DIY gasket gaskets. Problems of the carburetor when operating the engine on gas

Repair of the head of the lawn mower. Is it possible to repair the lawn mowed on your own? REPAIR OF LARING MOLE: How to cut and change the gasket under the carburetor

To quickly and without unnecessary efforts to put in order a summer cottage or adjacent territory, motorcycles are used. Their most intensive use falls on the warm season. Before work, preparation is carried out. lubricating moving parts, checking and replacing the cutting headset, refueling with a fuel mixture. Not always everything goes smoothly. the engine may not get started or stall almost immediately. To identify and repair the malfunction, they look into the attached documentation. On the repair of the lawn mower, with photos and illustrations, as well as about its most common malfunctions, it will be discussed in the article.

The main element is the internal combustion engine, as a rule, a two.stroke. A shaft, closed with a tubular bar, is connected to it through the gearbox to the cutting headset. The cutting part in the form of knives or fishing line rotates with large (10-13 thousand.about./min.) speed. There are technological holes for the supply of lubrication on the protective casing. For comfortable use, the lawn mower is equipped with a belt.

- Fishing line for a trimmer with a cross section of 1.6-3 mm for the head of the trimmer for grass. When working, a fishing line for a trimmer wears out, and a bastard with a fishing line, or rewinding and replacing fishing line is performed either.

- Duple.hot steel knives for cutting small shrubs, or thick and thick vegetation. The difference between them is both in form and in sharpening.

The handle attached to the bar is equipped with buttons and levers of motorcade control. A protective casing is installed on the cutting mechanism.

The refueling is made in the available tank mixed in the necessary proportion with gasoline and oil, while gasoline is used with an octane number of at least 92. Lawn mowers with a four.stroke ICE are refueled differently. they separately season gasoline, separately poured into the crankcase oil.

It is impossible to start the engine. reasons

The first thing to do is to check if there is gasoline in the tank, and if there is. what quality it is. The use of poor.quality or low.octane gasoline leads to the failure of the piston system. Repair of the piston at the lawn mower will cost almost half of its total cost. The correct proportion of gasoline and oil, given in the attached instrument operation instructions, is also important.

The manufacture of a large amount of the mixture is undesirable, since it eventually becomes unusable. Do not use the old mixture for some time.

The engine may not start with a serious suction of the fuel filter. In the case of his strong blockage, he must be replaced. The use of a lawn mower with a disconnected fuel filter is unacceptable. Blocking air filter is possible. In this case, it is washed with water with a detergent and dried, in extreme cases, soaked in gasoline. The dried filter after installation is moistened with oil used in the mixture.

If, after the above measures, I did not start, it is adjusted at idle with a screw on a carburetor.

Blog named after. SANCTA → Production of gaskets (my experience)

Today I want to talk about how I make gaskets.

On the Internet, I found a description of which the people make gaskets. I used to make them from a paronite. But I don’t like the material itself. From oil, the paronyte becomes soft as a snot. The compounds need to be constantly extended, it is wet and looks extremely inaccurate.

The paper is the best choice. And t.to. I work in printing. I could choose paper for gaskets more consciously. I say right away. I do not like coated paper (from the covers of the magazine, how is it advised in

Internet), although it was it that I had a huge selection. I think of its main disadvantage that it is practically consisting of one chalk (and now there is just a shaft of low.quality paper from China). Like it or not. abrasive. Though very weak. Nobody wants to have an abrasive in the engine. or less suitable paper. chrome Erzats (as on magazines with doctors, medical records). But still. there is also chalk on this paper.

I had a criterion. without chalk. And it seems to be a print of such paper simply does not exist! But it is in a different form. So. I found her. Write down the name. calibrated cardboard (I had Pavan) 0.5 mm, color. gray. Refers to subcode materials (puts under offset tires). You can find in firms trading consumables for printing. As well as in printing houses with offset machines. This cardboard changes printers and is simply disposed of after a while. If there are friends, we go and ask.

The main plus of this cardboard is really hard. There is no chalk in it. And it is very accurate (the difference in thickness is not more than 0.01mm).

My method is not fast, but as neat for home use.

We take the sealant and apply a thin layer to the surface. I just take a sealant on my finger and put it slightly (approximately also apply thermal paterpery to the processor). Then I put the sheet on a flat surface and press the lid to the paper with something heavy.

In my case, I pulled the lid through the hole in the center using a hairpin.

Next, I’m waiting for about a day (therefore, the method is not fast). Roughly cut around the perimeter with a margin of a couple of centimeters with scissors.

Cardboard with the help of sealant has already qualitatively glued to the surface.

We take a clerical knife in such a grip and cut out the outer circuit.

Next, to find the internal contour, we push the contour with your fingers. The photo was not visible, but after that the inner circuit begins to be clearly visible. Cut the internal contour similarly

I neatly drilled the holes with the punch made (it is good to have a turning tower on the farm!)

And here is the result. quite decent. Next, purging, washing with alcohol.

Applying the sealant to the return part (try to use the very minimum sealant).

And one more “trick”. a broach with an electric screwdriver with a limit of the moment. Gradually adding the moment we stretch all the bolts. We leave a couple hours and reach the key (without fanaticism).

This is not the first repair using this technology. Already several times I have used such gaskets and there are no problems with them. They don’t get wet, they don’t sweat. Hold perfectly. Knowing this technology, I am not afraid to open the engine even for inspection. T.to. I know that I myself can make this gasket for free.

I hope this information and good luck on the roads will help someone!

Paronite water gaskets: as a choice of manufacturer, description of models

Paronite gaskets are products made of asbestos, rubber, special additives. With their help, create hermetic compounds in various pipelines. These products are used in water supply systems of apartments, houses, enterprises. Provides the strength of the compounds.

Features of paronite gaskets

Paronyte is a sheet material, contains 2/3 of the asbestos fibers, synthetic rubber, sulfur and special fillers.

The strength of the product is enhanced by reinforcing with a metal mesh. Parts are made from this material to compile any compounds. Under a certain pressure, the paronyte turns into a traction mass. In this form, it fills out unevenness, provides tightness.

On modern equipment, parts of a non.standard shape are produced. To do this, develop an algorithm for the release of elements. Gaskets are made using industrial cutting.

The material is very plastic. Details of the desired shape are cut out of a sheet of paronite of a certain thickness.

Paronite gaskets are used in various fields:

Basically, parts are used to seal water supply pipes, pumps, heating systems. In pipelines with gaseous and liquid agents. They serve as adapters at the joints of flat pipes.

Products have the following advantages:

- high heat resistance, used for cars, engines;

- withstand increased pressure;

- retain the properties at different temperatures.

At a temperature mode of 200 degrees and a pressure of 40 bar, uninhabited gaskets are used. Reinforced products withstand higher pressure and temperature.

Popular models

Release more than 10 brands of paronite with different characteristics and area of application. Pon marks are used in a neutral environment. PMB is used in machine, diesel departments, when working with oil products.

Pon, Pon-A, B, B is used for the tightness of the compounds in the neutral environment. Hold high temperatures. rubber and asbestos provide the elasticity of details. They are easily cut and stamped.

At a pressure of 32 MPa, the material becomes fluid, fills all the gaps and gaps. Sealing any fixed joints of pipelines, locking reinforcement, mechanisms.

The surface of the part is treated with graphite to prevent sticking with metal.

Pon-A: The brand is used in saline solutions, steam, overheated water.

Pon-B is used for tightness with saturated pairs. Among neutral and dry inert gases, complex oil products.

Pond gaskets are used to seal the joints of communications and equipment transporting the overheated liquid, water and steam under pressure. At electric and thermal stations, boiler rooms. In metallurgy and chemical industry, heating systems, household appliances.

PMB, PMB-1 are resistant to an aggressive environment of any type, withstand high temperatures. Used for compressors, internal combustion engines, oil products, oxygen, nitrogen.

The PMB brand is used to seal joints in various devices, pumps, compressors, pipelines. Among oils, molten wax, liquefied and gaseous substances. In the production of electricity. In metallurgy, coke and food and food industry.

PC is resistant to the effects of aggressive environment, acids and alkalis. It is used in a chemical environment, withstands maximum pressure of 10 MPa, temperature. 250 degrees.

Criterias of choice

Paronite gaskets meet the requirements of GOST. When choosing products, the appearance is taken into account. They should be even, without bloating, flaws, folds, faults. During the give, the details should not crumble and break. Slight villus is allowed, the material may not be painted.

The thickness of the sheet is an important criterion when choosing. If it is smaller, this will not provide high.quality sealing, will not fill the space. The product does not withstand strong pressure with a greater thickness, tightness and protection are disturbed.

For paronite parts, standard length, width and weight are installed.

Installation and mount

Before installation, a new gasket is treated with oil and graphite. This prevents sticking to the surface of the flange. The edges of the product should touch the bolts, the inner diameter coincides with the diameter of the pipe. The external size corresponds to the parameters of the bolts. Installation procedure:

- The main and response flange is selected in one type and align.

- Fasteners should not exceed the required load.

- Additional tightening of the bolts is performed after exposure to elevated temperature.

- There should not be corrosion on fasteners, this weakens the ability to withstand the load.

- The brand of laying corresponds to the specification of the connection.

- Wasis and nuts are chosen from one material.

- If necessary, a lubricant is applied to the thread.

- Details use permissible thickness.

Paronite gaskets strictly comply with GOST standards. Uniform thickness guarantees the reliability and strength of the compounds.

Types of breakdowns

Paronyte. durable and high.quality material, wear of parts is quite rare. The causes of breakdown are the loss of tightness associated with mechanical or chemical influences. A breakdown occurs or a gesture of the gasket.

- incorrect installation or replacement of the element;

- too strong puff of bolts;

- incorrect selection of gaskets;

- overheat;

- the presence of malfunctions.

In case of problems, the gasket is changed to a new.

Paronite. unique material, used in the form of gaskets for reliable sealing of compounds. Differs in high operational properties. Raw materials are available, durable. Among the advantages. the low cost of the material.

General view of a home.made suspension motor

gearbox body from PM “Salute”; 2. Deidwood; pipe 3.2×3; light alloy; 3. suspension from PM “Salute”; 4. rumpel; 5. Gas Manet; 6. engine “D5”; 7. fuel tank from a plastic can; 8. tank mounting bracket; 9. rubber hose of coolant water; 10. exhaust pipe 15 × 1.5; 11. water intake.

In addition to a two.stroke single.cylinder gasoline engine, D5 (or “D6”), two more mass.produced nodes: the crown of the suspension from the “Salut” (or “satellite”) and a gearbox with a rowing screw from the same motor, are the basis of a home.made boat engine. From the “salute” you can use the carburetor, which is installed in an upright position.

The main parameters of the engine: cylinder diameter 38 mm; piston stroke. 40 mm; working volume. 45.8 cm³; The nominal speed of rotation is 4500 rpm; The power developed in this case is 1.2 liters. With. Specific fuel consumption. about 400 g/l. With. h.

D5 and D6 engines are very reliable and durable. Despite the relief of only one crank mechanism per kilogram, for several years of intensive operation there was not a single serious breakdown.

Laying under the cylinder reason for air flow and manufacturing a new laying

The engine intended for alteration is completely disassembled. The cylinder is redone for water cooling. To do this, all the hairpins of the head mount are twisted, all the ribs of air cooling are removed and the outer surface is processed to a diameter of 57 mm. The combustion chamber is pulled to an external diameter of 43 mm.

The water cooling system is 12 cylindrical holes drilled in the body of the cylinder and sequentially connected by channels-crossings. The diagram of holes with the required dimensions is shown on the scan of the cylinder.

carburetor heat soak and fuel boiling issues, fixed by just a gasket?

Crankshaft

The crankshaft is pre.disassembled into two halves, which are connected by the finger of the crookeder with an interference. The part of the crankshaft on which Magneto is attached, we will call the upper, the part on which there is a tsapfa with a suction hole is the bottom.

From both parts we cut off massive rings at the place of welding. The upper tsapfu needs to be lengthened to the possibility of planting a radical bearing, a magneto rotor, a fist of ignition and a flywheel. At its end, the M10 thread is cut. During the final assembly, the Magneto rotor, the cam and flywheel are installed on the shaft and pulled together by the M10 nut. To lengthen the tsapfa, a blank of round steel of a brand is 45 with a diameter of at least 18 mm and a length of 100 mm. On one end, a shank with a thread M10x1.0 10 mm long is pulled out on a lathe. Then, the upper part of the shaft is installed in the lathe and thoroughly centered along the shaft with a shaft with a diameter of 17p. From the left end of this half, at a distance of 13 mm, the tsapf is cut off. A hole under the thread m10x1 is spent in the remaining part of the tsapfa.0 to a depth of 12 mm. The workpiece with a threaded end is connected into the hole of the tsapp and tighten the key with a moment of 3 kg/cm. At the junction of the V-shaped groove is pulled. Having wrapped a tsapf as an asbestos cord (except for a groove), we weld the junction of the joint with manual electric welding to a seam diameter of at least 18 mm. After that, the final turning of the shaft can be done.

Having processed both halves to the size indicated in the drawing, you can collect the crankshaft. After its assembly and final centering, the finger of the crank from the ends is welded to the cheeks at three points with electric welding, followed by cleaning the welding places.

The square shank of the lower tsapfa (cross section B-B) is performed in a simpler way, since the threaded hole in the tsapf is already. The square is made of 45 steel, hardened and, after entering the tsapfu, is welded by manual electric welding without subsequent mechanical processing.

The coordinates of the twelve holes with the diameter and depth of 7 mm on the cheeks of the crank are selected arbitrarily in place; They are made to facilitate the shaft. Finally processed crankshaft should weigh 0.6 kg; In combination with other rotating masses (Magneto rotor, flywheel), it provides sustainable engine operation.

The landing hole in the rotor of the magneto is melted to a diameter of 12 mm and when landing on the shaft is fixed with a pin with a diameter of 2 mm.

The spark plug should make a new one of the steel 35. Its working profile is performed on a regular fist, then the fist is polished and tempered. On the rotor, the fist is mounted with a pin. Therefore, the Magneto rotor on both sides should have holes for pins.

Flywheel (a) and a fist (b)

The flywheel is made of 35 steel and is stopped by the shaft with three M5X10 mm installation screws, under which the conical recesses need to be sprinkled on the shaft (section B-V). This is done after the Magneto rotor, the fist of the ignition and the flywheel with the holes are planted on the shaft are planted on the shaft, but without a thread, and everything is finally pulled out by the M10 nut. The recesses for the screws are drilled through the flywheel, due to which the necessary accuracy is achieved during the final assembly.

Daidwood of the suspension motor is made of a round aluminum pipe 32×3 mm. In addition to the ends of the Argonoduga welding, annexing flanges made of aluminum with a thickness of 6 mm are welded to the ends. Deadwood length 345 mm. To its upper flange is attached through the gasket of the engine, to the lower, as well as through a gasket made of oil.resistant rubber with a thickness of 4 mm. a gearbox with a rowing screw. A vertical shaft made of a steel pipe 12×1 rotates inside Deidwood. Its length along with welded squares is 335 mm. The bracket of the suspension from the “salute” or “satellite” type is freely put on Deidwood, whose internal hole is abrupted to a diameter of 32 mm.

The Reducer from the Salute engine is subjected to the greatest refinement. All parts of the water pump are removed and the holes are brewed or sealed with epoxy. The main thing is that with the assembled motor, the water does not fall into the cavity of Deadwood and the gearbox. Water for cooling the cylinder is supplied due to the hydrodynamic pressure of the screw along an aluminum pipe 8×1 mm. It is attached to the lower flange of Deidwood. Its end, facing the plane of rotation of the screw, is broken to a diameter of 12 mm and has a funnel.shaped shape. The center of the circumference of this hole is located at a distance of 10 mm from the rotation plane of the rear edge of the screw and 80 mm from the screw axis. The second end of the tube is connected to the engine with a thin rubber hose.

Trimmer malfunctions for grass

Trimmer for grass is a convenient and affordable replacement for the lawnical mower. Its cutting part is made in the form of fishing line, knives or disk installed on the drum, which is closed on top of the protective casing. The basis of the design is a bar, which is adjustable in height, at the end there is a comfortable handle and shoulder belt.

Like any other technique, a trimmer for grass may be unknown, and so that the breakdown does not lead to the final failure of the tool, we suggest you familiarize yourself with this article. Unit can break down for various reasons. Breakage occurs both in new trimmers and those that have long been operated.

lawn mower. He stalls hot. Possible reason and elimination

I immediately draw your attention that unfortunately this is not a carburetor. (My site.

The lawn mower stalls when you press the gas

As practice shows, in most cases, the cause of engine stopping is the dumping of the carburetor associated with long.term storage or operation of the tool in an aggressive environment (temperature changes, high humidity, dustiness), high loads or wear of individual parts. The characteristic signs of the need to configure the carburetor include increased vibration. If you have experience in repairing the fuel system of gasoline engines, you can eliminate the problem without any problems, otherwise you can familiarize yourself with the detailed instructions for setting up the carburetor.

The hole in the fuel cover (saepun) of a trimmer for grass

The second of the possible reasons why the trimmer for the grass stalls when pressed on gas is blocking the hole in the lid of the fuel tank (sapuna). If small particles of dust, the remnants of grass and sand gets into it, a vacuum is created in a gas tank, as a result of which the fuel ceases to enter the carburetor. You can clean the benzotrimmer’s saapun with a conventional sewing needle and subsequent blowing with compressed air. Experts recommend when completing the work once a few mowing to clean the cabin. If it is not possible to clean the lid, it is necessary to replace.

With a similar problem, it is worth paying attention to the fuel valve, which, when clogging, ceases to normally pass the fuel mixture. By solving this malfunction, it is weakening using a suitable tool. In addition, the problem with the circulation of the fuel mixture may cover in the contamination of the valve. To do this, just blow it with a stream of compressed air.

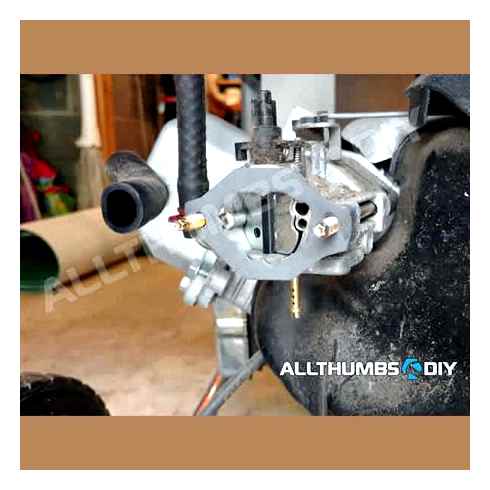

Replacing cardboard laying

The installation of cardboard laying will not take much time, but when carrying out this operation, accuracy and caution are needed so as not to damage the fragile internal parts of the carburetor, as well as exclude the likelihood of a float chamber of dust and dirt from the entry of the float chamber.

Carburetor gaskets can be purchased at the auto parts store or ordered in an online store. In the latter case, you definitely will not have to stand in line

Sogers can be found separately for carburetors sold separately, cardboard gaskets. In this case, the cost of repairs will be almost invisible to the budget.

After the carburetor is dismantled, five bolts are unscrewed with which the lid is fixed. Then the lid is removed, and a float is removed from it, which is held with a pin.

The pin should be carefully knocked out of the hole using thin cloves and hammer.

When the pin is removed, the float is disconnected from the needle and completely removed. The old gasket can now be easily removed from the top cover of the carburetor, and a new cardboard part is installed in its place.

Then we collect the carburetor and set in the reverse removal order.

Twisting the bolts of the carburetor, which hold the upper cover, it is necessary to do evenly and crosswise to eliminate the skew and the air leakage in this case in the mixing chamber of the carburetor.

When you need to replace the carburetor VAZ 2109

There are times when repair does not bring a result or repair is unprofitable. For example, the complete lawsuing of air or fuel channels or curvature of the connecting planes that cause air leaks or fuel leakage. Then the only correct action will be. replacing the carburetor VAZ 2109.

Removing the carburetor VAZ 2109/2108 The procedure is quite simple, and it takes a little time. Immediately it is worth bringing the list of tools that will be needed to perform this car repair:

- flat and cross screwdrivers;

- Rozhki key “at 10” and “on 13”;

- a unit key with the head “at 8” and “for 13”;

- Carburetor Solex 21083 DAAZ for VAZ 2108/2109/21099 (21083110701000).

Before installing the VAZ 2109 carburetor, you should carefully check the ceramic, remote insert for cracks and chips. Replace paranite gaskets standing under a carburetor to exclude air from, not through air channels.

The key “at 10” is removed the nut of the filter cover fastening and unfasten four latches.

Blitz-councils and recommendations

Replacing the gasket of the carburetor or making it from cardboard will not be difficult, but you should be very responsible to the selection of the material, as well as the accuracy of the manufacture of this part. After replacing the product, the carburetor is installed on the engine and the engine test is made, as a result of which it will be clear how correctly all repair operations were performed.

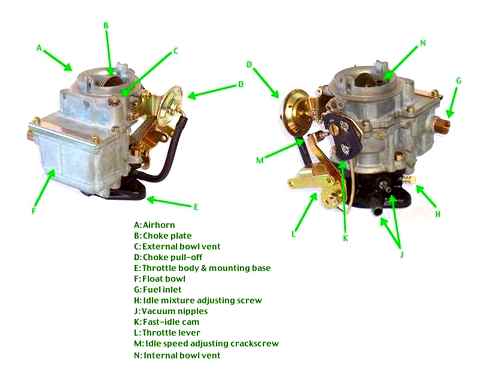

Sogers carburetor (2108, 2109, 21099) is installed on the inlet collector of the car engine. Three gaskets are used to seal this connection. Rather, two gaskets and one heat.insulating spacer. The gaskets for the carburetor prevent the suction of extraneous air into the intake manifold and thereby the overheating of the fuel mixture of the engine entering the cylinders. The heat.insulating spacer prevents overheating of the carburetor.

gaskets and heat.insulating spacer of the carburetor Solex 2108, 21081, 21083

laying between the collector and the heat.insulating spacer. It is the first on the plane of the intake manifold. Made of paronite.

reinforced laying. It is installed between the heat.insulating spacer and the lower plane of the carburetor (flange).

Laying under the cylinder of the chainsaw from what to make

Then a long search for catalogs of garden technology. You will certainly find at a price less than 10, take several pieces for your friends at once. Delivery will depend on the seller’s greed of 5-30 (therefore it is profitable to take a few pieces and something else). The package will come somewhere in a month.

P.S. I gradually purchase such “consumables” for the future. Now I ordered a dozen different models of candles for all engines that we fly. For example: Ngk BR9HS at the officer. The paramotor diller costs more than 8 euros, and I cost less than 3.

I found in our city a craftsman who knows how to make a gasket for different diameters of the zillindra, cuts the ring himself and occurs paranin. There is such a miracle in its manufacture of approximately 5-8 BKS. The technology is extremely simple: the main thing is to have templates for the diameter of the zillindra. It turned out like this: http: // paraplan.ru/forum/viewpost.PHP?p = 539045 And here is my similar question about laying: http: // paraplan.ru/forum/viewtopic.PHP?t = 51794

If cut without a ring, just from reinforced paranite. he will burn out very quickly.

If you put a gasket from paranite, then there will be poor heat transfer, and as a result, the temperature sensor (thermocouple or thermal resistance of what you have) that is placed under the candle on the head will show not the true value. Well, this is okay, the uneven heating and cooling between the cylinder and the head is more important, therefore it is better to put the gasket of metal and it is from soft and thermal wirewalls like: alluminum, copper. In princesses, even thin allumin from a regular beer can suit you. But if possible, it is better to choose something thicker. I recently set myself an aluminum laying cut out of the sheet that was in the spotlight (I accidentally discovered that in some spotlights there are such aluminum sheets) in thickness this gasket is close to the standard, approximately 0.15mm. In addition to aluminum gaskets, I used a high.temperature car sealant on the part of the field where I have a Siberovsky groove for the elastic band (I have Siberovsky Simon2) but only on that part of the field where the gum is, since if you cover the entire field, then the heat transfer is also violated.

PS You are tormented by grinding with grinders if it is better to fly this time

PPS cut the gaskets with ordinary paper scissors, leisurely adjusting to the landing field on a lobe of mm. Good luck in the flights.

Cutting. gasket

Cutting gaskets are as follows. A sheet of paronite, under which you need to put a sheet of plywood, slightly press the head and turn on the rotation of the spindle at a speed of 3. 4 rpm. When lowering the spindle with a mandrel, cutting rollers, rolling along a paronyte, cut out the gasket. During the clipping under the action of the compressed spring, the clamping head, remaining motionless, tightly presses the paronite sheet. Such a mandrel allows you to cut gaskets with a diameter of up to 300 mm. Cutting gaskets with both tools is made on a wooden lining. To reduce friction, the cutting edges during cutting must be wetted with soap water.

Cutting gaskets are as follows. A sheet of paronite, under which you need to put a sheet of plywood, slightly press the head and turn on the rotation of the spindle at a speed of 3. 4 r. When lowering the spindle with a mandrel, cutting rollers, rolling along a paronyte, cut out the gasket. During the clipping under the action of the compressed spring, the clamping head, remaining motionless, tightly presses the sheet. Such a mandrel allows you to cut gaskets with a diameter of up to 300 mm.

Cutting gaskets with both tools is made on a wooden lining. To reduce friction, the cutting edges during cutting must be wetted with soap water.

Cutting gaskets are carried out on drilling machines using special devices, as well as in cutting stamps on drive mechanical and hydraulic presses.

| Cuttled cutting. |

Cutting the gasket is as follows: a sheet of cushioning material is attached to the lattice of the lathe. Depending on the width of the gasket, the appropriate transverse cutting of the cutter is established. The transverse supply of the caliper is turned on. The cutter, moving from the center to the periphery, cuts out the gasket on the spiral of Archimedes.

| Universal device for the manufacture of round gaskets.| Circular saw for cutting discs and gaskets.| Roller scissors (zig-machine. |

Cutting large sizes can also be carried out on universal discs adapted for circular cutting, or on zig machines, equipped with a special device for this purpose.

Cutting gaskets are carried out with a circular cutter or chisel; Rubber gaskets are cut out with a knife. Such gaskets give a much worst seal and require a significantly higher consumption of material for the manufacture. If there is a prepared new laying, they begin to develop the flange connection, for which the appropriate section of the pipeline is previously turned off; A bucket of fluid contained in the pipeline is substituted under a developed flange connection; flanges are thoroughly cleaned of the remnants of the old gasket, insert two adjacent bolts; introduce a new gasket between the flanges, pre.processed accordingly; Correctly cut the gasket will take a proper position if the edge of both adjacent flanges of flanges affects its edge; After applying the laying, the remaining bolts are installed, nuts are put on and wrap them up. The nuts on the bolts are wrapped gradually, in sequential order, at a time not more than 1/2 turnover.

Cutting the gasket of the cushion of the cargo car seat (size 430 x 880) is made of waterproof cardboard 2 mm thick in a knife stamp (FIG.

| Hydraulic device for spreading flanges.| Gasket replacement device. |

A variety of devices are used to cut the gaskets. The device is inserted into the cartridge of the drilling machine.

| Hydraulic device for spreading flanges. |

Blitz-councils and recommendations

Replacing the gasket of the carburetor or making it from cardboard will not be difficult, but you should be very responsible to the selection of the material, as well as the accuracy of the manufacture of this part. After replacing the product, the carburetor is installed on the engine and the engine test is made, as a result of which it will be clear how correctly all repair operations were performed.

If you have questions, leave them in the Комментарии и мнения владельцев under the article. We or our visitors will be happy to answer them

Repair of the carburetor

If necessary, it is possible to disassemble and thoroughly clean the node with your own hand, using gasoline, cleaning the nozzle and channels is used by compressed air.

Launcher of the starter and gearbox

The gearbox conveys the rotational moment from the engine shaft to the cutting tool, its gears during operation should be absolutely clean and necessarily lubricated with special lubricant.

Conducting a technical inspection on their own once a season will get rid of the need to carry out the repair of the gearbox or its replacement, with the acquisition of an expensive new node.

The starter is necessary to bring a trimmer for grass to working condition, its diagnosis is to check the tension of the lace of the starter coil with the teeth of the coil, which are often destroyed at a sharp launch.

A non.working starter in a benzocos is not subject to repair, it must be replaced with a working unit, as part of a mandatory inspection or a set of repair measures.

How to use RTV and properly make a gasket

Separate attention and care require cutting elements that must always be cleaned of dirt and mowed grass after operation. Regular inspection and thorough preparation of the device for work will help to avoid expensive and costly repair time, always be sure of the operation of the lawn mower.