How flail mower works. Flail Mover Blade

Flail Mower vs Rotary Cutter – Which Is Best for Your Job?

Most people think that all lawnmowers are the same, but that couldn’t be further from the truth. There are a variety of cutting attachments that can be used with skid steers, tractors, wheel loaders and excavators. Two attachments in particular, diamond blades and brush cutters, are particularly popular.

Flail vs rotary cutters:

To better understand the difference between a flail mower and rotary cutter, you must first understand the basics of how each machine works, and what makes each machine different. One difference is the size of the blades on the rotary attachment to a lawnmower. rotary cutters have larger blades with less precision than those found on a household lawnmower. This is because rotary cutters are usually used for clearing overgrown grass or brush, whereas most lawnmower blades are designed for cutting lawns.

Rotary Cutter:

Both types of machines can cut through brush or grass, but they are designed differently which lends to the difference in their cutting properties. rotary cutters have horizontally spinning blades, while flail mowers have sideways swinging blades. These two types of design give each machine different cutting strengths, and make them better suited for certain kinds of jobs.

Flail Mower

Flail mowers cut grass differently from rotary cutters. Unlike a rotary cutter, which has blades that move in a circular motion, the blades on a flail mower are Y or T-shaped and spin around the shaft. The blades on a flail mower work together in order to cut grass evenly and leave behind a finished look. This type of mower is typically powered by a PTO drive or hydraulically driven.

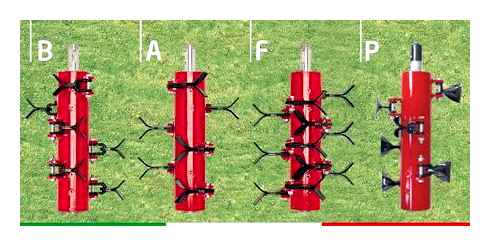

Flail vs Rotary : The knife

When choosing between a flail and rotary cutter, one of the first things to consider is what type of project you will be working on. Both types of mowers can be used on brush and grass, with varying degrees of effectiveness. Flail mowers are good for thick vegetation that may be overgrown. rotary cutters are perfect for brush, grass, and trees. However, rotary cutters have dull blades which won’t provide a clean cut on grass.

I know that most people will prefer to use a rotary cutter for many reasons, but I personally prefer a flail mower. This is the type of mower you want if you’re looking for a well-manicured cut or to mulch your grass. They’re great for high-volume maintenance jobs, especially when there’s a large, level surface to work from.

You can also use them for other purposes too, such as cutting brush. They take longer to catch and mulch the brush, so they’re not ideal for trimming tree branches. Likewise, they can only be used to a limited extent on very young saplings. But some flail mowers, like the heavy duty boom mounted kind by Diamond, are specially designed for brush cutting. They might not be quite as effective as a rotary cutter though.

Jerry Kong

Hi, I’m Jerry Kong, the sales rep of Mateng, Mateng is a factory in China that makes farm implements for more than 10 years now, and the purpose of this article is to share with you the knowledge related to farm implements from a Chinese supplier’s perspective.

Flail Mover Blade

Flail mowers are useful for tough jobs, such as cutting grass on uneven ground, cutting high grass, weeds and even brush or mowing in areas that have debris and rocks. A flail mower does not throw grass; instead it cuts grass finely, almost pulverizing it, and leaves the cuttings on the ground. The teeth or flail blades, also called knives, are short pieces of metal attached to an axle that turns rapidly, cutting grass and other plants. A flail mower can be mounted on the front, back or side of a compact, garden or farm tractor. For the best results, the horsepower rating of the flail mower gear box needs to match or be compatible with the horsepower of the tractor. Some flail mowers require a tractor to have a minimum of 25 horsepower, which some garden tractors have.

Flail Mover Blades

Due to the different brands and sizes of flail mowers, flail mover blades come in different sizes. Each size is the width of the drum or rotor, and the sizes usually range from 48 to 102 inches. The number of flail mover blades and their arrangement varies. Flail mover blades are measured as blades per foot of rotor; a mower with a large number of flail mover blades generally gives a closer and cleaner cut than a mower with fewer flail blades. Individual flail mover blades usually are attached to the rotor in pairs, forming a Y- or T-shaped configuration. In some mower models, flail mover blades are attached in staggered rows to provide a smoother cut.

Types of Flail Mover Blades

Flail Hammer blades (T shape)

Flail hammer blade is the blade that assembled to the flail mover using a bolt nut,which is a type pf powered garden or agricultural equipment, such equipment is used to deal with heavier grass or scrub which can not be removed by normal lawn mover. Flial hammer blades are attached to the rotating horizontal drum. And the rows of blades are usually staggered to offer a complete cut. If a flail hammer blades strikes an immovable object, it simply bounces off. Other rotary type mowers have a tendency to grab and throw the object out of the mower deck if its small enough.This fact makes the flail mower best suited for areas where thrown objects would cause damage.

Flail Knife Blades (Y shape)

Flail Knife blades is the blade with a Y shape apperance using a clevis.

Flail Hammer Blades VS. Knife Blades

When you design o buy a new flail mower, you will have a choice of the Y Knife Blades or Hammer Blades. The Y-Blades are great when cutting tall weeds and overgrowth and can also offer a nice cut to your lawn. However,if you are need to cut tree saplings and dense overgrowth,the flail hammer blades are used,which are wider, heavier blades than the Y-blades. No matter Flail hammer blades or Y knife blades,either set of blades will make a perfect solution for cutting.

Although flail movers are very effective when cutting overgrown grass,clearing brambles,and the perfect tool for hedge cutting even like a tree branch,it is very important for you to choose the right option.Below we will introduce different types of blades(hammer blades vs knives blades) for flail movers.

When cutting grass and brambles,a flail mower head fitted with knives,or Y shape blades is the best choice.They are more of a knife and less of a mulcher and they leave a very clean cut and a much tidier looking finishing. Besides,the Y shape blades(knives blades)can also be used for light hedges and they can cut branches up to 2 inches (some of our customers use them to cut much thicker things but this is not recommended!!) The knives are standard fitting for the LS1 series of hedgecutter, for mini diggers from 1,5 to 2 Ton, but can be used with flail mower heads up to 1200 mm for machines up to 16 Tons.

However,in most cases,more “cutting power” is required to remove thicker branches, or simply don’t want to worry about what they are going to hit when cleaning an area or they cut hedges. In this case,we suggest the flail mower head fitted with flail hammer blades.Flail movers with hammer blades can cut up branches up to 4 inches,and moreover,they can cut everything the Y shaped blades can do (grass, brambles, briars and bushes).So the fuction of hammer blade flail mover is stronger than that of Y blade flail movers.That is why flail hammer blades are more common sold in the market.

Maintenance of Flail Mover Blades

Smooth or fine-cut flail blades are largely self-cleaning. In order to extend their life, the blades can be resharpened. Sharp cutting edges reduces the horsepower needed for the blades’ operation.

Steel Forging for Flail Mover Blades

CFS Forge is the direct steel forging company for custom flail mover blades. Flial mover blades are recommended in steel forging production process because our closed die forging technique can produce flail mover blades in higher strength and better working performance.

Why Steel Forging for Flail Mover Blades?

- High production efficiency. In the chamber cavity of mould, the deformation of the steel billet is proceeding, so we can quickly obtain the required flail mover blades.

- Steel forging can produce any complex shaped flail mover blades, and the distribution of metal flow line is more reasonable. Besides, steel forging process can improve the serving life of flail mover blades.

- The size of steel forged flail mover blades is accurate,we can also achieve better surface quality, and smaller machining allowance.

- This closed die forging process will also reduce material waste and reduce machining work. Under the condition of enough batch, it will reduce the cost of flail mover blades eventually.

- The production operation is easy, so the work force is low.

Material of Forged Flail Mover Blades

Considering the wear resistance of flail mover blades, suggested material grade of flial mover blades is 42CrMo.

Heat Treatment of Flail Mover Blades

Quenching Tempering is the most cost effective heat treatment method to improve the hardness of flail mover blades. Normally forging blanks could only reach hardness around 20HRC. But after heat treatment, an ideal hardness 48-52HRC can be achieved. Higher hardness will help to improve the wear resistance of flial mover blades, thus to longer the serving life.

About

CFS Forge is the top custom steel forging manufacturer in China. We can supply all kinds of different closed die steel forging parts in stainless steel, carbon steel and alloy steel.

Pls contact us if you have any need for steel forging solution!

Flail Mover Blade

Flail mowers are useful for tough jobs, such as cutting grass on uneven ground, cutting high grass, weeds and even brush or mowing in areas that have debris and rocks. A flail mower does not throw grass; instead it cuts grass finely, almost pulverizing it, and leaves the cuttings on the ground. The teeth or flail blades, also called knives, are short pieces of metal attached to an axle that turns rapidly, cutting grass and other plants. A flail mower can be mounted on the front, back or side of a compact, garden or farm tractor. For the best results, the horsepower rating of the flail mower gear box needs to match or be compatible with the horsepower of the tractor. Some flail mowers require a tractor to have a minimum of 25 horsepower, which some garden tractors have.

Flail Mover Blades

Due to the different brands and sizes of flail mowers, flail mover blades come in different sizes. Each size is the width of the drum or rotor, and the sizes usually range from 48 to 102 inches. The number of flail mover blades and their arrangement varies. Flail mover blades are measured as blades per foot of rotor; a mower with a large number of flail mover blades generally gives a closer and cleaner cut than a mower with fewer flail blades. Individual flail mover blades usually are attached to the rotor in pairs, forming a Y- or T-shaped configuration. In some mower models, flail mover blades are attached in staggered rows to provide a smoother cut.

Types of Flail Mover Blades

Flail Hammer blades (T shape)

Flail hammer blade is the blade that assembled to the flail mover using a bolt nut,which is a type pf powered garden or agricultural equipment, such equipment is used to deal with heavier grass or scrub which can not be removed by normal lawn mover. Flial hammer blades are attached to the rotating horizontal drum. And the rows of blades are usually staggered to offer a complete cut. If a flail hammer blades strikes an immovable object, it simply bounces off. Other rotary type mowers have a tendency to grab and throw the object out of the mower deck if its small enough.This fact makes the flail mower best suited for areas where thrown objects would cause damage.

Flail Knife Blades (Y shape)

Flail Knife blades is the blade with a Y shape apperance using a clevis.

Flail Hammer Blades VS. Knife Blades

When you design o buy a new flail mower, you will have a choice of the Y Knife Blades or Hammer Blades. The Y-Blades are great when cutting tall weeds and overgrowth and can also offer a nice cut to your lawn. However,if you are need to cut tree saplings and dense overgrowth,the flail hammer blades are used,which are wider, heavier blades than the Y-blades. No matter Flail hammer blades or Y knife blades,either set of blades will make a perfect solution for cutting.

Although flail movers are very effective when cutting overgrown grass,clearing brambles,and the perfect tool for hedge cutting even like a tree branch,it is very important for you to choose the right option.Below we will introduce different types of blades(hammer blades vs knives blades) for flail movers.

When cutting grass and brambles,a flail mower head fitted with knives,or Y shape blades is the best choice.They are more of a knife and less of a mulcher and they leave a very clean cut and a much tidier looking finishing. Besides,the Y shape blades(knives blades)can also be used for light hedges and they can cut branches up to 2 inches (some of our customers use them to cut much thicker things but this is not recommended!!) The knives are standard fitting for the LS1 series of hedgecutter, for mini diggers from 1,5 to 2 Ton, but can be used with flail mower heads up to 1200 mm for machines up to 16 Tons.

However,in most cases,more “cutting power” is required to remove thicker branches, or simply don’t want to worry about what they are going to hit when cleaning an area or they cut hedges. In this case,we suggest the flail mower head fitted with flail hammer blades.Flail movers with hammer blades can cut up branches up to 4 inches,and moreover,they can cut everything the Y shaped blades can do (grass, brambles, briars and bushes).So the fuction of hammer blade flail mover is stronger than that of Y blade flail movers.That is why flail hammer blades are more common sold in the market.

Maintenance of Flail Mover Blades

Smooth or fine-cut flail blades are largely self-cleaning. In order to extend their life, the blades can be resharpened. Sharp cutting edges reduces the horsepower needed for the blades’ operation.

Steel Forging for Flail Mover Blades

CFS Forge is the direct steel forging company for custom flail mover blades. Flial mover blades are recommended in steel forging production process because our closed die forging technique can produce flail mover blades in higher strength and better working performance.

Why Steel Forging for Flail Mover Blades?

- High production efficiency. In the chamber cavity of mould, the deformation of the steel billet is proceeding, so we can quickly obtain the required flail mover blades.

- Steel forging can produce any complex shaped flail mover blades, and the distribution of metal flow line is more reasonable. Besides, steel forging process can improve the serving life of flail mover blades.

- The size of steel forged flail mover blades is accurate,we can also achieve better surface quality, and smaller machining allowance.

- This closed die forging process will also reduce material waste and reduce machining work. Under the condition of enough batch, it will reduce the cost of flail mover blades eventually.

- The production operation is easy, so the work force is low.

Material of Forged Flail Mover Blades

Considering the wear resistance of flail mover blades, suggested material grade of flial mover blades is 42CrMo.

Heat Treatment of Flail Mover Blades

Quenching Tempering is the most cost effective heat treatment method to improve the hardness of flail mover blades. Normally forging blanks could only reach hardness around 20HRC. But after heat treatment, an ideal hardness 48-52HRC can be achieved. Higher hardness will help to improve the wear resistance of flial mover blades, thus to longer the serving life.

About

CFS Forge is the top custom steel forging manufacturer in China. We can supply all kinds of different closed die steel forging parts in stainless steel, carbon steel and alloy steel.

Pls contact us if you have any need for steel forging solution!

How flail mower works

For many years, folks asked me: “Don’t you have a company logo?” And we really didn’t, as I just never took the time to come up with one…we just had “Earth Tools” written out in a blocky font, and that passed for a logo.

Finally, though, I decided to put some effort into it, and I hired my sister-in-law Trina Peiffer (my wife’s twin sister) to make a line drawing of the Earth Tools sign we have here at the shop. This sign is made out of a 4-foot length of Eastern Red Cedar log; the letters are carved with a chain saw.

I made this sign about 15 years ago (below is a photo). I figured this was a logo with some “meaning”…not just some arbitrary design. Hope you like it!

HAVING TROUBLE GETTING THROUGH ON OUR MAIN NUMBER ABOVE?TRY 502-484-5550 or 0704

SUPPLY-CHAIN ISSUES

The supply chain issues / delays caused by Covid are pretty much worked out now, BUT.- we STILL get VERY busy in the late Winter Spring, and assembling/shipping wait times increase, just because of the log-jam of Tractor / Implement orders coming in all at once at the last minute. So.- DON’T wait until the last minute to order! If you want equipment for this upcoming growing season, ORDER EARLY! Keep in mind that we ship orders on a first-paid, first-shipped basis. we do NOT offer expidited assembling/shipping of tractor implement orders for an extra charge. We appreciate your business and your patience, and we work as hard as we can to get orders out as fast as possible, WITHOUT cutting corners on the proper equipment setup, prep checkout that we are famous for.

- Home

- Frequently asked questions

- Updated SPECIALS

- New Products

- Walk-behind Tractors

- Implements

- Tractor Implement Accessories

- Used Equipment

- Professional Motor Hoe

- Product Videos

- Warranty Info

- Garden Tools

- Use, Repair, and Maintenance

- Replacement Parts

- Acme Engine Parts

- Ordering/Contact Info

- Competitors

- About Us

- Other Resources

- Employment Opportunities

- Articles

NEW: REGIONAL DELIVERY SERVICE!!

We are now offering a “regional” delivery service for tractor implement orders within a 400-road-mile radius of our location in Owenton KY. Earth Tools’ owner’s Father-in-law (Charles) will be doing the deliveries. Charges for this service will be a bit more than for shipping by truck freight (call for a quote to your specific location), but delivery will be with a pickup truck (and trailer, if needed) that can get to most any location – unlike a semi-truck. Also, scheduling of the delivery will be more flexible, to better meet your needs. “perks” of this service are that the equipment will be FULLY assembled, and Charlie will show you basic operation of the tractor. Minimum merchandise order for this service: 6500. Call for a delivery quote!

Why are new BCS tractors BLACK or SILVER?

Beginning in late 2017, the BCS factory started a new “paint scheme” for their tractors and implements: The tractors are just painted BLACK, and the BCS-branded implements are painted SILVER. (and in 2023, the tractor bodies started coming through SILVER as well) So, on the tractors, the only blue parts are now the plastic “beauty” shrouds for the handlebars.

WHY?

Because the BCS factory in Italy produces 3 brands of walk-behind tractors on the same assembly line: BCS, Ferrari, and Pasquali (BCS purchased these other 2 companies in the 1990s…and no, this is NOT the automotive “Ferrari!”). Historically, they had different paint-lines for each tractor and implement line (Blue for BCS, Green for Ferrari, and Yellow for Pasquali)…but sometime in 2017, they decided to optimize efficiency by painting all the tractors and implements “neutral” colors and just letting the plastic shrouds and decals delineate what brand tractor it would be. Hence, non-blue BCS tractors started appearing in the USA in early 2018. (We have told BCS that we think this is a bad idea. the blue was a color most people associated with BCS, and now, if the plastic beauty shrouds are discarded or lost, there is no color for brand recognition, and that would hurt them more in the long run than the few bucks a tractor they’re saving by not having separate paint lines in their factory. We’ll see if they ever bring the Blue back. )

Flail Mowers. Berta, BCS, Bellon, and Green Technik Brands

Flail mowers feature a horizontally-mounted rotor with numerous hinged (flailing) blades that pulverize a variety of materials in a single pass: Cover Crops, Weeds, Grass, and Brush up to 1” diameter. These heavy-duty mowers are the most forgiving mower type in rocky conditions due to the fact that the blades can easily “fold back” when hitting a hard object. The blades “flail” out by centrifugal force (at a drum speed of about 3000 rpm) to pulverize material. Flail mowers are excellent for reducing mowed material to a very small size for quick incorporation/breakdown into the soil. They are very popular for cover crops for this reason. A six-foot tall cover crop can be reduced to 2” – 4” pieces in a single pass and left evenly distributed across the width of the mower.

Because of the time and horsepower required to “grind up” the material that is being mowed, the taller and denser the material is, the slower this type of mower typically has to travel (unlike a Cutter [sickle] Bar Mower, which only cuts material off at the bottom and therefore doesn’t care how tall it is…or a Brush Mower, which will give a decent cut at higher speeds but just not grind the material up much).

HOWEVER, with the introduction of the BERTA brand (the same company that builds our Rotary Plow) flail mowers in 2010, this has changed…Berta is the first manufacturer to offer flail mowers with an adjustable-size discharge port on their flail mower. The adjustment is achieved via a removable “baffle”: If installed, the discharge port is SMALLER, and the material stays inside the mower longer and gets chopped up more; If the baffle is removed, the discharge port is LARGER, and the mower discharges the cut material in larger pieces, therefore requiring less power, and the mower can be run at higher ground speeds. This allows the Berta flail mowers to double as an effective and fast Brush General-Purpose Mower, as well as being a great cover-crop / vegetable residue mower.

The Berta and Green Technik Flail Mowers come standard equipment with a full-width steel roller behind the blade rotor which can be adjusted (by removing 2 bolts) up or down to regulate cutting height from about 0-3 inches (varies somewhat by tire size on tractor). Berta also offers a set of caster wheels as optional equipment which mount in front of the mower…these result in slightly easier side-to-side maneuvering, but make the mower physically longer and can “press down” the grass, weeds, etc. where the wheels roll, resulting in the material not being cut as evenly. Cutting height is fully and easily adjustable with the caster wheels as well, and virtually limitlessly within the 1 to 4 inch range, with a couple quick-pins. The Berta casters can also be “unlocked” and flipped back up over the mower to get them out of the way in rough conditions. IMPORTANT NOTE FOR RAISED BEDS: If you are using the flail mower to mow cover crop or vegetable residues on top of raised beds, the full width steel roller that the Berta mowers come standard with is essential…because caster wheels will fall off the edges of the bed, resulting in the blades contacting the soil and “scalping”, which damages the blades, and possibly stalls the engine.

BCS Blade Runner flail mower

The BCS brand (“Blade Runner”) flail mowers have caster wheels standard equipment; they adjust via a screw-crank. On the BCS BladeRunner mowers, the wheels can also be lifted and locked in a “straight up” position, if desired, to get them out of the way (like the Berta caster wheels in the picture above), and then the BCS BladeRunner mowers rest on “skids” (which are NOT adjustable in height). The BCS BladeRunner mowers do have an option available of a full-width “anti-scalp” steel roller for height regulation (like what the Berta mowers come with standard)…this is NOT adjustable in height; cutting height is about 2” with this installed. Also, the BCS and Green Technik brand flail mowers DO NOT have a removable discharge baffle like the Berta mowers, so they chop up the material to the same size all the time. NOTE: BCS claims that their “High-Dome” chamber design on their “BladeRunner” models eliminates the need for a removable discharge baffle…but in reality, the end result is that the BCS flail mowers (like tractor-mounted flail mowers) do NOT have a way to control the amount the material gets chopped up. The “High-Dome” design simply means that the material is not held as closely to the blades, so it will never get chopped up as fine as what a Berta can do with the discharge baffle installed.

The Berta flails have an oscillating PTO mount (IF the tractor is equipped with a quick coupling) which allows the mower to “float” on uneven terrain, for an even cut. The BCS and Green Technik flails do NOT have a “floating” feature.

In late 2016, BCS introduced a new flail mower option: The “RollerBlade”, which is available in a 30” width only. Interestingly, it is modeled almost precisely after the Berta brand flails, except it does NOT have a “floating” feature to aid the quality of cut on uneven ground, and it does NOT have a removable discharge-baffle to adjust material-discharge size. However, we offer this model as well, if someone should want it.

Here is a chart comparing the Berta and BCS Brand Flail mowers:

All the flail mowers have an oil bath input-shaft gearbox with grease fittings on rotor bearings. They use two V-belts to transfer power to the blade rotor. Belts are easily adjustable and replaceable.

18 Green Technik flail mower

While the Berta brand flail mower definitely offer the best features, quality price, Berta unfortunately does not offer anything smaller than a 26” width. So, for narrower flail mowers (for small tractors and/or narrow spaces), we tapped into the Bellon and Green Technik lines, which are good quality machines, but just not with as many features as Berta.

All our Flail mowers come standard with Y-blades, which will cut anything from grass and weeds to ¾” hardwood or 1” softwood saplings. The mowers can also be equipped with straight “scarification” blades, which will do light slitting of the ground for overseeding. Another blade option is “lawn/finishing” blades, which will do a smoother, nicer-looking job on a lawn. (NOTE: The Y-blades on the BCS BladeRunner flails are not as heavy-duty as the ones on the Berta or Green Technik mowers, so they will not cut material quite as large [½” hardwood / ¾” softwood saplings], and they are not as durable.)

NEW FOR 2023: Berta now offers “Anti-Scalp Skids” for their flail mowers, to help prevent scalping when mowing on lumpy / uneven terrain…see below.

Anti-Scalp “Skids” for Berta flail mowers