop again, but you need to cut.

This article is designed to answer this question. A review of options will go from simple to complex. Unfortunately, not all ways will be illustrated (I ask you to forgive me in advance), I will try to compensate for this shortage with text 😉

LUXURY Adventure with HOME Theater, Corner Shower, Walkable Solar

Grandfather’s method. Previously, a laminated wood-bruise plate covered with a thick layer of varnish was used for sawing a Soviet. Now it is rarely used. With him, we scratch the margin or a simple nail on the ruler for a trimmer for a trimmer to the thickness of the decorative coating.

After that, we saw along the line, trying to ensure that the edges of the teeth of the saw fall exactly into the scratch and not a step past. You can saw, both a jigsaw and a hand hacksaw.

In principle, the photo of the right shows that all the chips were left on a piece without a scratch, and they did not go for the scratched line.

Detailed lesson by this method

The cut is much cleaner than when sawing without scratches, but chips are found. It is difficult to maintain the tool strictly along the line. So slow.

Method 2. Electric

Small in length of the cut of acceptable quality can be carried out by a simple electrician. To do this, you must fulfill several conditions. Firstly, the file should be with a minimum size of teeth (that is, for metal) and new. At the same time, on the one hand (where the teeth are included in the material), the cut will be almost pure. With the opposite. there will be chips, but relatively little.

Secondly, you need to submit the tool smoothly, without pressure. The revolutions are not set maximum (slightly above average.

The disadvantage of the method is quite difficult to withstand the strict rectilony of the cut, as well as the presence of a small number of chips.

Method 3. circular saw

To work with the circular, we need a “final” saw disk (again, with a small tooth). Circular saws are more convenient than the jigsaw to draw long direct cuts. But chips are formed much more (the side where the teeth cut into the material (bottom), as a rule, clean. Slows up pieces from the opposite side (from above)).

You can saw it as a freely saw (leading exactly along the line is quite difficult). It is difficult to cut a few identical details. a lot of frosts with markings.

And a saw fixed in the table. When using the guides, it is much more convenient to saw. Both hands are free. You can use the guide, which will increase the accuracy of the cut and allow you to stamp the same parts.

Even when using a final disk, on the one hand there will be many chips.

Method 4. cutting with cutting

This is a modification of work with a circular saw. Ideally, it will need a submersible saw, but, in principle, you can do with an ordinary circular. To work, we need a ruler (tire), which is fixed on the workpiece with clamps. It can be purchased or homemade (in the photo a simple circular with a home.made bus).

The whole chip is, by analogy with a format-sprinkle machine, draw two cuts strictly along one line.

A cut on the tire (long ruler) will help us with this). The tire is placed on the marking line, after which we first make the first cut, cutting a laminate, about 6-10 mm deep. In this case, the teeth go almost parallel to the surface of the laminate, without tearing its pieces. In the photo, my household submersible saw Elitech. I highly recommend.

If you increase the photo, it will turn out something like this

The second cut through. At the same time, at the place of entrance to the tooth into the material, as we recall, chips are not formed. And at the place of exit, the laminate is already cut and nothing to prick.

Another article dedicated to the revealing saw of professional, however, a class, but still informative-read.

A good way to cut the incorrectly marked parts, but you can’t drink the whole cabinet in this way. Chips, of course, are present, but in an amount that is quite correlated with the format (he, too, in secret, leaves a small number of small chips). Many hassle with marking. Only rectilinear cuts can be done.

Why is the jigsaw saw crookedly

In some cases, the master may get a curve cut. A similar nuisance arises due to:

Working with too thick materials is difficult to achieve even cut.

Ways to eliminate problems

To obtain an acceptable result, you should be patient and work correctly with the tool. Do not press too much on it and push it forward. This will only worsen the quality of sawing and will cause chips on the material. It is important to apply a fishing line for a trimmer for a trim.

Sprinkle metal shields, wooden countertops and other products must be a device with a well.sharpened file.

Errors when working with a jigsaw

If the carpentry did not bring an acceptable result, it is worth considering how correctly the sawing procedure was carried out and whether all the conditions were met.

Among the main errors arising in the course of work with the jigsaw, it is worth highlighting:

- Lack of experience in working with the device. In this case, only practice can help.

- Insufficiently reliable fixation of the material. When trying to cut the workpiece, the sheet begins to move off, which causes a crooked section.

- Too fast.

- The use of homemade devices. If you cut the material with such a tool, it will be difficult for the master to achieve a good result.

- The use of a large weight unit. Against the background of a significant mass, the tool starts to the side during carpentry work.

Curved sections can occur in cases where the master uses a faulty tool.

Starting to sawing any material, it is important to familiarize yourself with information on how to configure an electrician for a flat saw. This will make it possible to make a workpiece with correct geometric outlines and an attractive appearance. So that thin sheets do not deform during work, you can use the substrate. Using life hacks in working with a jigsaw, you can learn to professionally handle the tool.

Why the electrician saws crookedly and takes it to the side

In the process of cutting blanks, an unpleasant situation may arise in which the saw blade goes to the side and an uneven cut is obtained. The main reasons affecting this are:

- Inappropriate canvas. Each saw canvas has the shape and angle of sharpening of teeth specially designed for a specific material. Inconsistency can lead to a breakdown of the canvas, blackening the ends of the workpiece, as well as to the departure of the jigsaw from a given trajectory of movement;

- Lack of marking. Many masters try to cut the canvas exactly without marking the cutting line, relying only on adaptations. It should be remembered that the parallel emphasis and the guide tire do not give 100% confidence as a result. Marking must be done necessarily;

- Excessive pressure pressure. The increased pressure on the handle of the jigsaw inevitably leads to the departure of the canvas from the cutting line. To achieve a good result, you only need to direct the tool, giving it the opportunity to cut it yourself.

Which electrician allows you to make a perfectly even cut

High.quality cut in any material make electrical jigsaws with an additional guide for the saw. Among them can be highlighted:

The use of an additional latch instead of a support rink allows you to minimize the back of the saw blade and ensure the optimal cut quality.

We also recommend reading about the best electrician this year and how to choose a suitable jigsaw.

An electric jigsaw is an indispensable tool in a home and professional workshop. It allows you to produce quick and high.quality cutting of any material, as well as perform figured sawing. After reading the article, everyone will be able to understand how to make a straightforward and curly cut with its help.