How much oil to fill a cultivator.

Useful information

Cultivator oil change is required regularly, it affects the duration of operation and full performance of the machine. The serviceability of all units and mechanisms in the equipment will also be affected by correct lubricant change and its selection. Nowadays there is a great variety of oils for power tillers. Focus on a particular brand can be based on the recommendations of the engine manufacturer. In addition, the type of grease used is influenced by weather conditions and air temperature. Always use high quality lubricant to keep the machine running efficiently and without interruptions.

Synopsis. Engine oils reduce friction between internal combustion engine components and their degree of wear.

What is the difference between two-stroke and four-stroke oil?

Some engine oils are intended for four-stroke engines but others for two-stroke engines. They are not interchangeable, and should be poured according to their purpose. different requirements for lubricants for engines with different duty cycles. For example, oils for four-stroke high-speed engines, which use a forced lubrication system, are designed for long-lasting effects and are designed to provide a more stable coating of parts. In two-stroke engines the oil comes with fuel and should be dissolved in it immediately, burning smokelessly with minimum soot and ash deposits. That’s why two-stroke oils are characterized by good refinement and minimal aggressive additives. They, unlike the four-stroke fluid, do not contain ash, anti-seize and anti-wear additives. It allows them burning together with fuel without producing soot and toxic exhaust.

A feature of oils for four-stroke engines is a set of metal-organic additives, which are aimed at improving their physical and mechanical properties and increasing the efficiency of action. And if you pour such a mixture into an engine with a duty cycle of two strokes, it will lead to the formation of ash deposits on the surface of the piston and the walls of the combustion chamber. Increased accumulation of deposits, in turn, can provoke the appearance of various troubles that can only be eliminated by making a complex and costly repair of the engine, motoblock or motobucket. Soot, which clogs the air filter and settles in the grooves of piston rings, if the wrong petroleum product is used, also causes a lot of damage. The accumulation of soot is fraught with loss of ring mobility, which is a direct way to reduce the power of your power tiller engine, its performance deterioration and even complete failure.

How to change the oil

For smooth operation of the motor equipment and served for a long period, you should periodically replace the lubricant in the gearbox and engine. The first time it is done after the running-in period, and then every 50-100 hours of use (with heavy loads “fill up” will need even more often), unless otherwise specified by the manufacturer.

Changing the oil in the gearbox

To lubricate the gearbox use any gear oil, for example, TAD-17, TAP-15V or other markings according to GOST 23652-79. Before pouring it in, check the presence of old fluid. If necessary, it must be changed, checking the volume of the tank beforehand. Checking in such models of motor-block as the Neva is carried out as follows:

- Place the equipment on a horizontal surface so that there was access to the gearbox, and it was in an inclined position (so it will be more convenient to pour the liquid).

- Insert the dipstick (it can be a 65-70 cm long metal bar bent in an arch) into the hole on the gearbox and measure the level of the substance by it.

If the dipstick submerged in the gearbox is about 30 cm into the fluid, you do not need to refill it. If not, fill in the lubricant to the correct level. A minimum of 2 liters of lubricant should be poured into a completely dry gearbox.

Changing the oil in the engine

Lubricant replacement procedure in the engine is as follows:

- Start and warm up the engine.

- Place the single-axle tractor on an elevated horizontal surface.

- Open the drain hole of the tank to drain the contents into a separate container, and then close it tightly.

- Pour in new lubricant through the filler hole, checking the level with the dipstick.

- Wipe the drain and filler holes with a dry rag, carefully removing any residual lubricant.

Engine oil is not cheap, but you should not cut down on it, just like fuel. Only original oil of good quality should be used, because the performance and durability of your power tiller depends on it. Only high-quality products and properly chosen parameters can provide the most useful action and ensure minimum wear of internal engine parts. The instructions are suitable for power tillers like S htenli (Shtenli), Patriot, Tarpan, Kaskad, Khoper, Agat, Oka, Luch, MTZ.

How much oil to use?

Another important issue is the amount of oil required. Before answering the question. how much oil to fill a gearbox of a power tiller, for example a Crosser, VIKING, Forza, Sadko, Don, Huter, Pro, LANDER, Champion, Carver you should first check the oil level in the gearbox. For this purpose, it is necessary to perform certain actions:

- The single-axle tractor must be placed on a level surface so that its wings are strictly parallel to the surface.

- We take a wire or rod with a length of about 70 cm, which will act as an oil dipstick.

- Bend the improvised dipstick into an arc.

- Insert the dipstick all the way into the fill hole.е. all the way. After that pull it back out.

If the wire at 30 cm in the oil, this is the optimum, i.e.е. it is not necessary to fill up the oil. If a little less, it is necessary to refill within these values.

If the gearbox is dry, you need at least two liters of transmission oil.

single axle tractor Neva, what gasoline to fill. Diesel engines

Most farmers try to use any resources rationally, including fuel for power tillers. Diesel engines are considered a more economical option than gasoline engines because of less rapid fuel consumption.

The main advantages of the diesel engine are:

- high efficiency (coefficient of performance);

- long service life;

- Economical fuel consumption;

- Suitable for large areas of land;

- works more effectively at low revolutions;

- has a greater pulling power.

There is an opinion that diesel engine parts wear less than its “gasoline competitor”.

Owners of “Neva MB-23SD” motor-blocks, according to numerous reviews on the forums, confirm that the service life of the diesel engine is longer than that of the gasoline-powered unit. In addition, the high efficiency allows you to spend less fuel, which means that financially this option is more acceptable.

Important! In order to lengthen the service life of a diesel motoblock it is necessary to start the single-axle tractor at full power from time to time, at least for a few hours, so it wouldn’t stand idle for years. it will significantly increase the service life of the diesel engine.

Main problems of the diesel engine and their elimination

A machine that runs smoothly is every farmer’s dream. However, in practice it often happens that there are problems with the engine of the motor block “Neva”.

The most common problems and factors leading to diesel engine malfunctions are:

- fuel thickening (fix fuel dilution);

- nozzle clogging (can be removed by cleaning);

- Low air temperature (when working in cold weather, for example);

- low fuel injection pressure (adjust the injection system);

- low compression level in the cylinder (caused by a number of reasons, including loose cylinder head nuts, which can be eliminated by adjusting the nuts; damaged gasket, which can be replaced; destroyed piston rings, their jamming; damaged components of the cylinder-piston group; too much clearance between valves, which can be eliminated by adjusting the gap size; jammed valve stem. removing the valve to flush it and clean the guide will help).

Another serious problem is the malfunctioning of the transmission. The main causes of these failures are as follows:

- Slipping of the clutch due to unbalanced belt or cable, high wear of discs or springs;

- clutch is not fully disengaged (it is necessary to check the serviceability of friction discs and cable tension);

- the gearbox is making a lot of noise (the first thing to do is to check the oil level and quality as well as the wear of the gears and bearings. If necessary. replace worn parts);

Finally, if the motor-block “Neva” with a diesel engine does not switch speeds, the causes may be as follows:

- gear ends are out of order (this problem can be eliminated by disassembling the gearbox and grinding or replacing the defective gears);

- the bearings and splines of the shafts have worn out, causing the shafts to shift along the axis (installing another set of retaining rings and, of course, replacing the bearings helps);

- The clutch system is out of adjustment (if the power tiller is operated by a beginner, it is likely that the wrong gear shift method was used). In this case, the adjustment of the clutch system should be entrusted to a professional).

Are You Doing It RIGHT? Tilling with a Tractor

Maintenance of the diesel engine. key points

In order to ensure trouble-free operation of diesel power tillers “Neva” the manufacturer recommends to perform the following types of engine maintenance works:

- check the oil level, refill or replace the oil;

- clutch cable adjustment;

- checking the gears;

- check the clutch friction assemblies;

- check and tighten bolts and nuts;

Before installing a Neva diesel motor-block “on the simple”, the following actions should be carried out without fail:

Maintenance of the diesel engine filter should be carried out after 8-50 hours of operation (depending on the degree of load and the duration of continuous operation).

after 100 hours of operation, you need to change the oil, clean the oil filter and the oil distribution box, and do the lubrication work.

After 500 hours of operation the same operations are performed as after the first 50-100 hours of operation, in addition removing the soot and dirt from the cylinder head, oil filters and oil distributor. The water tank should also be cleaned of scale.

Champion Cultivator (Champion) BC 6712. instructions, characteristics

Champion BC 6712 cultivator (Champion) is one of the most popular in the model range of this manufacturer. Cultivator is designed to work in a garden and vegetable garden. Keep the engine horizontal during operation to avoid penetration of oil into the combustion chamber. Engine tilt over 10° should be brief.

| Dimensions L x W x H (mm) in shipping condition | 600х420х740 |

| Dimensions L x W x H (mm) | 1240 x 820 x 870 |

| Blade speed (rpm) | 130 |

| Working width (mm) | 300-550-850 |

| Gripping depth(mm) | 330 |

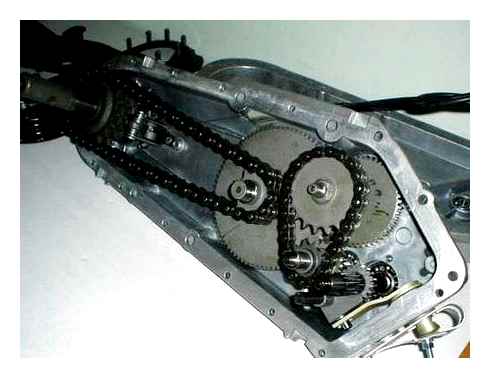

| Type of gear | BeltChain |

| Forward/reverse gear | 1/1 |

| Weight (kg) | 49 |

| Oil volume in the crankcase, (l) | 0,6 |

| Gear ratio | 30:1 |

| Engine | |

| Model | G200F |

| Type | Single-cylinder, 4-stroke, air-cooled, horizontal shaft, overhead valve (OHV) |

| Power rating (kW/l.с. at 3600 rpm./min) | 4,1/6,5 |

| Maximum torque (Nm/at 2500 rpm)./min.) | 12,4 |

| Fuel tank capacity(L) | 3,6 |

| Fuel consumption (g/kWh) | ≤395 |

| Idle stroke (rpm)./minute.) | 1400±150 |

| Piston diameter/stroke (mm) | 6854 |

| Engine displacement ( cm 3 ) | 196 |

| Compression | 8.5 |

| Lubricant type | Sprinkle |

| Start type | Manual |

| Ignition type | Electronic |

| Spark plugs | F7RTC or its equivalents (Champion-RN6YC, NGK- BPR7ES, Bosch- WR5DC) |

Champion Cultivator (Champion) BC 6712. Operation manual download

Champion Cultivator (Champion) BC 6712 Official Manufacturer’s Site. http://championtool.ru

Maintenance of the Champion cultivator (Champion) BC 6712

In order to maintain the high efficiency of the cultivator, it is necessary to periodically check its technical condition and perform the necessary maintenance work. Regular maintenance will also extend the service life of the cultivator. The table below shows the maintenance intervals and the types of work to be performed.

Cultivator gearbox is supplied from the factory filled with grease. It is recommended that the gearbox grease should be changed every 150 hours of operation. Have the gearbox grease changed at an Authorized Service Center.

To replace the lubricant, remove the gearbox from the cultivator, unscrew the bolts securing the gearbox housing halves Fig. To remove old grease, flush gearbox parts with kerosene or diesel fuel. Replace worn and damaged parts. Put some fresh lubricant in, assemble the reducer.We recommend replacing with Champion EP-0 or comparable lubricant from other manufacturers. The full amount of lubricant in the gearbox is 120-130 grams.

Champion Cultivator Oil (Champion) BC 6712

The engine is shipped without oil. Before starting the engine, fill the crankcase with oil to the proper level. Do not exceed oil level. Engine oil is the main factor that affects engine performance and determines its service life.

It is recommended to use Champion 4-stroke engine oil, or a similar high-quality, air-cooled 4-stroke engine oil with high detergency, which meets the requirements of the SF,SH API classification (oils classified as SF,SH must be marked accordingly on the package).The engine oil viscosity should match the average air temperature in your area.

Running with a low oil level in the engine crankcase or running without oil will cause engine damage and is not repairable under warranty. Always check the engine oil level before you start. To check the oil level, the cultivator must be installed on a flat area, the engine must be shut off. The engine oil level should be at normal operating temperature. To check the oil level, let the engine idle for 4-5 minutes after stopping the engine., for the oil to drain into the crankcase.

Running-in: When you start up a new engine, change the oil after 5 hours of operation, and after 25 hours of operation, change the oil again. Each subsequent engine oil change after 50 hours of operation.

Gasoline for Champion Cultivator (Champion) BC 6712

Use unleaded gasoline, 92 octane.Never use old, contaminated gasoline or oil/gasoline blend. Do not allow dirt or water to get into the fuel tank. Engine failure due to improper octane rating or old fuel is not covered under the warranty.

Recommended spark plug is F7RTC or equivalent (Champion-RN6YC, NGK- BPR7ES, Bosch- WR5DC). WARNING! The use of a spark plug with parameters different from those recommended for the engine may result in engine failure and void the manufacturer’s warranty.

When installing a new spark plug, use a wrench to tighten the spark plug 1/2 turn after the bead on the spark plug seals on the washer. When installing a used spark plug, use a wrench to tighten the plug a 1/4 to 1/8 of a turn after planting the rim of the plug on the sealing washer to ensure proper torque.

The spark plug must be tightened securely. Not properly wrapped spark plug is strongly heated when the engine is running and can cause damage to the engine. A lot of effort to tighten the spark plug can damage the threads of the cylinder head.

Repair instructions

Repair of the Mole motoblock is simple and quite realistic at home. Just take some time to read the manual and take apart the scheme of the machine. Then you can carry out the repair of the Mole motoblock with your own hands without much difficulty.

There are things that will help you to carry out the repair of a Mole motoblock with your own hands. Here is a video. Skillful people will visually show you how and in what sequence to fix the equipment. Although the technique is reliable, but even it, because of its use in conditions of prolonged multifunctional work, can break down.

But it is also important to understand what ails a single-axle tractor “Mole”. The repair instructions may be without the video.

- The problem is in the ignition. This, unfortunately, happens quite often with this brand of power tillers. First thing to do is check the spark plug. To do this, unscrew it and perform a visual inspection. If the spark plug is completely dry, it indicates that the fuel-air mixture is not entering the cylinder.

- If it is completely wet, you need to pump the engine with the recoil starter. This will dry out the cylinder. The spark plug is caked. flush it with gasoline and clean it with a fine sandpaper.

- Faults motoblock “Mole” can also be associated with the fact that the plug does not just need to be cleaned, but replaced. This is if there is no spark.

- If there is still no spark from a new spark plug, there is a possibility that there is no contact in the electrical circuit.

- The ignition is also in direct relation to the condition of the gasoline hoses, the insulation of the high-voltage wires or their connection. Look closely to see if the flywheel plates are touching the magneto wire. This shouldn’t happen.

- And, of course, check the air filter for contamination. By the way, even a dirty muffler has a negative impact on the unit’s performance.

Gearbox Repair

A gearbox of Mole must transform and transmit torque. Sometimes the machine is noisier and not as quiet as before. In this case, it may not be necessary to touch the gearbox of the Mole motoblock. Repair may not be necessary.

Noise often indicates a lack of oil in the system. Fill it up, or better yet replace it altogether. Oil can leak due to gland wear. Another option, why the single axle tractor is noisy. the fasteners of the assemblies need to be tightened, because they are loose. This can be done with your own hands.

The Mole single axle tractor, for all thirty-odd years of its existence, has proven to be a simple, reliable and multifunctional machine and a faithful helper to dacha owners and gardeners.

It’s easy to repair without going to a workshop, it fits many parts, even the non-original ones, and it can be easily upgraded and modified with your own hands.

On the other hand, there are a number of more modern and progressive power tillers, more powerful, economical and with more features, which are already present right out of the factory.

How to do maintenance on your tiller | Muratori Tillers | Acreage Tractor Tillers

Technical characteristics of Tarpan MK-03 cultivator with Honda engine, briggs stratton

| Basic parameters | value | |

| Overall dimensions, mm, not more (control handles folded) | length 1300 (760)width 700 height 1060 (760) | |

| Weight, kg | 45 | |

| working width, mm | 560 | |

| Cultivator cutter diameter, mm | 320 | |

| Tillage capacity, ha/h (at normal soil and tilling depth 180 mm) | 0,06 | |

| Max. ripping depth., mm | 200 | |

| Tilt angle limits at work, deg., longitudinal and transverse. not more | 15 | |

| Engine | briggs stratton | Honda |

| Model | 12j802 | GCV-160 |

| Type | 4-stroke, carburetor | |

| Operating volume, cc. see. | 190 | 160 |

| Max. power, l.с., not less | 5,5 | 5.5 |

| Fuel tank capacity, l | 1,1 | |

| Volume of filled oil, l | 0,6 | 0,55 |

| Fuel and oil according to “Engine manual” | ||

| Hourly fuel consumption, l/h, not more | 1,1 | |

| Clutch | Dry automatic centrifugal | |

| Start-up | Manual operation | |

| Switching off | Remote gas lever | |

| Gearbox | Single-stage worm | |

| Oil for worm gear lubrication. TAD-17I GOST 23652-79. Allowable replacement. SAE 90, SAE 75W/90, API GL-4, GL-5 grades | ||

| Volume of oil in gearbox, l | 0,35 | |

| Sound level at operator workplace, not more dBA | 81 | |

| Vibration velocity correction level at control handle, max. dB | 118 | |

| Number of speeds | 1 forward | |

A Briggs Stratton 12j802 or Honda GCV-160 engine is installed on the MC Tarpan

What fuel and oil to fill in the Tarpan cultivator you can know from the engine user manual or from the given table in the manual.

Honda GCV-160 engine manual download

briggs stratton 12j802 engine. user manual parts catalog download (useful when ordering parts).

Manufacturer of Tarpan cultivators. Tarpan Ltd. Tula, official site. www.tulamash.ru/static/tarpan/history.html

Motor cultivator Tarpan. user manual download

Tillage operations are carried out with the help of the working body MK. rotary cultivator. Cultivator cutters as they rotate, crumbling and mixing the soil layers, while causing forward motion of the MC.

Advantage of rotary cultivator as compared to the plough is better soil loosening, chopping and weed embedding as well as uniform mixing of organic and mineral fertilizers on the whole working depth.

Application of the MK is also recommended on clay heavy soils, as it has a high torque on the shaft and grinds the soil well.

It is not recommended to till virgin soil by milling. This will break the cultivation technology.

MK Tarpan consists of the following main parts ;

- power unit including engine, coupling device, centrifugal clutch, steering

- power unit, including worm gear, rotary cultivator left, rotary cultivator right, depth regulator, bracket, protective hood.

To enhance functional capabilities of this cultivator additional attached implements and accessories were developed and delivered separately. They can be used to perform hilling, furrow cutting, weeding and other types of work.

Cost of attachments

If you are interested in “Tarpan” brand products, you may have to buy additional attachments for power tillers. For example, an arrowbar used with “Tarpan 03” and “Tarpan 04” is available for 940, while a frame with carrying wheels costs 1033

Sometimes customers are also interested in the tines. If their size is 260 x 80 mm, then the set will have to pay 1480 If the size of 400 x 170 and 500 x 170 mm gruntozatsepy will cost 1790 Attachments for motokultivatorov are also potatovykapivateli that cost 624 will cost 1100, and skidders, or rather their set. 1160 Universal hitch used to attach to motobloc, costs 2100, cutter “goose feet”. 2880

Today, tarpans are not only called the unbridled wild horses that previously existed on our planet. This is the name given to domestic power tillers, which are designed for plowing plots of up to 15 acres. They are characterized by a reliable and powerful engine, high quality parts and excellent performance.