How a jackhammer works. What’s better with a hammer or a chipping hammer??

How a jackhammer works

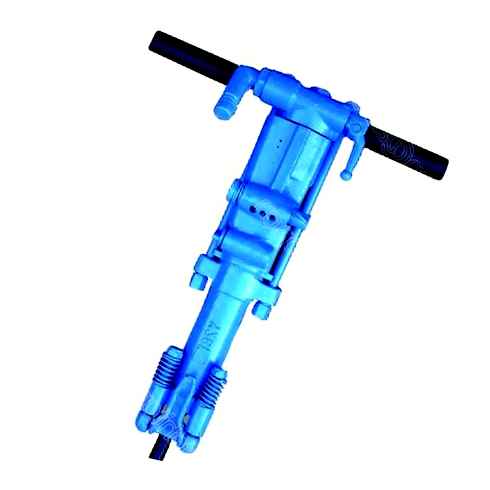

The hammer is a piston-operated pneumatic percussion machine with valve air distribution, operating under compressed air.They are equipped with a motor with free movement of the piston and are categorized according to the principle of the applied system of air distribution, which is carried out by means of leaf valves or tubular spools.

Consists of an air distribution and hammer mechanism and a handle with a trigger mechanism. The air distribution-impact mechanism performs compressed air supply to the barrel cylinder in turn in the forward and backward stroke chambers of the striker and exhaust air release to the atmosphere, converting the energy of compressed air into the mechanical work of the moving striker.

To prevent the threaded joint between the link and the barrel from turning back on itself, a stopper is provided which is held in place by a retaining ring to prevent the barrel and threaded joint from falling out. Retaining ring has vent hole for exhaust air. Belleville spring is used to press the air distribution unit against the end of the barrel. Air hose is connected by a union nut and nipple.

Additional stabilization of the spade is provided by the ring spring applied to the shaft of the hammer. Start-up is achieved by pushing the handle down on the valve. The pressing force must overcome the resistance of the spring, shock absorber and valve supported by compressed air. For the initial start it is necessary to apply a force of up to 120 N, the value depending on the air pressure. Disengages automatically when the grip is released.

Pressing the handle moves the valve to the right and opens the orifice connected to the valve’s annular chamber. With the help of valve distribution, striker and barrel, compressed air is directed alternately into chambers of forward and reverse stroke of striker, forcing it to make reciprocating motion, periodically striking the shank of the working executing tool.

handle; 2. shock-absorber; 3. valve; 4. plug; 5. box; 6. valve; 7. clamp; 8. stop ring; 9. barrel; 10. hammer; 11. pipe connection; 12. nipple

The main components of the hammer are the air-distributing percussion mechanism, the handle with the trigger, and the silencer cover.

The pneumatic distribution percussion mechanism is used to convert the compressed air action into mechanical energy to enable the percussion head to work. Structurally, it consists of the following components:

The firing pin in the barrel must move freely and without difficulty. The triggering device includes:

Special retainer with safety locking ring prevents spontaneous unscrewing of the threaded components of the barrel and intermediate link. The purpose of the valve cover is to hold the air diffuser against the end of the barrel. The hose is used to drive the hammer with compressed air, it is connected by means of a nipple and a coupling nut. An end spring with a rubber sleeve aids in holding the tool. spades, blades, etc.д. from falling out of the product shank. The intermediate link must be screwed tight and secured with a stopper. MO and MOP demolition hammers have built-in vibration protection, as well as noise mufflers, which allows you to operate the equipment without any harm to human health. Safety of products is confirmed by Russian certificate of conformance of State Standard.

§ 1. FUNCTION, AREA OF APPLICATION, DEVICE

Pneumatic hammer is a hand-held percussion tool that is used in operation as a wedge and lever. Its actuator (spade) plunges into the coal (or rock), separating it from the massif.

Demolition hammers are used mainly when working steep seams in complicated mining and geological conditions, when it is impossible to use other, more effective means of mechanization. shearers and plows. In addition, they find application in development of soft shale, ores, construction and auxiliary works.

Pneumatic demolition hammers are manufactured by the Tomsk electromechanical plant named after V.I. Lenin. В. В. Vakhrushev. Their technical specifications are given in Table IV. IV.9. Working air pressure in hammers is taken as 0,5 MPa.

Great work on typeization and unification of the main units and details of the pneumatic demolition hammers is carried out. The only exceptions are barrels and strikers, which have different sizes, but their diameters are also unified. Further improvement of demolition hammers is conducted in the direction of increasing their productivity, efficiency, reliability in operation, as well as improvement of working conditions of the worker when using them: reduction of recoil, vibration, noise, dust formation.

Electric demolition hammers are not used in underground conditions, because of lower productivity, reliability and greater weight than pneumatic demolition hammers. They have some use on the surface of mines in construction and other work.

Pneumatic hammer hammer MO39 (fig. IV.43) consists of an actuating element. a spade, a spring holding it back 16, trunk 11с intermediate link 4, with air distribution and percussion mechanisms, handles / with vibration-damping device.

Compressed air is fed to the hammer by means of a flexible hose connected by a nipple 22, sockets 20 and a nut 21. To prevent the self-retraction of the nozzle, a spring washer is installed 19. The sleeve has a diameter of 220 mm 16 mm and not more than 12 m long.

percussion mechanism consists of a barrel with a pin pressed into it 15 and barrel bridging 14 and the striker 12. The hammer mechanism is designed to convert the energy of compressed air into the mechanical work of a moving striker, which strikes the shank of the pick.

Air distribution mechanism consists of a valve box 6 with a ring 5 and two valves 7 made in the form of flat segments. The air distribution mechanism is designed to supply compressed air to the barrel cylinder, t. е. into the chamber Г the forward stroke of the striker and into chamber D of the return stroke, and to release the exhaust air into the atmosphere.

How demolition hammers work

Demolition hammers are also often referred to as pneumatic drills or demolition hammers, depending on the type of power tool. The classic jackhammer is one of the tools you may be familiar with from road repair scenes. larger tools are driven by compressed air.

There are also less massive demolition hammers weighing up to 13 kg, which are used in the interior to split walls to open space for pipes, for example.

Most of them use a rotating mechanism that drives a piston inside the cylinder. The faster the gear spins, the more energy the piston receives as it flies down the cylinder until it hits the air cushion at the end of the cylinder.

The pressure drives another piston, which crashes into the working end of the tool, as a result of the impact of the flow of compressed air that comes out of the ventilation holes.

Some demolition hammers skip the air completely, such as in models that have a direct metal-to-metal interaction design.

Design and operating principle of a jackhammer

The unit consists of the body, drive, striker, percussion tool, handle and chuck for fastening the tool. Despite the advantages and disadvantages of demolition hammers with different types of engines, the principle of operation is the same.

Pulling the trigger sets the rotor in motion, which in turn triggers the striker. The hammer interacts with the main working body of the tool. peak. creates a percussive motion that determines the force of the blow.

Differences in operation between different types of bumpers:

The differences between kinds of demolition hammers are also in weight and dimensions. Smaller and lighter models are suitable for working by weight, in narrow openings, where a bulky tool will cause inconvenience. Heavy tool blades have a vertical configuration of the motor and are most often used when working with foundations and the ground. Holding a demolition breaker horizontally is extremely difficult.

You should also take into account the vibrations created by the tool. Because this has a direct effect on the duration of the work. So choose models with a good anti-vibration system, especially if you have to use the hammer intensively.

Functionality

Now let’s talk directly about the tasks to be performed. Although demolition hammers are multifunctional, they do not handle different tasks equally well. The weight of the tool and its impact force are decisive here. And that is precisely what determines the devastating effect on a surface. But the principle “the more, the better” does not work here. A jackhammer that demolishes a concrete wall with a single blow is obviously not suitable for more delicate work.

The standard demolition hammer weighs up to 10 kg. Gasoline units can be heavier, while pneumatic units can be lighter. As for the impact force, it can reach up to 55 J. Demolition hammers with these characteristics are designed for road works, construction and repair. Powerful enough for demolition of asphalt, concrete and brick.

Lighter units weighing up to 7 kg are typically used for creating openings, cavities or for local demolition. Also suitable for finishing. The low weight and compact design make the demolition hammer easy to handle out of the way. Can actually be used as a pioneer. The impact force of such a tool does not exceed 15 Joules, but the frequency of blows is noticeably higher than that of other demolition hammers. This allows you to work more accurately.

If you need something more powerful, you will need a concrete breaker. It weighs at least 10 kg, and some models have a weight of up to 30 kg. The impact force is also high, not lower than 55 J. With a lower impact frequency than standard models. This is to increase the destructive effect of each shock. It can even work with reinforced concrete and hard rocks.

Other articles

How to choose a peorator: recommendations, nuances

The torch is not only a powerful impact tool for drilling concrete walls, but also a universal household helper. Using various accessories we can use our rotary tool for drilling holes, mixing mortars, assembling drywall and cutting out undercuts, and with shock mode for full-fledged chipping jobs (for example, tile demolition).

“Pistol” vs “barrel”, or What mistakes do you make when choosing a peorator?

Numerous articles on “How to choose a peorator” provide various parameters to look for if you want to purchase this tool. Just follow this link to see for yourself. In this article we want to talk about the other. Once there was a story with one of our consultants that made me write about the difference between vertically and horizontally mounted rotary drills. But first things first.

Rating of peorators that your neighbors will appreciate

The main problem of purchasing tools in the Internet store is too big assortment and lack of possibility to test the machine in work before the purchase. Narrow down the applicants help reviews and consultation with a store employee, but not all buyers are willing to spend their time looking for more information. To simplify the task of choice, we have made a rating of the best submersible torches according to the number of sales and opinion of our customers.

The difference between the peorator and the impact drill

An impact drill and a torch are similar in appearance, and this misleads many customers. Tools do not seem to differ from each other, or they differ slightly. It’s not. The drill and the rotary hammer are different tools, performing different tasks. This article will help to understand when it is worth buying a peorator, and when an impact drill is enough.

The working principle of a demolition hammer

A jackhammer is necessary for professional construction work. With its help, masters perform openings in walls made of brick or concrete or its complete destruction, as well as use for the destruction of frozen soil, rock, removal of asphalt.

Choosing

First of all, it should be noted that demolition hammers are mainly professional equipment. This is due to their non-demanding use in domestic and domestic purposes, as well as the high cost of.

Consequently, the main factor in choosing a demolition hammer is the purpose, i.e. the amount and nature of the planned work. This determines the required parameters and functions of the device. In addition, it is not reasonable to purchase such a device for one-time work.

There are several basic parameters for demolition hammers.

- Weight determines the ability to hold the device on the weight. So, models weighing up to 6 kg are relevant for high-altitude work or cramped conditions. It is possible to hold hammers up to 10 kg horizontally when carrying out horizontal works on dismantling walls and making holes. With heavier hammers you can work vertically on foundations, in the ground, etc.д.

- The impact force is equivalent to the amount of material that can be torn off. Thus, the efficiency of the tool and the speed of work directly depend on this indicator. It can be from 2.8 to 63 Joules.

- Blow frequency that reflects the number of blows per unit time, also determines the speed of work, but is inversely related to the previous parameter. That is, as the force of the blows increases, their frequency decreases. For example, the light models have a sharpening capacity of up to 3,500, while the heavy models have a sharpening capacity of up to 1,100.

- Power determines the breaking capacity of the demolition hammer and the duration of the work cycle. It is 0.5-2 kW. For finishing work, 1.2 kW is enough. To break down a concrete or brick wall you need 1.6 kW. The greatest power requires the dismantling of the pavement.

The above specifications of demolition hammers are largely determined by the type of drive. That is, one of the classifications is of great importance. To understand how to choose a model, you need to know the peculiarities of the types allocated to it.

Pneumatic devices, compared to electric and engine hammers, due to a simpler design, are considered more reliable and durable at a much lower cost. In addition, they have the lowest mass, ranging from 1.5 to 16 kg. In addition, these hammers are very powerful. Finally these models are suitable for working in high humidity and close to flammable substances. The main disadvantage is tied to the power supply in the form of a compressor, which must be purchased separately at a considerable cost. And it is necessary to select this device based on the hammer parameters. The main characteristics are volume and working pressure. Compressor parameters determine the operating time.

Electric demolition hammers are tied to the power source, as well as pneumatic ones. In contrast, such devices can not be used near flammable substances due to the sparking of the motor during operation. They are also not suitable for high humidity conditions. Despite this, they are a very common type of demolition breaker. This is primarily due to the significantly greater efficiency compared to pneumatic demolition hammers and models with internal combustion engines. They are also the most environmentally friendly, with the least amount of vibration and noise. Despite the external power source, it is not represented by additional equipment, provides unlimited operating time and ease of connection. Finally, with a more sophisticated design, they are easy to maintain. In addition to the basic parameters, the motor power is very important for these models of hammers. For domestic purposes, the most often used demolition hammers of this type are.

In addition, there are battery versions, which combine the positive qualities of electric hammers with the autonomy of gasoline hammers. Yet they are not so mobile, because the duration of operation is determined by the battery capacity, which requires further charging.

Models with an internal combustion engine are the most mobile. At the same time they are characterized by high noise level, presence of toxic emissions. What’s more, instead of being tied to a power source, they require a reserve of fuel, the amount of which determines the duration of work. Finally, demolition hammers with an internal combustion engine are the most difficult to maintain: they need to drain the fuel residue, clean filters, etc.

Besides, the advantageous working position of a demolition hammer is of great importance.

Horizontal versions have low weight and corresponding handles: rear retaining and front controlling.

Tool Repair: Makita Jackhammer (Trigger and Cable Replacement)

Vertical demolition hammers are heavier and equipped with side handles.

Finally, the manufacturer has a considerable value in the choice. There are a number of brands known for high quality products. The manufacturers producing the best demolition hammers include Bosch, Sparky, AEG, Makita, DeWALT, Hitachi, Metabo, Milwaukee.

WHERE A DEMOLITION HAMMER IS NEEDED NOWADAYS

Today they are productive, compact and ergonomic hand tools. It greatly facilitates and accelerates heavy and time-consuming work when remodeling or decorating buildings, carrying out the dismantling of various building structures and so on.

With the help of a demolition hammer you can easily make a hole in the foundation or a reinforced concrete slab, dismantle masonry or brickwork, break the old screed, break the asphalt pavement, etc.п.

During repairs in an apartment, a private house or other premises it is effective to knock down tiles and plaster, make large holes and niches for engineering communications, etc.д. Also, this tool can be used to compact the soil or gravel layer, hammer a variety of rods into the ground (e.g., grounding systems for external lightning protection), loosen frozen soil.

Type of demolition hammers by drive type

To ensure the functioning of the baffle must be equipped with a drive that will rotate the crank mechanism:

Electric are the most popular and widespread because of the many advantages. They are superior to all other varieties in terms of efficiency, as well as cheap maintenance. These whipcrackers have a relatively low weight, but a rather large destructive power. They create a low level of vibration on the handle, which is especially important if the work is done for hours. The only disadvantage of electric breakers is the inability to work in conditions of high humidity. Too humid air leaves condensation on the running motor, which can lead to short circuits. Also of note is the attachment of this tool to a power outlet. If you have a generator, this drawback can be completely bypassed by connecting the bomber to the station.

Gasoline-powered ones are self-contained. They are equipped with internal combustion engine, which works by burning gasoline. Diesel units are not made due to the fact that these motors are much heavier, so they are difficult to carry. Gasoline hammers are used in the field when performing road works, dismantling sleepers on the railroad, as well as for drilling in hard rock to install supports. These breakers are quite heavy and noisy. In addition to the sound of the saw itself hitting the material being broken up, there’s also the noise of the motor as it vibrates. It is not possible to work with gasoline-powered devices indoors. the engine produces exhaust fumes. The cost of using such a blower is the highest, because the price of gasoline is much higher than that of electricity.

Pneumatic demolition hammer is used in conditions where emission of exhaust gases is unacceptable, as well as the use of electric wires. They are the kind of equipment you would expect to find in a mine. A high-pressure pneumatic hose is connected to the device, coming from a compressor working on the surface or nearby. The advantages of this equipment include the possibility of use in conditions of high humidity, as well as the lack of arcing flashes inside the body, which certainly occur when using an electric motor.

Types of hammers depending on the shape of the body

Depending on the shape of the body, breakers are divided into horizontal and vertical. Horizontal planes are the lightest. They are designed to work on horizontal planes. These are the tools used in repair work. With their help, you can break down walls in a room, as well as perform other varieties of work. Horizontal blowers look like an ordinary drill or a rotary tool. They are quite light, but have relatively low productivity.

Vertical punches are the heaviest. They are designed for vertical installation and destruction of the surface on which the operator stands. This kind of equipment is used by road builders to remove asphalt, etc.п. The weight of such tool can often be up to 30 kg or even more. The impact force generated is very high. The height of these bumpers is designed to reach up to the operator’s waist.

Criteria for choosing a jackhammer

Choosing a demolition hammer, you should be guided not only by the type of drive and design features, but also by other criteria:

Power

The power of a jackhammer ranges from 500W to 2000W. Too weak models under 1200 watts are hardly any better than a regular peorator because of their low output and weak impact force. To fully engage in finishing work in the renovation of the premises, you need a hammer power in the range 1200-1600 watts. It can break concrete, brick and stone. The more powerful ones are quite heavy, and are usually used by road builders, as they are capable of crumbling elastic asphalt and t.п.

Tool Weight

The more powerful the hammer, the heavier it is. To work with such a tool, it is necessary to have physical strength and endurance. The hammer should be chosen according to your physiology. By weight, demolition hammers can be divided into three categories:

Lightweight up to 6 kg. They are used for work at heights. Usually they are used by industrial climbers to clear inter-panel joints. Although this equipment does not have a high breaking efficiency, it is not always possible to take a heavier tool.

HOW TO JACK HAMMER CONCRETE EFFICIENTLY

Weight of medium hammers is 5 to 10 kg. This category is usually represented by horizontal bumpers, which are used in demolition of walls, as well as for cutting holes and openings.

Heavy hammers have a mass between 10 and 30 kg. They’re used by miners and road builders. These are vertical models, capable of penetrating even a massive reinforced concrete foundation.

Impact force

The impact force is a very important indicator of how well the hammer works. The higher it is, the more material it will chip off with the spade. This is measured in joules. The demolition hammers on the market usually have the impact force from 2,8 to 60 Joules. Light hammers can deliver up to 15 J, medium up to 35 J, and heavy up to 60 J

How much you can work with a jackhammer?

For medical reasons, one person is not recommended to work more than 5 hours with a chipping tool. If it’s the machine itself, you can increase the time to 15 hours, but you need to take breaks and change operators.

The main working tool is the pike. It is it that impacts and breaks the material to be treated. The following forms of peaks are distinguished:

- The crowbar is for removing asphalt, concrete, and loosening hard and subfrozen rocks;

- A rammer is used to compact soil and asphalt, and seal cracks;

- Chisel is used for cutting metal products, making holes;

- The shovel is designed for chipping ice, scraping walls.

Working with a jackhammer is simplified by a set of additional functions. The most useful is a beat frequency controller or power control. This useful feature makes the tool multifunctional and allows you to work on different materials.

An anti-vibration system reduces vibrations and protects the operator from harm.

Peorators and bumpers are indispensable equipment (just like vibratory plates and rollers) on any construction site. Atlas Copco equipment has high capacity, quality, and long service life. Atlas Copco’s demolition hammer is available in the most inaccessible environments.